Hanil J1250 User manual

USER MANUAL │ J1250

Product name

Continuous Centrifuge J1250

Manufacturing company

Hanil Science Industry Co., Ltd.

16, Arayuk-ro, Gochon-eup, Gimpo-si, Gyeonggi-do

www.ihanil.com

packaging unit

1 set including main body, control unit and accessories

The contents of the user manual are subject to change without notice.

© 2022 Hanil Scientific Inc. All rights reserved.

UM-J1250(E)(Rev.1), 2022.09.29

USER MANUAL │ J1250

USER MANUAL │ J1250

CONTENTS

- - - - - - - 6

- - - - - - - 6

- - - - - - 7

- - - - - - 8

1. Precautions for safety

1.1 General safety instructions

1.2 Precautions for use

1.3 Precautions when installing the product

2. Product overview and composition

2.1 Technical Specifications Main Unit

2.2 Technical Specifications Control Unit

2.3 Product composition

2.3.1 Main unit configuration

2.3.2 Accessories

2.4 Configuration for each part

2.4.1 Main unit configuration and dimension

2.4.2 Tool kit and use

2.4.3 Sample feeding pump

2.4.4 Control unit configuration and dimension

- - - - - - 9

- - - - - - - 10

- - - - - 11

-- - - - 12

- - - - - 12

- - - - - 12

- - - - - 13

- - - - - 13

- - - - - 15

- - - - - 18

- - - - - 20

- - - - - 21

- - - - - 21

- - - - - 23

- - - - - 24

- - - - - 24

- - - - - 26

- - - - - 27

- - - - - 27

- - - - - 28

- - - - - 29

- - - - - 30

- - - - - 31

- - - - - 32

- - - - - 34

- - - - - 35

- - - - - 36

- - - - - 37

- - - - - 38

- - - - - 43

HANIL Scientific Inc. │ ihanil.com │Service: +82-2-3452-8966 / [email protected] 4

