Company Confidential

Copyright 2004© Siemens AG

3

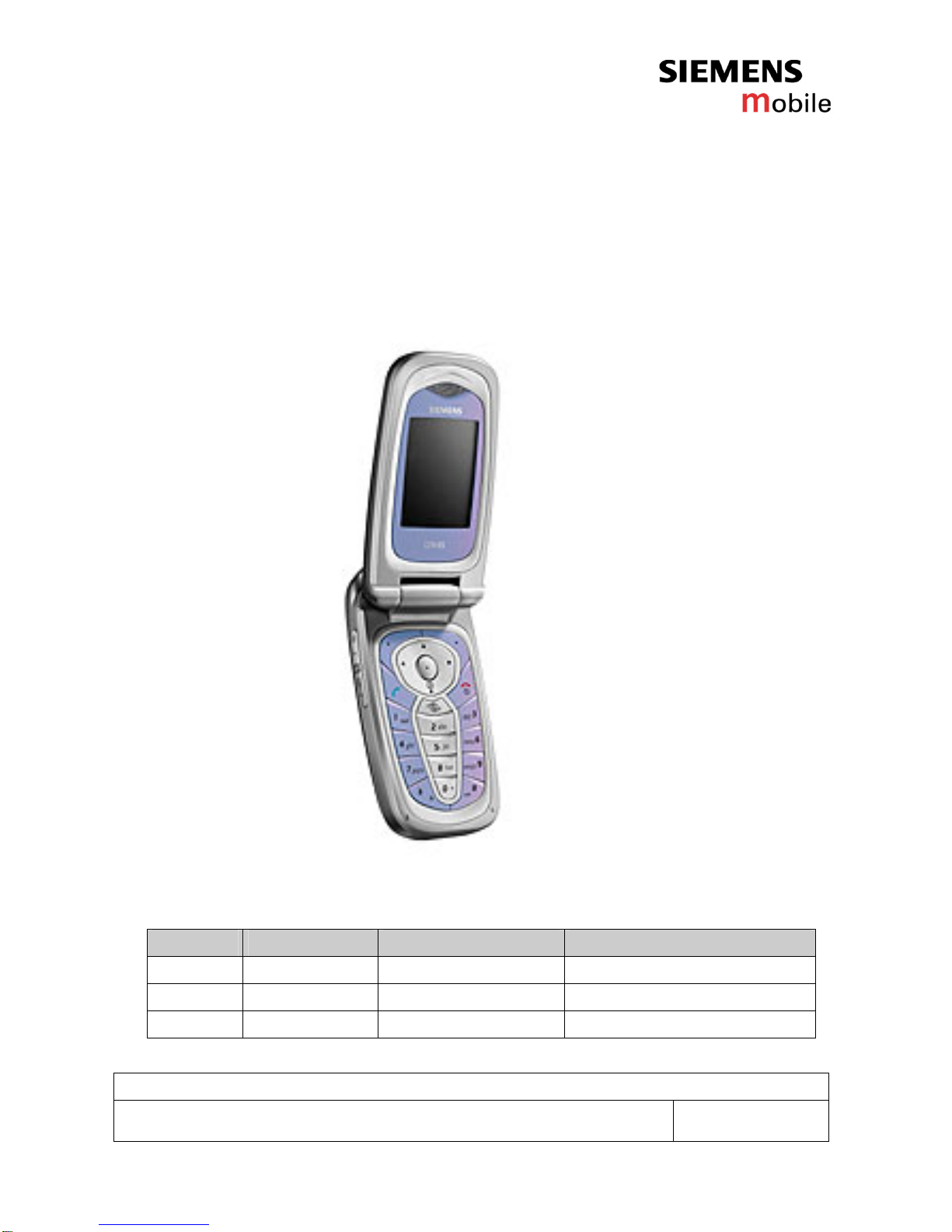

Service Repair Documentation

Level 2.5 - CFX65 V1.0

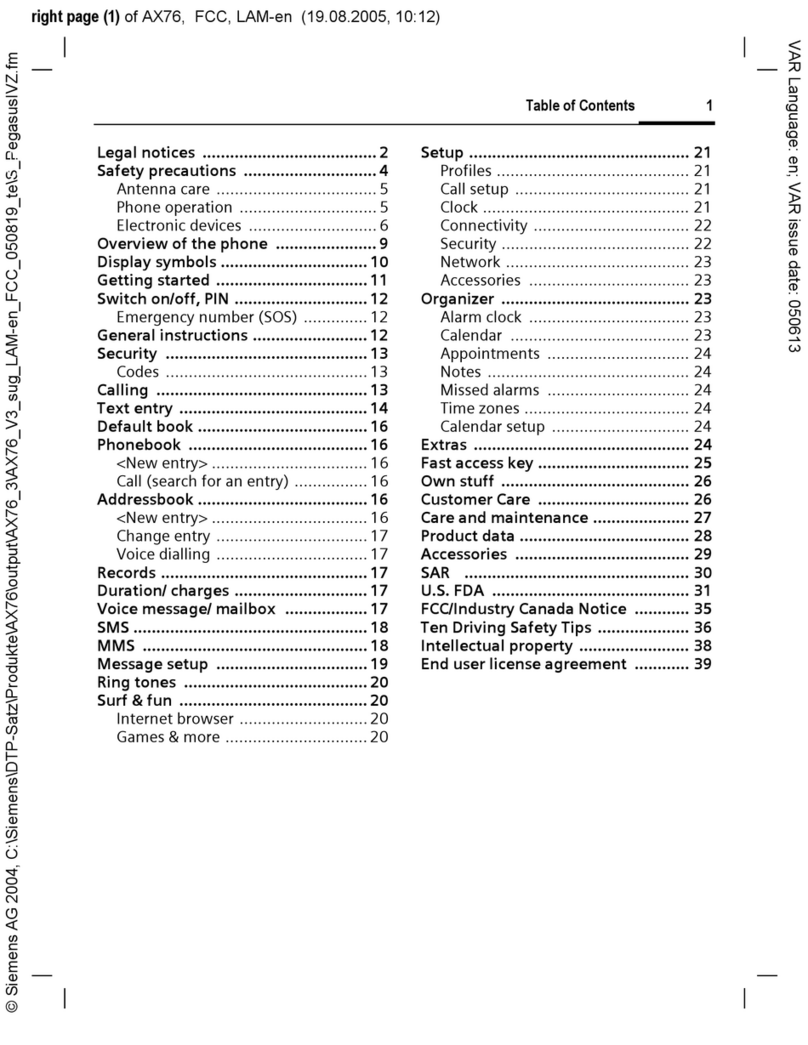

