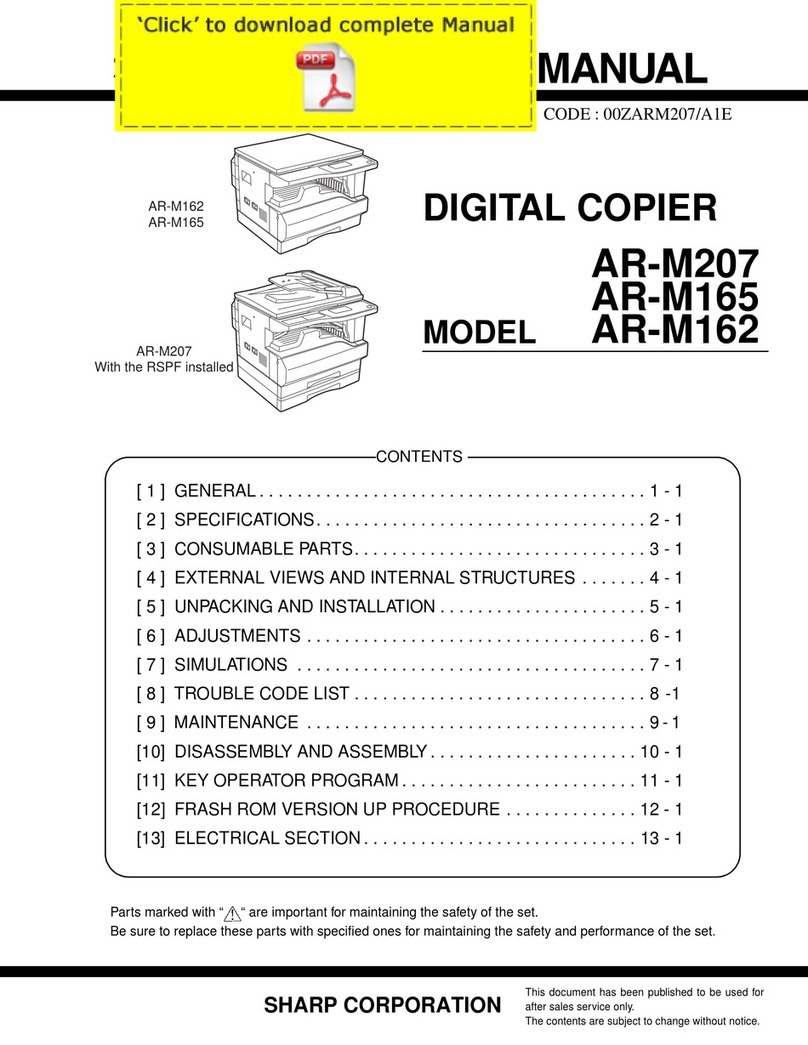

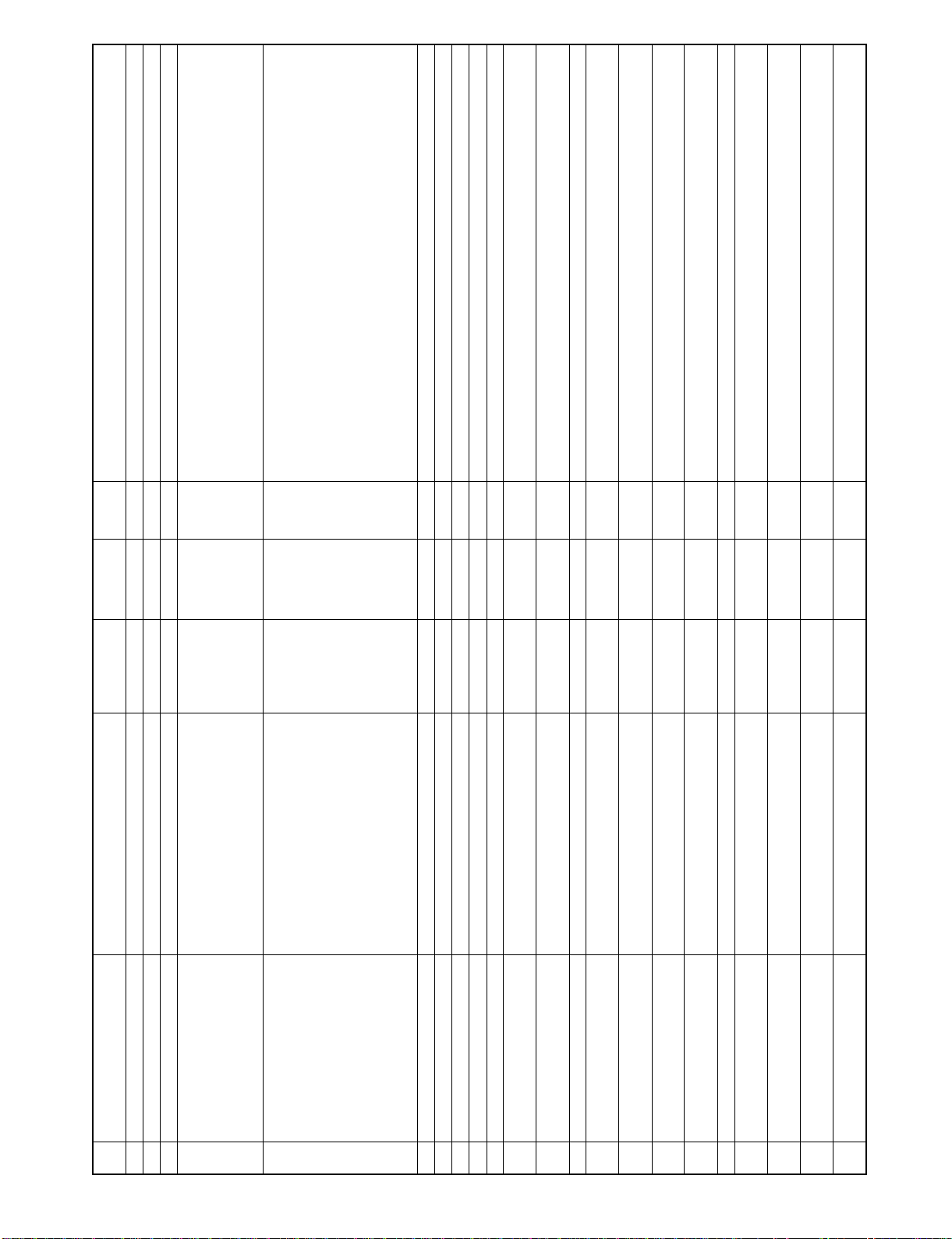

CONTENTS

[ 1 ] GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1. Features of copying functions . . . . . . . . . 1-1

