Contents

EB 8355-2 EN

1 Safety instructions and measures ................................................................1-1

1.1 Notes on possible severe personal injury ......................................................1-3

1.2 Notes on possible personal injury ................................................................1-3

1.3 Notes on possible property damage.............................................................1-4

1.4 Special instructions concerning explosion protection ......................................1-5

2 Markings on the device ..............................................................................2-1

2.1 Nameplate .................................................................................................2-1

2.2 Article code................................................................................................2-2

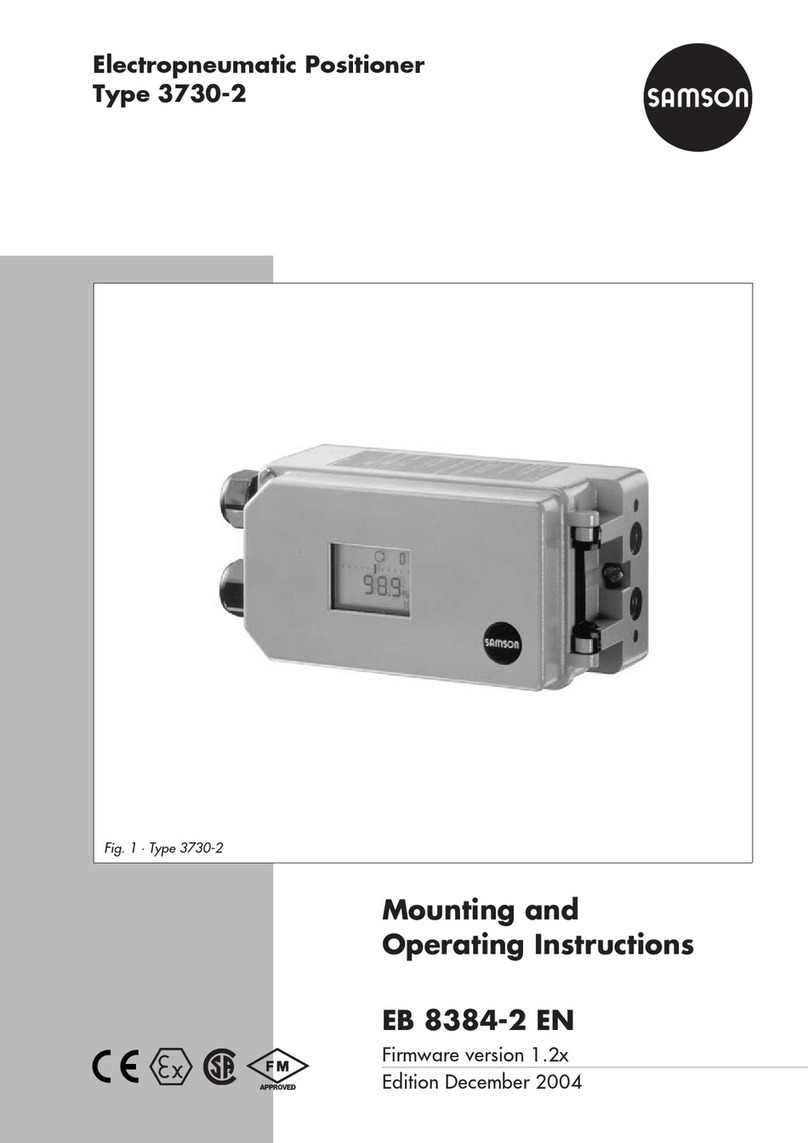

3 Design and principle of operation ...............................................................3-1

3.1 Technical data ............................................................................................3-4

3.2 Options......................................................................................................3-5

3.3 Summary of explosion protection approvals..................................................3-6

4 Shipment and on-site transport ...................................................................4-1

4.1 Accepting the delivered goods .....................................................................4-1

4.2 Removing the packaging from the positioner.................................................4-1

4.3 Transporting the positioner...........................................................................4-1

4.4 Storing the positioner ..................................................................................4-1

5 Installation.................................................................................................5-1

5.1 Installation conditions..................................................................................5-1

