5.1. MONTHLY MAINTENANCE

Lubrication is critical to jacks. Any restriction due to dirt or rust can cause either slow or extremely

rapid jack movement, causing damage to the internal components. To keep the jack well

lubricated, carry out the following steps.

5.1.1. Lubricate the ram, the linkages and the saddle and pump mechanism with light oil.

5.1.2. Grease the wheel bearings and axles.

5.1.3. Keep all jack surfaces and warning labels clean.

5.1.4. Check and maintain the ram oil level.

5.2. THREE MONTHLY MAINTENANCE

5.2.1. At three monthly intervals, check the ram for any signs of rust or corrosion. Clean the ram as

required and wipe with an oiled cloth.

5.3. CHECKING THE OIL LEVEL

5.3.1. Fully retract the ram by turning the release valve counter-clockwise.

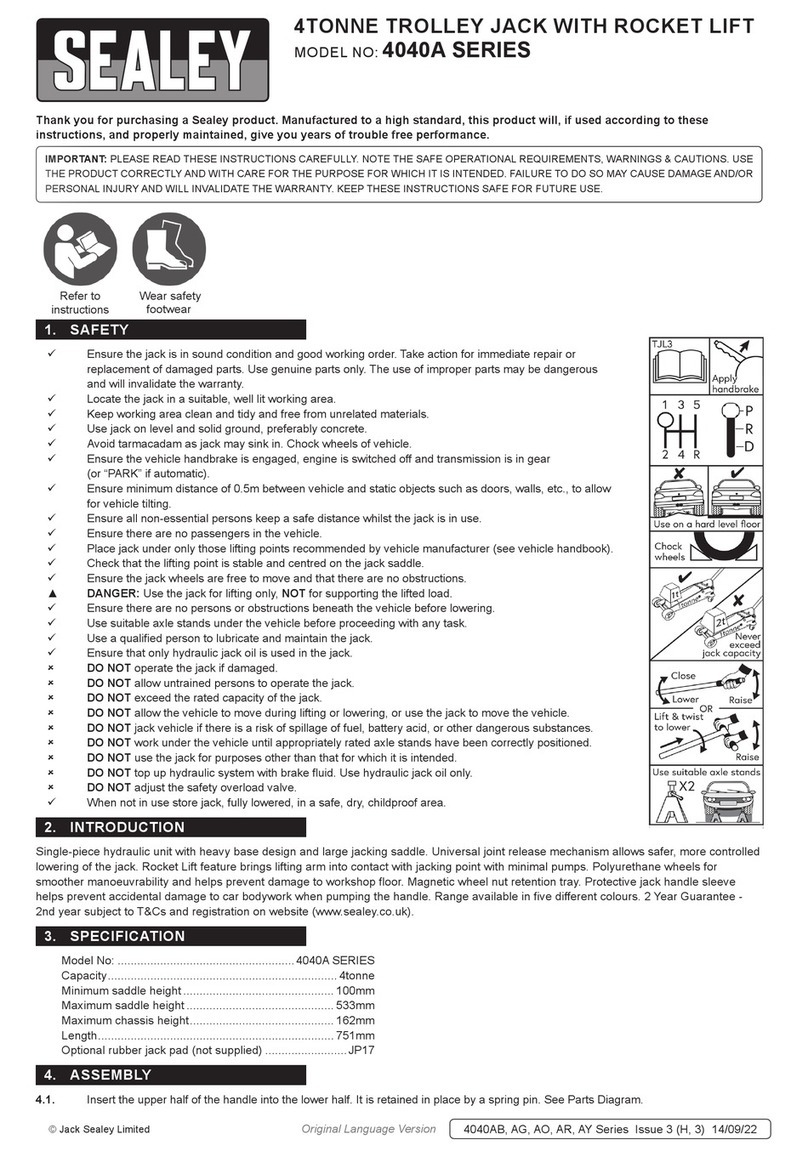

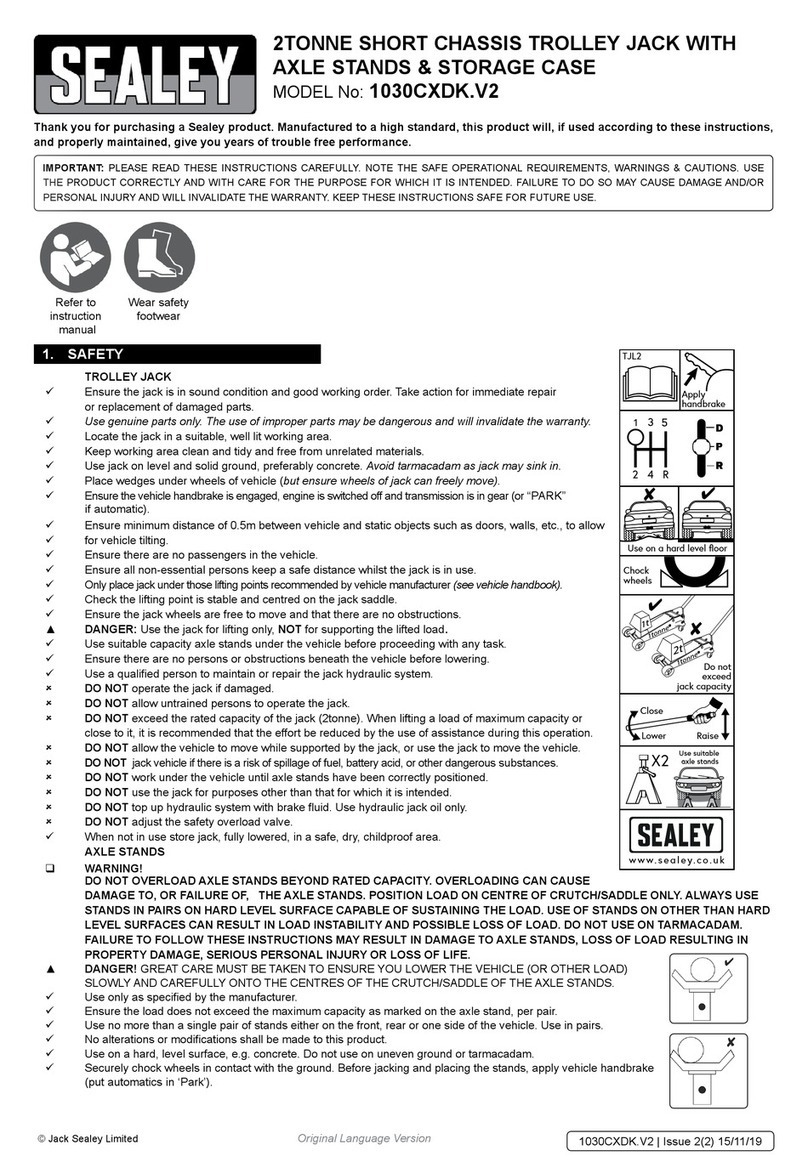

5.3.2. With the jack in the level position, remove the oil ller plug found under the removable magnetic wheel nut retention tray (g.3).

5.3.3. The oil should be level with the bottom of the oil ller hole. If it is not, top up with clean hydraulic jack oil.

5.3.4. Replace the oil ller plug and check the jack operation.

5.3.5. Purge air from the hydraulic unit as required.

NOTE: Always store the jack in the fully lowered position. This will protect critical areas from excessive corrosion.

Owing to their size and weight, hydraulic products should ideally be repaired by local service agents. We have service /repair agents in most

parts of the UK. Before returning your product please call our technical helpline on 01284 757505 for advice and troubleshooting guidance. If

the jack is under guarantee please contact your stockist.

6. TROUBLESHOOTING

PROBLEM POSSIBLE CAUSE REMEDY

Jack will not lift the load 1) Overloaded

2) Oil level low

3) Release valve not correctly closed

4) Air in system

5) Piston rod not functioning

6) Packing worn or defective

1) Be sure to use jack with adequate

capacity

