eng eng

2. Start-up

2.1. Electrical connection

WARNING

Caution: Mains voltage present!Beforeconnectingthepipecuttingmachine,

checkwhetherthevoltagegivenontheratingplatecorrespondstothemains

voltage.Onbuildingsites,inawetenvironmentorforsimilartypesofapplica-

tion,onlyoperatethepipecuttingmachineonthemainsviaa30mAfault

currentprotection(FIswitch).Observethecross-sectionnecessaryforthe

output of the pipe cutting machine when using an extension cable.

2.2. Installing the pipe cutting machine

REMS Cento

Fasten the pipe cutting machine e.g. to REMS Jumbo (Fig. 1) (Art. No. 120200)

or to the base frame (Fig. 2) (Art. No. 849315) with 4 or 2 M8 screws. Make

surethatthereisenoughroomforthepipecuttingmachine,REMSJumbo/

baseframeandthepipetobecut.LongerpipesmustbesupportedbyREMS

Herkules(Fig.2)(Art.No.120100)orREMSHerkulesY(Art.No.120130),on

bothsidesofthepipecuttingmachineifnecessary.Movethecuttingwheel

drive(1)forwardsbyturningthefeedlever(6)untilthepipetobecut(5)can

beplacedontherollers(3).To settheheightofREMSHerkules,placethepipe

to be cut in the centre of the rollers (3) of the pipe cutting machine. Do not allow

thepipe(5)toknockagainstthecuttingwheel(2),thecuttingwheelcould

otherwisebedamaged.OpentheclampingleverofREMSHerkules,lowerthe

piperestofREMSHerkules,placeREMSHerkulesunderthepipenearthe

pipecuttingmachine,liftthepiperestagainstthepipeandtightentheclamping

lever.PlacethepresetREMSHerkulesundertheendofthepipe.Placeother

material rest(s) between the pipe cutting machine and the pipe end(s) if neces-

sarytoreduceuntruerunningofthepipe.

