11

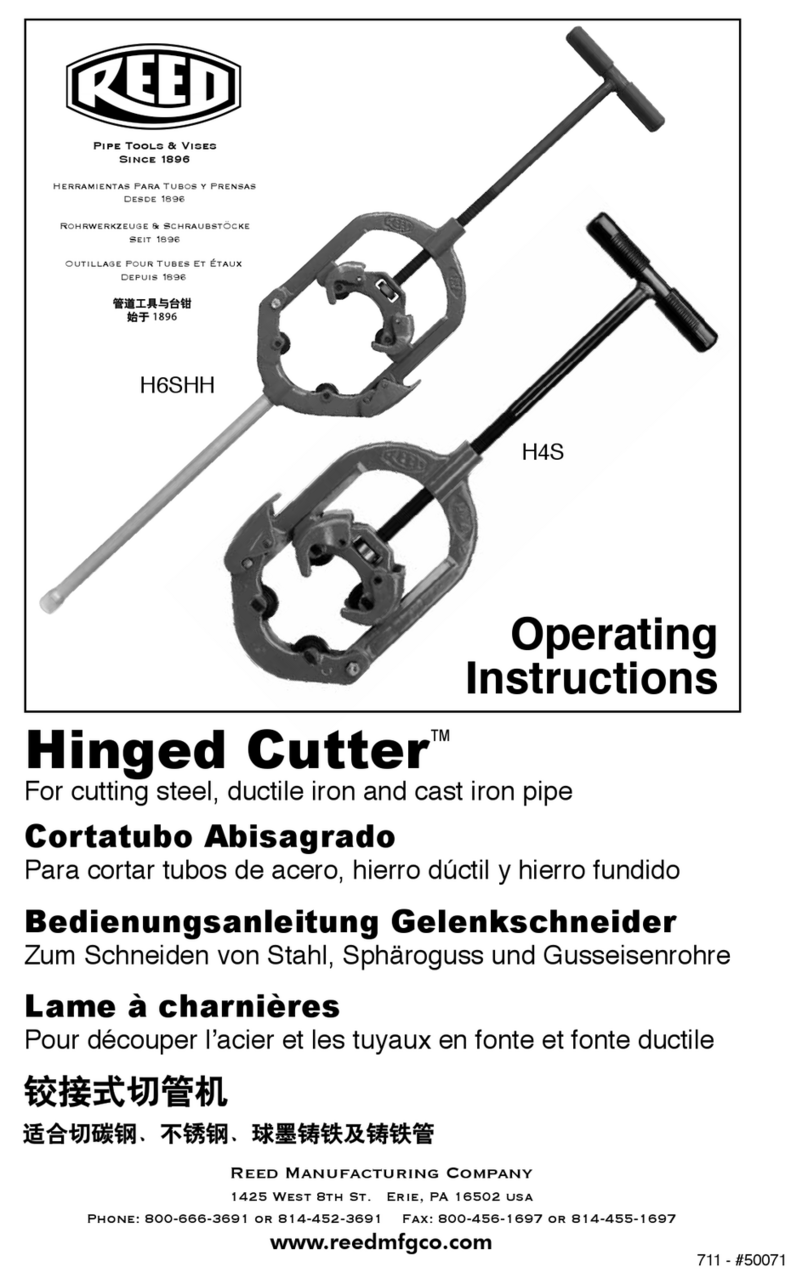

Ref. H2-1/2 H4 H6 H8 H12

No. Description Item Code Item Code Item Code Item Code Item Code Qty

1 Upper Yoke 93150 93151 93152 93153 93154 1

2 Lower Yoke 93120 93121 93122 93123 93124 1

3 Crosshead 93135 93136 93137 93138 93139 1

4 Handle & Screw 93125 93126 93127 93128 93128 1

5 Latch 93115 93116 93117 93117 93117 1

6 Guide 93043 93046 93049 93049 93049 2

7 Crosshead Locknut 93140 93141 93142 93143 93143 1

8 Set Screws 40083 40090 40090 40090 40090 2

9 Guide Spring 40341 40035 40036 40036 40036 2

10 Latch Spring 40046 40030 40030 40030 40030 1

11 Thrust Washer 93044 93010 93052 93052 93052 1

12 Wheel Pin 93310 93310 93112 93112 93112 4

13 Guide Pin 30030 30030 30013 30013 30013 2

14 Latch Pin 93019 93018 93018 93018 93018 1

15 Lower Yoke Pin 93181 93008 93008 93008 93008 1

16 Locknut 30179 30143 30143 30143 30143 1

17 Hinge Bolt 93155 93146 93156 93156 93156 1

18 Handle Grips Not Used 40196 40197 40197 40197 2

19 Cutter Wheel See Cutter Wheel Reference Chart: Table 2

20 Crosshead Assembly 93130 93131 93132 93133 93134 1

Parts List

Bez. H2-1/2 H4 H6 H8 H12

Nr. Beschreibung Art-Code Art-Code Art-Code Art-Code Art-Code Menge

1 Oberer Bügel 93150 93151 93152 93153 93154 1

2 Unterer Bügel 93120 93121 93122 93123 93124 1

3 Kreuzkopfeinheit 93135 93136 93137 93138 93139 1

4 Griff & Schraube 93125 93126 93127 93128 93128 1

5 Sperre 93115 93116 93117 93117 93117 1

6 Führung 93043 93046 93049 93049 93049 2

7 Kreuzkopf-Feststellmutter 93140 93141 93142 93143 93143 1

8 Gewindestifte 40083 40090 40090 40090 40090 2

9 Führungsfeder 40341 40035 40036 40036 40036 2

10 Sperrfeder 40046 40030 40030 40030 40030 1

11 Anlaufscheibe 93044 93010 93052 93052 93052 1

12 Radstift 93310 93310 93112 93112 93112 4

13 Führungsstift 30030 30030 30013 30013 30013 2

14 Sperrstift 93019 93018 93018 93018 93018 1

15 Unterer Bügelstift 93181 93008 93008 93008 93008 1

16 Feststellmutter 30179 30143 30143 30143 30143 1

17 Kopplungsbolzen 93155 93146 93156 93156 93156 1

18 Griffe Nicht benutzt 40196 40197 40197 40197 2

19 Schneidrad Siehe Bezugstabelle für Schneidräder, Abb. 2 auf Seite 2

20 Kreuzkopfeinheit 93130 93131 93132 93133 93134 1

Ersatzteilliste