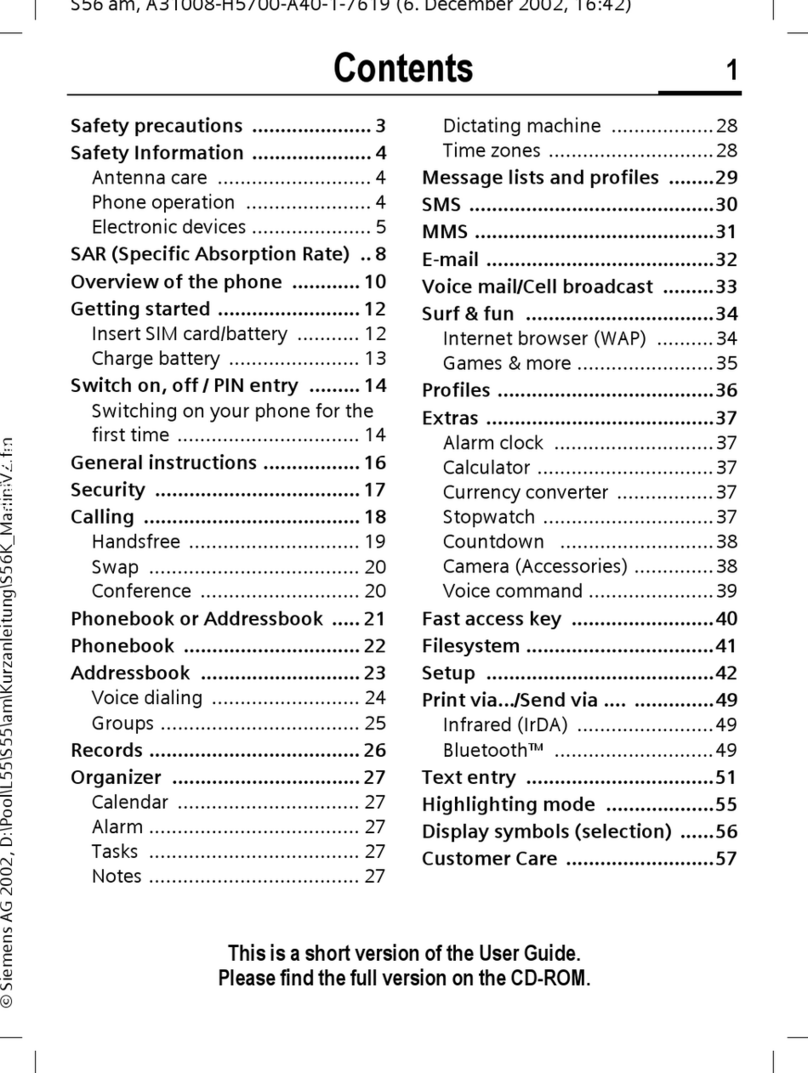

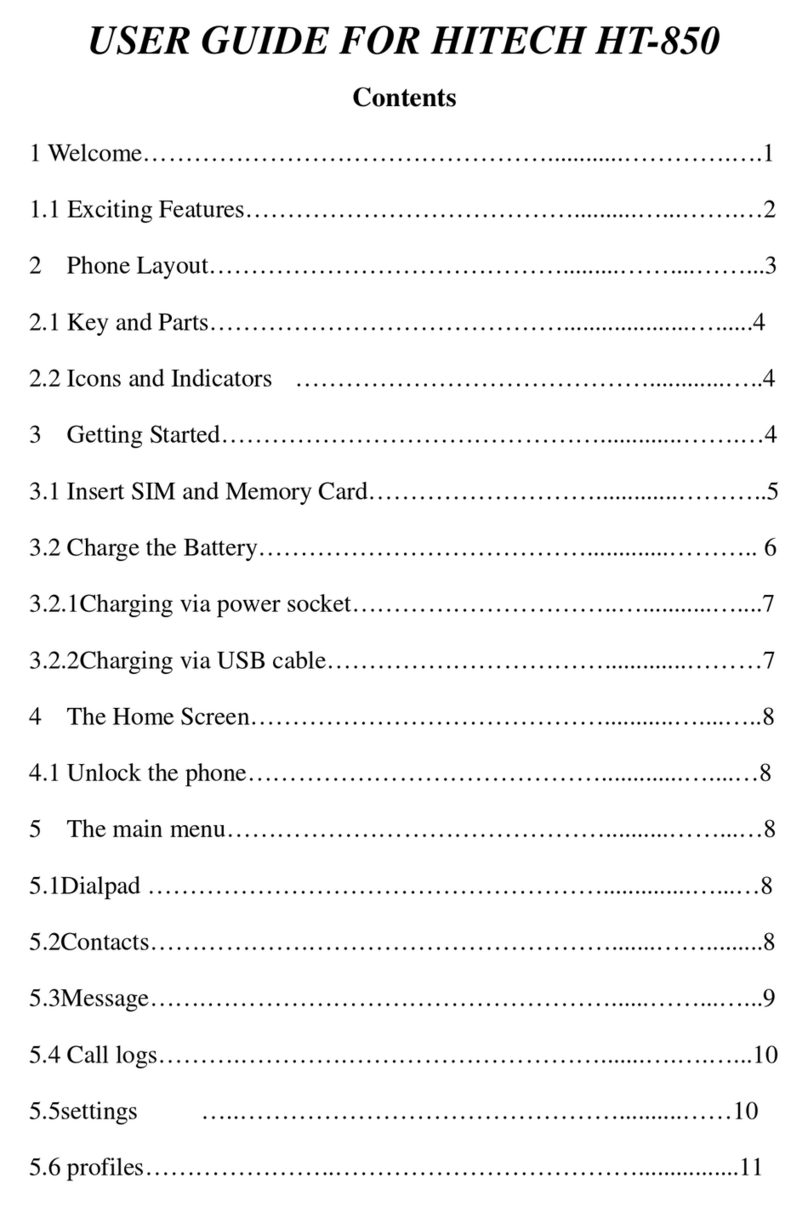

Table of content

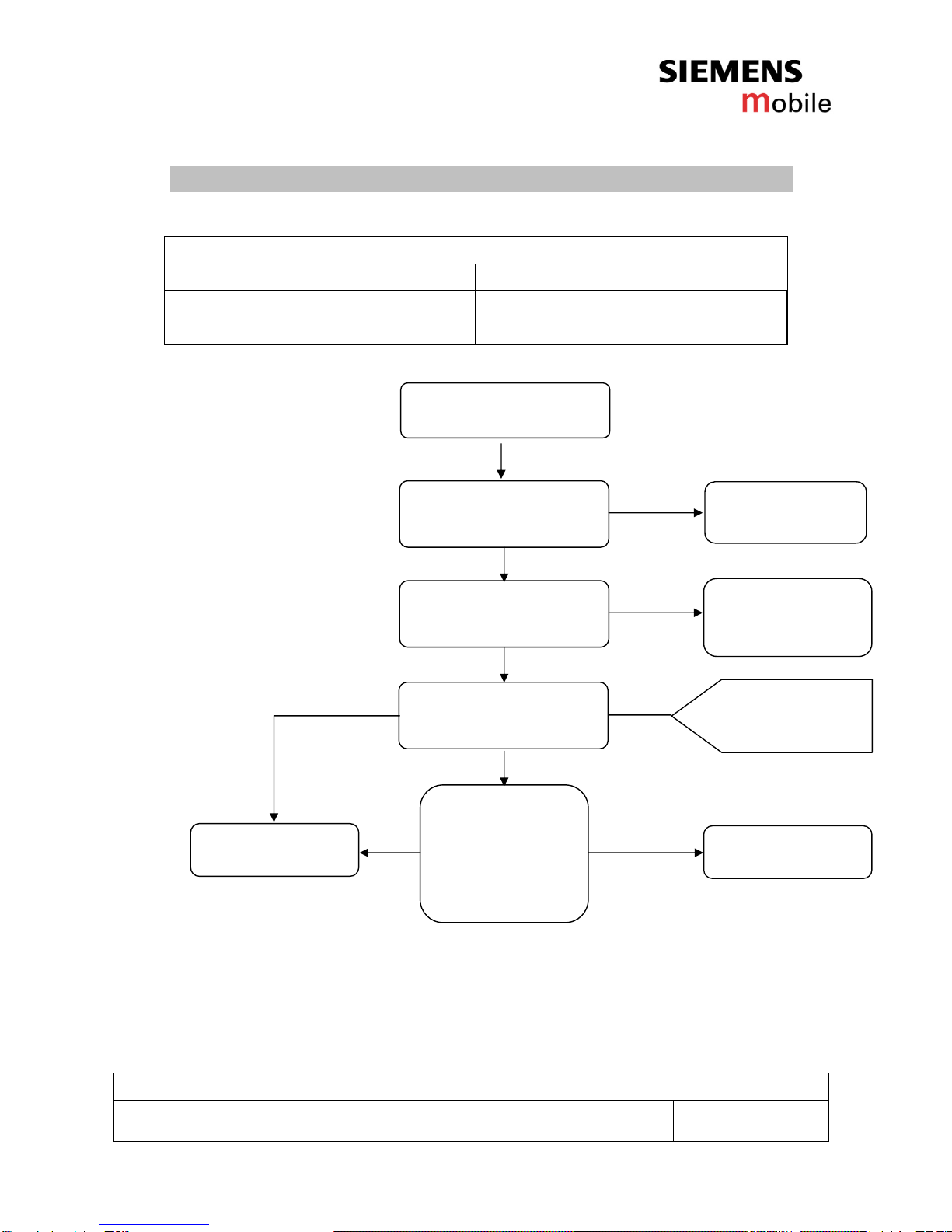

CFX 65 BOARD LAYOUT ...................................................................................................................... 4

LCM LAYOUT......................................................................................................................................... 6

1. B TO B CONNECTOR (J305) .......................................................................................................... 7