3.Product installation

3.1 Instrument installation and balancing

3.2 Power Connection

4. How to use the control unit and precautions

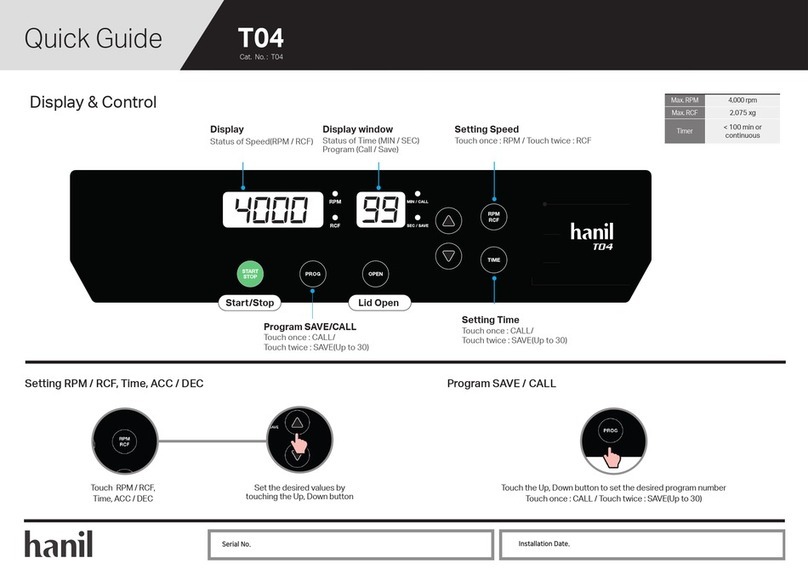

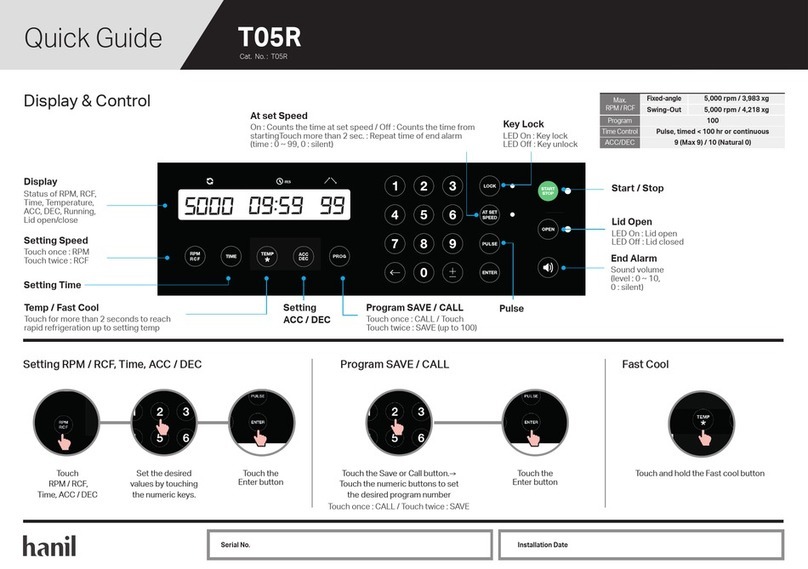

4.1 Control panel

4.2 Overall operation flow chart

4.3 Loading screen

4.4 Setting the speed

4.5 Time setting

4.6 Acceleration/deceleration step setting

4.7 History screen

4.8 Saving History

4.9 Saving, Recalling and Deleting Programs

4.10 Start/Stop

4.11 Emergency stop

4.12 Pump Operation

4.13 Operation completion status display

4.14 Setting screen

4.15 Error status display during operation

USER MANUAL │ J1250

CONTENTS

5. Preparing and How to Drive

5.1 Bowl assembly

5.1.1 Insert Teflon sheet

5.1.2 Inserting the triangular rotor blade

5.2 Drag body assembly mounting

5.3 Bowl installation

5.4 Bowl and Motor Spindle fastening

5.5 Things to check before driving

5.6 Driving

- - - - - 44

- - - - - 44

- - - - - 45

- - - - - 46

-- - - - 48

- - - - - 48

- - - - - 50

-- - - - 52

- - - - - 53

- - - - - 54

- - - - - 54

- - - - - 54

- - - - - 55

- - - - - 55

- - - - - 57

6. Disassembly and maintenance

6.1 Disassembly

6.2 Cleaning

6.3 Daily Inspection

6.4 Maintenance

6.5 Bad Code Description

7. Ordering Information - - - - - 58

USER MANUAL │ J1250

1. Precautions for safety

Because this equipment rotates at high speed, the risk of accidents is very high if mishandled. In

order to use the centrifuge effectively and safely, please read the following precautions. Since the

instruction manual is part of the product, always place it around the product.

1.1 General safety instructions

① Before supplying power, remove all packaging materials used to prevent damage during

transportation.

·Install in a dry environment, avoiding high temperature and high humidity.

·Use only cables and devices supplied by the manufacturer. The manufacturer is not responsible

for any problems caused by the user's arbitrary change and use.

·The manufacturer is not responsible for any problems caused by improper operation by the user

outside the range allowed by the device.

·Before use, be sure to check each part to make sure that there is no abnormality in the

centrifuge. In particular, do not use the centrifuge that has been operated by another person

without checking the status.

⑥Do not place near objects such as towels or cloths that may get caught in rotating parts

(Pulley, Spindle, etc.) while driving. It is very dangerous to touch rotating parts, especially with

cotton gloves.

·Do not open the door of the outer bowl frame until the rotation is completely stopped.

·Perform regular inspections on equipment, wiring, and piping.

·If you find a stripped or broken cable, you must replace it immediately.

·Use a suitable electric extension device or power outlet, and do not overload it.

·Do not touch the device, socket outlet or switch with wet hands.

·Do not change the electrical parts of the device or parts.

USER MANUAL │ J1250

1.2 Precautions for use

Since this equipment is used in combination with a high-speed rotating continuous

centrifuge and a control box, it is necessary to familiarize yourself with the precautions for

use of each component.

Please check once more before use.

·Check if any of the necessary parts and devices are missing. (Refer to p12~13, p15~17)

·Check the power supply status and connection wiring conditions between the main body

and the Control Box.

(see p23)

·Since it rotates at high speed, the rotating parts must be well balanced.

·Check if the Serial No. of the body, cap, and triangular rotor blades composing the bowl

match before use. (see p8)

. For the best operation, use the bowl set that matches the serial number of the bowl attached

to the front of the body. (see p8)

·The product installation site must be leveled and firmly fixed on a flat place.

·Check that there is no problem with the wiring connected to the device, and connect the

power cord to the device that requires power.

·Do not place any obstructive objects within 60cm of the device.

·Do not touch or impact the main body while it is operating.

·As this is a device that uses electricity, be careful not to get an electric shock when handling it.

·Do not use flammable, hazardous, or radioactive substances that can generate volatile or

explosive vapors.

·In case of an emergency, operate the emergency switch and open the door after confirming

that the product is stopped. (see p35)

·When not operating the device, turn off the power.

HANIL Scientific Inc. │ ihanil.com │Service: +82-2-3452-8966 / [email protected] 7

USER MANUAL │ J1250

1.3 Precautions when installing the product

1.3.1 Installation

This equipment is installed on a flat concrete floor and is used by balancing it with 6 balancing

feet on the corners of the iron H-beam base at the bottom of the main body. For more reliable

use, it can be operated by driving anchor bolts into the floor. When installing this equipment, it is

recommended to proceed after sufficiently consulting with the technical person in charge of the

manufacturer.

In the installation space, a work space of 60cm or more must be secured on the left, right, and

rear of the equipment, and sufficient space must be secured in the front.

