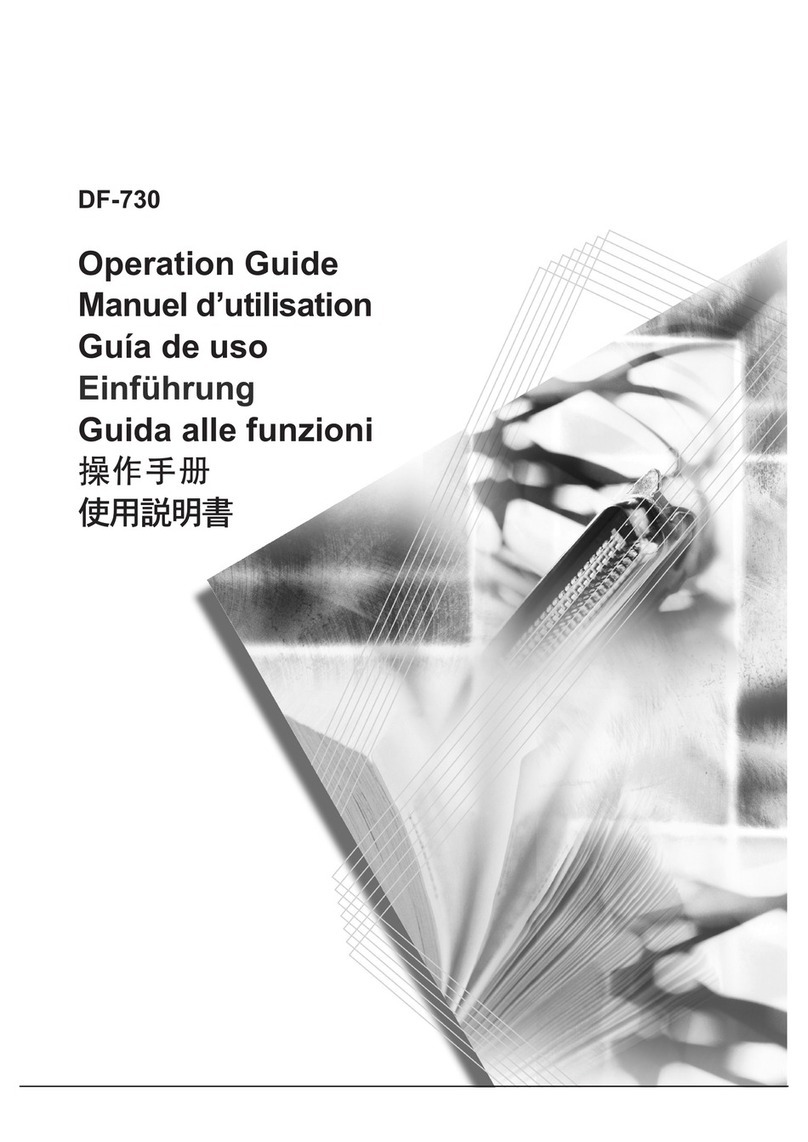

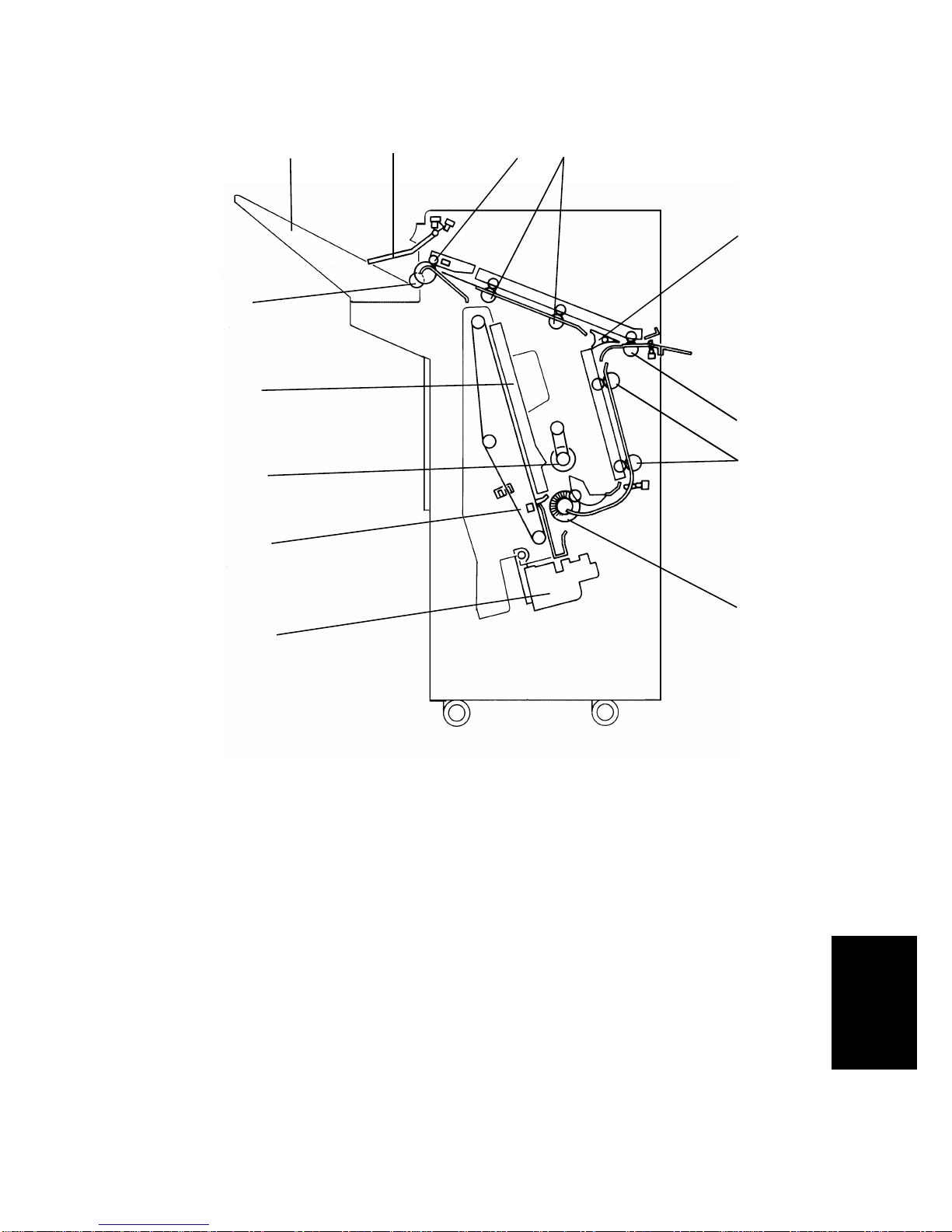

2.2 SHIFT TRAY UP/DOWN MECHANISM

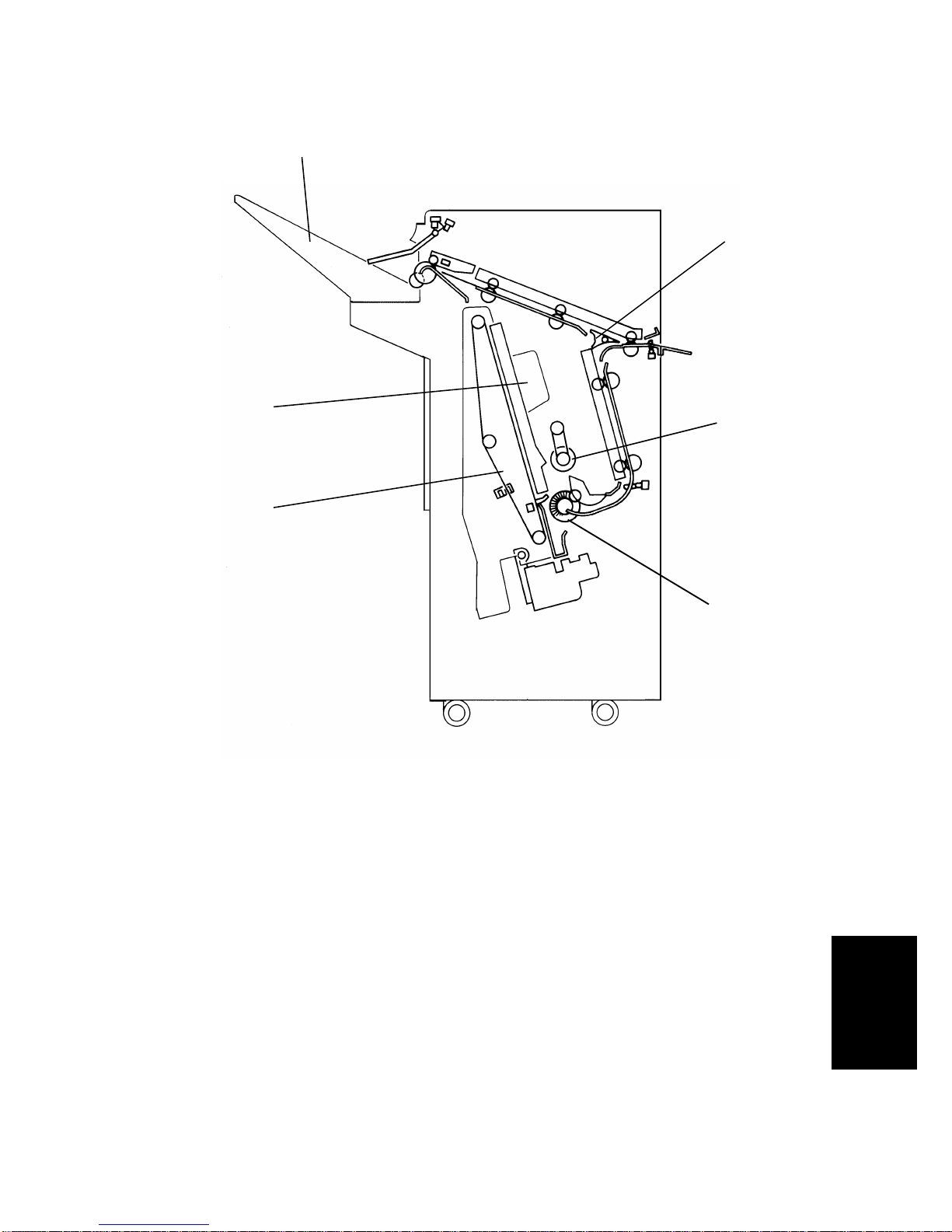

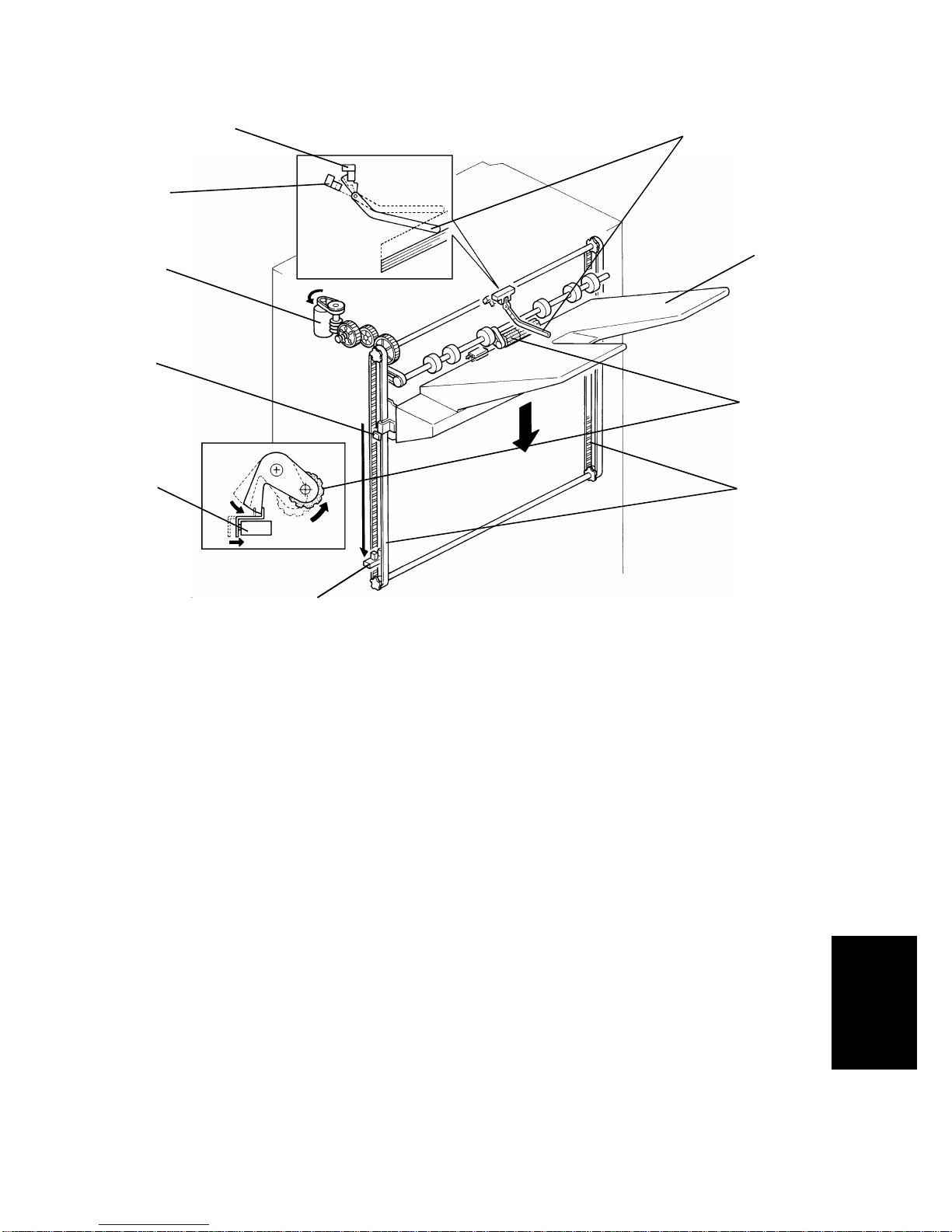

The vertical position of the shift tray [A] is controlled by the shift tray lift motor

(dc motor) [B] through gears and timing belts [C]. When the main switch is

turned on, the tray position is initialized to the upper position. The tray’s

uppermost position is detected when the shift tray pushes up the actuator [D]

to deactuate the stack height sensor 1 [E].

While copying, the actuator [D] is gradually raised as the copy stack grows. In

the sort/stack mode, when stack height sensor 2 [F] remains actuated for 4

seconds, the shift tray lift motor [B] rotates, lowering the tray unit for 50 ms.

In staple mode, when the stack height sensor 1 remains deactuated for 4

seconds, the motor rotates, lowering the tray until the sensor [E] is actuated.

When the tray reaches its lower limit position, the lower limit sensor [G] is

actuated by the actuator [H], and copy operation stops.

After the copy process is finished and the machine stops, the tray is raised to

its upper most position 4 seconds after the copies are removed.