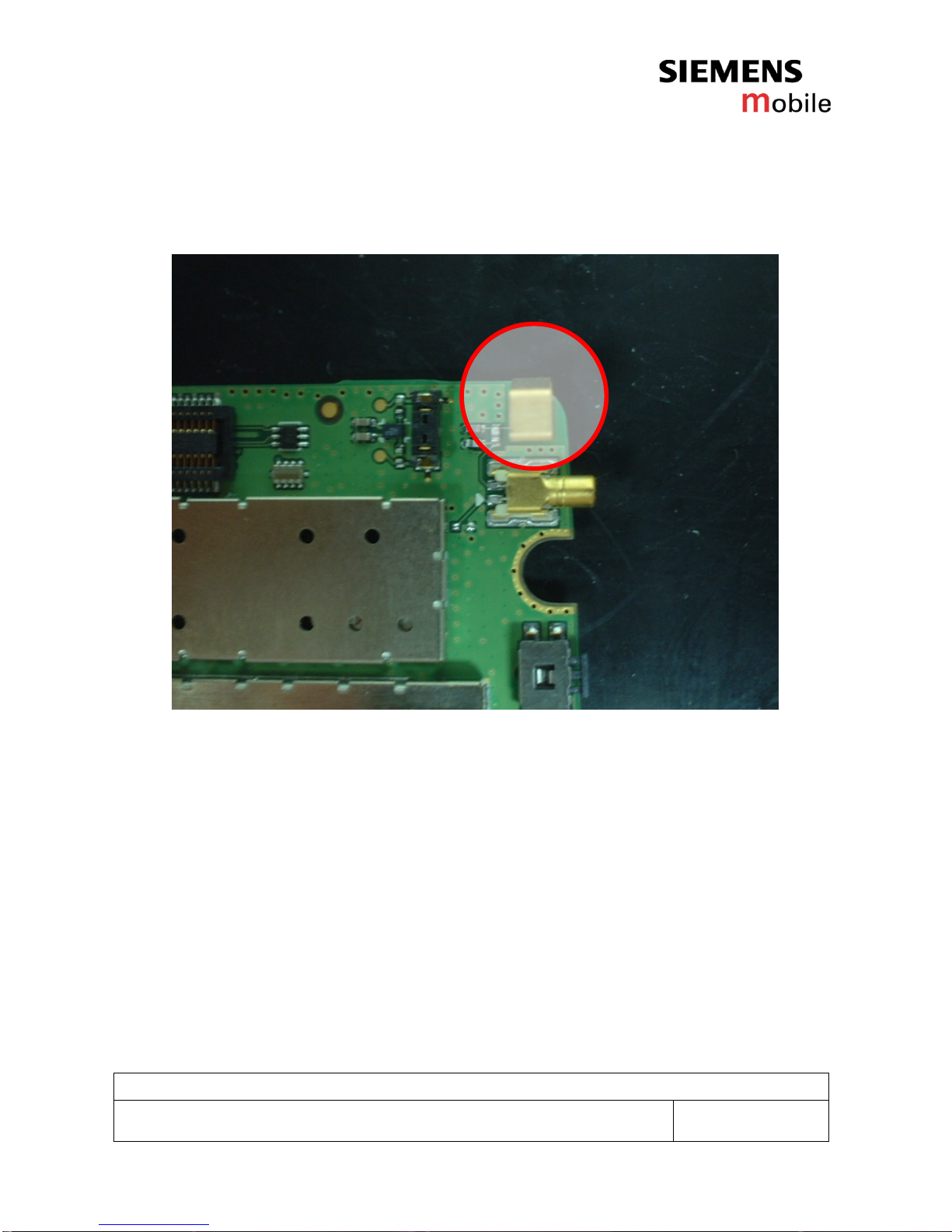

2. RF SWITCH (ANT300) ..................................................................................................................... 8

3. ANTENNA SPRING (J301) .............................................................................................................. 9

4. SPEAKER CONNECTOR (J200)................................................................................................... 11

5. SIDE KEY SWITCH (S400,S401)................................................................................................... 13

6. SIM READER (J302)...................................................................................................................... 15

7. I/O CONNECTOR (J304)................................................................................................................ 17

8. BACKUP BATTERY (BT414R)...................................................................................................... 18

