975 Combo Roll Groover

Groove and Drive Roll Set Change-out Instructions

Kit Includes:

• 32838 Driveshaft for 2" - 8" Copper

• 30893 Driveshaft Key

• 32843 Groove Roll for 2" - 8" Copper

WARNING

Read and understand the threading machine and roll groover

operator’s manuals and instructions for all other equipment

being used before operating. Failure to follow all instruc-

tions may result in property damage and/or serious personal

injury.

Make sure the machine FOR/OFF/REV switch is in the OFF

position and the machine is unplugged before performing any

maintenance or making any adjustments.

SAVE THESE INSTRUCTIONS!

Contact Ridge Tool Technical Service Department at (800)

questions.

Changing Roll Sets

When changing roll set parts, always make

sure drive and groove roll markings match. Mismatched

parts can make improper grooves and cause leaks.

Remove the roll groover from the power drive or threading

machine and place on a stable work bench.

Required Tools:

•3/8" Hex Wrench

•3/32" Hex Wrench

• .070" External Retaining Ring Pliers

Removing and Installing Drive Roll

1. Remove 6 screws that hold rear cover to the housing.

2. Remove the rear cover

(See Figure 1)

.

Figure 1 – Removing Rear Cover

3. Remove pinion.

4. Remove the driveshaft assembly out of the back of the

975 Roll Groover.

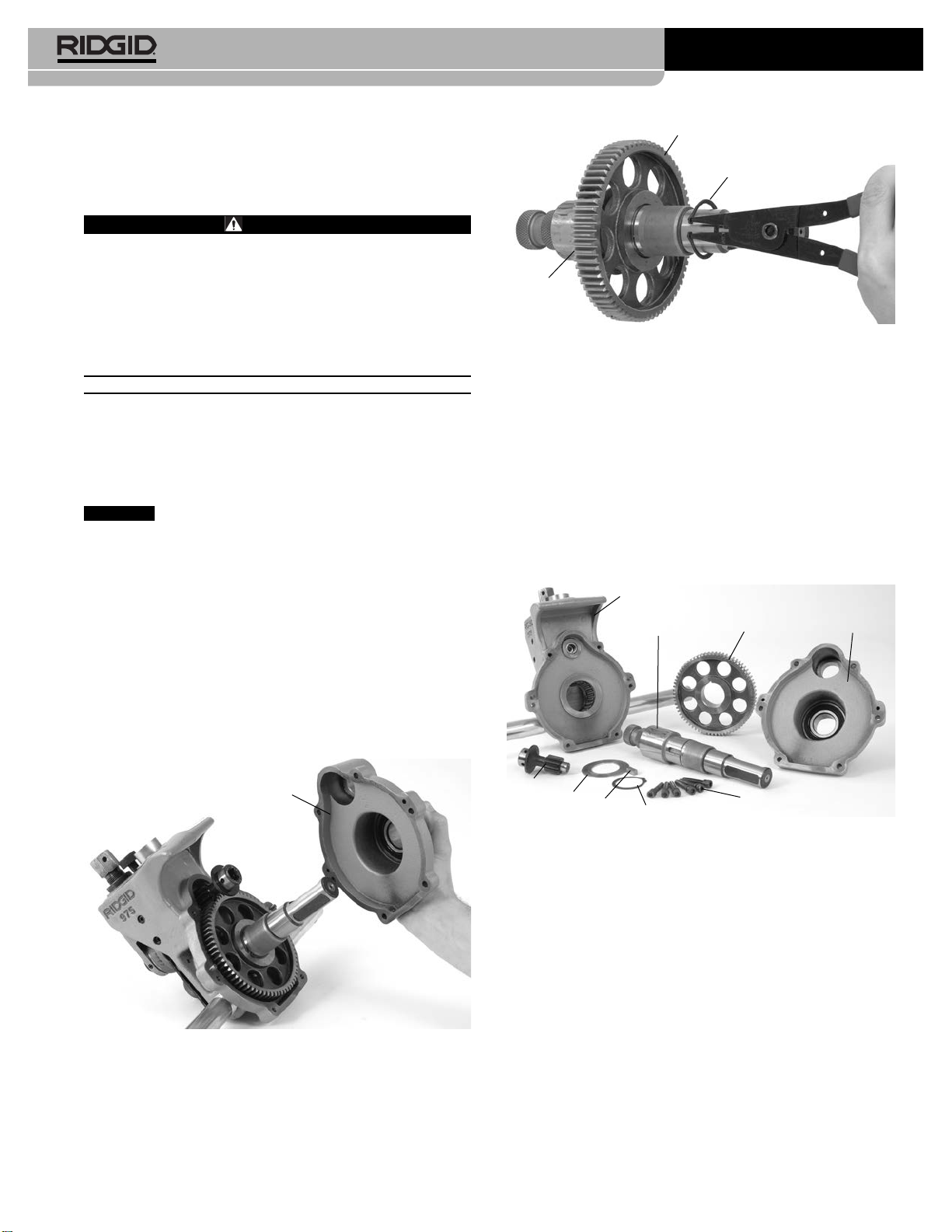

5. Remove retaining ring from driveshaft and slide gear off.

(See Figure 2.)

Figure 2 – Removing Retaining Ring

6. Remove key and then thrust washer.

7. Slide thrust washer onto new driveshaft.

8. Insert key and install gear.

9. Install retaining ring into driveshaft groove.

10. Place driveshaft assembly into main housing.

11.Grease from the gearbox may have been lost during

the driveshaft change. Make sure the bearings and

gear teeth are coated sufficiently with a good general

purpose grease.

12. Insert pinion and reinstall rear cover. Tighten screws to

12-16 ft*lbs of torque.