5.2 Preparation for installation...........................................................................5-1

5.2.1 Determining the operating direction of the positioner control loop...................5-2

5.3 Positioner attachment ..................................................................................5-2

5.3.1 DirectattachmenttoType3277Actuator ......................................................5-2

5.3.2 AttachmentaccordingtoIEC60534-6..........................................................5-6

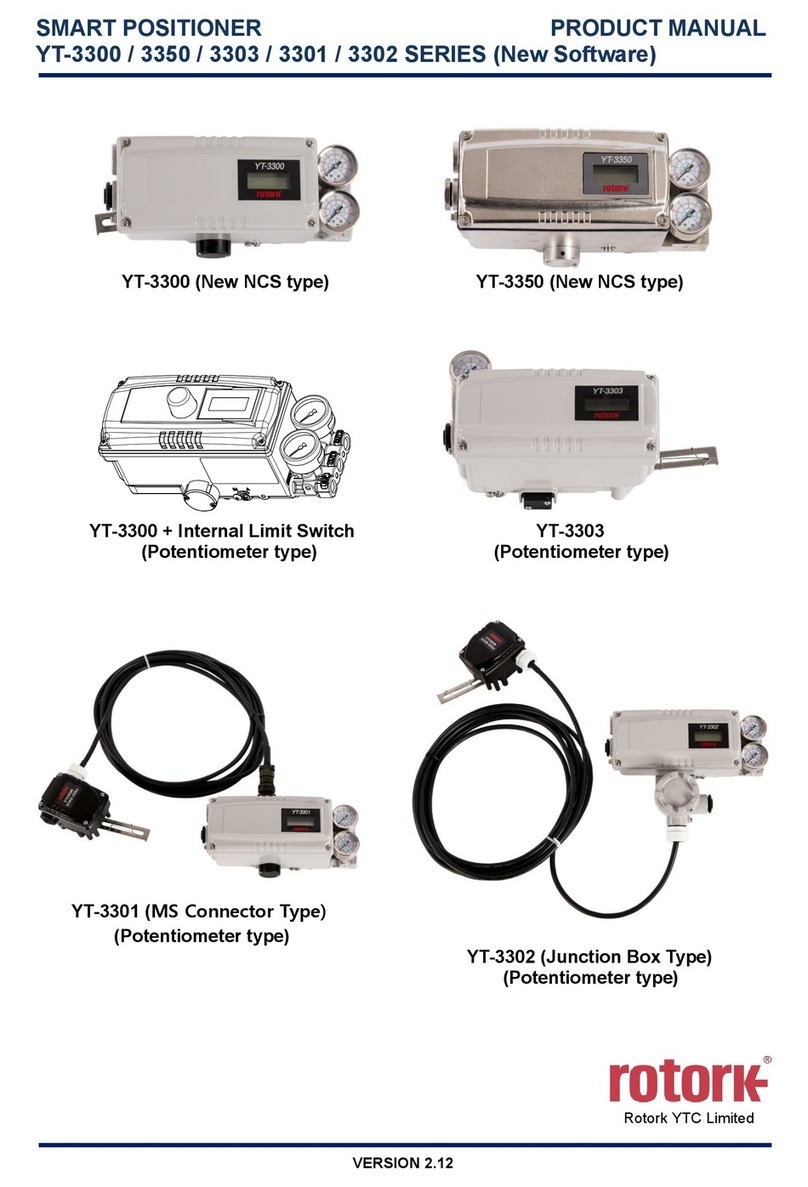

5.3.3 Attachment to rotary actuators ...................................................................5-10

5.3.4 Reversingamplierfordouble-actingactuators ...........................................5-16

5.4 Pneumatic connection................................................................................5-18

5.4.1 Pressure gauges........................................................................................5-18

5.4.2 Supply pressure ........................................................................................5-18

5.5 Adjusting the positioner.............................................................................5-19

5.5.1 Air output capacity and proportional band XP.............................................5-20

5.5.2 Zero and span..........................................................................................5-21

5.5.3 Adjusting the optional limit switches ...........................................................5-23

5.6 Adjusting the optional position transmitter...................................................5-25

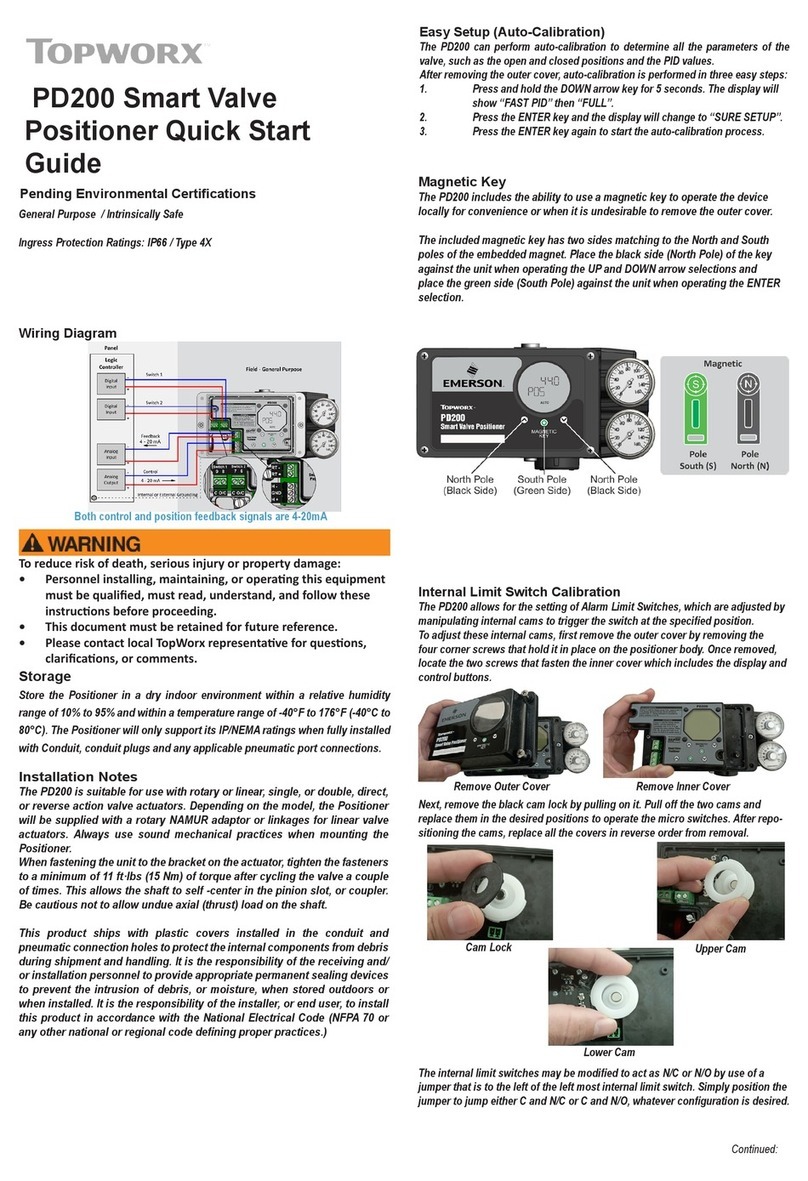

5.7 Electricalconnection..................................................................................5-27

5.7.1 Switchingamplier ...................................................................................5-28

5.8 Mounting accessories ................................................................................5-29