1. Technical data

Use for the intended purpose

WARNING

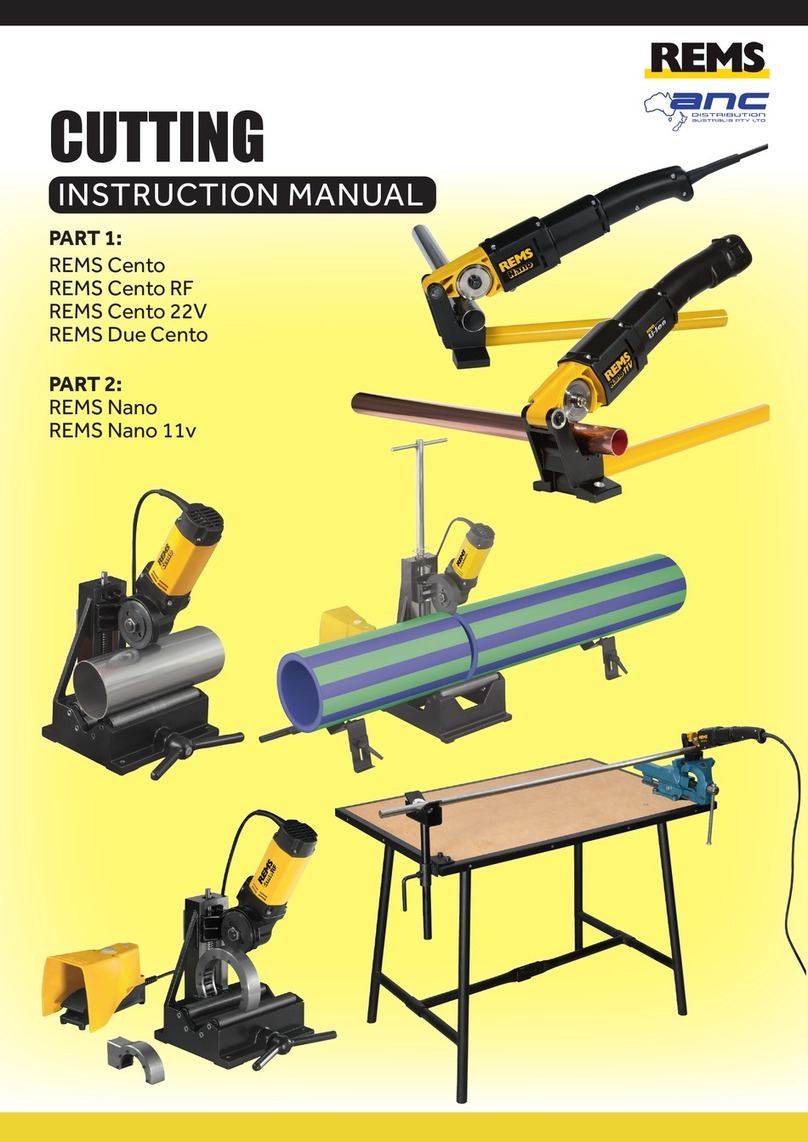

REMS Cento and REMS DueCento are intended for the purpose of cutting and deburring the inside and outside of pipes.

All other uses are not for the intended purpose and are therefore prohibited.

1.1. Scope of Supply

REMSCentoBasic: Pipecuttingmachine,ringspannersize27/17,instructionmanual.

REMSDueCentoBasic: Pipecuttingmachine,ringspannersize27/17,2heightadjustablepiperests,feedlever,springplug,instructionmanual.

1.2. Article numbers REMS Cento REMS DueCento

Pipecuttingmachine 845000 845005

REMScuttingwheelCu-INOXforpipesofthepressttingsystemsof

stainlesssteel,copper,carbonsteel 845050 845050

REMScuttingwheelCuespeciallyforpipesofthepressttingsystemsofcopper 845053 845053

REMScuttingwheelStforsteelpipes,castpipes(SML) 845052 845052

REMScuttingwheelC-SFespeciallyforpipesofthepressttingsystems/pushtting

systemsofcarbonsteel,simultaneouslyproducesachamfer 845055 845055

REMScuttingwheelV,s10,forplasticandcompositetubes,wallthicknesss≤10mm 845051 845051

REMScuttingwheelP, s21,forplasticandcompositetubes,wallthicknesss≤21mm 845057

Base frame 849315

Rollers INOX (set) of tubular stainless steel 845110

Roller insert for cutting pipes Ø 40 – 100 mm 845060

Ring spanner size 27/17 849112 849112

REMSHerkules3B,materialrestwithtripod 120100

REMSHerkulesY, materialrestwithclampingdevice 120130

HeightadjustablepiperestØ100–225mm 845220

HeightadjustablepiperestØ40–100mm 845230

REMSJumbo,foldingworkbench 120200

REMSREG10–54E,outside/insidepipedeburrer 113835

REMSREG28–108,insidepipedeburrer 113840

REMSCleanM,machinecleaner 140119 140119

1.3. Area of application REMS Cento REMS DueCento

Stainlesssteelpipes,copperpipes,compositetubes,

Carbonsteelpipesofthepressttingsystems Ø(8)22–108mm Ø(54)108–225mm

SteelpipesDINEN10255(DIN2440) DN(10)20–100;(⅜”)¾–4” DN(50)100–150;(1½”)4–6”

Cast pipes (SML) DIN 19522 DN 40 – 100 mm DN (40) 100 – 200 mm

PlastictubesSDR11,compositetubes Ø(10)25–110mm Ø(50)–110mm

Wallthickness,copperpipes,castpipes(SML) ≤4.5mm ≤5.0mm

Wallthicknessplastic/compositetubes ≤10.0mm ≤21.0mm

1.4. Speed

Cutting wheel idle speed 115 rpm 115 rpm

1.5. Electrical data

230V~;50–60Hz;1,200W;5,7A.Fuse(mains)10A(B),intermittentmodeS320%(AB2/10min),protectiveinsulated,radiointerferencesuppressed,or

110V~;50–60Hz;1,200W;11,4A.Fuse(mains)20A,intermittentmodeS320%(AB2/10min),protectiveinsulated,radiointerferencesuppressed.