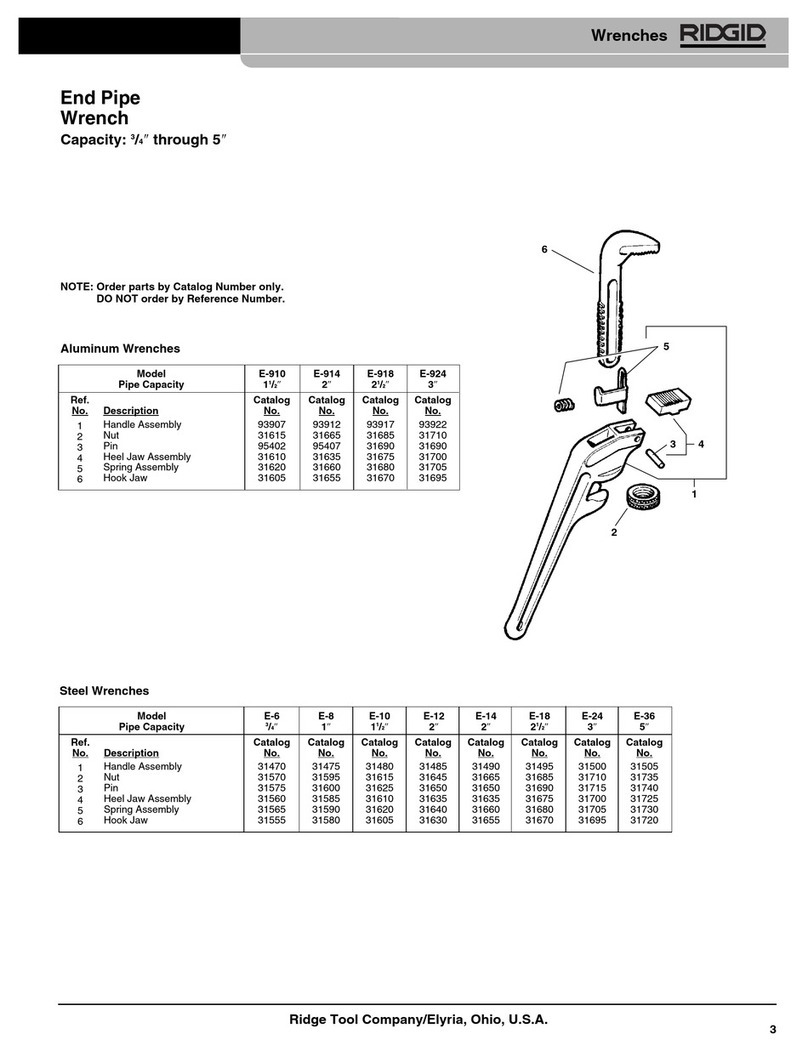

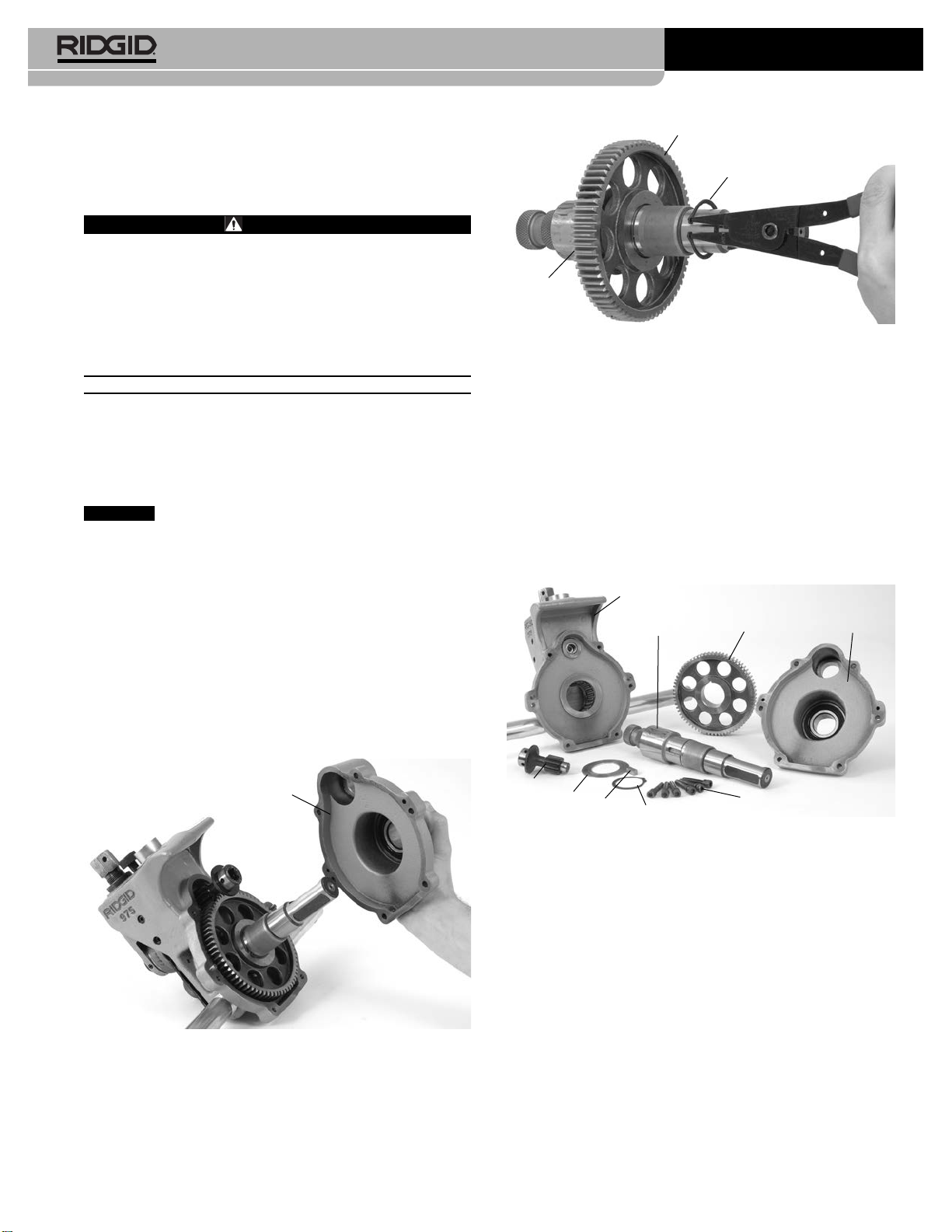

Figure 3 – 975 Combo Roll Groover Parts Diagram

Removing and Installing Groove Roll

1. Remove the setscrew that holds the groove roll shaft in

place.

2. Pull the groove roll shaft out of the slide block and

remove the groove roll and thrust washer.

3. Insert the thrust washer and new groove roll into the

slide block. Ensure that the internal retaining ring in

the groove roll is closest to the main housing, and that

the groove roll is between the thrust washer and main

housing.

(See Figure 4.)

4. Replace the groove roll shaft and the set screw.

5. Visually inspect the alignment between the groove roll

and the drive roll. If they are not aligned, check orienta-

tion of groove roll and thrust washer.

058-005-726.10

NOTICE

Gear

Thrust

Washer

Retaining Ring

Main Housing

Pinion

Driveshaft Rear Cover

Gear

Screws

Retaining Ring

Thrust

Washer Key

Rear Cover

Test Equipment Depot - 800.517.8431

99 Washington Street, Melrose, MA 02176

TestEquipmentDepot.comTe