[6] ADJUSTMENTS

(1) RSPF sub scanning direction magnification

ratio adjustment

Note: When performing this adjustment, check that the CCD unit

is properly installed.

: When performing this adjustment, check that the OC mode

adjustment in copying is completed.

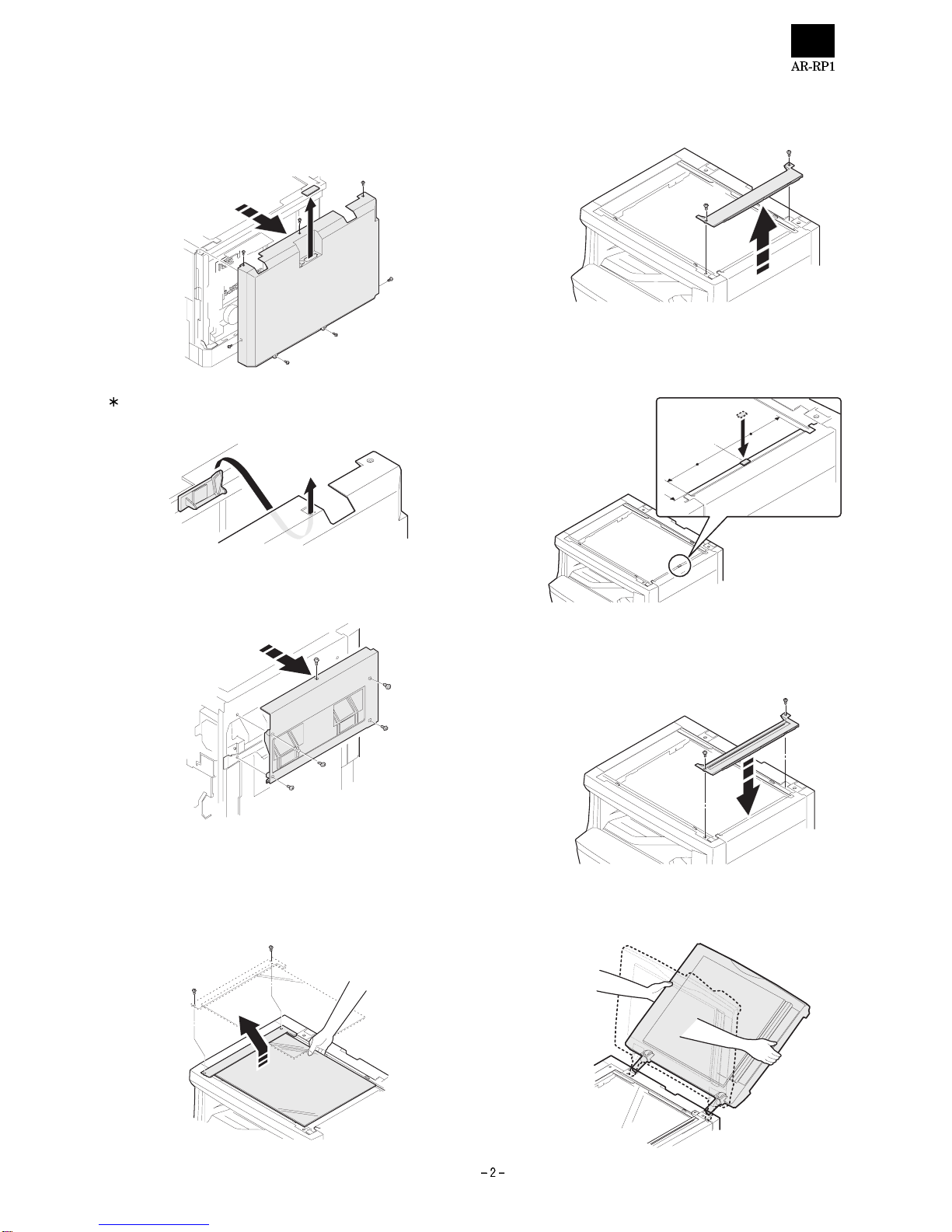

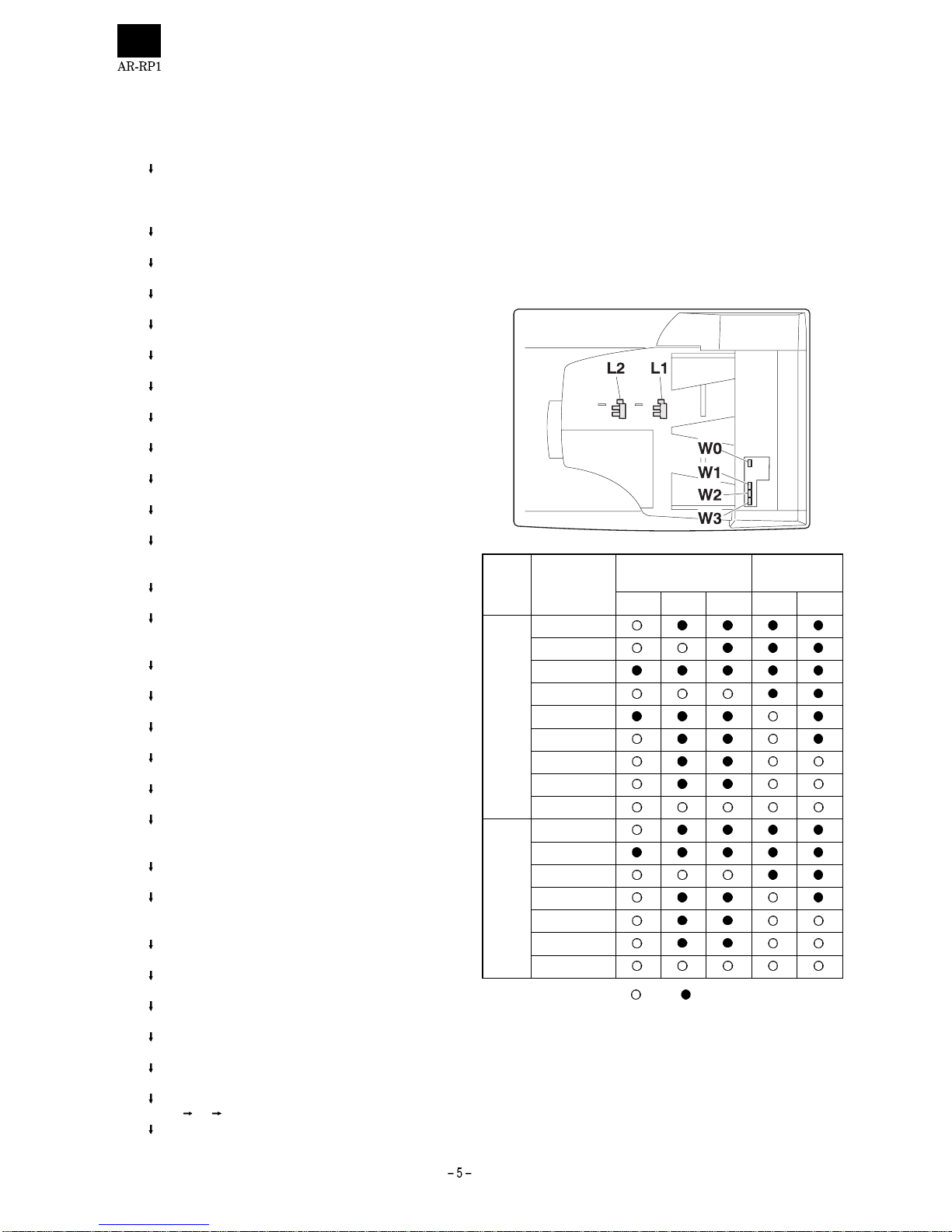

1) Place a scale on the document table as shown below, and make a

normal copy to make a test chart.

2) Set the test chart to the SPF and make a normal copy.

3) Compare the copy and the test chart.

If an adjustment is needed, perform the following procedures.

4) Execute SIM 8-5. The auto exposure lamp lights up.

5) After warming up, shading is performed. The current correction

value of the front surface sub scanning direction magnification ratio

is displayed on the display section in two digits.

6) Enter the set value, and press the START key.

The entered correction value is stored and a copy is made.

7) Change the duplex document mode to the simplex document

mode.

The MANUAL lamp lights up, and the current correction value of

the back surface sub scanning direction magnification ratio is dis-

played on the display section in two digits.

8) Enter the set value, and press the SATART key.

The entered correction value is stored and a copy is made.

