2418C JAN 00 1.5.5

CORRIGO C10-LON

DI7 Eingang für verlängerter Betrieb bei Betrieb mit

Ventilatoren mit einer Geschwindigkeit bzw. verlängerter

Betrieb mit hoher Geschwindigkeit beim Betrieb mit

Ventilatoren mit zwei Geschwindigkeiten.

DI8 Eingang für Start vom verlängerten Betrieb, niedrige

Geschwindigkeit beim Betrieb mit Ventilator mit zwei

Geschwindigkeiten.

DI7 und DI8 werden, in Abhängigkeit von der

Einstellung, entweder an momentan schließenden

Druckknopf oder z.B. an einem Timer, angeschlossen.

Falls DI7 und DI8 gleichzeitig geschlossen werden, wird

Corrigo das Gerät abschalten.

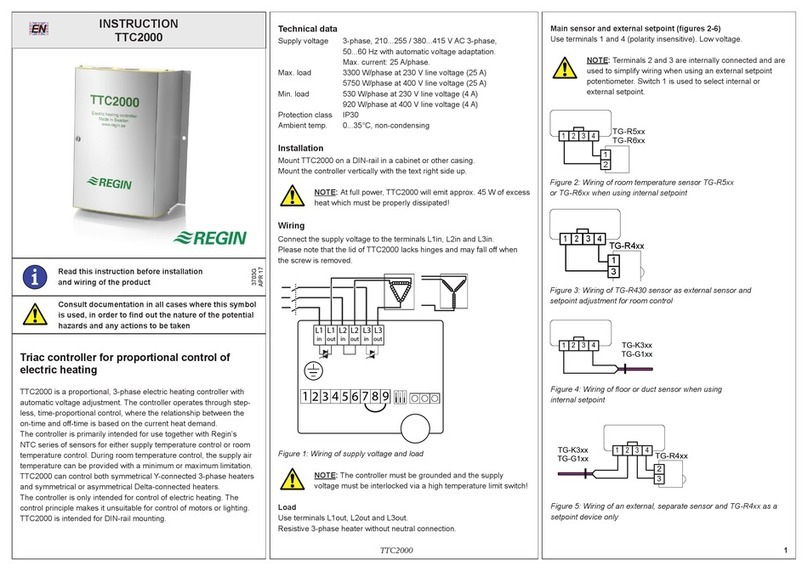

Bei der Montage mit externen Handschaltern für die

Steuerung der Betriebsarten, gemäß Bild 1 und 2

anschließen.

ANWEISUNG ANWEISUNG 2

Ausgänge

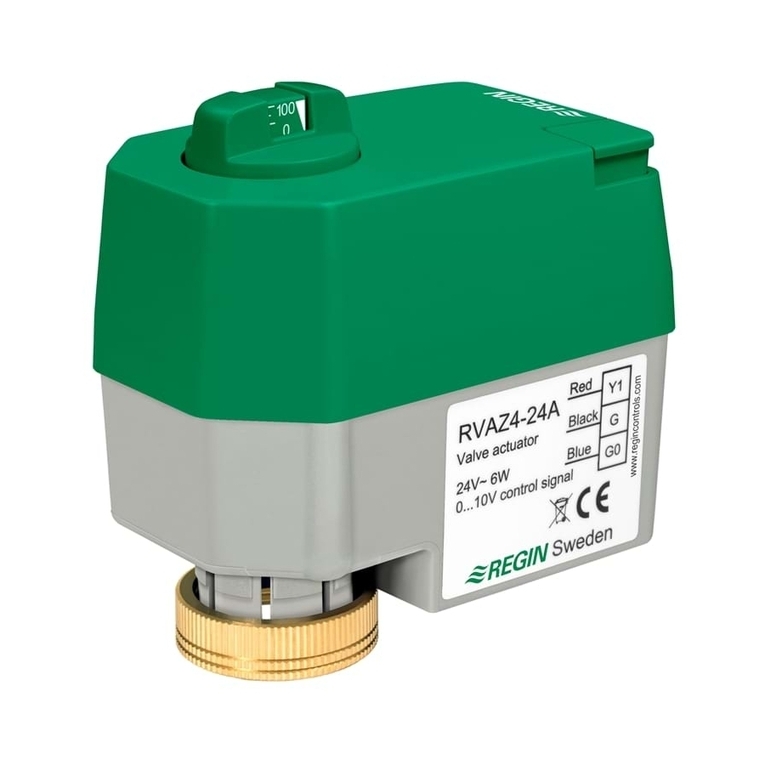

Analoge 0...10V DC Steuerausgänge AO1,AO2,AO3

Ausgangssignal 0...10V DC, 5 mA. Kurzschlusssicher.

AO1 Steuerausgang Y1

AO2 Steuerausgang Y2

AO3 Steuerausgang Y3

Diese Ausgänge sollen zur Klemme 41, Meßnull

referieren.

Da die Meßnull von Stellantrieben an Klemme 41

angeschlossen werden, auch wenn der Stellantrieb und

Corrigo an dem gleichen Transformator angeschlossen

sind.

Die Funktion der Ausgänge ist abhängig von der

Konfiguration, aber die Sekvenzfolge ist immer Y3-Y2-

Y1 bei steigendem Wärmebedarf.

Weitere Steuerausgänge DO1... DO7

Die digitalen Ausgänge DO1...DO6 sind Triac-gesteuert,

0,5 A, 24 V AC. Kurzzeitige Belastung 1 A.

Die Ausgänge werden Paarweise mit 24 V AC (siehe

Klemmenliste) gespeist.

