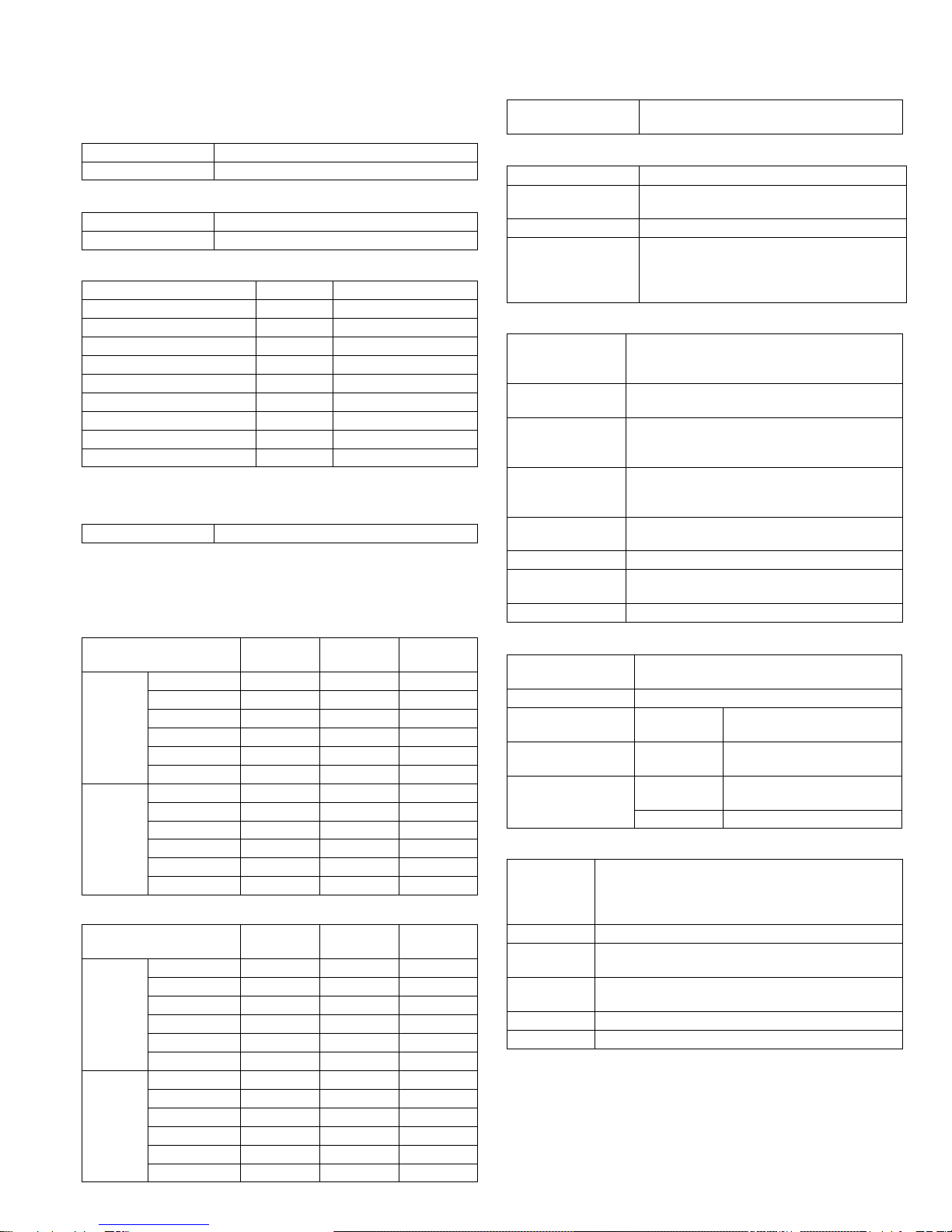

AR-M205 SPECIFICATIONS 2-2

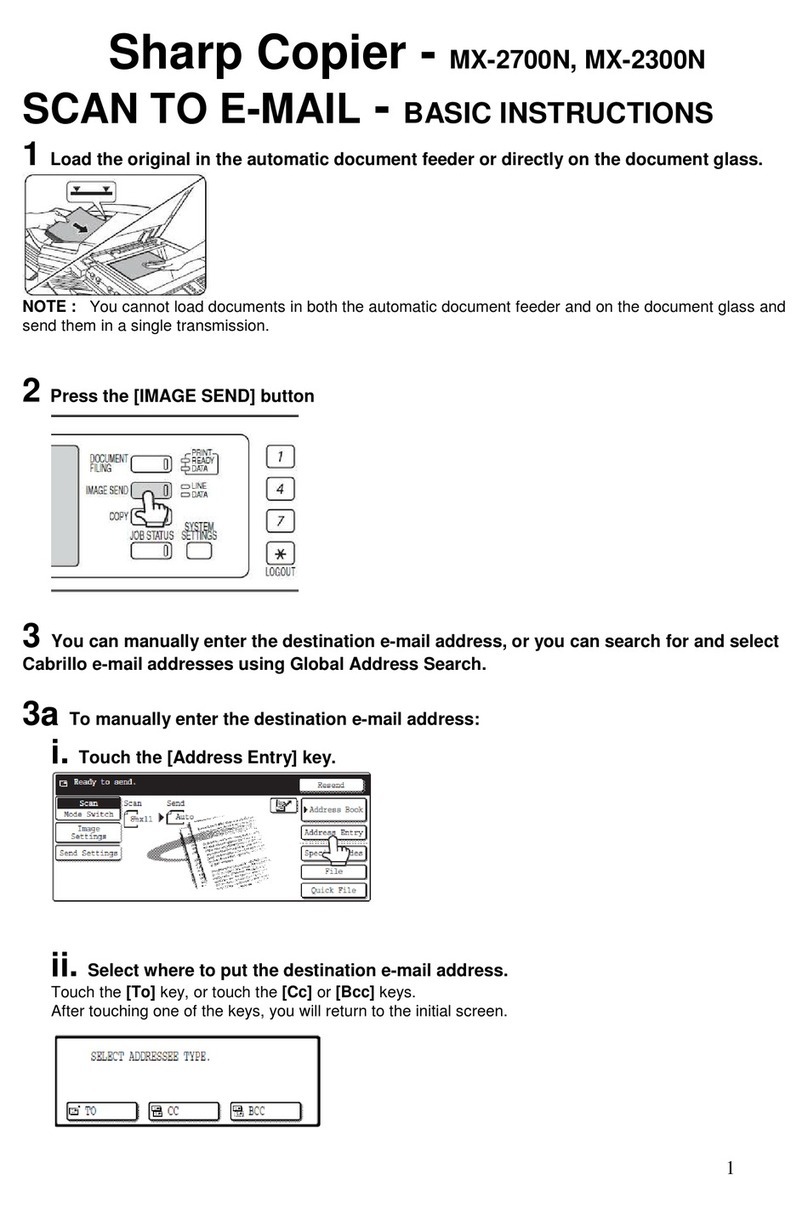

(2) Manual paper feed section

(3) Option paper feed unit

G. Job speed

Condition:With SPF/RSPF A4/Letter Normal 1cassette

H. Multi copy

I. Warm-up time

J. Copy magnification ratio

K. Print density

L. Void width

M. Auto duplex

N. Paper exit / finishing

(1) Electronic sort board (Option)

Paper feed

size A3 ~ A6, 11" x 17" ~ 8.5" x 5.5"

Paper feed

capacity 100 sheets(56 ~ 80g/m²)

Detection Size detection not available,

paper empty detection available

Weight 56 ~ 200g/m² (15 ~ 34 lbs.)

