Contents

1 About this document........................................................................ 4

1.1 Information on the operating instructions.............................................. 4

1.2 Explanation of symbols............................................................................ 4

1.3 Further information................................................................................... 5

2 Safety information............................................................................ 6

2.1 Intended use............................................................................................. 6

2.2 Improper use............................................................................................. 6

2.3 Internet protocol (IP) technology.............................................................. 6

2.4 Limitation of liability................................................................................. 6

2.5 Modifications and conversions................................................................ 7

2.6 General cybersecurity notice................................................................... 7

2.7 Requirements for skilled persons and operating personnel.................. 7

2.8 Operational safety and particular hazards.............................................. 8

3 Product description........................................................................... 11

3.1 Overview.................................................................................................... 11

3.2 System requirements............................................................................... 11

3.3 Solving a Deep Learning application....................................................... 12

4 Operation............................................................................................ 14

4.1 Installation................................................................................................ 14

4.1.1 SICK AppManager.................................................................... 14

4.1.2 Installing the SensorApp on a device..................................... 14

4.1.3 Installing tools.......................................................................... 15

4.2 User interface........................................................................................... 15

4.3 Run mode.................................................................................................. 16

4.4 Configure mode........................................................................................ 16

4.4.1 Tool tree.................................................................................... 17

4.4.2 System settings......................................................................... 18

4.4.3 Job settings.............................................................................. 18

4.4.4 Saving, importing and exporting a configuration................... 23

5 Annex.................................................................................................. 24

5.1 Licenses.................................................................................................... 24

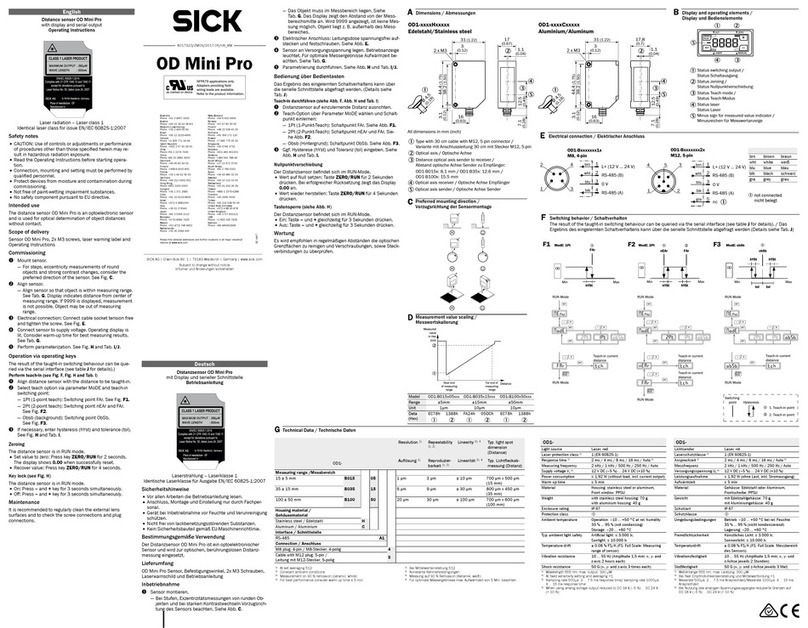

5.2 Tool box - System...................................................................................... 24

5.2.1 Interfaces tools.......................................................................... 24

5.2.2 Calibration tools......................................................................... 26

5.3 Tool box - Jobs........................................................................................... 27

5.3.1 Analysis tools............................................................................. 27

5.3.2 Results tools.............................................................................. 34

5.3.3 Communication tools.................................................................. 39

CONTENTS

8025818/0000/2020-06 | SICK O P E R A T I N G I N S T R U C T I O N S | Intelligent Inspection 3

Subject to change without notice