2

I . SAFETY INSTRUCTIONS & WARNING

A. Always Comply With:

1. General Industry Safety & Health Regulations, Part

1910, OSHA 2206. Available from: Sup’t of Docu-

ments, Government Printing Office, Washington, DC

20402.

2. ANSI Specification Nos. B186.1, B7.1 Available from:

American National Standards Institute, Inc., 1430

Broadway, New York, NY 10018.

3. State and Local Regulations.

B. Abbreviated Form of Above Regulations:

These regulations are not all inclusive—study and

comply with all above regulations.

1. Check Cutter Speed Before Mounting Cutter.

2. Use Tachometer

Actual speed must not exceed rated speed.

3. Perform Speed Checks When:

a. A tool is issued for use.

b. After all tool repairs.

4. Use Tools Only For Intended Purpose

Refer to Product Catalog.

5. Test & Operate Tools at 90 PSIG Maximum

Only exception is if tool is marked otherwise.

6. Use Recommended Air Line Equipment

This includes air line filters, regulators, and lubricators.

7. Stop Immediately If:

a. Unusual sound is heard, or...

b. Unusual vibration is experienced (Refer to Section

III to check if proper assembly was followed).

8. Check Speed Rating Of Blade

Must equal or exceed speed rating of air motor.

9. Mount Blade According To Regulations

Refer to manufacturer’s instructions regarding spindles,

lock nuts, spacers, keys, flanges, etc. (Sec. IIIA,

Items 4 and 6).

10. Mount Proper Blade Guard

a. Refer to Sec. IIIA, Items 3 and 7 for proper and

secure mounting.

— TABLE OF CONTENTS —

l. SAFETY INSTRUCTIONS & WARNING 2

ll. DESCRIPTION/CAPACITIES 2, 3

lll. ASSEMBLY 3, 4, 5

lV. OPERATION 5, 6

V. MAINTENANCE 6

Vl. REPLACEMENT PARTS LIST 6, 7

b. Sample Warning Label:

WARNING

HIGH SPEED ROTATING BLADES

PERSONAL INJURY CAN OCCUR IF HANDS ARE NOT

KEPT CLEAR OF BLADES. ALWAYS WEAR PROPER EYE

AND EAR PROTECTION. DO NOT OPERATE THIS UNIT

WITHOUT THE BLADE GUARD IN PLACE.

DO NOT USE THIS CUTTER ON AC PIPE. FREE AS-

BESTOS FIBERS ARE HAZARDOUS TO YOUR HEALTH.

DO NOT USE THIS CUTTER ON FRP(GRP) PIPE. FREE

FIBERGLASS FIBERS MAY BE HAZARDOUS TO YOUR

HEALTH.

REED MFG. CO. ERIE, PA. U.S.A.

11. Inspect Blade

a. Refer to aforementioned regulations. (Sec. I, Item A)

b. Discard if chipped, cracked or otherwise damaged.

12. Always Wear Protective Equipment When Tool

is in Use

a. Refer to aforementioned regulations (Sec. I, Item A)

concerning goggles, face shields, and other

protective clothing.

b. Appropriate hearing protection which reduces noise

to acceptable levels must be worn.

13. Employ a Safety Program

Refer to ANSI and OSHA specifications for inspection

and maintenance procedures.

WARNING: Failure to comply with all safety

regulations may result in serious injury.

