instabus EIB

Technical product information

April 2005

Switching actuator N 567/01 5WG1 567-1AB01

4 x 230V AC / 8A

Siemens AG N 567/01, 4 pages Technical manual

Automation and Drives Group

Electrical Installation Technology © Siemens AG 2005 Update: http://www.siemens.com/gamma

P.O. Box 10 09 53, D-93009 Regensburg Subject to change without further notice

2.4.4.9/1

Product and functional description

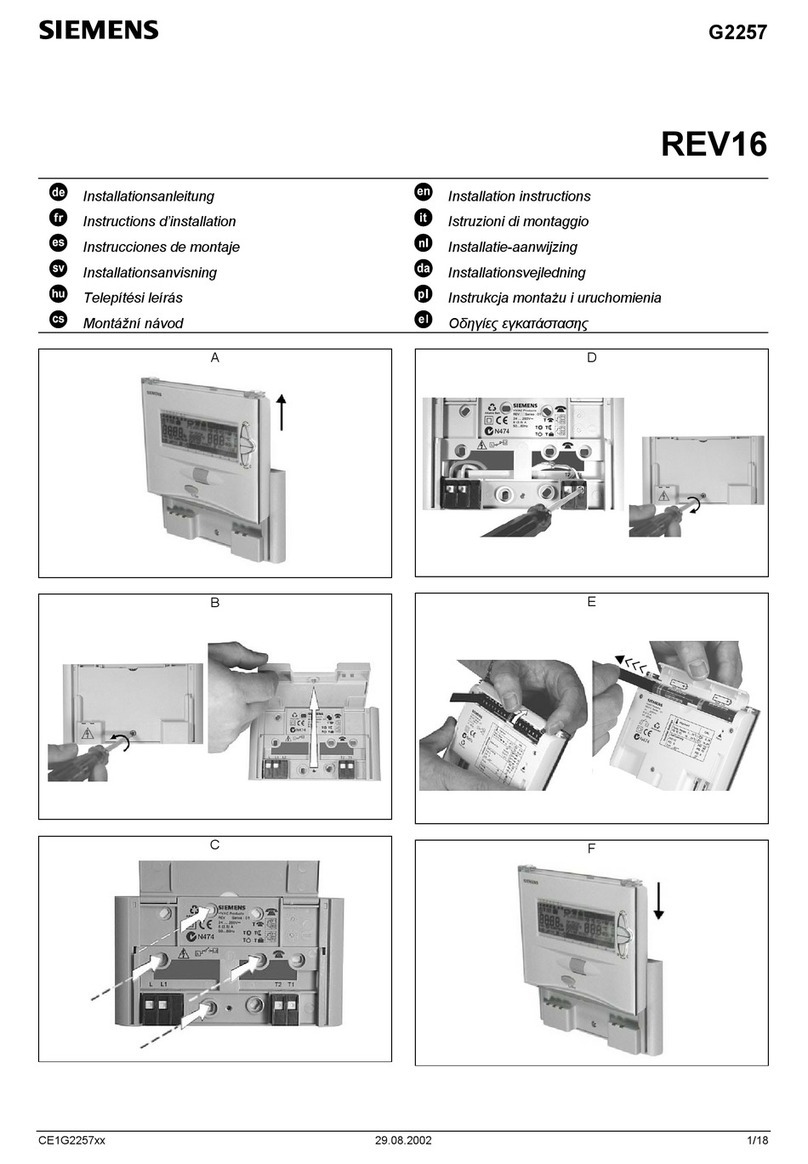

The switching actuator N 567/01 is an N-type device for

DIN-rail mounting. With its four relay contact outputs

(channels) it can switch four groups of electrical

consumers independently of each other. The connection

to the bus line can be carried out either via a bus terminal

block or by a contacting system to a data-rail installed in

the DIN-rail.

Application program

The switching actuator N 567/01 needs the application

program "25 A4 Binary, Flash Before Off 980303". With

this program there is a distinction between bus mode and

direct mode. In bus mode each channel can be provided

with a communication object for switching, for status

check and for logic operation. In addition it is possible

with each channel to change over from permanent

switch-on to time-limited switch-on (e.g. for cleaning

light) using an optional object "Night mode".

If required it is possible to activate an 8 bit scene control

function, which is integrated in the application program,

and to incorporate each channel in up to 8 scenes. In

addition you can choose whether all channels shall be

parameterized jointly and hence identically or each

channel separately and individually. The following

parameterizations are possible per channel:

•Operating mode (normal / time switch mode)

•Logic operation (none, AND, OR)

•ON delay

•OFF delay

•On period in night mode

•Warning before switching-off by multiple

switching Off/On (flashing) in case of a time-

limited On period in night mode or in time

switch mode

•Switching state after mains voltage recovery.

The application program can be loaded with ETS2 V1.3

and higher.

Bus mode / direct mode

The switching actuator N 567/01 has an integrated power

supply unit for 230 V AC in order to supply power to the

actuator electronics. The power supply unit enables

operation of the actuator and direct switching of the

actuator channels in "direct mode" even if no bus voltage

is available, the N 567/01 still has to be taken into

operation with the ETS (Engineering Tool Software) or

communication over the EIB has been interrupted.

With the N 567/01, "direct mode" is switched on by means

of a pushbutton at bottom left on the upper side of the

actuator. When this pushbutton is pressed for the first

time, the yellow LED shines with a steady light to indicate

the direct mode. In direct mode, each channel can be

switched by a toggling function using the pushbutton

assigned to it on the upper side of the actuator: pressing

the pushbutton once switches ON the channel, pressing it

a second time switches OFF the channel. The switching

state of the channel is indicated by a red LED integrated in

the pushbutton.

A parameter is available to set whether direct mode can

be switched on permanently or for a limited time. In the

default setting, direct mode is limited to an On period of

15 minutes. Each time the pushbutton is pressed in direct

mode the timer for limiting the On period is restarted with

the parameterized On period. If the On period expires

without the pushbutton being pressed again, direct mode

is switched off automatically and "bus mode" reactivated

(provided communication over the EIB is possible).

Alternatively, direct mode can be terminated at any time

with another press of the "direct mode" pushbutton. The

yellow LED for indicating direct mode then goes out and

the actuator is back in bus mode. In bus mode, nothing

happens if you press the pushbuttons for directly

switching a channel on or off which are located on the

upper side of the actuator. Switching and scene calling

commands received over the bus when direct mode is

active are buffered and automatically executed after

having returned to bus mode.

Behavior in case of power failure / recovery

The actuator electronics is powered from the mains

supply; a power failure thus results in failure of the

actuator. With the N 567/01, a power failure also forces all

actuator channels to be switched off. However, for each

channel it is possible to select which switching state is to

be adopted after power recovery: the state that existed

before the power failure, ON or OFF.