Für höhere Spannungen und Ströme, Relaismodul

RM6-24/D oder RM6H-24/D, die für diesen Einsatz

angepaßt sind, einsetzen. Manche Ausgänge erhalten

alternative Funktionen in Abhängigkeit von der Applika-

tion. Dies bedeutet z.B., daß eine Kältemaschine nicht

mit einer Steuerung eines Gebläses mit zwei

Geschwindigkeiten kombiniert werden kann.

DO1 Steuert Zuluftsventilator oder hohe

Geschwindigkeit für Zuluftventilatoren mit zwei

Geschwindigkeiten

DO2 Steuert Fortluftsventilator oder hohe

Geschwindigkeit für Fortluftventilatoren mit zwei

Geschwindigkeiten

DO3 Steuert Umwälzpumpe falls vorhanden.

DO4 steuert Kältemaschine 1 falls vorhanden oder

Zuluftsventilator niedrige Geschwindigkeit bei zwei

Geschwindigkeiten.

DO5 Steuert Kältemaschine 2 falls vorhanden oder

Fortluftsventilator niedrige Geschwindigkeit bei

zwei Geschwindigkeiten.

DO6 Steuert externe Frostschutzverriegelung oder

Feuerklappenrutine (siehe Kästchen DO6/DI6)

DO7 Potentialfreier Relaisschalter der für die

Sammelstörmeldung genutzt wird, 1 A, 24 V AC/

DC. Schließt bei Alarm

Steuertasten und Fenster

Sprachauswahl

Corrigo ermöglicht das Anzeigen von Text im Fenster in

verschiedene Sprachen. Die Wahl der Sprache wird

durch drücken auf der Taste !während Corrigo an die

Spannung angeschlossen wird, ermöglicht. Um die

Sprache zu ändern, nochmals auf die Taste !drücken.

Ein Anzeige wird neben der aktuellen Sprache

angezeigt. Zum Ändern éoder êdrücken. Wenn die

gewünschte Sprache gewählt ist, OK drücken.

Nochmals OK drücken um wieder in das normale

System zu gelangen. Jede Information die im Fenster

angezeigt werden kann ist in Abschnitten in einen

Eingabe/anzeigebaum organisiert. Mit Hilfe der Tasten

an der Gerätefront kann man verschiedene Abschnitte

im Eingabe/anzeigebaum wählen, Parameter

überprüfen, Einstellungen ändern, Alarme ablesen und

quittieren.

Verschiedene Loginebenen führen zu verschiedenen

Zugang und Befugnissen.

Der Stamm des Eingabe/anzeigebaumes besteht aus

den folgenden Abschnitten:

Einloggen

Konfigurierung wird nur in Ebene 3 angezeigt

Regelung Temp. Anfangskästchen im Eingabe/

anzeigebaum

Betriebsart

AI Analoge Eingänge

DI Digitale Eingänge

AO Analoge Ausgänge

DO Digitale Ausgänge

Kalender

Alarmeinstellungen wird in Ebene 0 nicht angezeigt

Einstellungen wird nur in Ebene 2 und 3

angezeigt

Unter normalem Betrieb, wenn die Tasten nicht betätigt

werden, wird eine wiederholende Serie von Informatio-

nen angezeigt. Die Anzeige wechselt zwischen

Startkästchen mit Produktbezeichnung und Uhr,

Sollwert/Istwert für die Temperaturregelung und dem

Regelstatus für die Ausgänge Y1, Y2 und Y3.

Um zum Eingabe/anzeigebaum zu kommen, OK

drücken, wobei Corrigo zum Abschnitt Regelung Temp.

wechselt.

Mit éund êbewegt man sich aufwärts oder abwärts

entlang dem Stamm. Die Pfeile Rechts im Fenster

zeigen an ob es Abschnitte über oder unter dem

aktuellen gibt.

Um auf eine Verzweigung zu kommen, OK drücken. Auf

der Verzweigung kann man sich in der gleichen Weise

mit dem Pfeilen bewegen. Mit Esc bewegt man sich

zurück zum Stamm.

In den Abschnitten mit variablen Parametern wechselt

man zu „Ändern“ durch drücken auf !.

Eine blinkende Anzeige ist im ersten variablen Feld zu

sehen. Mit den Pfeiltasten kann der Wert geändert

werden. Wenn ein richtiger Wert eingestellt ist, wird dies

mit OK bestätigt, wobei die Anzeige in das nächste Feld

springt.

Nach OK im letzten Feld wird der geänderte Wert

gespeichert und das System verläßt „Ändern“.

Um eine Änderung ohne Maßnahme zu verlassen, Esc

drücken, wobei die Anzeige ein Feld zurück springt.

„Ändern“ wird nach einigen Minuten Inaktivität automat-

isch abgebrochen.

%Öffnet Alarmliste. Anzeige von aktiven und nicht

quittierten Alarmen im Fenster. Die Leuchtdiode für

Sammelstörmeldung, oberhalb der Taste, leuchtet wenn

Alarme in der Liste vorhanden sind. Sind mehrere

Alarme vorhanden, werden éund êfür das Blättern

zwischen diesen, verwendet. Ein Alarm wird mit OK

quittiert. Um ohne Maßnahme abzubrechen, Esc

drücken.

*CORRIGO C10* Sollwert/Istwert Y1 / Y2 / Y3

Mo 980907 10:10 20.0ºC / 20.0ºC 0% / 45% / 0%

>Regelung Temp á

AI Analog eing. â

REGELFUNKT. á

>0 Zuluftsregl â