2. System outline (options) . . . . . . . . . . . . . . 1-2

[ 2 ] SPECIFICATIONS . . . . . . . . . . . . . . . . . . 2-1

1. Basic specifications . . . . . . . . . . . . . . . . . 2-1

2. Consumable parts . . . . . . . . . . . . . . . . . . 2-3

[ 3 ] OPTIONS SPECIFICATIONS . . . . . . . . 3-1

[ 4 ] PART NAME AND FUNCTION . . . . . . 4-1

1. External view . . . . . . . . . . . . . . . . . . . . . . 4-1

2. Internal structure . . . . . . . . . . . . . . . . . . . 4-2

3. Operation panel . . . . . . . . . . . . . . . . . . . . 4-3

4. Major parts . . . . . . . . . . . . . . . . . . . . . . . . 4-4

5. Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

6. Clutches and solenoid . . . . . . . . . . . . . . . 4-8

7. Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

8. PWB unit . . . . . . . . . . . . . . . . . . . . . . . . 4-10

9. Duplex copy tray . . . . . . . . . . . . . . . . . . 4-11

10. Desk unit (Major parts) . . . . . . . . . . . . . . 4-12

11. Desk unit (Sensor) . . . . . . . . . . . . . . . . . 4-13

12. RADF (Sensor) . . . . . . . . . . . . . . . . . . . . 4-14

13. RADF (Motor) . . . . . . . . . . . . . . . . . . . . . 4-15

14. RADF (Clutches and solenoid) . . . . . . . 4-15

15. RADF (PWB) . . . . . . . . . . . . . . . . . . . . . 4-16

[ 5 ] UNPACKING AND INSTALLATION .5-1

1. Use environment . . . . . . . . . . . . . . . . . . . 5-1

2. Unpacking . . . . . . . . . . . . . . . . . . . . . . . . 5-2

3. Setting-up procedure . . . . . . . . . . . . . . . . 5-4

[ 6 ] PICTURE QUALITY ADJUSTMENT . 6-1

1. Initial setting of process control . . . . . . . . 6-1

2. Picture quality adjustment procedure . . . 6-2

[ 7 ] DISASSEMBLY AND

REASSEMBLY . . . . . . . . . . . . . . . . . . . . . 7-1

1. Process unit . . . . . . . . . . . . . . . . . . . . . . . 7-1

2. Manual feed copy unit . . . . . . . . . . . . . . . 7-2

3. Paper feed unit . . . . . . . . . . . . . . . . . . . . . 7-3

4. Transport base unit . . . . . . . . . . . . . . . . . 7-4

5. Fusing unit . . . . . . . . . . . . . . . . . . . . . . . . 7-5

6. Auto duplex unit . . . . . . . . . . . . . . . . . . . . 7-7

7. Main components at rear frame side . . . . 7-8

8. Operation panel unit/Document size

sensor PWB (light reception side) . . . . . 7-10

9. Optical unit . . . . . . . . . . . . . . . . . . . . . . . 7-11

10. LSU . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-14

11. PWB . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-15

12. RADF . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-16

13. DESK UNIT . . . . . . . . . . . . . . . . . . . . . . 7-26

[ 8 ] ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . 8-1

1. Developing section . . . . . . . . . . . . . . . . . . 8-1

2. Process section . . . . . . . . . . . . . . . . . . . . 8-3

3. Laser unit . . . . . . . . . . . . . . . . . . . . . . . . . 8-6

4. Optical section . . . . . . . . . . . . . . . . . . . . . 8-7

5. Document detection section . . . . . . . . . . 8-12

6. Others . . . . . . . . . . . . . . . . . . . . . . . . . . 8-14

[ 9 ] SIMULATION AND DIAGNOSTICS . . 9-1

1. Start and end of simulations . . . . . . . . . . 9-1

2. Simulation main code input screen . . . . . 9-1

3. Simulation sub code input screen . . . . . . 9-1

4. Simulation in-progress screen . . . . . . . . . 9-1

5. Setting input activation . . . . . . . . . . . . . . . 9-2

6. Exception processing . . . . . . . . . . . . . . . . 9-2

7. Simulation list . . . . . . . . . . . . . . . . . . . . . . 9-2

8. Detail of simulation . . . . . . . . . . . . . . . . . . 9-7

9. SELF-DIAGNOSTICS . . . . . . . . . . . . . . 9-93

10. KEY OPERATOR PROGRAM . . . . . . . 9-100

11. RADF test mode . . . . . . . . . . . . . . . . . 9-106

[10] MAINTENANCE AND OTHERS . . . . 10-1

1. Maintenance intervals and items to be

serviced . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

2. Replacing ozone filter . . . . . . . . . . . . . . 10-2

3. Oiling and greasing positions . . . . . . . . . 10-2

4. Other maintenance intervals and items

to be serviced . . . . . . . . . . . . . . . . . . . . . 10-3