2VLBS-U-LT

This user manual contains information about

the correct and safe use of VLBS-U-LT.

Read the user manual carefully and in full

before using the RUD lifting point VLBS-U-

LT. Ensure that you have understood all the

contents. If you need further information,

ask your RUD retailer or RUD application

engineer.

Non-observation of the instructions can

lead to injuries or damage and will invali-

date the guarantee.

If doubtful or misunderstanding the German

version of this document is crucial.

1 Safety instructions

ATTENTION

Wrong assembled or damaged lifting points

as well as impropriate use can lead to

injuries of persons and property damage

when loads falls.

Inspect all lifting points before each use

carefully!

• Withdraw all body parts (ngers, hands, arms etc.)

from the danger zone during the lifting process (risk

of squeezing).

• The RUD lifting points VLBS-U-LT must only be

used by competent and designated persons which

have been trained and taking into account the DGUV

109-017, and outside Germany by respecting the

country specic regulations.

• Do not exceed the working load limit (WLL) indi-

cated on the lifting point.

• No technical alterations must be implemented on

the VLBS-U-LT.

• No persons are allowed in the danger zone.

• Staying below suspended loads is prohibited.

• Jerky lifting (strong impacts) should be prevented.

• Always ensure a stable position of the load when

lifting. Swinging must be prevented.

• Damaged or worn VLBS-U-LT must not be used.

2 Intended use

• The RUD VLBS-U-LT lifting point must only be used

for the assembly at loads or lifting means.

• The VLBS-U-LT is for the attaching of loads.

• The RUD lifting points can also be used as lashing

points for the attachment of lashing means.

• RUD lifting points must only be used for the inten-

ded described usage.

3 Assembly and user instruction

3.1 General information

• Capability of temperature usage:

RUD lifting points VLBS-U-LT are suitable for the

temperature range from -45°C up to 400°C. When

used in temperatures higher than 200°C, the WLL

of the lifting point must be reduced as follows:

-45°C up to 200°C no reduction

200°C up to 300°C minus 10 %

300°C up to 400°C minus 25 %

Temperatures higher than 400°C are prohibited!

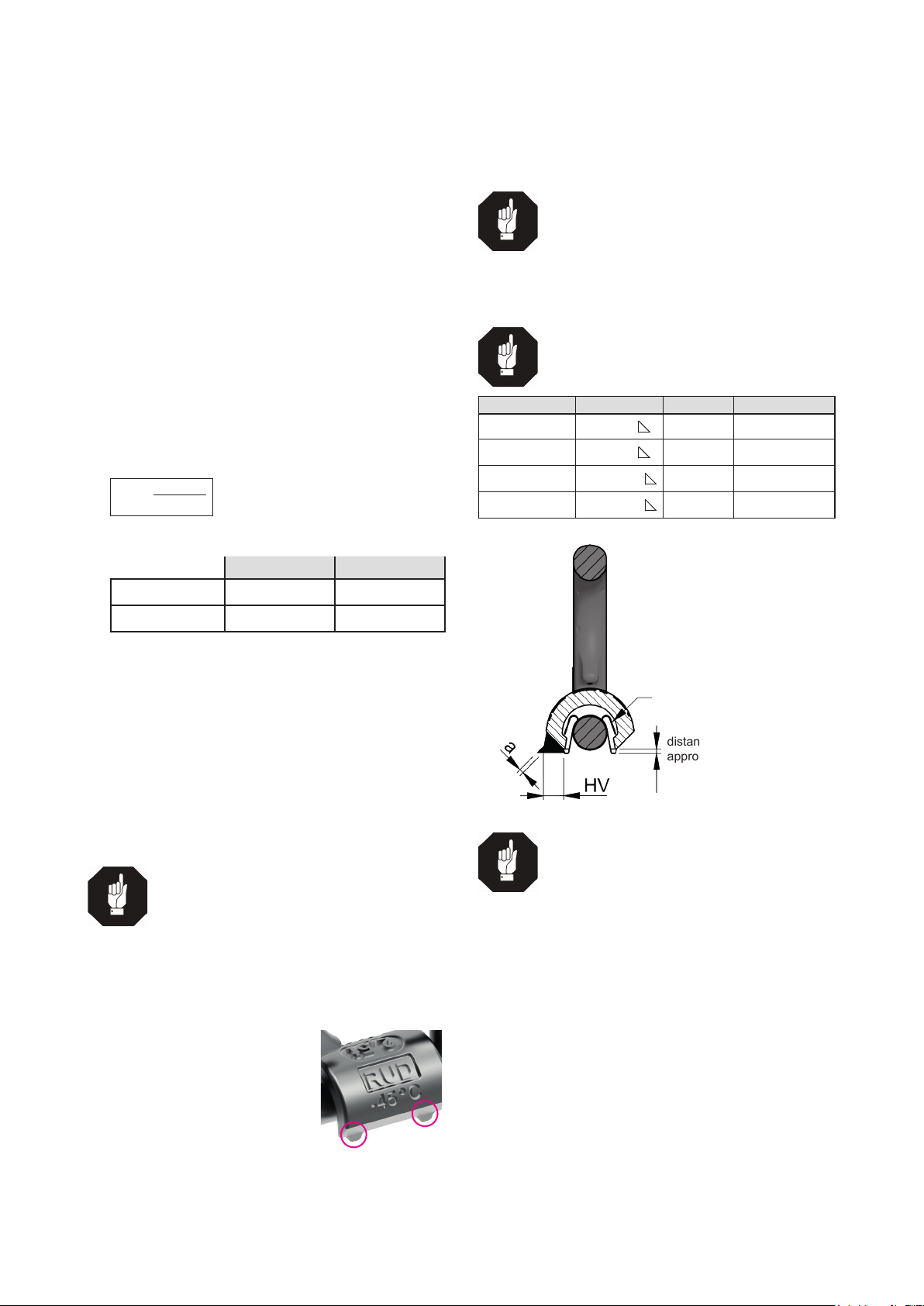

HINT

The VLBS-U-LT can be recognized by the

additional marking (-45°C) at the weld-on

block.

HINT

VLBS-U-LT lifting points can be stress-

relieved one-time together with the load (f.e.

as part of a welding construction), when

unloaded, one-time stress relieved.

(Temperature <600°C /1100°F - max. 1 hour)

Ability verification of the used welding

material must be determined with the cor-

responding supplier of electrodes resp.

welding ller manufacturer.

Impact energy >= 27 Joule at -45°C

• RUD lifting points VLBS-U-LT must not be used

in combination with aggressive chemicals (acids,

alkaline solutions and vapours).

• The places where the lifting points are xed should

be marked with colour

• The VLBS-U-LT has a protect on the inside po-

sitioned spring, which holds the load ring in the

desired position.

• The parts of the VLBS-U-LT are connected captive

and will be supplied assembled as a complete unit.

3.2 Hints for the assembly

Basically essential:

• The material construction to which the lifting point

will be attached should be of adequate strength to

withstand forces during lifting without deformation.

CONTENT

1 Safety instructions 2

2 Intended use 2

3 Assembly and user instruction 2

3.1 General information ..................................................2

3.2 Hints for the assembly ..............................................2

3.3 Hints for the welding .................................................3

3.4 Hints for the usage ...................................................4

4 Inspection / repair / disposal 4

4.1 Hints for periodical inspections.................................4

4.2 Test criteria for the regular visual inspection by the

user...........................................................................4

4.3 Additional test criteria for the

competent person / repair worker.............................4

4.4 Disposal....................................................................4