1.6. Dimensions REMS Cento REMS DueCento

L×W×H: 250×300×250mm(10”×12”×14”) 260×430×515mm(10.2”×16.9”×20.3”)

1.7. Weight

withoutsafetyfootswitch 17.8kg(39lb) 36.4kg(80.2lb)

1.8. Noise information

Acousticpressurelevel LpA = 87 dB LpA = 87 dB

Acousticpowerlevel Lwa = 98 dB Lwa = 98 dB

Acousticpressurelevel Lpc peak = 100 dB Lpc peak = 100 dB

K = 3 dB K = 3 dB

1.9. Vibrations

Weightedrmsvalueofacceleration <2.5m/s² <2.5m/s²

K = 1.5 dB K = 1.5 dB

Thespeciedvibrationemissionvaluewasmeasuredaccordingtoastandardtestmethodandcanbeusedforcomparisonwithanotherdevice.Thespeciedvibra-

tionemissionvaluecanalsobeusedforaninitialestimationofthecut-out.

CAUTION

Thevibrationemissionvaluemaydifferfromthespeciedvalueduringactualuseofthepipecuttingmachinedependingonthemannerinwhichthepipecutting

machineisused.Dependingontheactualconditionsofuse(intermittentmode),itmaybenecessarytodenesafetymeasurestoprotecttheoperator.

2. Start-up

2.1. Electrical connection

WARNING

Caution: Mains voltage present!Beforeconnectingthepipecuttingmachine,

checkwhetherthevoltagegivenontheratingplatecorrespondstothemains

voltage.Onbuildingsites,inawetenvironmentorforsimilartypesofapplica-

tion,onlyoperatethepipecuttingmachineonthemainsviaa30mAfault

currentprotection(FIswitch).Observethecross-sectionnecessaryforthe

output of the pipe cutting machine when using an extension cable.

2.2. Installing the pipe cutting machine

REMS Cento

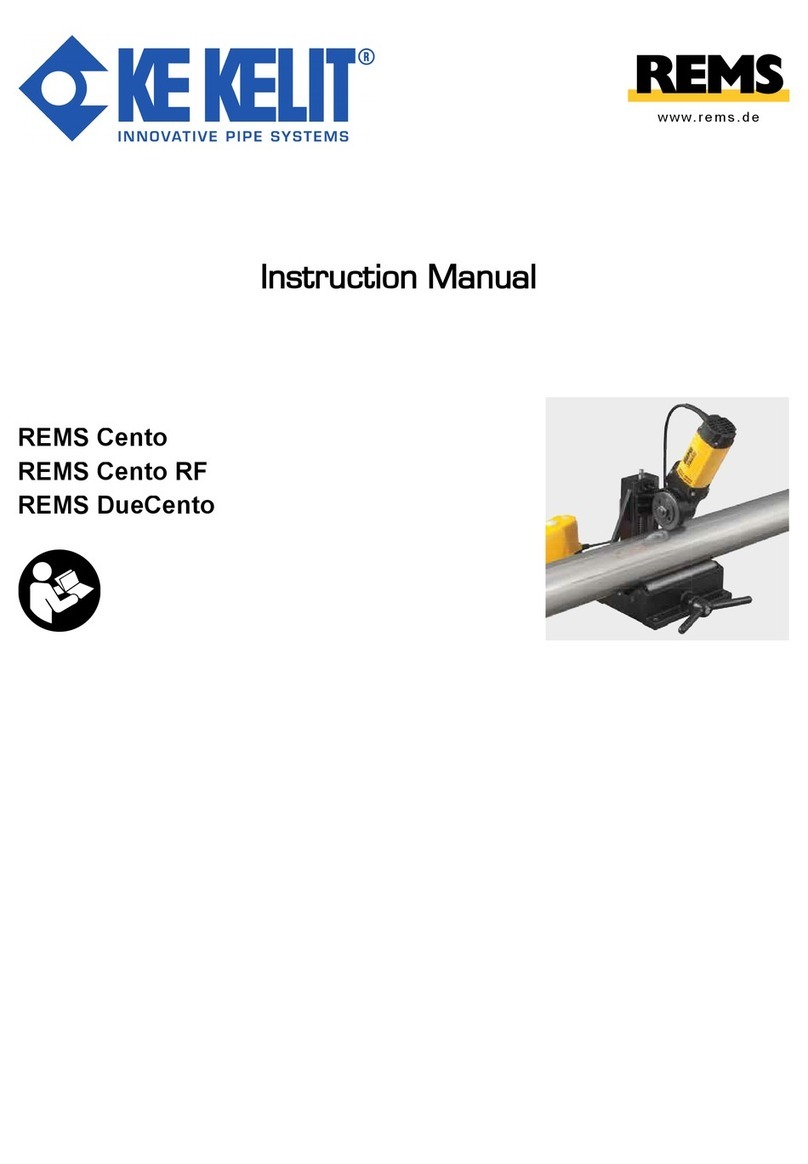

Fasten the pipe cutting machine e.g. to REMS Jumbo (Fig. 1) (Art. No. 120200)

