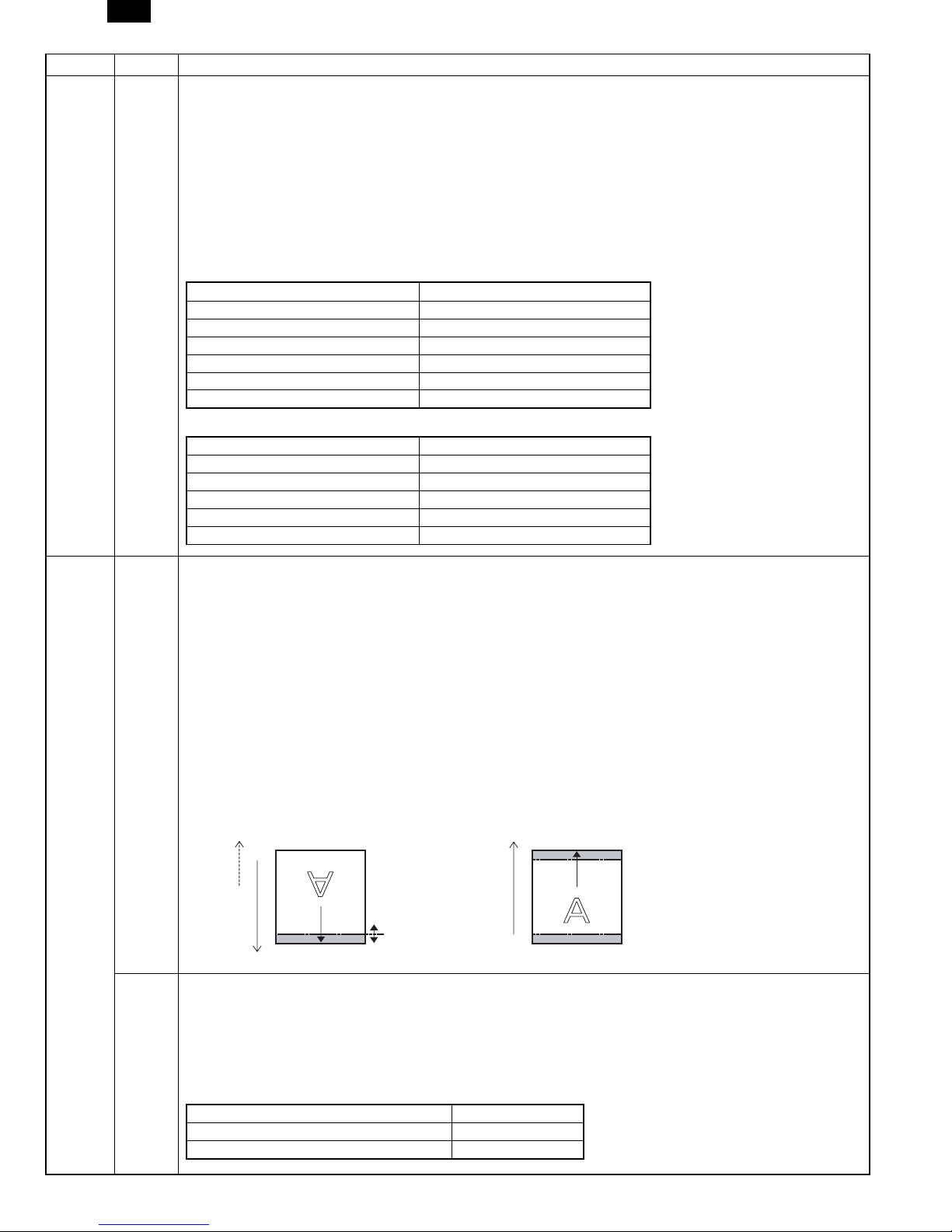

2. Control Panel

The control panel has keys and lights that are used to control and display the conditions of the WorkCentre.

1

Book Mode (XD104/124f only): Select

book mode when you want to make

copies from a bound document.

2

1-Sided/2-Sided Mode (XD155df only):

Use the 2-Sided copy feature to make

one or two-sided copies from one or

two-sided originals. Refer to the

Making Copies on the Automatic

Document Feeder section for detailed

information.

3

Image Quality Mode: The image quality

mode is used to maximize copy quality.

Auto- for originals with a colored

background or mixed text and graphics.

Text - for originals that contain mainly text.

Photo - for copying photographs.

Toner Save - decreases the overall

copy density.

4

Copy Contrast: Press the contrast keys

to lighten or darken copies while in the

Text, Photo, or Toner Save settings.

Refer to the Image Quality section for

detailed information. 5

Preset Reduction/Enlargement: Press

this key to select any of the preset

reductions or enlargements.

6

Percentage Indicator: The indicator will

light when any reduction or

enlargement setting is selected.

∗The (customer settable)

percentage has been set at the

factory for 50%. Refer to

Customizing Your WorkCentre for

information about changing this

percentage.

7

Variable Percentage: Press the down

key to decrease the percentage. Press

the up key to increase the percentage.

Any percentage from 50% to 200%

may be selected.

8

%: Press this key to display the

reduction/enlargement percentage

selected. 9

Display Window: Copy quantity,

reduction/enlargement settings, and

status codes appear in this area.

10

Quantity Keys: Select up to 100

copies. Press the 1 key to increase

the quantity by one. Press the 10 key

to increase the quantity by 10. 11

WorkCentre Diagram: Helps you locate

areas that require your attention. The

indicators will flash in the area

requiring attention. For additional

information refer to the Problem

Solving section. 12

Paper Supply Selection

(XD104/105f/120f/124f/155df only):

Press to change the selected paper

supply. The selected paper supply

location will be indicated by a green

light on the WorkCentre diagram.

∗To display the number of copies

requested during the copy run press

the 10 key.

∗Press the Clear key to clear the

selected quantity.

13

SPF/ADF Misfeed Indicator: This

indicator will light when a misfeed

occurs in the SPF or the ADF. 14

On-line/Off-line Key: Press this button

to alternate between On-line and Off-

line status. When the light is lit, the

printer is On-line. 15

Ready Indicator: When the light is ON

(not flashing), the WorkCentre is ready

to make copies. When the light is

flashing after the Start key is pressed,

the WorkCentre is warming up and the

copy cycle will begin automatically.

16

Start: Press this key to begin copying.

17

Clear/Stop: Press this key to stop the

WorkCentre while making copies or to

clear copy quantity. If the key is

pressed twice quickly, all programming

will be cleared.

∗The display will change to 1 and

increases by 1 as each copy is

made.

78%

Auto

86%

10 0%

129%

20 0%Ma x

10 1

C

134567810 1416171592 1311 12

AL-1550

3 – 2