Contents

1 About this document........................................................................ 5

1.1 Information on the operating instructions.............................................. 5

1.2 Scope......................................................................................................... 5

1.3 Explanation of symbols............................................................................ 5

1.4 Further information................................................................................... 6

2 Safety information............................................................................ 7

2.1 Intended use............................................................................................. 7

2.2 Improper use............................................................................................. 7

2.3 IP technology............................................................................................. 8

2.4 Limitation of liability................................................................................. 8

2.5 Modifications and conversions................................................................ 8

2.6 General cybersecurity notice................................................................... 9

2.7 Requirements for skilled persons and operating personnel.................. 9

2.8 Operational safety and particular hazards.............................................. 10

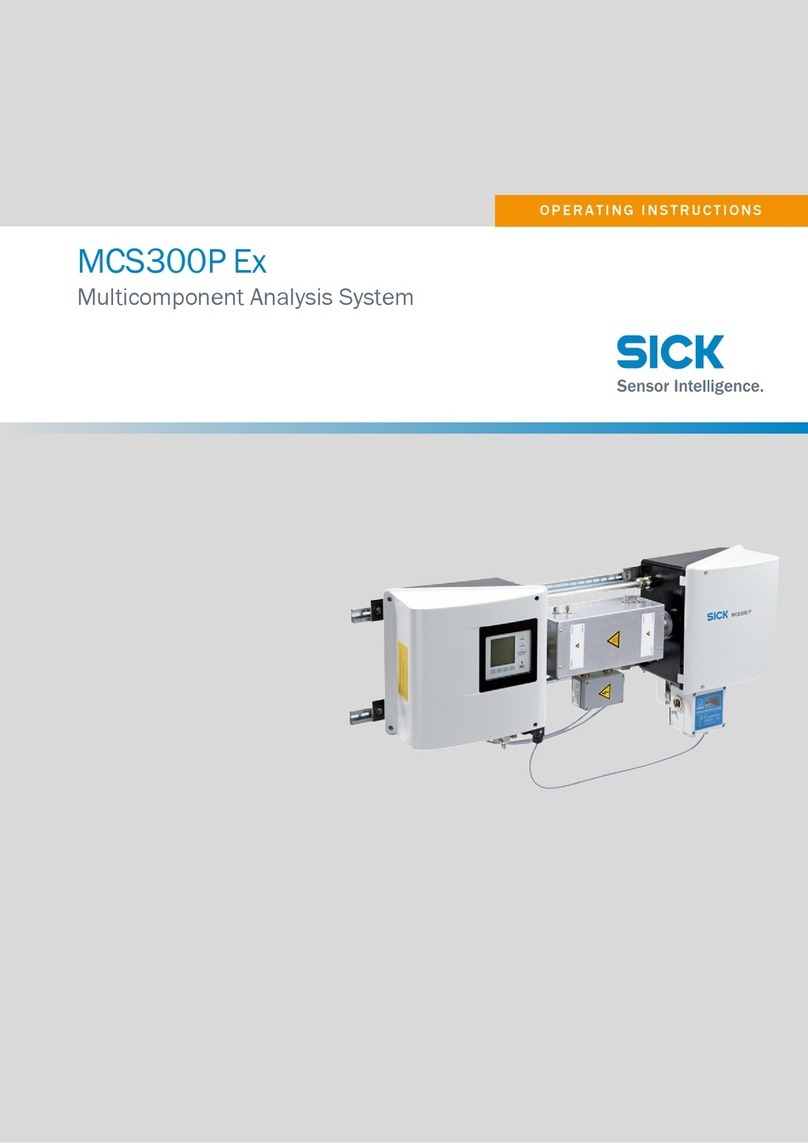

3 Product description........................................................................... 13

3.1 Product ID.................................................................................................. 13

3.2 Scope of delivery....................................................................................... 14

3.3 Product characteristics............................................................................ 15

3.4 SICK AppSpace......................................................................................... 19

4 Transport and storage....................................................................... 21

4.1 Transport................................................................................................... 21

4.2 Unpacking.................................................................................................. 21

4.3 Transport inspection................................................................................. 21

4.4 Storage...................................................................................................... 21

5 Mounting............................................................................................. 22

5.1 Mounting instructions............................................................................... 22

5.2 Preparation for mounting......................................................................... 22

5.3 Mounting location..................................................................................... 23

5.4 Mounting the device................................................................................. 25

5.5 Mounting an external trigger sensor (optional)...................................... 26

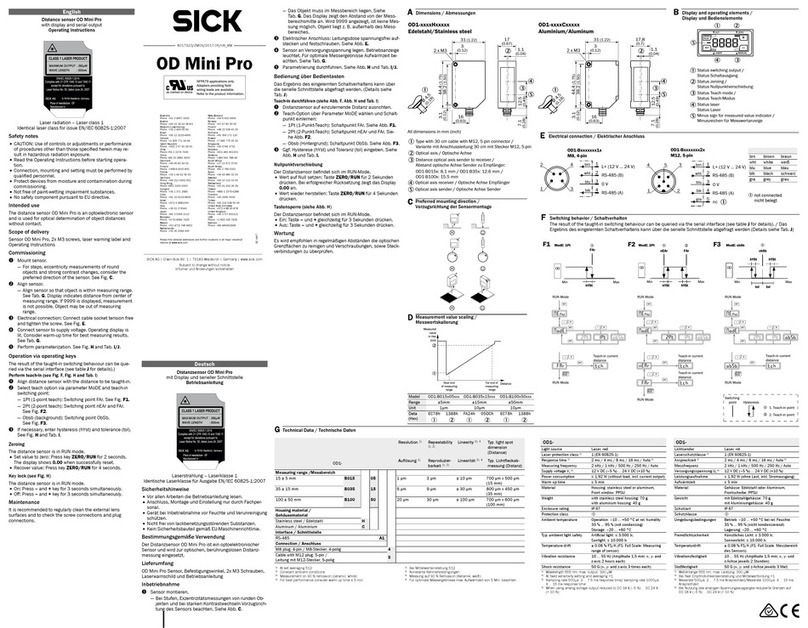

6 Electrical installation........................................................................ 27

6.1 Safety......................................................................................................... 27

6.2 Wiring instructions.................................................................................... 31

6.3 Connection diagrams............................................................................... 32

6.4 Pin assignments of electrical connections............................................. 33

6.5 Connecting the device.............................................................................. 34

7 Commissioning.................................................................................. 40

7.1 PC Software............................................................................................... 40

7.2 Network communication settings............................................................ 40

CONTENTS

8024439//2019-06 | SICK O P E R A T I N G I N S T R U C T I O N S | InspectorP621 3

Subject to change without notice