PZ240EK 6.1.0 10/2019. 2.0

MOTION | POSITIONING

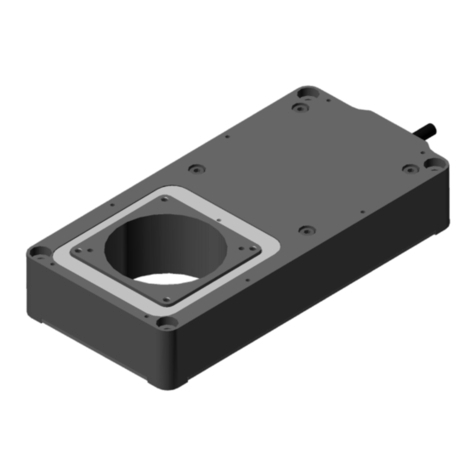

Intended Use

The posioner is a laboratory device as dened

by DIN EN 61010-1. It is intended for indoor use

and use in an environment that is free of dirt,

oil, and lubricants.

The posioner is designed for ne posioning

as well moving smaller objects quickly and

precisely. The posioner is not intended for

applicaons in areas where failure would be

a considerable risk for people or the environ-

ment.

It is only possible to use the posioner as inten-

ded when completely installed and connected,

and in conjuncon with suitable electronics.

The posioner may only be installed, operated,

maintained, and cleaned by authorized and

appropriately qualied personnel.

Electrical Dangers

Temperature changes and compressive stress

can induce charges in the posioner. Aer

disconnecon from the electronics, the piezo

actuators can remain charged for several hours.

Touching charged parts can result in minor

injuries from electric shock.

XDo not touch the contacts in the connector.

XBefore mounng, connect the posioner

to the switched-o electronics for a few

seconds to discharge it.

XSecure the connectors with screws against

being pulled out.

XDo not pull connectors out of the electro-

nics during operaon.

If a protecve earth conductor is not properly

connected, touching the posioner in the case

of malfuncon can result in minor injuries from

electric shock.

XOperate the posioner only with a properly

connected protecve earth conductor.

XDo not remove the protecve earth con-

ductor from the posioner during opera-

on.

XPay aenon to the applicable standards

for aaching the protecve earth conduc-

tor .

Moisture, liquids, and electrically conducve

materials (e.g., metal dust) that penetrate the

posioner can destroy the posioner's piezo

actuator.

XOperate the stage only under the permissi-

ble ambient condions (see manual).

XDo not operate a vacuum-compable posi-

oner during evacuaon.

Excessively high or wrongly connected

operang voltages can cause damage to the

posioner.

XPay aenon to the operang voltage ran-

ge of the posioner (see manual).

XPay aenon to the correct pin assignment.

Connuously high voltages can reduce the

lifeme of the posioner.

XKeep the maximum operang voltage as

low as possible during operaon.

XDischarge the posioner appropriately

when it is not in use.

Mechanical Dangers

Mechanical forces can destroy the posioner.

XAvoid shocks and drops.

XPay aenon to the maximum permissible

forces (see manual).

XDo not pull the connecng cable of the

posioner out of the electronics during

operaon.

XIf the connecng cable is accidentally pul-

led out of the posioner during operaon:

Switch o the electronics before you recon-

nect the posioner.

XShip the posioner in the original packaging

only.

Incorrectly ed screws can cause damage.

XDo not allow screw heads to protrude.

XSelect the screw length according to the

depth of the mounng holes.

Collisions can damage the posioner, the load

to be moved, and the surroundings.

XMount the posioner and the load so that

the load cannot get jammed or blocked, or

collide with objects in the workspace.

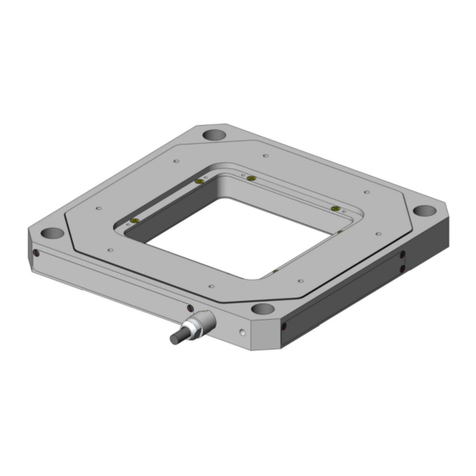

Unsuitable mounng could warp the posioner

and reduce the accuracy.

XMount the posioner on a at surface with

similar thermal expansion properes (see

manual for recommended atness).

General Safety Instrucons