9. IRDA (U103) ................................................................................................................................... 20

10. BATTERY CONNECTOR (J300).................................................................................................... 22

11. FUSE (F300).................................................................................................................................... 24

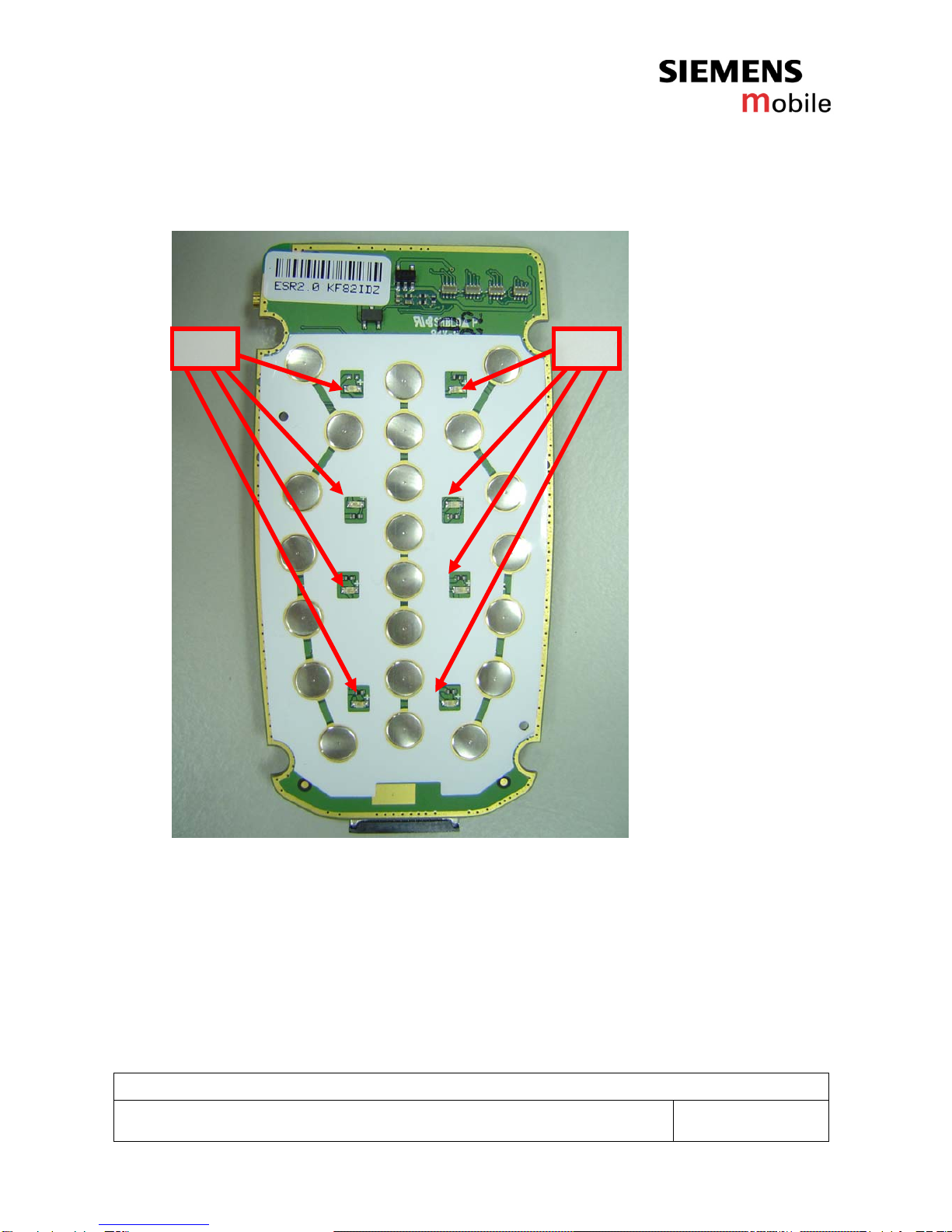

12. LED ON PCBA................................................................................................................................26

13. CAMERA CONNECTOR................................................................................................................. 28

14. CAMERA MODULE ........................................................................................................................ 30

15. FLASH LED..................................................................................................................................... 32