or to the base frame (Fig. 2) (Art. No. 849315) with 4 or 2 M8 screws. Make

surethatthereisenoughroomforthepipecuttingmachine,REMSJumbo/

baseframeandthepipetobecut.LongerpipesmustbesupportedbyREMS

Herkules(Fig.2)(Art.No.120100)orREMSHerkulesY(Art.No.120130),on

bothsidesofthepipecuttingmachineifnecessary.Movethecuttingwheel

drive(1)forwardsbyturningthefeedlever(6)untilthepipetobecut(5)can

beplacedontherollers(3).To settheheightofREMSHerkules,placethepipe

to be cut in the centre of the rollers (3) of the pipe cutting machine. Do not allow

thepipe(5)toknockagainstthecuttingwheel(2),thecuttingwheelcould

otherwisebedamaged.OpentheclampingleverofREMSHerkules,lowerthe

piperestofREMSHerkules,placeREMSHerkulesunderthepipenearthe

pipecuttingmachine,liftthepiperestagainstthepipeandtightentheclamping

lever.PlacethepresetREMSHerkulesundertheendofthepipe.Placeother

material rest(s) between the pipe cutting machine and the pipe end(s) if neces-

sarytoreduceuntruerunningofthepipe.

1. Technical data

Use for the intended purpose

WARNING

REMS Cento and REMS DueCento are intended for the purpose of cutting and deburring the inside and outside of pipes.

All other uses are not for the intended purpose and are therefore prohibited.

1.1. Scope of Supply

REMSCentoBasic: Pipecuttingmachine,ringspannersize27/17,instructionmanual.

REMSDueCentoBasic: Pipecuttingmachine,ringspannersize27/17,2heightadjustablepiperests,feedlever,springplug,instructionmanual.

1.2. Article numbers REMS Cento REMS DueCento

Pipecuttingmachine 845000 845005

REMScuttingwheelCu-INOXforpipesofthepressttingsystemsof

stainlesssteel,copper,carbonsteel 845050 845050

REMScuttingwheelCuespeciallyforpipesofthepressttingsystemsofcopper 845053 845053

REMScuttingwheelStforsteelpipes,castpipes(SML) 845052 845052

REMScuttingwheelC-SFespeciallyforpipesofthepressttingsystems/pushtting

systemsofcarbonsteel,simultaneouslyproducesachamfer 845055 845055

REMScuttingwheelV,s10,forplasticandcompositetubes,wallthicknesss≤10mm 845051 845051

REMScuttingwheelP, s21,forplasticandcompositetubes,wallthicknesss≤21mm 845057

Base frame 849315

Rollers INOX (set) of tubular stainless steel 845110

Roller insert for cutting pipes Ø 40 – 100 mm 845060

Ring spanner size 27/17 849112 849112

REMSHerkules3B,materialrestwithtripod 120100

REMSHerkulesY, materialrestwithclampingdevice 120130

HeightadjustablepiperestØ100–225mm 845220

HeightadjustablepiperestØ40–100mm 845230

REMSJumbo,foldingworkbench 120200

REMSREG10–54E,outside/insidepipedeburrer 113835

REMSREG28–108,insidepipedeburrer 113840

REMSCleanM,machinecleaner 140119 140119

1.3. Area of application REMS Cento REMS DueCento

Stainlesssteelpipes,copperpipes,compositetubes,

Carbonsteelpipesofthepressttingsystems Ø(8)22–108mm Ø(54)108–225mm

SteelpipesDINEN10255(DIN2440) DN(10)20–100;(⅜”)¾–4” DN(50)100–150;(1½”)4–6”

