Table of contents

BAL_C127-SU_OFFSET_EN_1V0_REC_121-006454770 3 / 32

Table of contents

1 Safety................................................................................................................................................................. 5

1.1 Presentation of warning signs............................................................................................................... 5

1.2 Intended purpose of use ....................................................................................................................... 5

1.3 General hazards ................................................................................................................................... 6

1.4 State of technology ............................................................................................................................... 8

1.5 Personal protective equipment ............................................................................................................. 8

1.6 Spare parts and liability ........................................................................................................................ 9

2 General information ......................................................................................................................................... 10

2.1 Purpose and use of the instructions ..................................................................................................... 10

2.2 Copyright .............................................................................................................................................. 10

2.3 Product identification ............................................................................................................................ 10

2.4 Manufacturer agtatec ag....................................................................................................................... 10

2.5 Target groups ....................................................................................................................................... 10

2.6 Abbreviations ........................................................................................................................................ 10

3 Description........................................................................................................................................................ 12

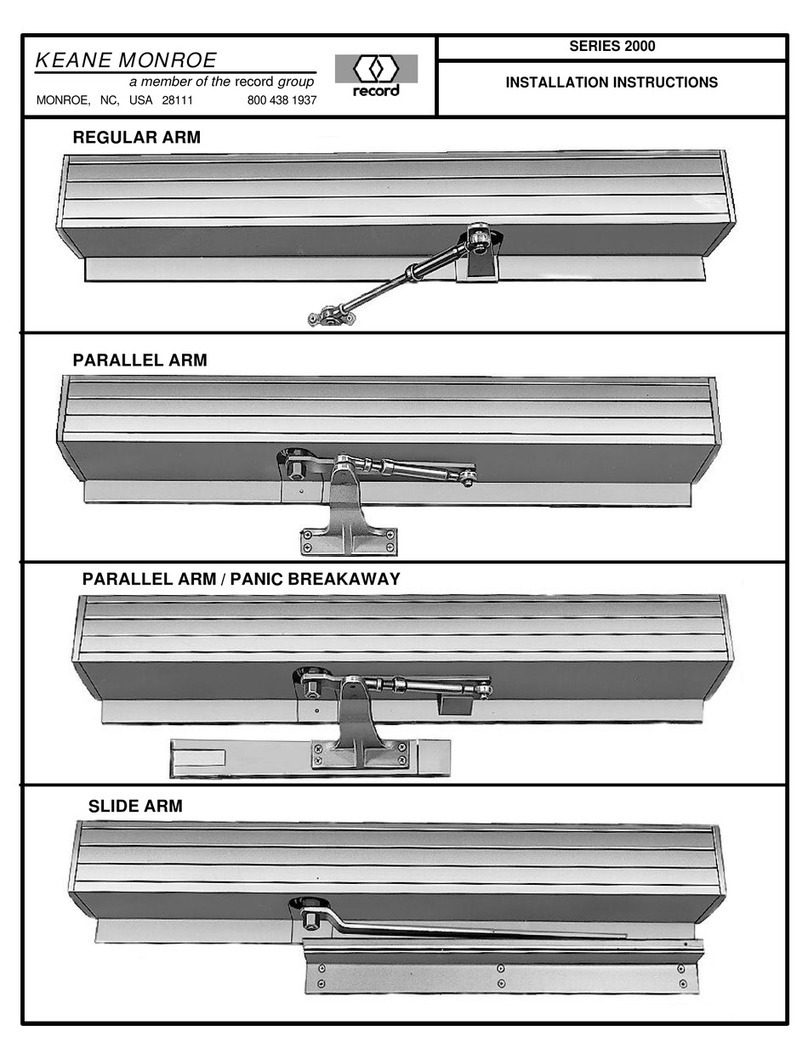

3.1 Construction.......................................................................................................................................... 12

3.2 Versions................................................................................................................................................ 13

3.3 Components ......................................................................................................................................... 14

3.4 Functional description........................................................................................................................... 14

3.5 Accessories .......................................................................................................................................... 15

3.5.1 Lever arm......................................................................................................................................... 15

3.5.2 Gearbox cover with position switch.................................................................................................. 15

3.5.3 Extended function module FEM 1.................................................................................................... 16

3.5.4 Wind load brake ............................................................................................................................... 16