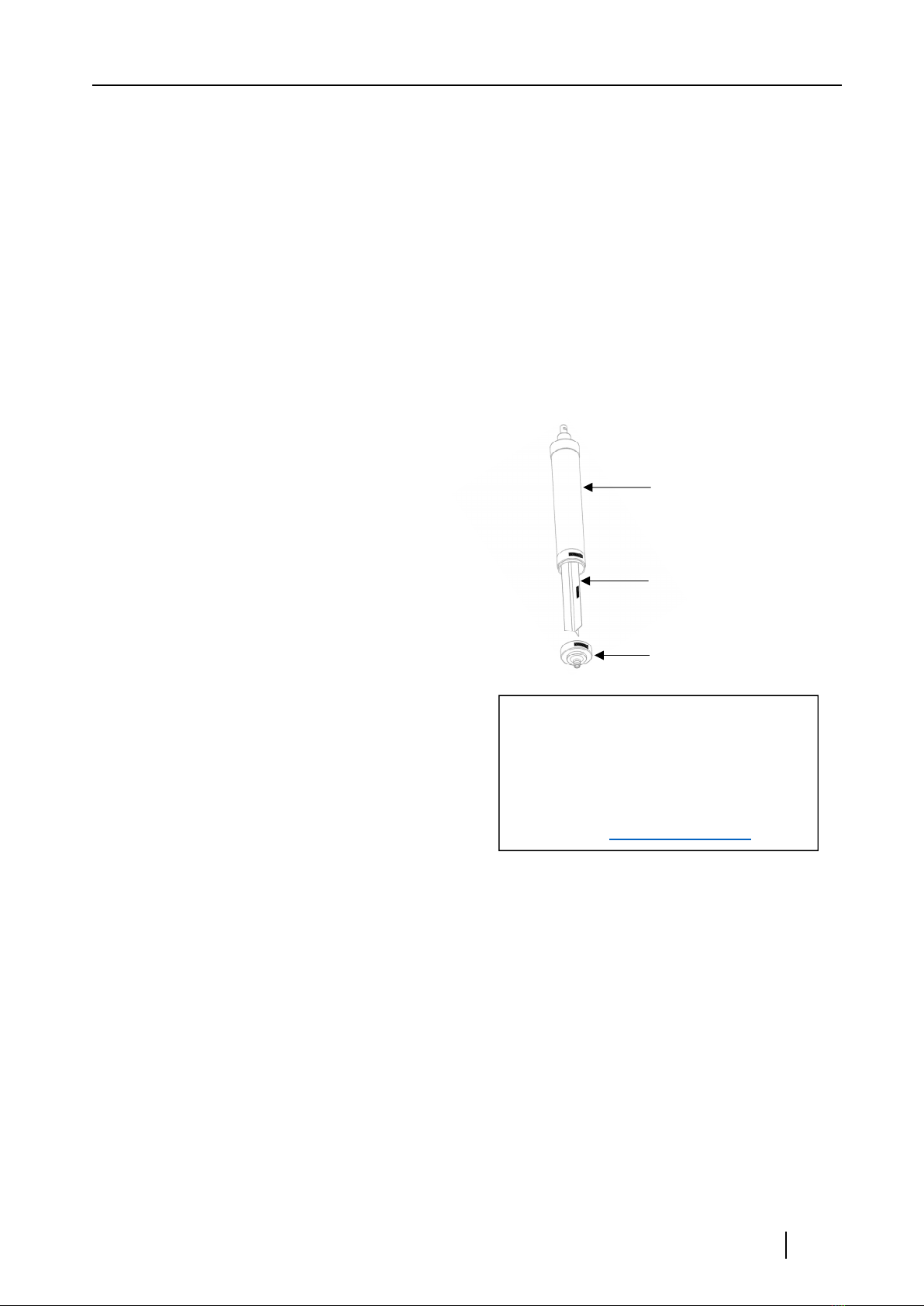

Bowl body

> > Precautions

Bowl configuration and configuration with the main body

-Serial No. is engraved on each of the 3 parts of

the bowl as shown in the picture on the right.

-Bowls must be configured in one set

with the same Serial No. for the best

operation, so never mix them.

-The sticker shown on the right is attached to

the outer surface of the main body, and the

Serial No. Use bowl sets from xxxxxx.

Triangular rotor blades

bowl cap

/ WARNING /

For optimal use, this product

Serial No. xxxxxx Bowl Setwith

use it.

inquiry :[email protected]

1.3.2 Electrical installation work

This equipment requires a 3-phase 4-wire 380V power supply, so electrical work is required

before installation.

-The control unit should be located where it is easy to operate.

-For electrical wiring and outlet specifications, be sure to inquire with the manufacturer

before installing the power supply.

1.3.3 Flexible tube

-Use flexible tube for piping for feed sample.

-If the supply pipe and sample collection container are located in the front, it may cause

inconvenience to work and movement, so be sure to place them on the left or right side.

-Select and use a pump suitable for the supply pressure. (Refer to p18~19)

USER MANUAL │ J1250

2. Product overview and composition

This equipment is for separating the supernatant, which is the liquid part of the sample, and

the sludge, which is the solid part, so that it is suitable for the process needs such as sample

precipitation, filtration and washing. designed.

