Instructions, use and maintenance manual Pag. 2/48

SRIZZA 40

1.

General information ............................................................................................................................ 4

1.1.

Foreword ...........................................................................................................................................4

2.

Content of the declaration of conformity.......................................................................................... 5

3.

Warranty conditions............................................................................................................................ 6

3.1.

Validity...............................................................................................................................................6

3.2.

Warranty mode of provision ..............................................................................................................6

3.3.

Wear parts.........................................................................................................................................6

4.

General safety standards ................................................................................................................... 7

4.1.

Safety standards. ..............................................................................................................................7

4.2.

Safety devices...................................................................................................................................7

4.3.

Educating and training of machine operators ...................................................................................7

5.

Customer set-ups................................................................................................................................ 9

5.1.

Instructions for ordering spare parts .................................................................................................9

6.

Safe work methods and procedures ............................................................................................... 10

6.1.

Risks for the operator......................................................................................................................10

7.

Organisation of the manual and how to consult it......................................................................... 12

7.1.

Glossary ..........................................................................................................................................12

8.

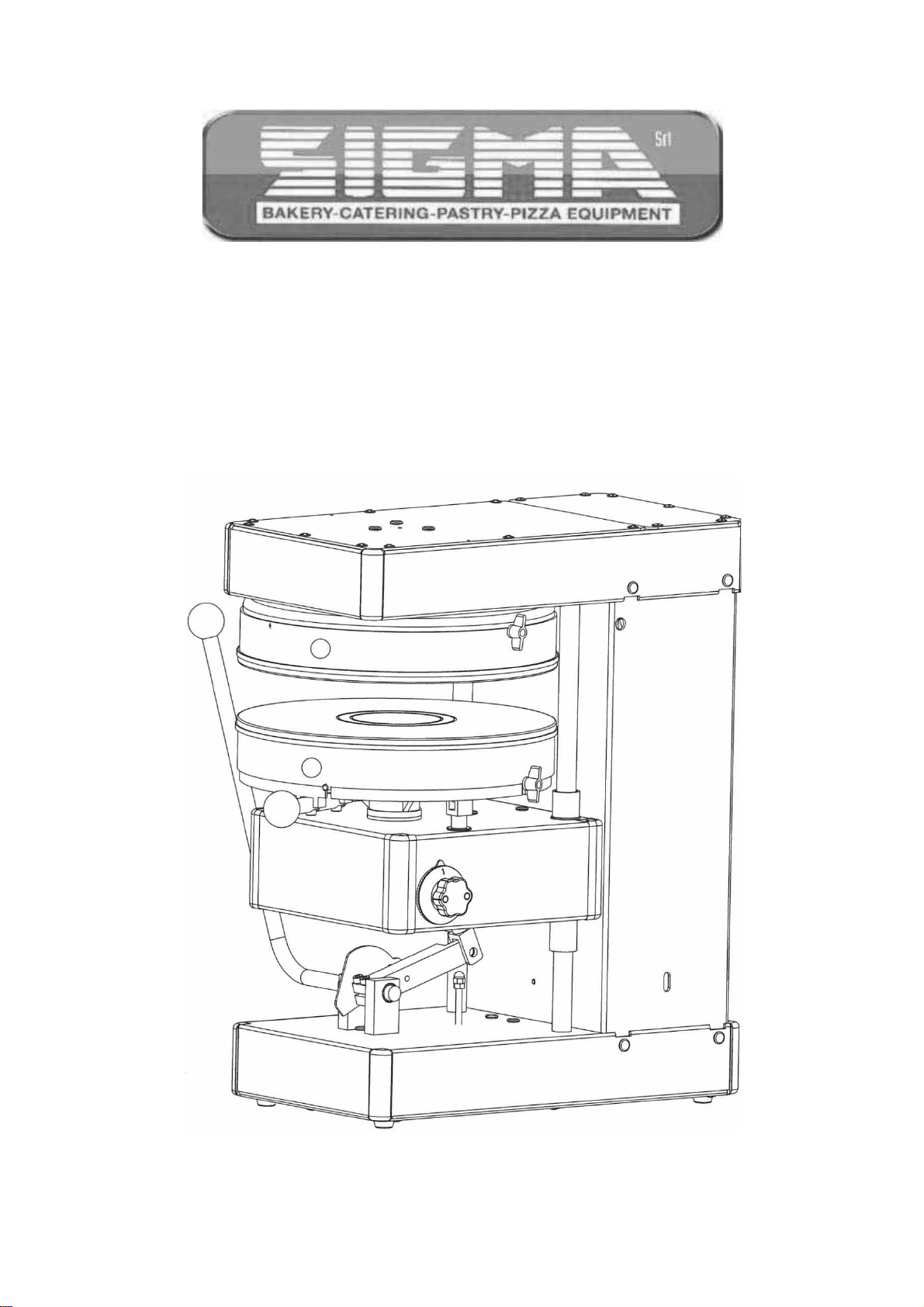

Machine description.......................................................................................................................... 13

9.

Machine identification....................................................................................................................... 14

9.1.

Main components............................................................................................................................14

10.

Technical data and features............................................................................................................. 15

10.1.

Units of measurement.....................................................................................................................15

10.1.1.

Technical data.............................................................................................................................15

10.1.2.

Dimensions .................................................................................................................................15

10.1.3.

Packaging ...................................................................................................................................16

10.2.

Control panel...................................................................................................................................16

10.3.

Type of drive and motor ..................................................................................................................17

10.4.

Storage and conservation of the machine.......................................................................................17

10.4.1.

Storage........................................................................................................................................17

10.4.2.

Storing the machine....................................................................................................................17

10.5.

Types and features of the product and of the treated materials .....................................................17

10.6.

Type and features of machine emissions........................................................................................17

11.

Transport and installation ................................................................................................................ 18

11.1.

Machine on pallet ............................................................................................................................18

11.2.

Machine without pallet.....................................................................................................................18

11.3.

Description of the adjustment and commissioning operations........................................................19

11.3.1.

Installation...................................................................................................................................19

11.3.2.

Electric line connection ...............................................................................................................20

12.

Adopted safety devices .................................................................................................................... 21

13.

User instructions............................................................................................................................... 22

13.1.

Operating instructions .....................................................................................................................22

13.1.1.

First maximum adjustment of the desired dough thickness........................................................22

13.1.2.

Using the machine ......................................................................................................................22

13.1.3.

Oservations.................................................................................................................................22

13.1.4.

Workable doughs........................................................................................................................23

13.1.5.

The doughs.................................................................................................................................23

14.

Scheduled maintenance and/or replacement interventions......................................................... 27

14.1.

Master switch ..................................................................................................................................27

14.2.

Master switch ..................................................................................................................................27

14.3.

Stop circuit and safety micro-switch................................................................................................27

14.4.

System checks ................................................................................................................................28