I I . DESCRIPTION

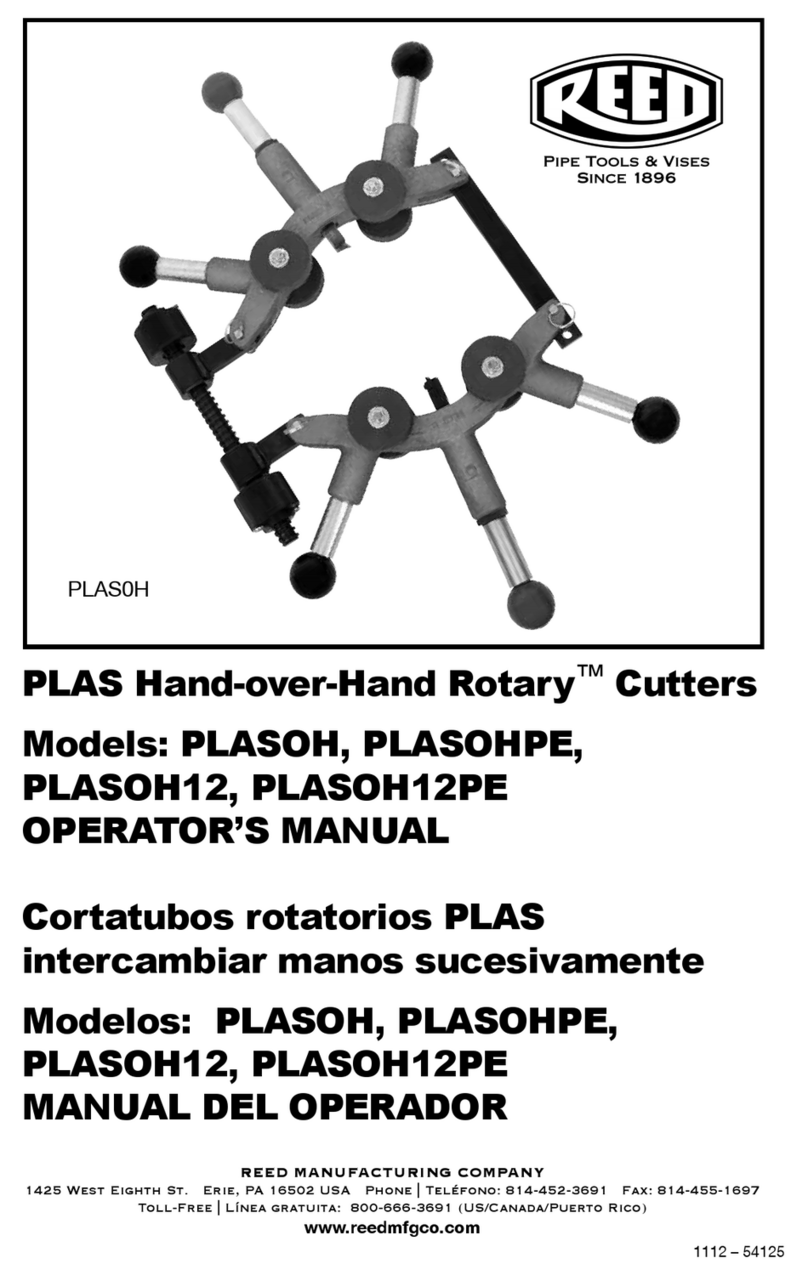

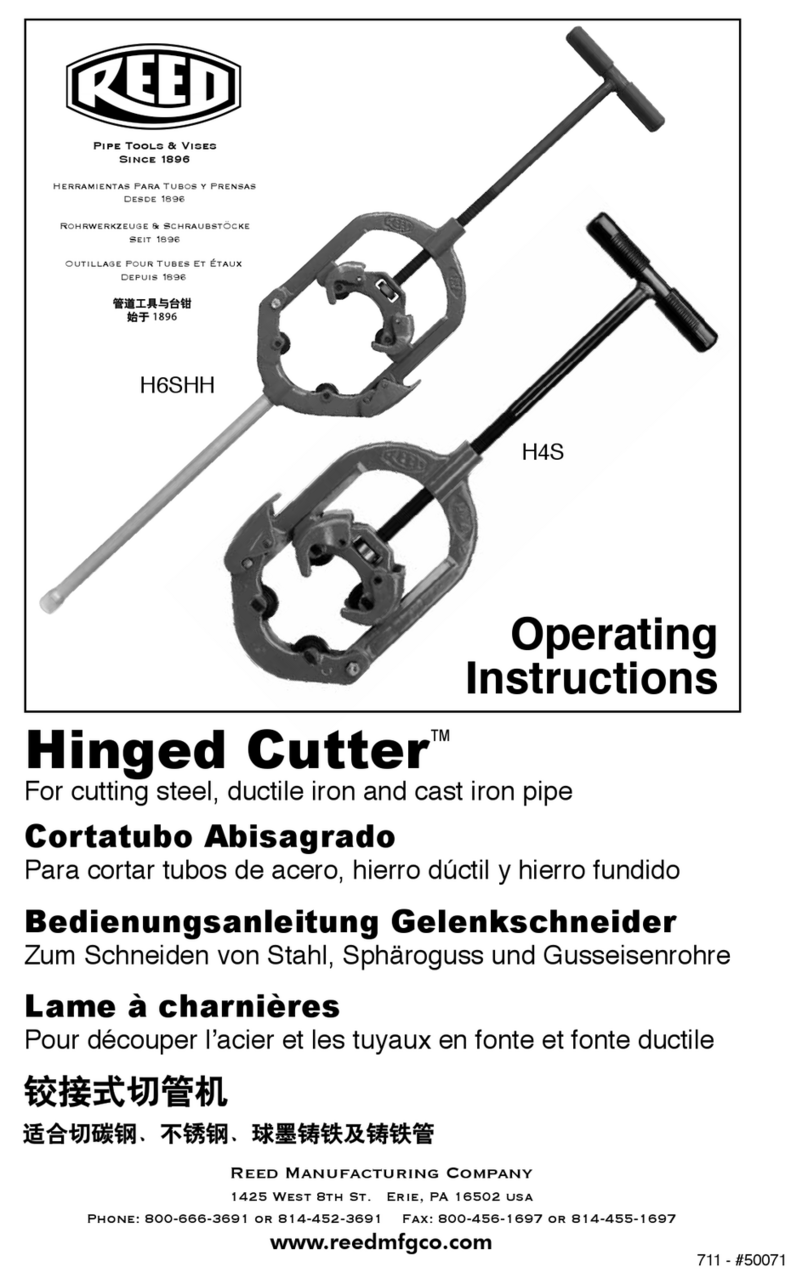

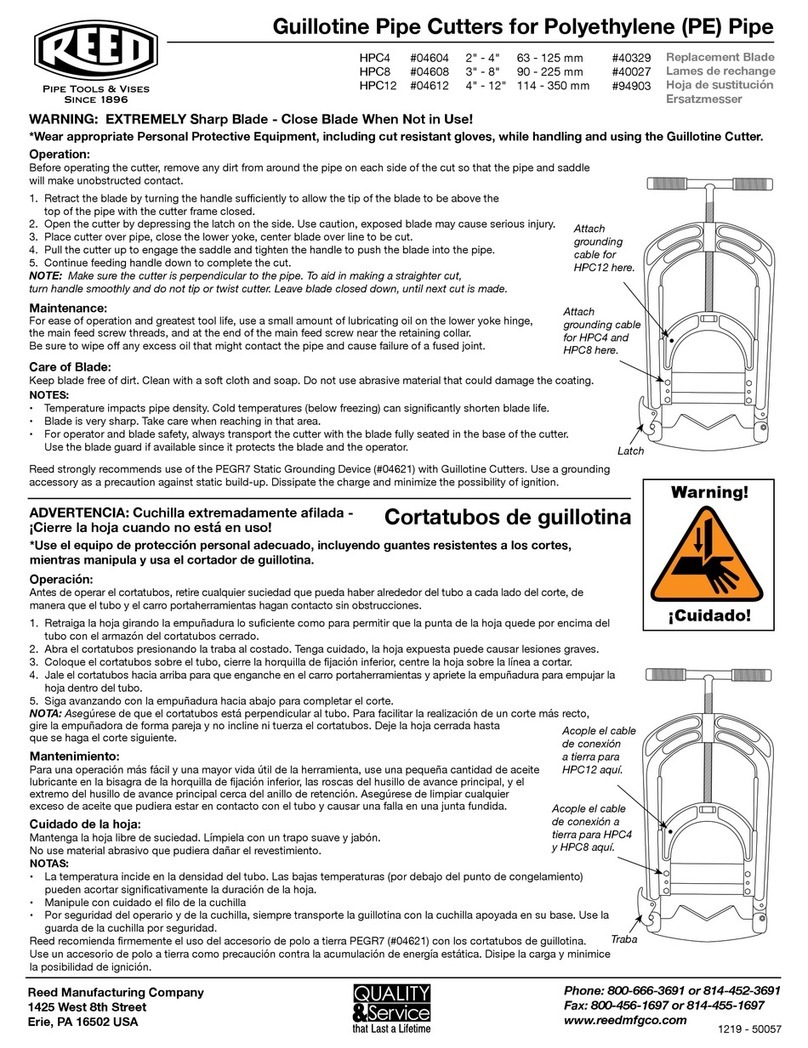

A. Pipe Cutter Model: UPC 616A, 636A and 648A

B. Motor Specifications:

Horsepower = 1.7 H.P.

Maximum R.P.M. = 3675

Air Consumption = 50 SCFM

Pressure = 90 P.S.I. Maximum

Shut -Off =

3

⁄4" Ball valve

Air Supply Fittings =

3

⁄4" Dixon “Air King” Coupling