Due to the long tube-shaped rotor, the distance through which the mixed solution injected

from the lower part of the rotor passes until it is centrifuged and discharged is long and receives

the effect of strong centrifugal force for a relatively long time, so the centrifugation of the mixed

solution is very good This can reduce process time and increase productivity compared to

general centrifugation methods.

-Tubular type industrial centrifuge for continuous sample separation

-Two phase separation of liquid and solid

-High recovery of sludge (cake type)

-Water jacketed cooling system (optional)

-Premium quality stainless steel bowl

-Intuitive 7” touch-screen control

-Accurate control of speed through inverter

-Speed control from 1,000 to 15,000 RPM

-Distinctive emergency stop switch

-During operation, the door open sensor is detected and the motor is automatically stopped

with an error phrase.

-The three-color blinking light can recognize normal operation status or emergency abnormal

situation; green for normal, yellow for standby status, and red for errors and emergency.

USER MANUAL │ J1250

2.1 Technical Specifications - Main Unit

Functions

main unit

Motor

Specification

Power 380V 3.7kW (3-phase)

Tubular Bowl

Net Capacity (L) / Weight (kg)

Dimension (inner/outer)

Material

Sample Collection Sheet

Sample Feeding pump

Frame and Door, Material

Frame Base

Trolley for Bowl and Tools

Dimensions (With Base)

Dimensions (W x D x H, mm)

with H-beam base

without pump or trolley

Net Weight

with bowl & H-beam base

without pump or trolley

9/27

157(Φ) x 142(Φ) x 960(L) mm

Stainless Steel 316L

Teflon with a dimension of 733x395x0.4 mm

Peristaltic Tubing Pump (WT600-2J)

Powder-painted Steel

(optional) Stainless steel 304

(optional) Water-jacketed

Powder-painted Steel H-beam with 4

wheels and 6 balancing foot

Stainless steel trolley with tools in a box

860(W) x 1085(D) x 1900(H) : Door closed

860(W) x 1430(D) x 1900(H) : Door open

564 kg

HANIL Scientific Inc. │ ihanil.com │Service: +82-2-3452-8966 / [email protected] 10

USER MANUAL │ J1250

2.2 Technical Specifications - Control Unit

Functions

control unit

Specification

display screen

speed control

Max. RCF

ACC/DEC ramps

program memory

Time control

data transport

History tracking

Inverter control

Pump control

Safeties

Actual speed sensing

Door close/open sensing

Emergency Stop switch

foot switch

Level sensor 1, 2

Dimensions (W x D x H mm)

7” wide touch (Capacitive type)

1,000 to 15,000 RPM

15,801 xg (Radius: 62.814 mm)

3/4

99

< 100 hours

Yes (USB port)

Yes

3P4W 380V, 7.5KW

Selectable, auto or manual

Yes

Yes

Yes

Optional

Optional

405x 460 x 1310 (incl. warning light)

Weight

without cables 47 kg

HANIL Scientific Inc. │ ihanil.com │Service: +82-2-3452-8966 / [email protected] 11