Special paper Recycled paper, OHP film, labels

Paper feed Single except for recycled paper

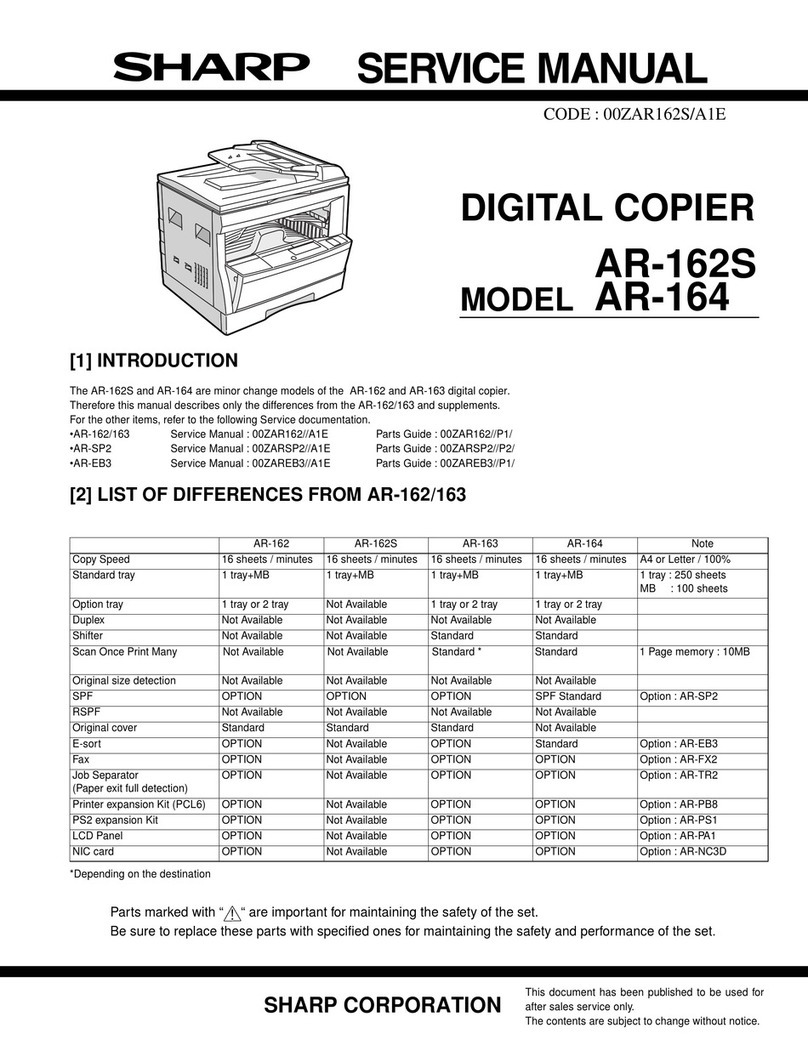

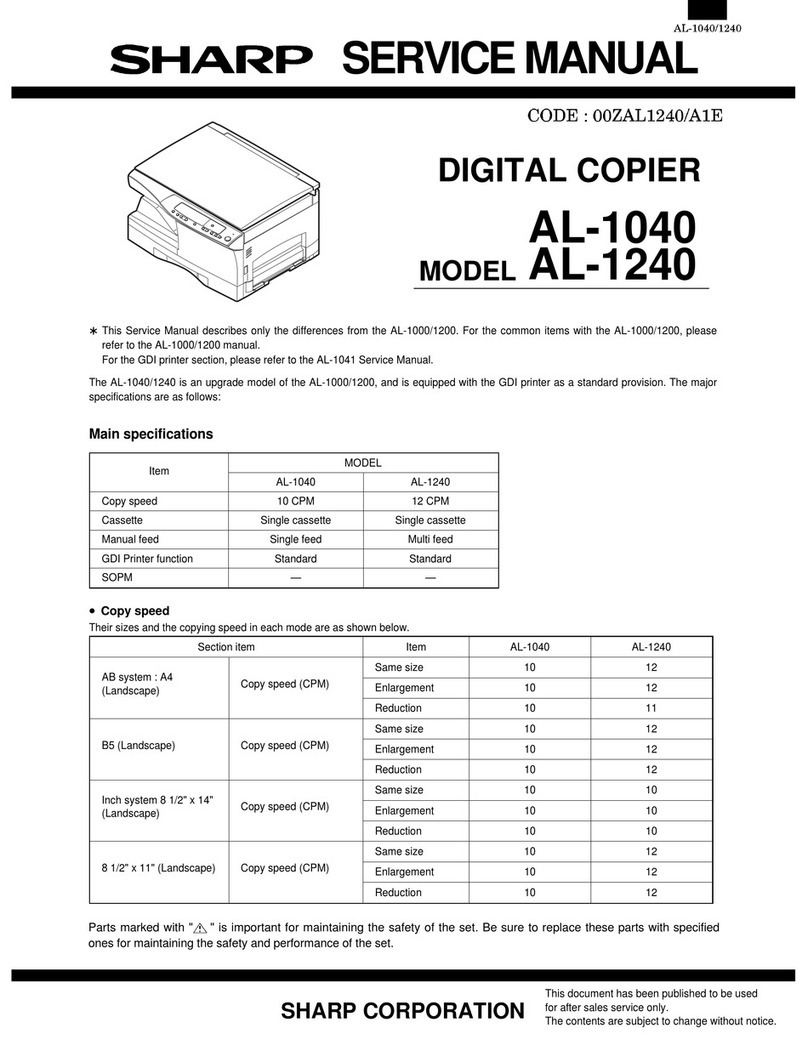

1-step paper feed unit 2-step paper feed unit

Model AR-D24 AR-D25

Paper feed size A3, B4, A4, A4R, B5, B5R

11" x 17", 8.5" x 14", 8.5" x 13",

8.5" x 11", 8.5" x 11"R

Capacity

(56 ~ 80gm²) About 250 sheets x

1 step About 250 sheets x

2 steps

Paper weight 56 ~ 90 g/m² (15 ~ 21 lbs.)

Moisture preserving

heater None

Paper empty detection Available

Paper size setting User setting

Paper size detection:None

External dimensions

(W x D x H) 590 x 471 x 88mm 590 x 471 x 173.5mm

Weight About 4.7kg About 10kg

Special paper Recycled paper

Power Supplied from the machine

S-S (1st step) 100% (document replacement rate)

Max. number of multi copy 999 sheets

Warm-up time 45 sec

Pre-heat Available

Jam recovery Within 45 sec

Fixed

magnification

ratio

AB system:

50, 70, 81, 86, 100, 115, 122, 141, 200%

Inch system:

50, 64, 77, 95, 100, 121, 129, 141, 200%

Zooming 25 ~ 400%

SPF/RSPF(50 ~ 200%)

Independent

zooming(vertical) Available (25 ~ 400%)

SPF/RSPF(50 ~ 200%)

Independent zooming

(horizontal) Available (25 ~ 400%)

SPF/RSPF(50 ~ 200%)

Density mode Auto / Text / Photo

No. of manual

adjustment 5 steps (Text / Photo)

Resolution Writing: 600 x 600dpi

Reading: 600 (main) x 600 (sub) (PHOTO mode)

600 (main) x 300 (sub) (AE mode)

Gradation Reading: 256 gradations

Writing: Binary

Toner save mode Set by the user program

Void area Lead edge 1 ~ 4mm,