4 Technical Data .................................................................................................................................................. 17

4.1 Door leaf weights and door widths........................................................................................................ 17

4.2 Operator in stainless steel casing......................................................................................................... 18

5 Operation........................................................................................................................................................... 19

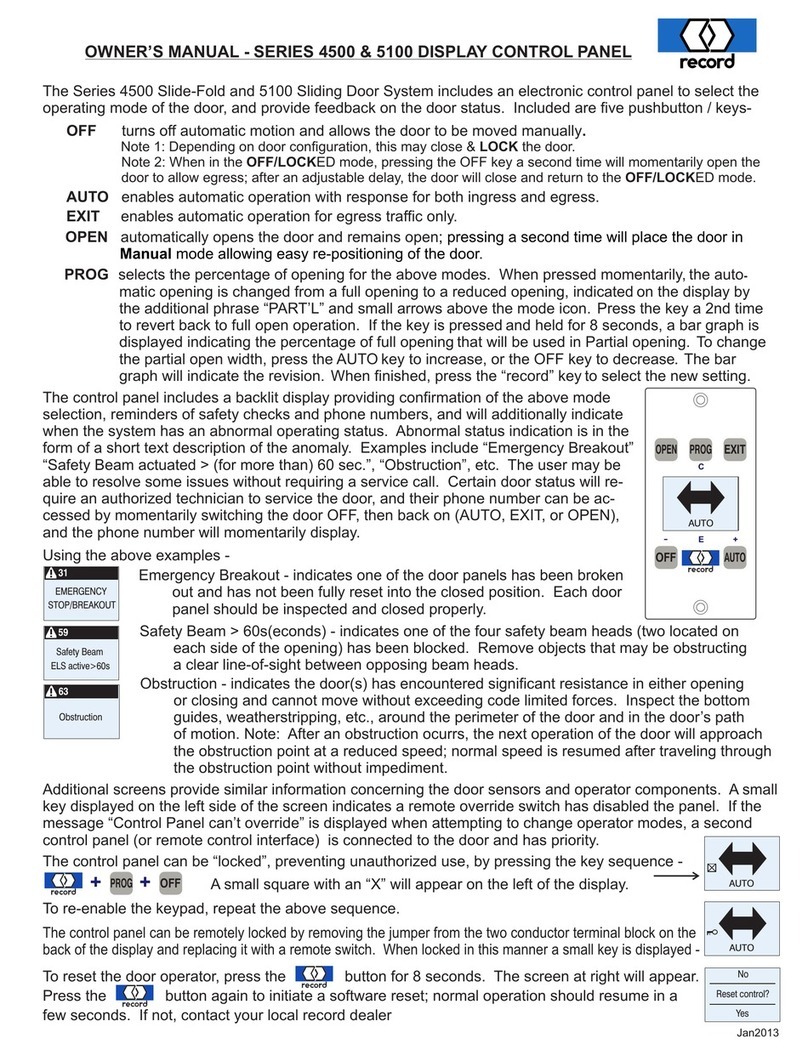

5.1 Control panel BDE-D ............................................................................................................................ 19

5.1.1 Operation modes and button functions ............................................................................................ 19

5.1.2 Perform reset ................................................................................................................................... 20

5.1.3 Display system information .............................................................................................................. 21

5.2 Parameter overview.............................................................................................................................. 21

5.3 Configuration C 127 STG 127 V3_00_E............................................................................................... 22

5.4 Configuration FEM V1_10 with STG127 V2_40_E............................................................................... 23

5.5 Description of parameters..................................................................................................................... 24

6 Servicing and maintenance ............................................................................................................................. 25

6.1 General remarks ................................................................................................................................... 25

6.2 Door care .............................................................................................................................................. 25

6.3 Logbook ................................................................................................................................................ 26

6.3.1 General information ......................................................................................................................... 26

6.3.2 Operator duties ................................................................................................................................ 27

6.3.3 Commissioned technician ................................................................................................................ 27

6.3.4 Legal principle.................................................................................................................................. 27

6.3.5 Extent of the inspection.................................................................................................................... 28

6.3.6 Requirements for documentation..................................................................................................... 28

7 Malfunctions ..................................................................................................................................................... 29

7.1 Status displays...................................................................................................................................... 29

7.2 Troubleshooting .................................................................................................................................... 29