USER MANUAL │ J1250

2.3 Product composition

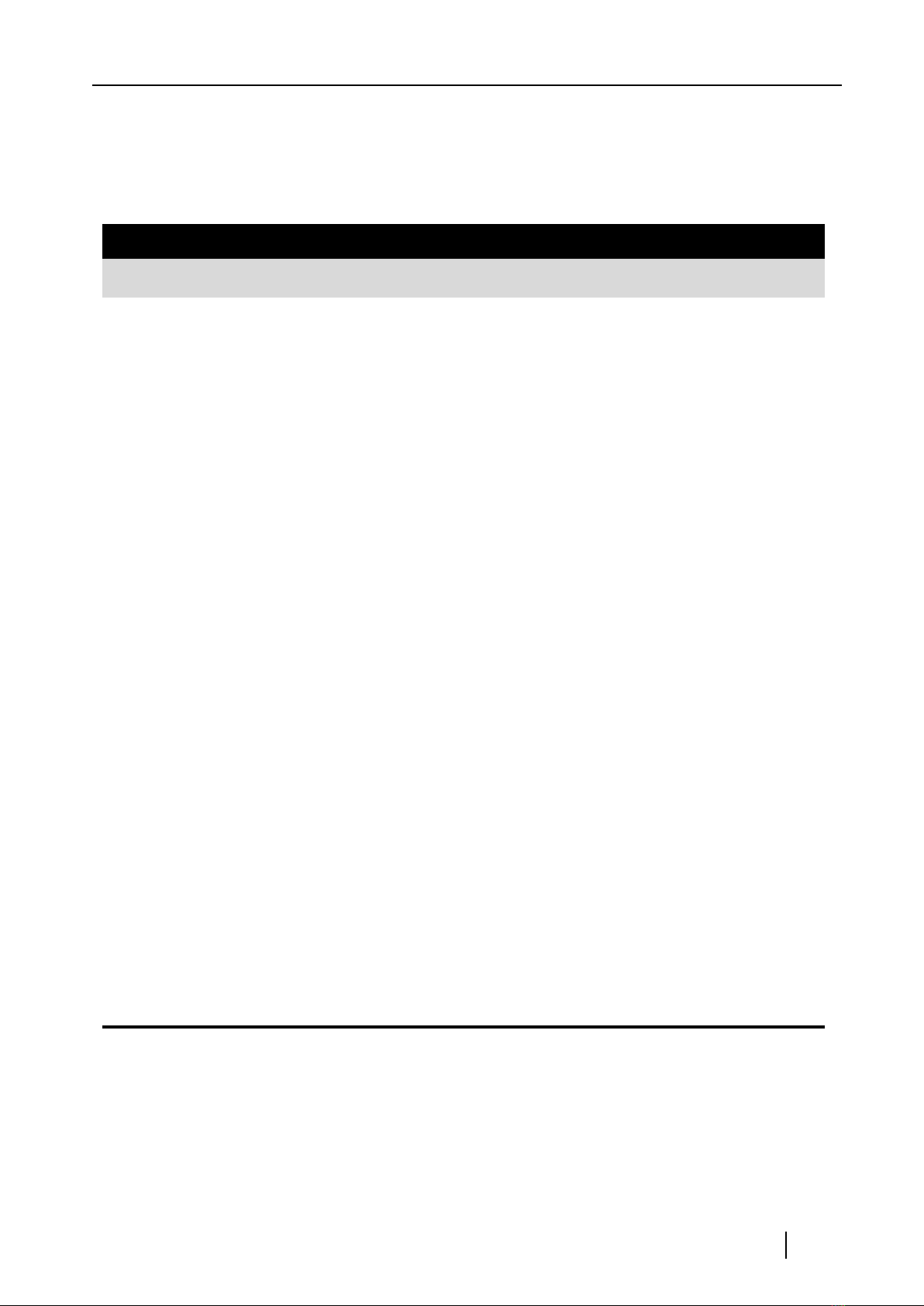

2.3.1 Main unit configuration

It is a tubular type continuous centrifuge and consists of a driving motor, a frame, a

door, an H-beam base, and a bowl, a high-speed rotating chain. is supplied with

Motor

control unit

main unit

Trolley Power

Cable

Bowl

Hose Tube

sample feeding pump,

Tube & rack

H-beam base

tool kit

(p15~17) filtrate tray

Operation

manual

2.3.2 Accessories

Drag bushings,

2ea

Inlet Nozzles(3,4,5Ø),

3ea

Bowl cap sealing

gasket, 2ea

rubber coupling,

2ea

Bowl cap nut

2ea

Teflon Sheet, 3 sheets

735x395x0.35 (W x L x T, mm)

Outlet Hose(1m)

HANIL Scientific Inc. │ ihanil.com │Service: +82-2-3452-8966 / techsupport@ihanil. com 12

USER MANUAL │ J1250

2.4 Configuration for each part

2.4.1 Main unit configuration and dimensions

[Main part name]

2

96-1

3

4

814

7

6

1

15

14

5

13 12

10 16

11

1. Frame 2. Motor 3. Drive motor cover

4. Pulley Flange 5 . Drag Body Assembly 6. Door

6-1. water jacket door

(optional) 7. Supernatant Outlet 8. Supernatant Outlet Lid

9. Balancing window 10. Base, steel 11. Balancing foot with nut 6 set

12. Sample in gate 13. Wheel 14. Bowl

15. Trolley 16. Tool kit

HANIL Scientific Inc. │ ihanil.com │Service: +82-2-3452-8966 / [email protected] 13

USER MANUAL │ J1250

[Main unit dimensions, mm]

Front

Right Left

HANIL Scientific Inc. │ ihanil.com │Service: +82-2-3452-8966 / [email protected] 14

