9

Only use a REMS rapid charger for charging. New Li-Ion batteries and Li-Ion

batteries which have not been used for a long time only reach full capacity after

REMS Cento

The cordless pipe cutting machine is equipped with an electronic machine

status check (Fig. 1 (18)) by a two-coloured green/red LED. The LED lights

green when the battery is fully or still suffi ciently charged. The LED lights red

when the battery must be charged. If this status occurs during cutting, cutting

must be completed with a charged Li-Ion battery. The LED lights red and the

cordless pipe cutting machine switches off if overloaded. After a short dwell time,

the LED lights green again and the cutting process can be continued. The LED

fl ashes red if the motor temperature has been exceeded. After a cooling time,

the LED lights green again and cutting can be continued. The cooling time is

reduced when the cordless pipe cutting machine is operated in idle mode.

If the cordless pipe cutting machine is not being used, the LED goes out after

approx. 2 hours but comes on again when the cordless pipe cutting machine

duated charging state display

of the Li-Ion 21.6 V battery

The graduated charging state display shows the charging state of the battery

with 4 LEDs. At least one LED lights f

or a few seconds after pressing the key

with 4 LEDs. At least one LED lights for a few seconds after pressing the keywith 4 LEDs. At least one LED lights f

with the battery symbol. The more LEDs that light green, the higher the charging

state of the battery. If a LED fl ashes red, the battery must be charged.

er (A

The left control lamp lights up and remains green when the mains plug is

plugged in. If a battery is inserted in the rapid charger, the green control lam

fl ashes to indicate that the battery is charging. The green light stops fl ashing

and remains on to signal that the battery is fully charg

ed. If the red control lamp

fl ashes, the battery is defective. If a red

this indicates that the temperature of the rapid charge

outside the permissible operating range of the rapid charger of 0 °C to +40 °C.

NOTICE

The rapid chargers are not suit

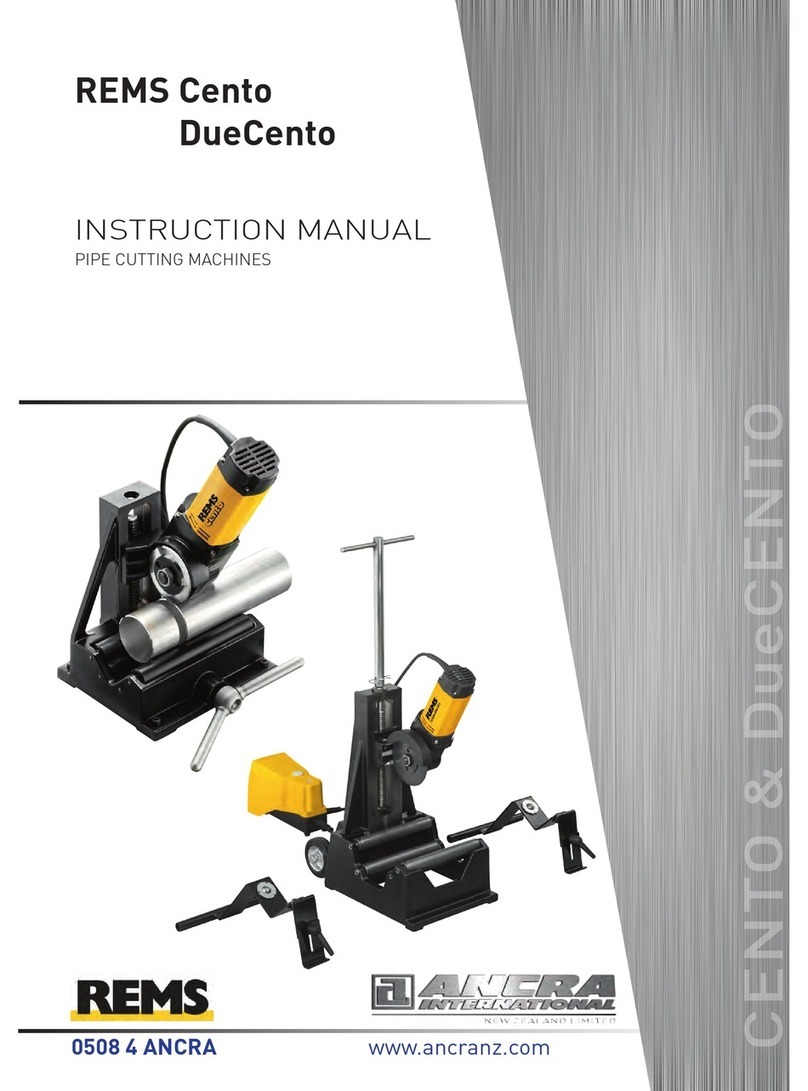

2.2. Installing the pipe cutting machine

REMS Cento / REMS Cento RF

REMS Cento / REMS Cento RF, REMS Cento / REMS Cento RF

REMS Cento

Fasten the pipe cutting machine e.g. to REMS Jumbo E / REMS Jumbo (Fig. 1)

