Contents

1. General................................................................................................................................... 4

1.1 Safety........................................................................................................................................................4

1.2 Installer and Operator’s Responsibilities.........................................................................................4

1.3 Maintenance............................................................................................................................................4

1.4 Limited Warranty ...................................................................................................................................4

1.5 Part Disposal ...........................................................................................................................................4

2. Intended Use .......................................................................................................................... 5

3. Product description ................................................................................................................ 5

3.1 Product identification...........................................................................................................................5

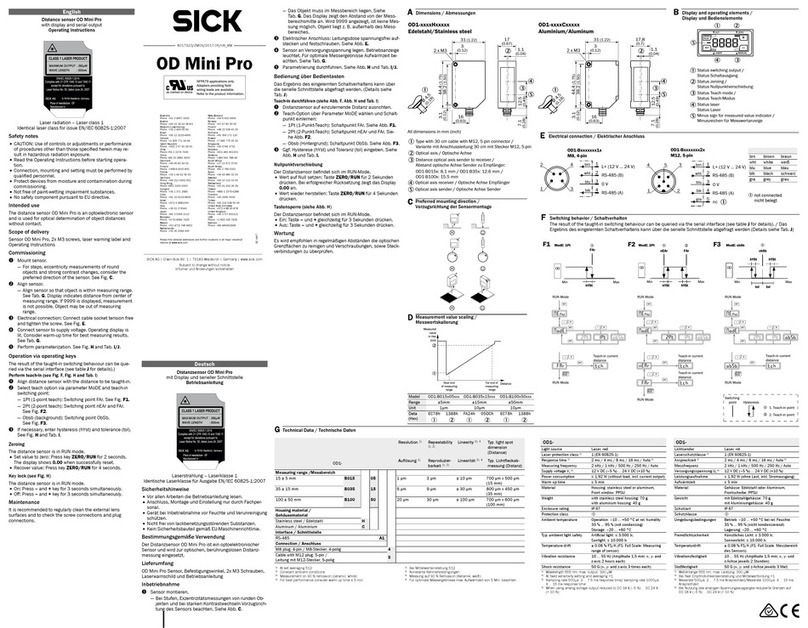

3.2 Layout and function ..............................................................................................................................6

3.2.1Gas Adjustment Kit ................................................................................................................................6

4. Operation ............................................................................................................................... 7

4.1 Operating Keys .......................................................................................................................................7

4.2 Status LED ................................................................................................................................................7

4.2.1Setting / Changing of Parameters and Set Points..........................................................................7

4.3 Measuring Point......................................................................................................................................8

5. Code Level.............................................................................................................................. 8

Code level 4 (password 1234, code not changeable)...................................................................8

6. Menu Overview ...................................................................................................................... 9

6.1 Error Status........................................................................................................................................... 12

6.2 Measuring Values................................................................................................................................ 12

6.3 Display Parameter............................................................................................................................... 13

6.3.1Software Version................................................................................................................................. 13

6.3.2Language............................................................................................................................................... 13

6.3.3Customer Password............................................................................................................................ 14

6.3.4Error Time Delay.................................................................................................................................. 14

6.3.5LCD Function ........................................................................................................................................ 14

6.4 MP Parameter....................................................................................................................................... 15

6.5 System Parameter............................................................................................................................... 15

6.5.1Maintenance Interval ......................................................................................................................... 15

6.5.2Average Function ................................................................................................................................ 16

6.5.3Power-On Time.................................................................................................................................... 16

6.5.4Error Time of the Sensor.................................................................................................................... 16

6.6 Operating Data .................................................................................................................................... 17

6.7 Calibration ............................................................................................................................................ 19

6.7.1Zero Point Calibration........................................................................................................................ 20

6.7.2Gain Calibration................................................................................................................................... 21

6.7.3Zero Point Calibration of Analog Output ...................................................................................... 22

List of Abbreviations .......................................................................................................................... 23

Glossary................................................................................................................................................. 23