USER MANUAL │ J1250

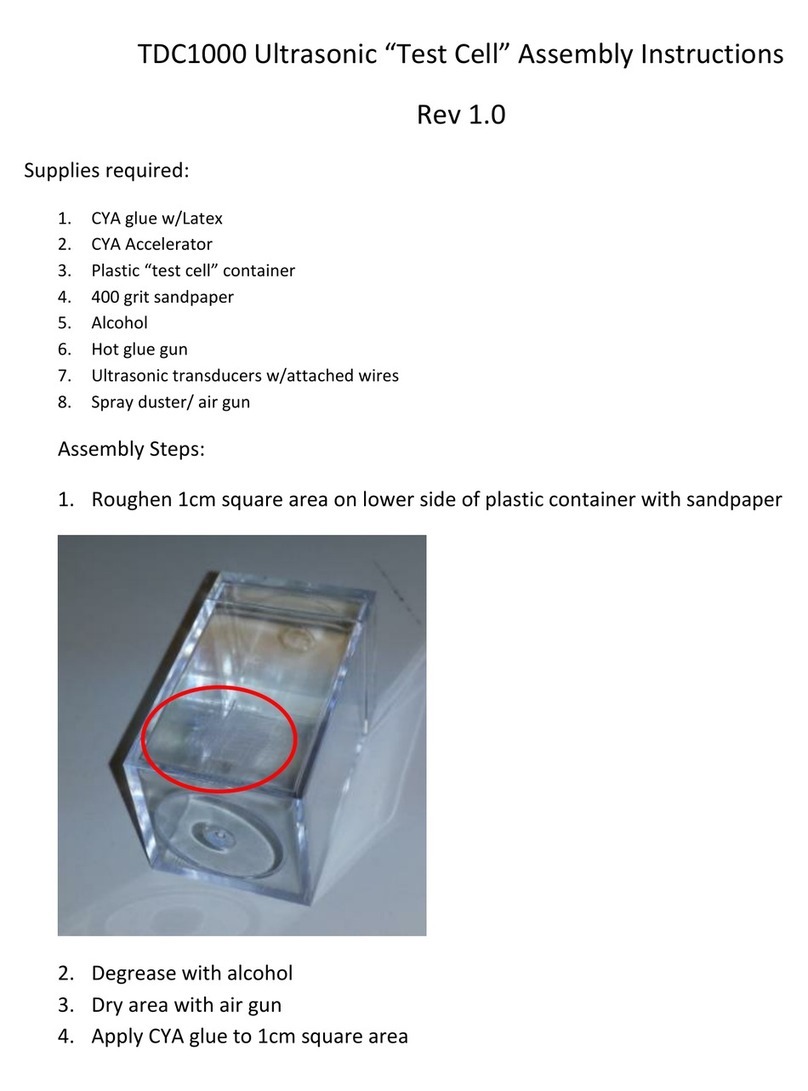

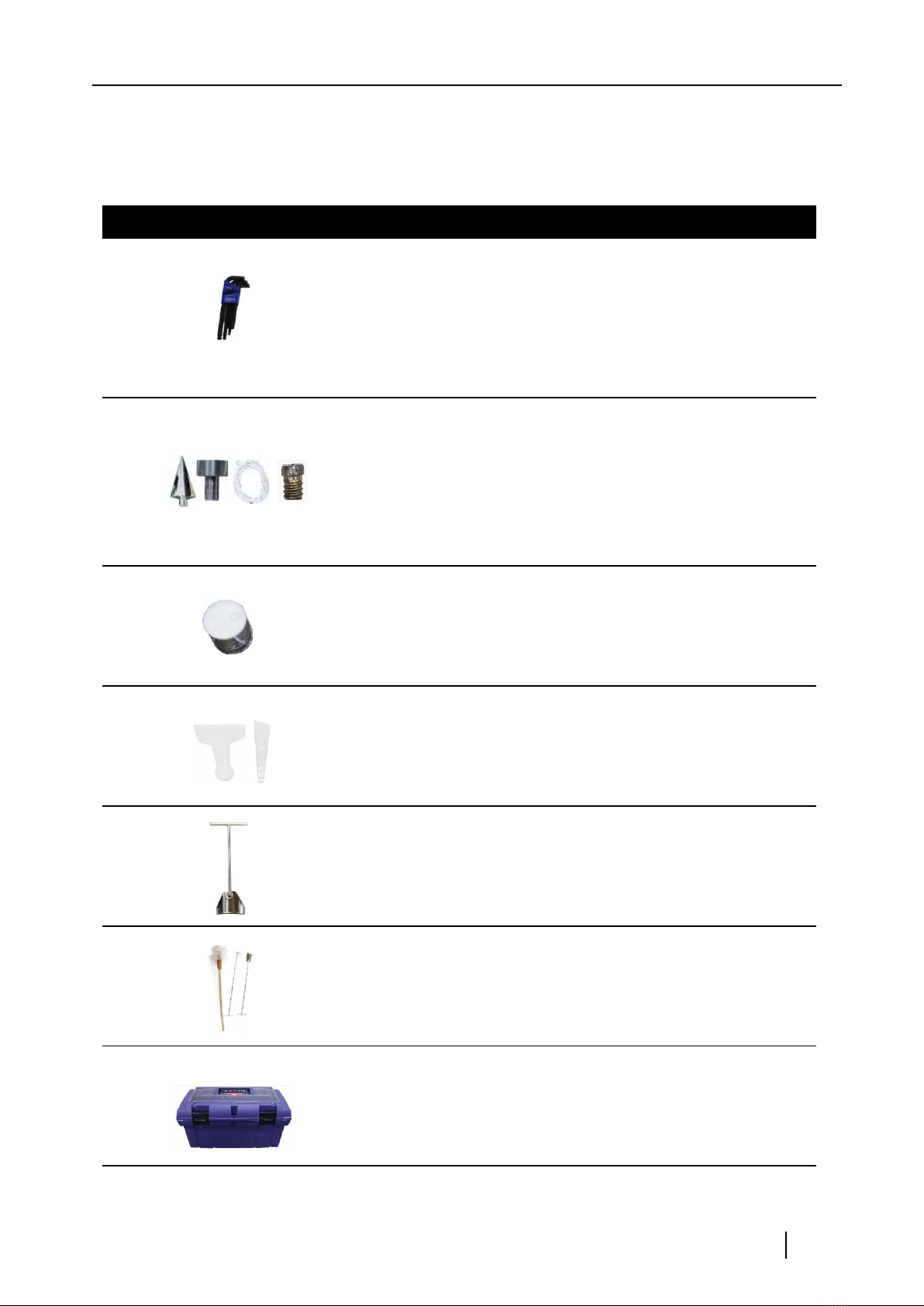