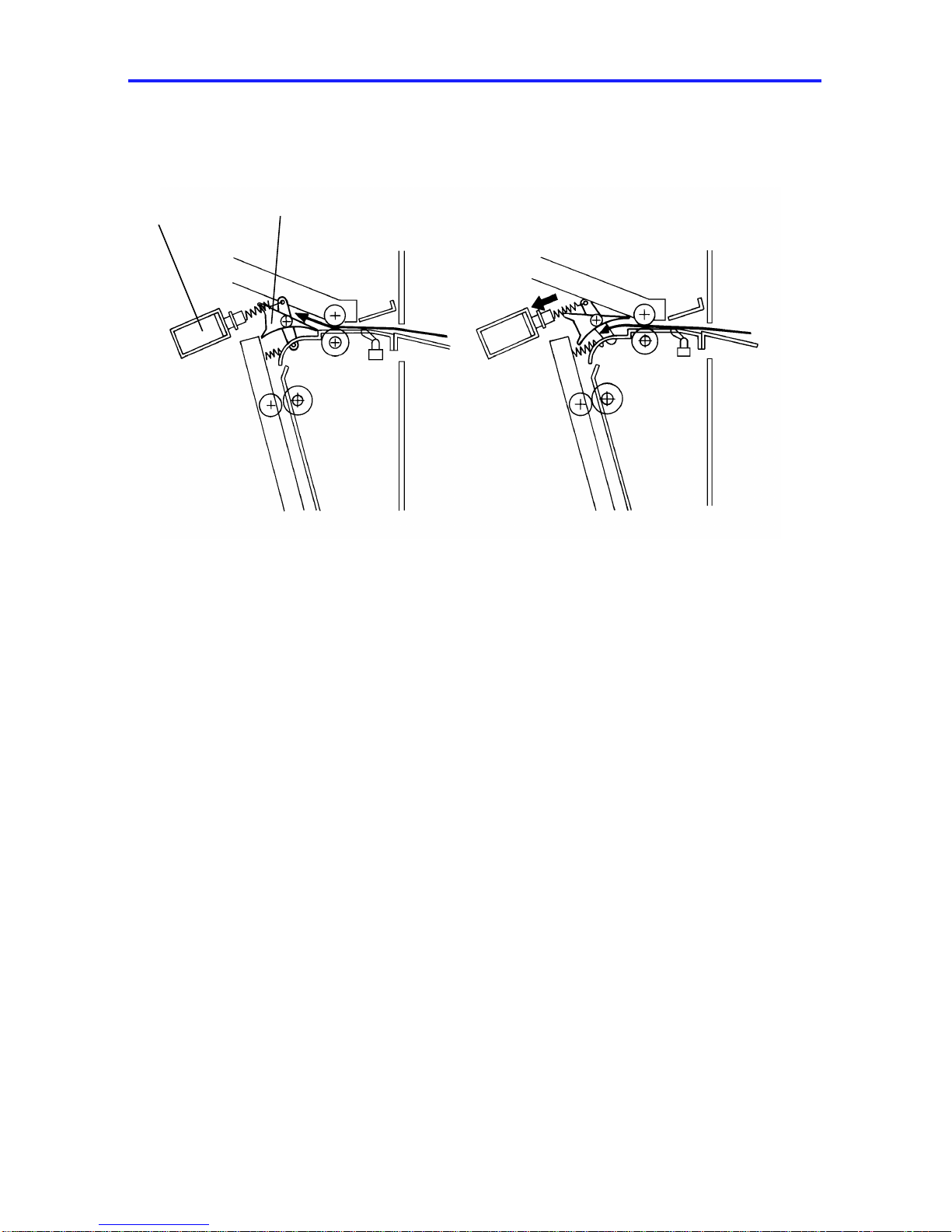

A mechanical safety switch [I] is installed to prevent the drive gears from

being damaged if the sensor does not work. When the shift tray pushes up

the shift tray positioning roller [J], the shift tray lift motor stops.

[A]

[E]

[F]

[H]

[J]

[C]

[I]

[G]

Finisher

23 April 1993 SECTIONAL DESCRIPTIONS

9