rear edge 4mm or less,

both sides 4mm or less

Image loss 4mm or less

Standard/

Option Standard provision (AR-M205 only)

(D →D / D →S enable only when RSPF is installed)

Not available for AR-M160

Paper exit section

capacity Face down 250 sheets

Full detection None

Finishing Dual function board:

Option (AR-EB7)

Electronic sort

capacity A4 (8.5" x 11") standard document 100 sheets

Offset function Available (by the shifter)

Staple function None

Electronic sort Sorting 100 sheets of A4 standard

documents

Grouping 100 sheets of A4 standard

documents

Rotation copy If there is paper of same size as the document,

the image is rotated to copy even though the

paper is set in the different direction from the

document direction.

2 in 1, 4 in 1 Copies of 2 pages or 4 pages are integrated into

one surface. Divided by solid lines,

(Selectable by the user program.)

Edge erase Images surrounding the document are erased

when copying. (Adjustable in 5 ~ 20mm by the

user program.)

Center erase The image at the center is erased when copying.

(Adjustable in 5 ~ 20mm by the user program.)

Margin shift Binding margin is made at the left edge of the set

documents.

(Adjustable in 5 ~ 20mm by the user program.)

Memory for

electronic sort 16MB

* Memory loading

capacity A4 standard 100 pages

Memory expansion DIMM memory slot x 1, max. 256MB x 1 slot +

16MB (Max. 272MB in total)

USB2.0 Standard provision of E-sort

SPLC (JBIG-GDI) Supported when E-sort is installed.

ROPM Supported when E-sort is installed.

!"#$%