2) Top up oil level

3) Check and close release valve

4) Open release valve and pump the

handle a few times. Close valve and re-try

5) Clean and replace oil

6) Replace packing

Jack does not lift high enough

Or feels “spongy”

1) Oil level too high or too low

2) Worn seals

3) Air in system

4) Release valve not closed

1) Fill or remove excess oil

2) Return jack to local service agent

3) Open release valve and pump the

handle a few times. Close valve and re-try

4) Check and close release valve

Jack lifts poorly 1) Pump packing or valves malfunctioning

2) Oil is dirty

3) Air in the system

1) Replace packing and/or clean valves

2) Replace oil

3) Open release valve and pump the

handle a few times. Close valve and re-try

Jack lifts but will not hold load 1) Release valve partially open

2) Dirt on valve seats

3) Air in system

4) Faulty seals

5) Packing worn or defective

1) Check and close release valve

2) Lower jack, close release valve. Place

foot on front wheel and pull up lifting arm

to it’s full height by hand. Open the release

valve to lower arm

3) Open release valve and pump the

handle a few times. Close valve and re-try

4) Replace packing or contact local

service agent

5) Replace packing

Jack will not lower completely 1) Unit requires lubrication

2) Piston rod bent or damaged

3) Jack frame/link system distorted due to

overloading/poor positioning

4) Air in system

5) Release valve partially closed

6) Jack spring damaged or unhooked.

1) Oil all external moving parts

2) Replace rod or contact local service

agent

3) Replace damaged parts or contact local

service agent

4) Open release valve and pump the

handle a few times. Close valve and re-try

5) Check and fully open release valve

6) Replace spring or contact local service

agent

Jack does not lower at all 1) Release valve closed 1) Check and fully open release valve

FIG.3

Original Language Version

© Jack Sealey Limited 4040TB.V1 Issue 4 (H,1,4,5,) 15/09/23