2.4.2 Tool kit and use

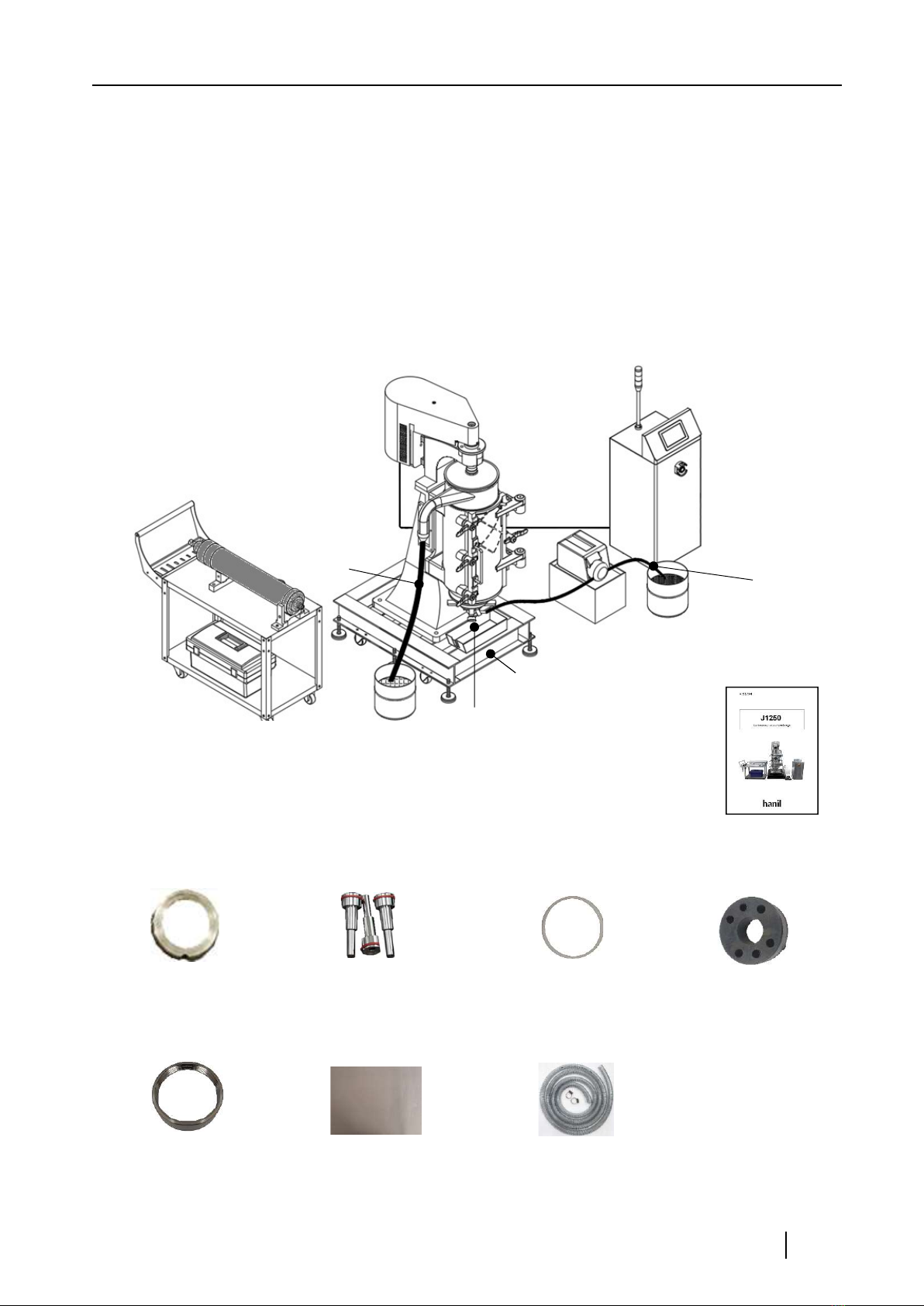

[Bowl assembly & Disassembly tools]

