CONTENTS

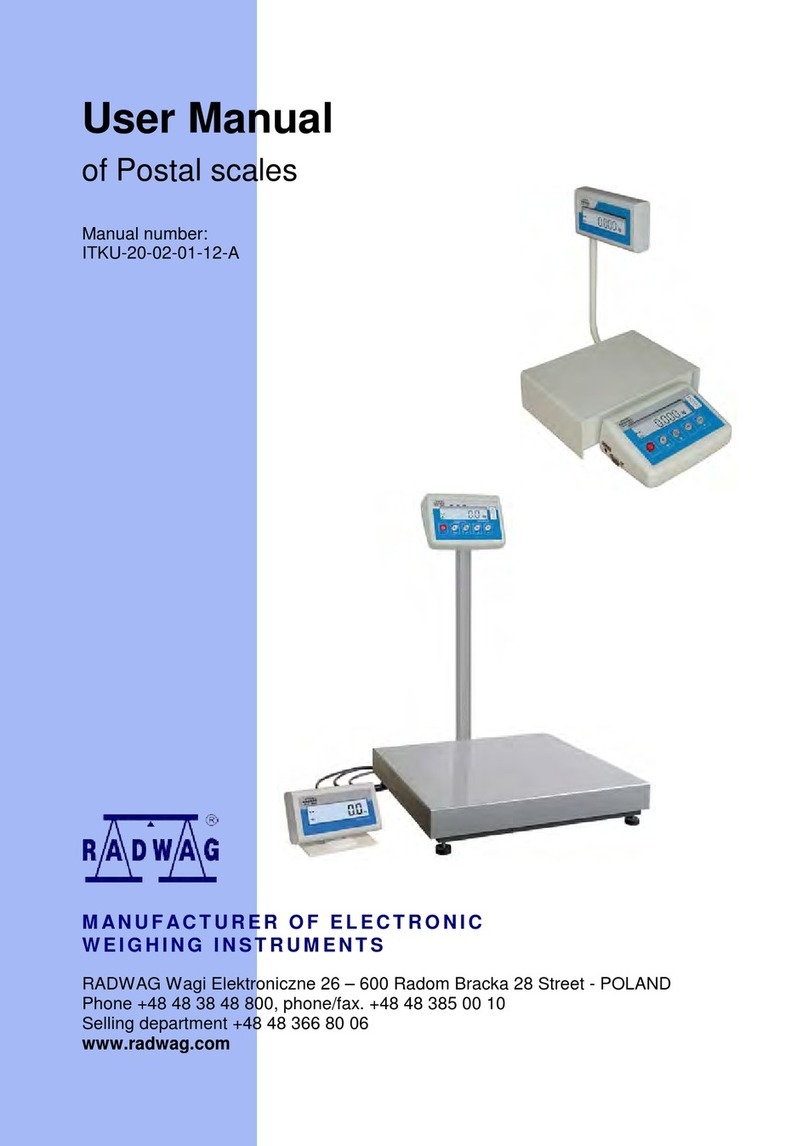

1. INTENDED USE .................................................................................................................................................5

2. WARRANTY CONDITIONS ...............................................................................................................................5

3. MAINTENANCE..................................................................................................................................................5

3.1. Cleaning Powder-Coated Components.......................................................................................................6

3.2. Cleaning Stainless Steel Components........................................................................................................6

3.3. Cleaning ABS Components.........................................................................................................................6

4. SERVICE AND REPAIR.....................................................................................................................................6

5. RECYCLING.......................................................................................................................................................7

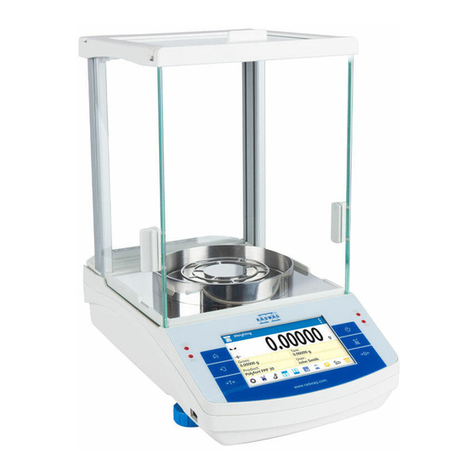

6. MECHANICAL DESIGN..................................................................................................................................... 7

6.1. 1-Load-Cell Scales......................................................................................................................................7

6.2. Multiple-Load-Cell Scales............................................................................................................................7

6.3. Scales with Load-Cell Modules...................................................................................................................8

6.4. Dimensions..................................................................................................................................................8

6.5. Models.........................................................................................................................................................8

6.6. Connectors ..................................................................................................................................................8

6.6.1. Pin Arrangement...............................................................................................................................9

