5

The operation of any appliance that uses electrical power demands that a number of fundamental safety precautions

be respected. In particular:

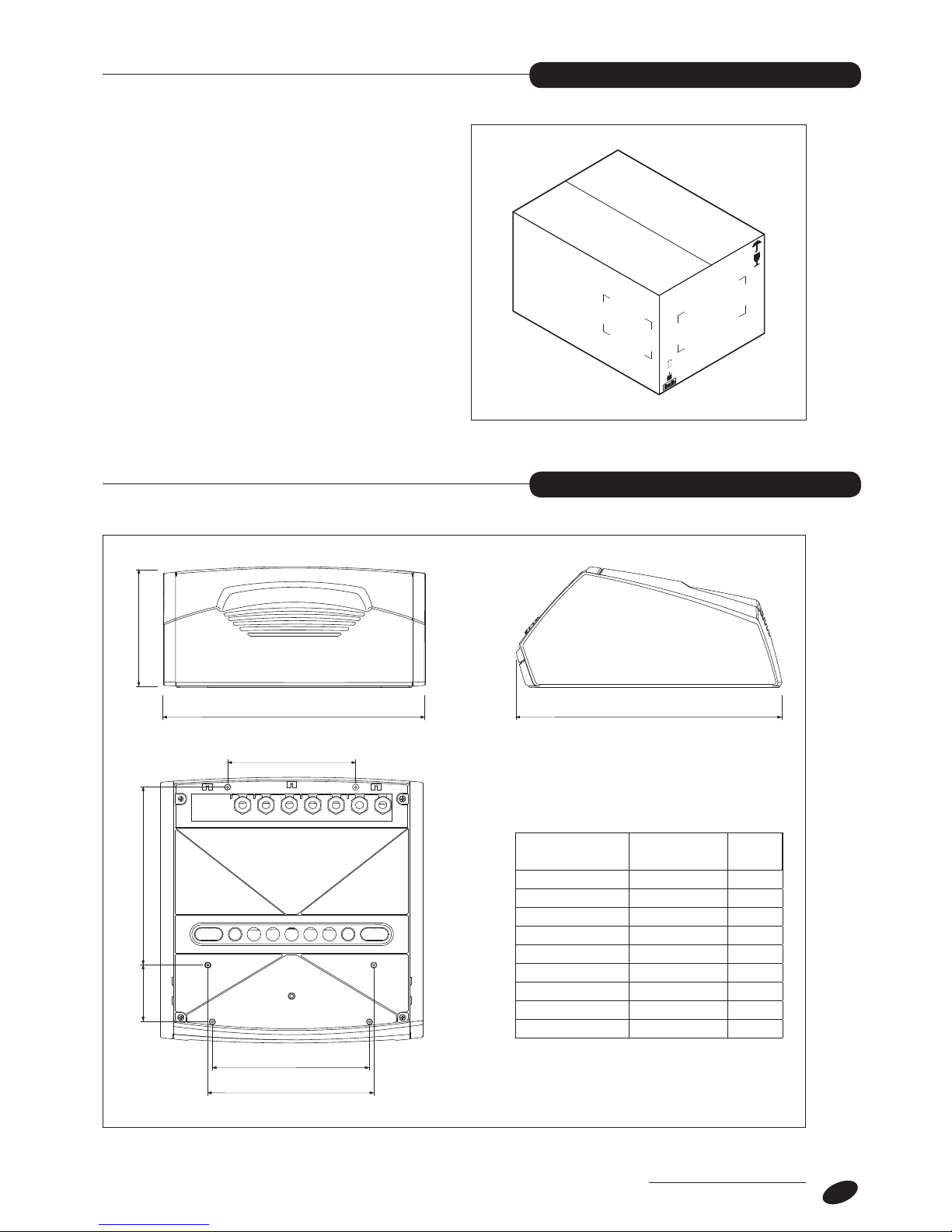

bCheck that the product is complete and undama-

ged as soon as you remove it from its packaging.

Contact the rreseller from whom you purcha-

sed the product if you notice any problems.

bThis product must be installed by a legally quali-

fied heating engineer. (In Italy heating engineers

are regulated by law no. 37 of the 22/01/2008.) On

completion of the installation, the installer must issue

the owner with a declaration of conformity confir-

ming that the installation has been completed to the

highest standards in compliance with the instructions

provided by rin this instruction manual, and that

it conforms to all applicable laws and standards.

bThis control panel is designed and made for use with

boilers generating hot water up to 110°C, and must

be used exclusively for this purpose and within its

specified performance limits.

bThe manufacturer declines all responsibility, con-

tractual or other, for damage to property or injury to

persons or animals caused by improper installation,

adjustment, maintenance or use.

bThis instruction manual is an integral part of the

product. It must be kept safe and must ALWAYS

accompany the product, even if it is sold to another

owner or transferred to another user or to another

installation. If you damage or lose this manual, order

a replacement immediately from your local r

Technical Assistance Centre.

GENERAL SAFETY INFORMATION

PRECAUTIONS

aAlways turn the electrical power supply OFF at the

main switch before commencing any cleaning or

maintenance.

aDo not tamper with or adjust the safety or control

devices without prior authorisation and instructions

from the boiler’s manufacturer.

aNever pull, disconnect, or twist the electrical cables

coming from the appliance even if it is disconnec-

ted from the mains electricity supply.

aDispose of packaging materials in compliance with

applicable standards and legislation governing the

disposal of urban, domestic and industrial waste.

aNever switch the control panel on even for a short

period if the safety devices are not functioning cor-

rectly or have been tampered with.

aAll maintenance and repairs must be carried out by

a legally qualified heating engineer.

aDo not use water to extinguish fire in the control

panel. Switch power OFF at the mains power switch

to isolate the control panel electrically first. Then

use a class E fire extinguisher (marked “SUITABLE

FOR LIVE ELECTRICAL ITEMS”) to extinguish the

flames.