Cast pipes (SML) DIN 19522 DN 40 – 100 mm DN (40) 100 – 200 mm

PlastictubesSDR11,compositetubes Ø(10)25–110mm Ø(50)–110mm

Wallthickness,copperpipes,castpipes(SML) ≤4.5mm ≤5.0mm

Wallthicknessplastic/compositetubes ≤10.0mm ≤21.0mm

1.4. Speed

Cutting wheel idle speed 115 rpm 115 rpm

1.5. Electrical data

230V~;50–60Hz;1,200W;5,7A.Fuse(mains)10A(B),intermittentmodeS320%(AB2/10min),protectiveinsulated,radiointerferencesuppressed,or

110V~;50–60Hz;1,200W;11,4A.Fuse(mains)20A,intermittentmodeS320%(AB2/10min),protectiveinsulated,radiointerferencesuppressed.

1.6. Dimensions REMS Cento REMS DueCento

L×W×H: 250×300×250mm(10”×12”×14”) 260×430×515mm(10.2”×16.9”×20.3”)

1.7. Weight

withoutsafetyfootswitch 17.8kg(39lb) 36.4kg(80.2lb)

1.8. Noise information

Acousticpressurelevel LpA = 87 dB LpA = 87 dB

Acousticpowerlevel Lwa = 98 dB Lwa = 98 dB

Acousticpressurelevel Lpc peak = 100 dB Lpc peak = 100 dB

K = 3 dB K = 3 dB

1.9. Vibrations

Weightedrmsvalueofacceleration <2.5m/s² <2.5m/s²

K = 1.5 dB K = 1.5 dB

Thespeciedvibrationemissionvaluewasmeasuredaccordingtoastandardtestmethodandcanbeusedforcomparisonwithanotherdevice.Thespeciedvibra-

tionemissionvaluecanalsobeusedforaninitialestimationofthecut-out.

CAUTION

Thevibrationemissionvaluemaydifferfromthespeciedvalueduringactualuseofthepipecuttingmachinedependingonthemannerinwhichthepipecutting

machineisused.Dependingontheactualconditionsofuse(intermittentmode),itmaybenecessarytodenesafetymeasurestoprotecttheoperator.

eng eng

2. Start-up

2.1. Electrical connection

WARNING

Caution: Mains voltage present!Beforeconnectingthepipecuttingmachine,

checkwhetherthevoltagegivenontheratingplatecorrespondstothemains

voltage.Onbuildingsites,inawetenvironmentorforsimilartypesofapplica-

tion,onlyoperatethepipecuttingmachineonthemainsviaa30mAfault

currentprotection(FIswitch).Observethecross-sectionnecessaryforthe

output of the pipe cutting machine when using an extension cable.

2.2. Installing the pipe cutting machine

REMS Cento

Fasten the pipe cutting machine e.g. to REMS Jumbo (Fig. 1) (Art. No. 120200)

or to the base frame (Fig. 2) (Art. No. 849315) with 4 or 2 M8 screws. Make

surethatthereisenoughroomforthepipecuttingmachine,REMSJumbo/

baseframeandthepipetobecut.LongerpipesmustbesupportedbyREMS

Herkules(Fig.2)(Art.No.120100)orREMSHerkulesY(Art.No.120130),on

bothsidesofthepipecuttingmachineifnecessary.Movethecuttingwheel

drive(1)forwardsbyturningthefeedlever(6)untilthepipetobecut(5)can

beplacedontherollers(3).To settheheightofREMSHerkules,placethepipe

to be cut in the centre of the rollers (3) of the pipe cutting machine. Do not allow

thepipe(5)toknockagainstthecuttingwheel(2),thecuttingwheelcould

otherwisebedamaged.OpentheclampingleverofREMSHerkules,lowerthe

piperestofREMSHerkules,placeREMSHerkulesunderthepipenearthe

pipecuttingmachine,liftthepiperestagainstthepipeandtightentheclamping

lever.PlacethepresetREMSHerkulesundertheendofthepipe.Placeother

material rest(s) between the pipe cutting machine and the pipe end(s) if neces-

sarytoreduceuntruerunningofthepipe.

1. Technical data

Use for the intended purpose

WARNING

REMS Cento and REMS DueCento are intended for the purpose of cutting and deburring the inside and outside of pipes.

All other uses are not for the intended purpose and are therefore prohibited.

