8

cutting accessory and the cable “under voltage” can also put

the exposed metal parts of the electrical tool “under voltage”

and can cause an electrical shock for the operator.

Position the cable far from the rotation accessory. If control

is lost, the cable can be cut or twisted and your hand or arm

could be pulled into the rotation accessory.

Never put the electrical tool back before the accessory has

completely stopped. The rotation accessory can be pressed

on the surface with the electrical tool put out of your control.

Do not operate the electrical tool while carrying it at the

side. Accidental contact with the rotation accessory can get

your clothes entangled and attract the accessory towards you.

Regularly clean the fan openings of the electrical tool. The

motor fan will attract the dust into the housing; excess dust

accumulation can cause electrical

hazards. Do not operate the electrical tool in the proximity

of flammable material. The sparks can ignite these materials.

Do not use accessories that need liquid coolants. The use

of water or other liquid coolants can cause electrocution or

electrical shock

SPECIFIC SAFETY WARNINGS

Verify that no loosened part of the polishing tool shroud or

the locking ties can rotate freely. Safely position or cut all

the loosened xing wires. Loosened or revolving xing wires

may twist around the operator’s ngers or get caught by the

work piece being machined.

COMMISSIONING

WARNING Observe the mains voltage! The mains

voltage should correspond the rated voltage of the

electrical tool.

HAZARD Before performing any intervention on the

electrical tool, unplug the same from mains outlet.

TOOL ASSEMBLY

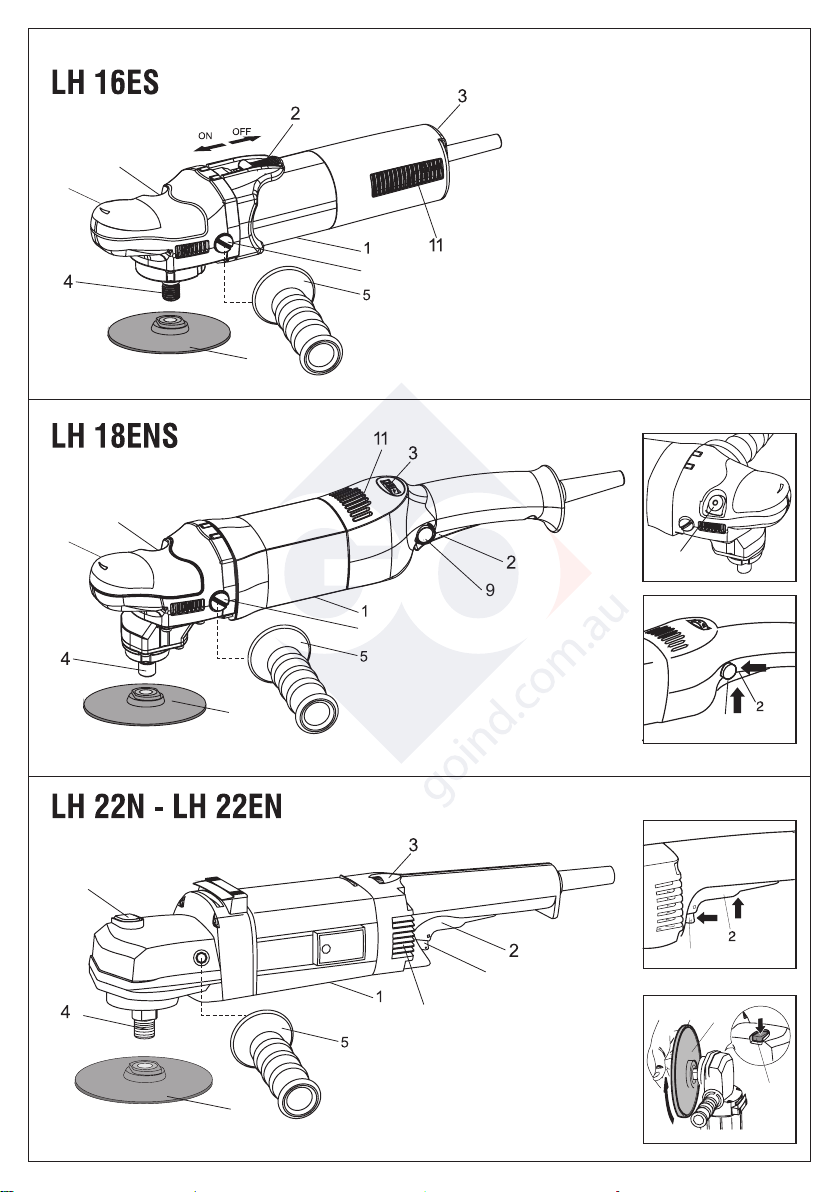

LH16ES – LH18ENS

Position the cap (6) on the gearbox such that the holes for mounting

the screws (5) are aligned with those on the gearbox (8).

LH16ES – LH18ENS – LH22N – LH22EN

Screw the side handle (5). Side handle may be positioned to

the right or to the left of the equipment.

ASSEMBLY / DISASSEMBLY OF ACCESSORIES

ASSEMBLY

PLATE PAD HOLDER

Screw plate pad holder (7) over spindle shaft (4) while

preventing it from moving or stop movement by enabling lock

button (10).

PAD

Apply pressure on polishing pad to join pad to plate.

DISASSEMBLY

PLATE PAD HOLDER

- Lock the spindle by pressing button (10), while at the same

time rotating the pad until it locks position.

- dismount the pad.

Never press the button to lock the pad or pas until the

tool has stopped moving and is perfectly stationary;

the gear box or the push button pin could be broken

and the guarantee would be invalidated.

- PAD

Tear off the worn pad and fit the new pad (see ASSEMBLY).

BEFORE COMMISSIONING

Before putting the machine into operation ensure that:

- the package is intact and there is no sign of damage due to

transport and storage;

- the machine is complete; check the number and the type of

parts to make sure they comply with those in this guide;

- the energy source complies with machine rated features;

- the power cable and its plug are in perfect condition;

- the ON/OFF (2) switch is effective and works with the plug

removed;

- all machine parts are correctly installed and free of damage;

- the ventilation slits (11) are not obstructed.

START AND STOPPING

LH16ES

- Starting: push the slide of the switch (2) forward; if the tool

is to be locked in the ON position, apply pressure to the front

part of the slide switch at the same time;

- Stopping: release the slide or, if locked in position, apply

pressure to the back part of the switch and allow it to return

to the stop position.

WARNING: after power cutout, if the ON/OFF switch is

inserted, it must be released (see Stop).

LH18ENS

- Starting: push the lever of the switch (2) towards the body

of the tool; if the tool is to be locked in the ON position,

press button (9) at the same time and keep it pressed while

releasing lever (2), thus locking the switch.

- Stopping: release the lever of the switch or, if locked in

position, push the lever to release the lock button.

LH22N – LH22EN

- Starting:move the switch lever (2) up; to lock it in “engaged”

position, move the switch block (9) forward towards the

machine body.

- Stopping: release the switch lever (2); if the switch is in

“engaged” position, move the switch lever (2) up in order to

release the switch block (9).

The tool continues to rotate after it is turned off.

SELECTING RPM

The rpm can be adjusted by rotating the wheel (3). The choice

of speed depends on the characteristics of the abrasive disc

and the material to be worked.

ALLOWED ACCESSORIES

Polishing foam and foam support pad up to Ø 200 mm max

(LH16ES: ø 178 mm max)..

NOISE/VIBRATION LEVEL

The equivalent noise pressure level and the mean squared

acceleration are measured according to standard:

EN 60745