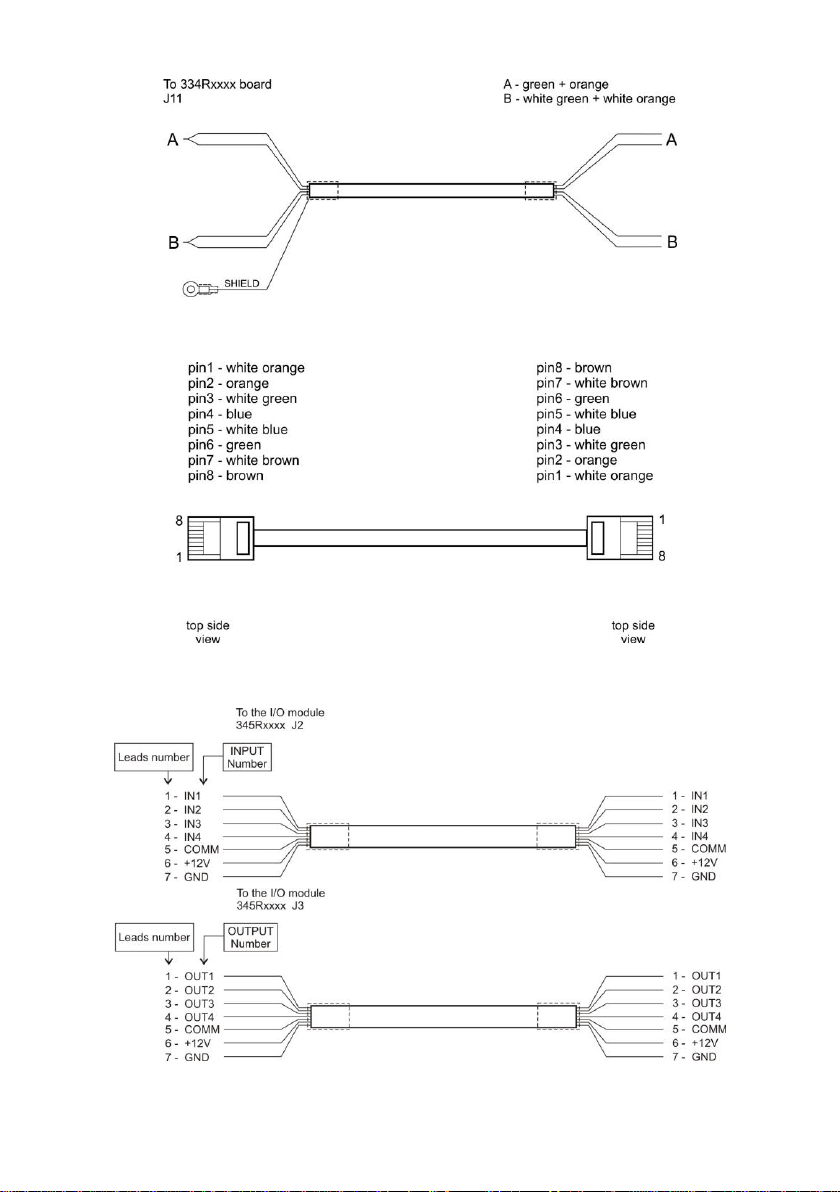

6.6.2. Diagrams of connection cables........................................................................................................9

6.7. Inputs / Outputs .........................................................................................................................................11

6.7.1. Technical Specifications.................................................................................................................11

6.7.2. Schematic Diagrams ......................................................................................................................11

6.7.3. Input / Output Signals.....................................................................................................................11

7. INSTALLATION................................................................................................................................................ 12

7.1. Unpacking and Installation........................................................................................................................12

7.1.1. 1-Load-Cell Plstform Scales of TWM4-x Series.............................................................................12

7.1.2. Platform Scales of TWM4-x.4.xx.C, TWM4-x.4.xx.H, TWM4-x.4.xx.H/Z Series ..........................12

7.1.3. Ramp Scales of TWM4-x.4N Series ..............................................................................................12

7.2. Levelling: 1-Load-Cell Platform Scales.....................................................................................................13

7.3. Levelling: 4-Load-Cell Platform Scales.....................................................................................................14

7.4. Start-Up .....................................................................................................................................................14

8. MwManager HOME SCREEN .........................................................................................................................15

9. OPERATING THE MENU................................................................................................................................. 16

10. WEIGHING .....................................................................................................................................................16

10.1. Good Weighing Practice: 1-Load-Cell Platform Scales..........................................................................17

10.2. Good Weighing Practice: Custom Scales...............................................................................................17

10.3. Zeroing ....................................................................................................................................................18

10.4. Taring ......................................................................................................................................................19

10.5. Dual Range Devices................................................................................................................................ 19

11. TECHNICAL SPECIFICATIONS....................................................................................................................19

12. ERROR MESSAGES .....................................................................................................................................20