1.1. Scope of Supply

REMSCentoBasic: Pipecuttingmachine,ringspannersize27/17,instructionmanual.

REMSDueCentoBasic: Pipecuttingmachine,ringspannersize27/17,2heightadjustablepiperests,feedlever,springplug,instructionmanual.

1.2. Article numbers REMS Cento REMS DueCento

Pipecuttingmachine 845000 845005

REMScuttingwheelCu-INOXforpipesofthepressttingsystemsof

stainlesssteel,copper,carbonsteel 845050 845050

REMScuttingwheelCuespeciallyforpipesofthepressttingsystemsofcopper 845053 845053

REMScuttingwheelStforsteelpipes,castpipes(SML) 845052 845052

REMScuttingwheelC-SFespeciallyforpipesofthepressttingsystems/pushtting

systemsofcarbonsteel,simultaneouslyproducesachamfer 845055 845055

REMScuttingwheelV,s10,forplasticandcompositetubes,wallthicknesss≤10mm 845051 845051

REMScuttingwheelP, s21,forplasticandcompositetubes,wallthicknesss≤21mm 845057

Base frame 849315

Rollers INOX (set) of tubular stainless steel 845110

Roller insert for cutting pipes Ø 40 – 100 mm 845060

Ring spanner size 27/17 849112 849112

REMSHerkules3B,materialrestwithtripod 120100

REMSHerkulesY, materialrestwithclampingdevice 120130

HeightadjustablepiperestØ100–225mm 845220

HeightadjustablepiperestØ40–100mm 845230

REMSJumbo,foldingworkbench 120200

REMSREG10–54E,outside/insidepipedeburrer 113835

REMSREG28–108,insidepipedeburrer 113840

REMSCleanM,machinecleaner 140119 140119

1.3. Area of application REMS Cento REMS DueCento

Stainlesssteelpipes,copperpipes,compositetubes,

Carbonsteelpipesofthepressttingsystems Ø(8)22–108mm Ø(54)108–225mm

SteelpipesDINEN10255(DIN2440) DN(10)20–100;(⅜”)¾–4” DN(50)100–150;(1½”)4–6”

Cast pipes (SML) DIN 19522 DN 40 – 100 mm DN (40) 100 – 200 mm

PlastictubesSDR11,compositetubes Ø(10)25–110mm Ø(50)–110mm

Wallthickness,copperpipes,castpipes(SML) ≤4.5mm ≤5.0mm

Wallthicknessplastic/compositetubes ≤10.0mm ≤21.0mm

1.4. Speed

Cutting wheel idle speed 115 rpm 115 rpm

1.5. Electrical data

230V~;50–60Hz;1,200W;5,7A.Fuse(mains)10A(B),intermittentmodeS320%(AB2/10min),protectiveinsulated,radiointerferencesuppressed,or

110V~;50–60Hz;1,200W;11,4A.Fuse(mains)20A,intermittentmodeS320%(AB2/10min),protectiveinsulated,radiointerferencesuppressed.

1.6. Dimensions REMS Cento REMS DueCento

L×W×H: 250×300×250mm(10”×12”×14”) 260×430×515mm(10.2”×16.9”×20.3”)

1.7. Weight

withoutsafetyfootswitch 17.8kg(39lb) 36.4kg(80.2lb)

1.8. Noise information

Acousticpressurelevel LpA = 87 dB LpA = 87 dB

Acousticpowerlevel Lwa = 98 dB Lwa = 98 dB

Acousticpressurelevel Lpc peak = 100 dB Lpc peak = 100 dB

K = 3 dB K = 3 dB

1.9. Vibrations

Weightedrmsvalueofacceleration <2.5m/s² <2.5m/s²

K = 1.5 dB K = 1.5 dB

Thespeciedvibrationemissionvaluewasmeasuredaccordingtoastandardtestmethodandcanbeusedforcomparisonwithanotherdevice.Thespeciedvibra-

tionemissionvaluecanalsobeusedforaninitialestimationofthecut-out.

CAUTION

Thevibrationemissionvaluemaydifferfromthespeciedvalueduringactualuseofthepipecuttingmachinedependingonthemannerinwhichthepipecutting

machineisused.Dependingontheactualconditionsofuse(intermittentmode),itmaybenecessarytodenesafetymeasurestoprotecttheoperator.