(accessory Art. No. 120240/120200) or to the base frame/mobile base frame

(Fig. 2) (accessory Art. No. 849315/849310) with 4 or 2 M 8 screws. Make sure

that there is enough room for the pipe cutting machine, REMS Jumbo/base

frame and the pipe to be cut.

Longer pipes must be supported by REMS Herkules

No. 120120) or REMS Herkules Y (Art. No. 120130),

REMS Herkules XL 12" (Art. No. 120125),

on both sides of the pipe cutting

machine if necessary. Move the cutting wheel drive (1) forwards by turning the

feed lever (6) until the pipe to be cut (5) can be placed on the rollers (3). To set

the height of REMS Herkules, place the pipe to be cut in the centre of the rollers

(3) of the pipe cutting machine. Do not allow the pipe (5) to knock against the

cutting wheel (2), the cutting wheel could otherwise be damaged. Open the

clamping lever of REMS Herkules, lower the pipe rest of REMS Herkules, place

REMS Herkules under the pipe near the pipe cutting machine, lift the pipe rest

against the pipe and tighten the clamping lever. Place the preset REMS Herkules

under the end of the pipe. Place other material rest(s) between the pipe cutting

machine and the pipe end(s) if necessary to reduce untrue running of the pipe.

Alternatively, the pipe cutting machine (manufactured as of 2014) can be used

on a fi rm, level ground with feed lever of REMS DueCento (Fig. 6 (6)) (acces-

sory Art. No. 845218). For this, remove the feed lever from the pipe cutting

machine (Fig. 1 (6)) by moving the cutting wheel drive (1) all the way up, then

turning the feed lever (6) abruptly further until the feed lever is released from

the thread. Push the feed lever of REMS DueCento (Fig. 7 (6)) onto the spindle

(Fig. 7 (8)). Make sure that there is a positive fi t between the groove of the feed

lever and the parallel pin of the spindle and push the spring plug (Fig. 7 (9))

into the holes of the feed lever and the spindle (Fig. 7). Make sure that there

is enough room for the pipe cutting machine and the pipe to be cut.

pipes must be supported with pipe rest(s) 1 Ø 40 –110 mm, Ø 1½ – 4" (acces-

sory Art. No. 845220),on both sides of the pipe cutting machine if necessary.

Move the cutting wheel drive (1) forwards by turning the feed lever (6) until the

pipe to be cut (5) can be placed on the rollers (3). To set the height of the pipe

rest, place the pipe to be cut in the centre of the rollers (3) of the pipe cutting

machine. Do not allow the pipe (5) to knock against the cutting wheel (2), the

cutting wheel could otherwise be damaged. Open the clamping lever of the

pipe rest, lower the pipe rest , place the pipe rest under the pipe near the pipe

cutting machine, lift the pipe rest against the pipe and tighten the clamping

lever. Place the preset pipe rest under the end of the pipe. Place other pipe

rest(s) between the pipe cutting machine and the pipe end(s) if necessary to

Remove the pipe from the rollers (3) if necessary to fi t the feed lever REMS

REMS Cento

22 V (Fig. 1 (6)). Pull out the spring plug

(Fig. 7 (9)) if necessary and remove the feed lever of REMS DueCento (Fig. 6

(6)). Screw on feed lever of REMS Cento / REMS Cento RF,

REMS Cento

(Fig. 1 (6)). Move the cutting wheel drive (1) down and pull the feed lever tight

abruptly. Always only use one feed lever.

