CONTENTS

48024250/18HT/V2-0/2020-12 | SICKOPERATING INSTRUCTIONS | ZIRKOR200Ex-G

Subject to change without notice

5 Installation................................................................................................31

5.1 Determination of the requirements for explosion protection ..................... 31

5.2 Information on installation in potentially explosive atmospheres.............. 31

5.3 Tools required ............................................................................................... 33

5.4 Material required .......................................................................................... 33

5.5 Preparing the measuring point ................................................................... 33

5.6 Transport....................................................................................................... 33

5.7 Storage information...................................................................................... 34

5.8 Scope of delivery .......................................................................................... 34

5.9 Installation .................................................................................................... 34

5.9.1 Fitting the counter flange on the duct ....................................... 35

5.9.2 Installing the control unit ............................................................. 35

5.9.3 Fitting the analyzer unit ............................................................... 36

5.9.4 Fitting the analyzer unit with cooling protection pipe................. 38

5.9.5 Installing the analyzer unit........................................................... 38

5.9.6 Aligning the V-shield..................................................................... 39

5.9.7 Laying the connection cable ........................................................ 40

5.9.8 Installing connection cables ........................................................ 41

5.9.9 Fitting the pneumatic unit............................................................ 42

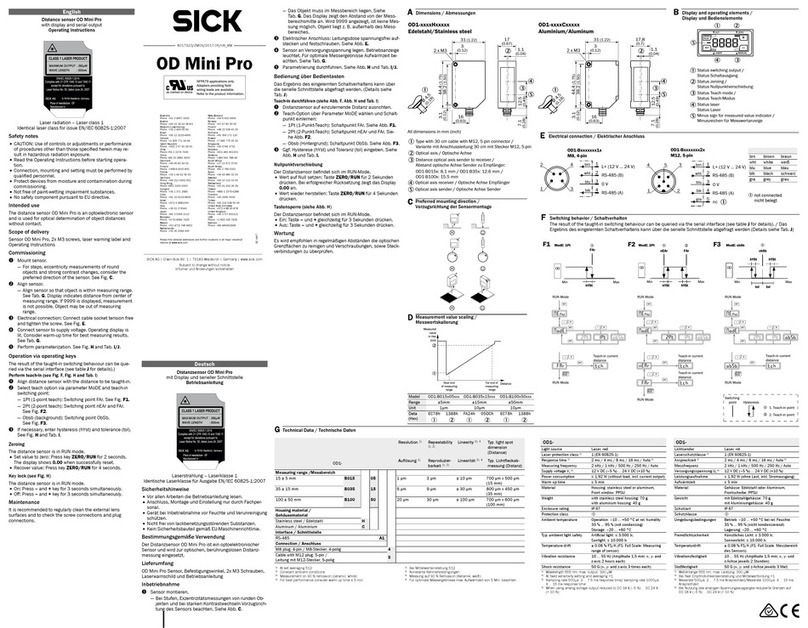

5.10 Electrical installation .................................................................................... 43

5.10.1 Accessing the connection terminals ........................................... 44

5.10.2 Instructions for the function of the spring-loaded terminal ....... 44

5.10.3 Potential equalization, (PE, ground) ............................................ 44

5.10.4 Connecting the control unit ........................................................ 45

5.10.5 Electrical connection plan (Ex-control unit and Ex-analyzer

unit)............................................................................................... 46

5.10.6 Power connection......................................................................... 48

5.10.7 Connecting the connection cable to the control unit ................. 49

5.10.8 Connecting the valve cable of the analyzer unit to the control

unit .............................................................................................. 49

5.10.9 Connecting the pneumatic unit line to the control unit ............. 49

5.10.10 Outputs/functions and relay assignment.................................... 49

5.10.11 Digital inputs ................................................................................ 50

5.10.12 Installing connection cables ........................................................ 50

5.10.13 Connecting the connection cable ................................................ 50

5.10.14 Connecting the analyzer electronics to the connection cable ... 52

5.10.15 Connecting the valve cable of the analyzer unit to the solenoid

valve.............................................................................................. 53

5.10.16 Connecting the pneumatic unit to the solenoid valve ............... 53

5.10.17 Closing the enclosure................................................................... 53

5.11 Pneumatic connections and settings .......................................................... 54

5.11.1 Pneumatic hose requirements ................................................... 54

5.11.2 Preparing the pneumatic hose .................................................... 54

5.11.3 Pneumatic connections on the analyzer unit.............................. 54