<Adjustment specifications>

Mode Spec SIM Set value Set range

SIM

48-5 1 ~ 99

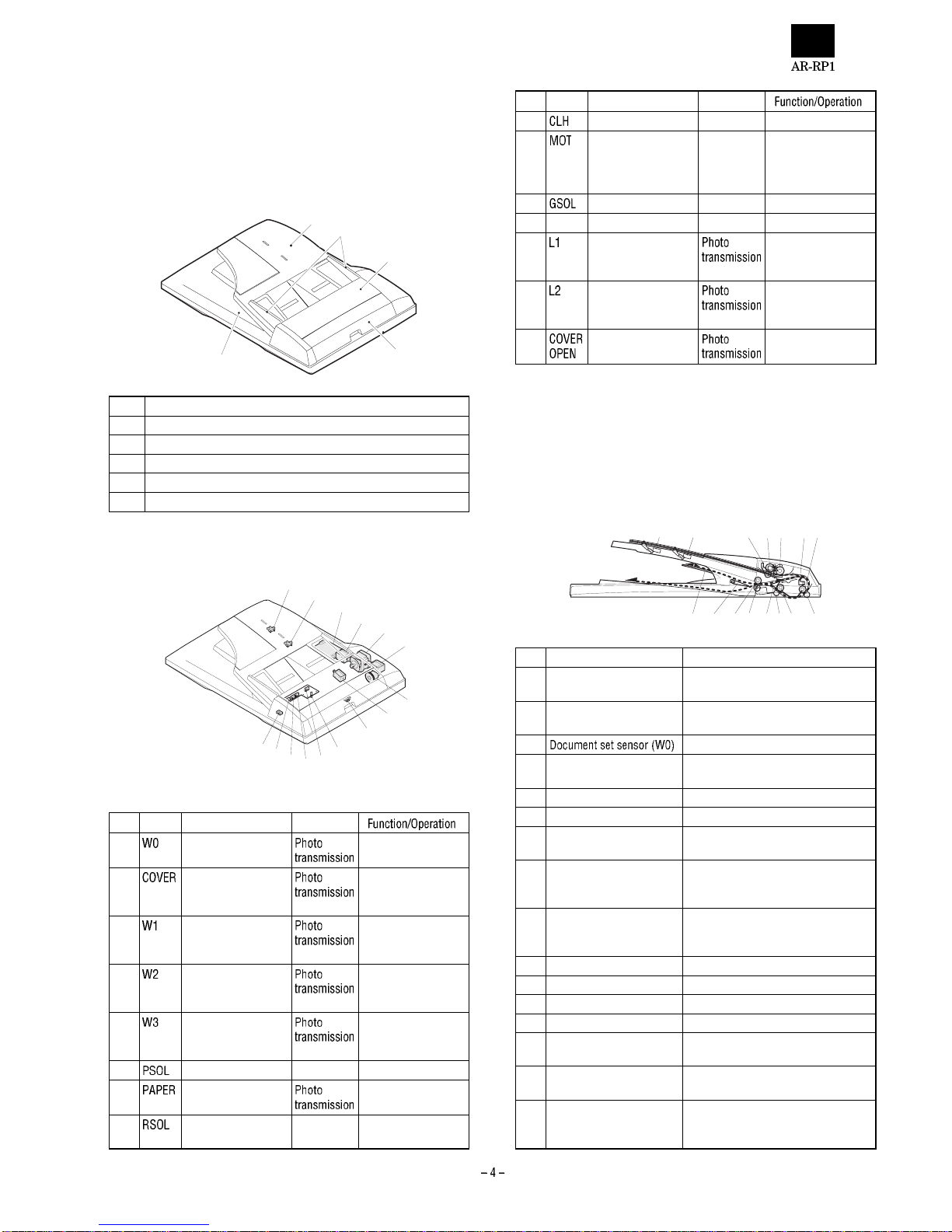

(2) SPF document off center adjustment

Note: When performing this adjustment, check that the paper off-

center is properly adjusted.

1) Set the center position adjustment test chart (made by yourself) on

the RSPF.

<Adjustment specifications>

Draw a line in the center of paper. (In the scanning direction)

2) Make a normal copy from the manual feed tray, and compare the

copy and the test chart.

If an adjustment is required, perform the following procedures.

3) Execute SIM 50-16.

4) After warming up, shading is performed and the current off-center

adjustment value at each paper feed port is displayed on the dis-

play section in two digits.

5) Enter the set value and press the START key.

The entered correction value is started and a copy is made.

<Adjustment specifications>

Mode Specification SIM Set value

SIM

50-16 1 ~ 99

(3) SPF image lead edge position adjustment

1) Set a scale on the OC table as shown below.

2) Make a copy, and use the copied paper as the document and

make a copy from SPF again.

3) Check the copied paper. If an adjustment is required, perform the

following procedures.

4) Execute SIM 50-1.

5) Set the SPF lead edge position set value (Exposure display <MAN-

UAL> ON) so that the image similar to the adjusted image at the

OC image lead edge position described previously is printed.

<Adjustment specifications>

Adjustment

mode SIM LED Set value Specification Set

range

SIM

50-1 1 ~ 99

Note: Since the printed paper is used as the test chart,

place the scale in parallel to both sides.

Note: Since the printed paper is used as the test chart,

place the scale in parallel to both sides.