REMS Cento / REMS Cento RF,

REMS Cento

22 V may only be moved or

carried by the feed lever of REMS DueCento (6) when this has been locked

with the spring plug (9) as described above. Otherwise there is a danger that

the feed lever (6) will come away from the spindle (8). REMS Cento / REMS

REMS Cento

22 V can fall over or drop. Danger of injury!

Use REMS Cento RF and REMS cutting wheel RF for cutting welded stainless

steel drainpipes/downpipes (EN 1124). To cut diameters 75 mm and 110 mm,

fi x the appropriate pipe guide (Fig. 5 (15)) to the stand (17) with the two cylinder

head screws (16). Move the cutting wheel drive (1) right up by turning the feed

lever (6). To place pipes with a diameter of 75 mm and 110 mm on the rollers

(3), push through the side of the pipe guide (15). Do not allow the pipe (5) to

knock against the cutting wheel (2), the cutting wheel could otherwise be

damaged. Use/set pipe rests as described above.

NOTICE

When the pipe guide (15) is fi tted, the hexagon nut for fi xing the cutting wheel

could hit the pipe guide (15) if the cutting wheel drive (1) is moved too far down.

Place the pipe cutting machine on a fi rm, level base. Make sure that there is

enough room for the pipe cutting machine, the height adjustable pipe rests and

the pipe to be cut. Push the feed lever (6) onto the spindle (8). Make sure that

there is a positive fi t between the groove of the feed lever and the parallel pin

of the spindle and push the spring plug (9) into the holes of the feed lever and

the spindle (Fig. 7). Longer pipes must be supported with height-adjustable

pipe rests (Fig. 6 (10)) on both sides of the machine if necessary. Move the

cutting wheel drive (1) forwards by turning the feed lever (6) until the pipe to

be cut (5) can be placed on the rollers (3). To set the height of the height adjust-

able rests (10), place the pipe to be cut in the centre of the rollers (3) of the

pipe cutting machine. Do not allow the pipe (5) to knock against the cutting

wheel (2), the cutting wheel could otherwise be damaged. Open the clamping

lever (11) of the height adjustable pipe rests (10). Place the height adjustable

pipe rests (10) under the pipe near the pipe cutting machine (Fig. 8), lift against

the pipe and tighten the clamping lever (11). Place the preset pipe rests under

each end of the pipe. Place other pipe rest(s) between the pipe cutting machine

and the pipe end(s) if necessary to reduce untrue running of the pipe.

Do not fasten REMS DueCento and height adjustable pipe rests (10) to the

base because otherwise a pipe running off centre could break the cutting wheel.

REMS DueCento may only be moved or carried by the feed lever (6) when this

has been locked with the spring plug (9) as described above. Otherwise there

is a danger that the feed lever (6) will come away from the spindle (8). REMS

DueCento can then fall over or fall off. Danger of injury!

2.3. Fitting (changing) the cutting wheel (2)

Pull out the mains plug or remove the battery! Choose suitable cutting wheel.

Loosen the hexagonal nut for fastening the cutting wheel (right-hand thread)

with the size 27 ring spanner provided. Insert (change) cutting wheel (2). Make

sure that the driver pins of the drive shaft engage in the holes of the cutting

wheel. Tighten the hexagonal nut.

NOTICE

An unsuitable cutting wheel will be damaged or the pipe will not be cut.

only original REMS cutting wheels!

2.4. Cutting pipes Ø 40 –

Place roller insert for cuttin

g pipes Ø 40 – 110 mm, Ø 1½ – 4" (14) (

845060), on the rollers (3). For pipes Ø 40 – 70 mm or for pipes

Ø 70 – 110 mm, place roller insert in the rollers (3) as shown in Fig.

pipes must be supported by height adjustable pipe rests 2

sory Art. No. 845230), on both sides of the pipe cutting machine if necessary,

Wear suitable clothing. Do not wear loose clothing or jewellery. Keep hair,

clothing and gloves away from moving parts.

Loose clothing, jewellery or

long hair can get caught in moving parts.

Support longer pipes (see 2.2)! The cut pipe sections can fall to the fl oor

immediately after being cut!

Move the cutting wheel drive (1) forwards by turning the feed lever (6) until the

pipe to be cut (5) can be placed on the rollers (3). Outside burr (sawing burr)

must be removed from the pipe otherwise the rollers will be damaged. Make

sure that the REMS cutting wheel (2) suitable for the pipe to be cut is selected/

fi tted. Do not allow the pipe (5) to knock against the cutting wheel (2) when

inserting, the cutting wheel could be damaged. Mark the cutting point on the

pipe and position it to the cutting wheel. Press the safety foot switch (7). Turn

the feed lever (6) until the cutting wheel sets the pipe in rotation. Then turn the