No. Photo Name Purpose

1Bowl wrench bowl cap open and close

22 Coupling

wrenches

Bowl spindle assembly and

disassembly

61mm: for disassembling and

assembling the pulley sleeve

54mm: for disassembling and

assembling the bearing pulley

32 Pulley wrenches

Bowl boss

sleeve

wrench

4Bow cap nut disassembly and assembly

5hook spanner For triangular wing separation

USER MANUAL │ J1250

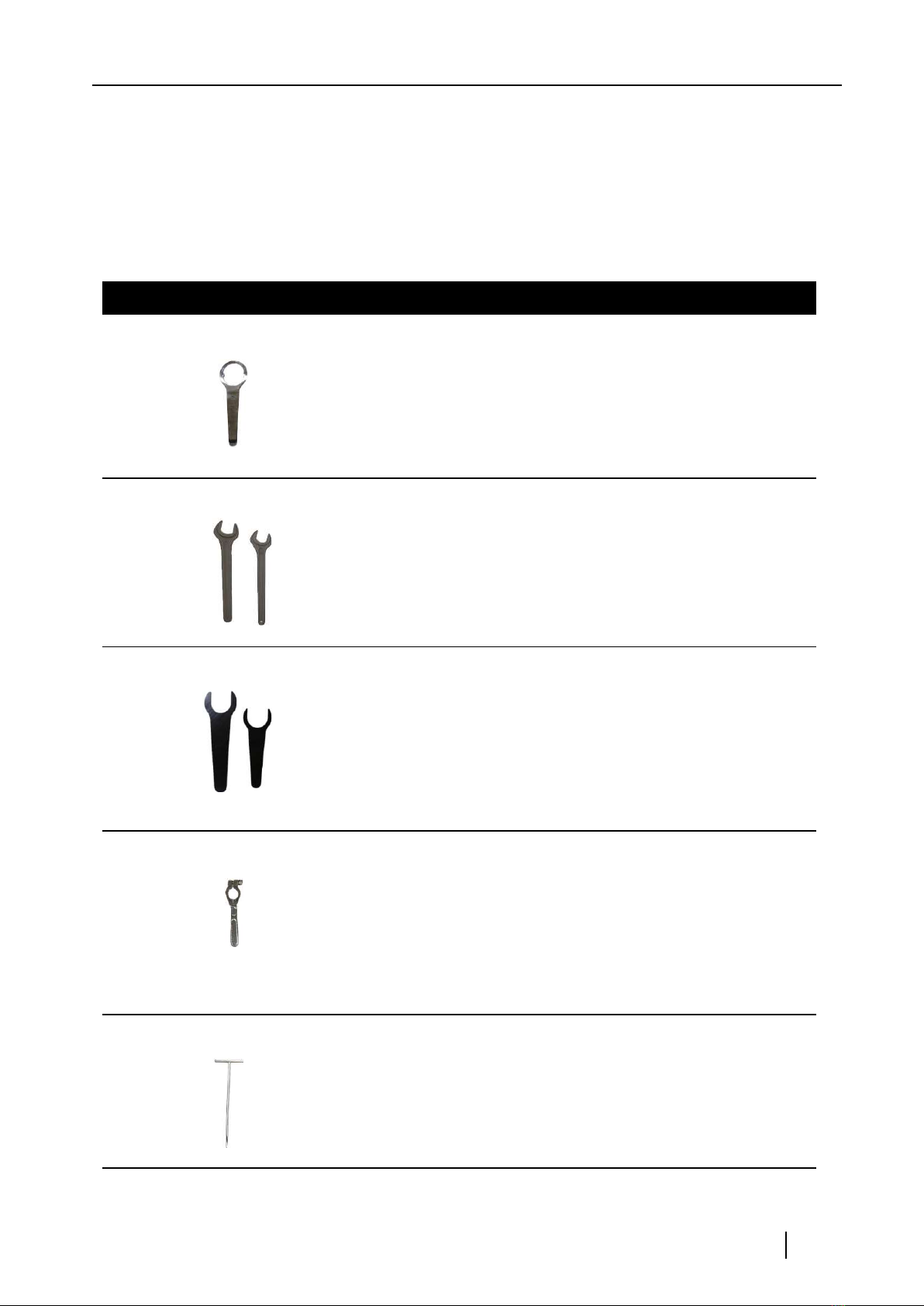

[Drag Assembly & Disassembly Tools]

1Drag wrench Drag shell disassembly and assembly

For disassembling and

assembling the parallel cap

For disassembly and assembly of

sample receiving hose nipple

2Pliers

3Drag bushing tool Drag bushing disassembly and assembly

[General Tools] - 1

Drain pipe, grease, elbow, motor fixing

bolt, cover fixing bolts, other assembly

and disassembly

1Monkey wrench

For bowl, drag assembly, and drag hand

nut separation and fastening

Opening and closing the door

2Urethane hammer

No. Photo Name Purpose

No. Photo Name Purpose

USER MANUAL │ J1250

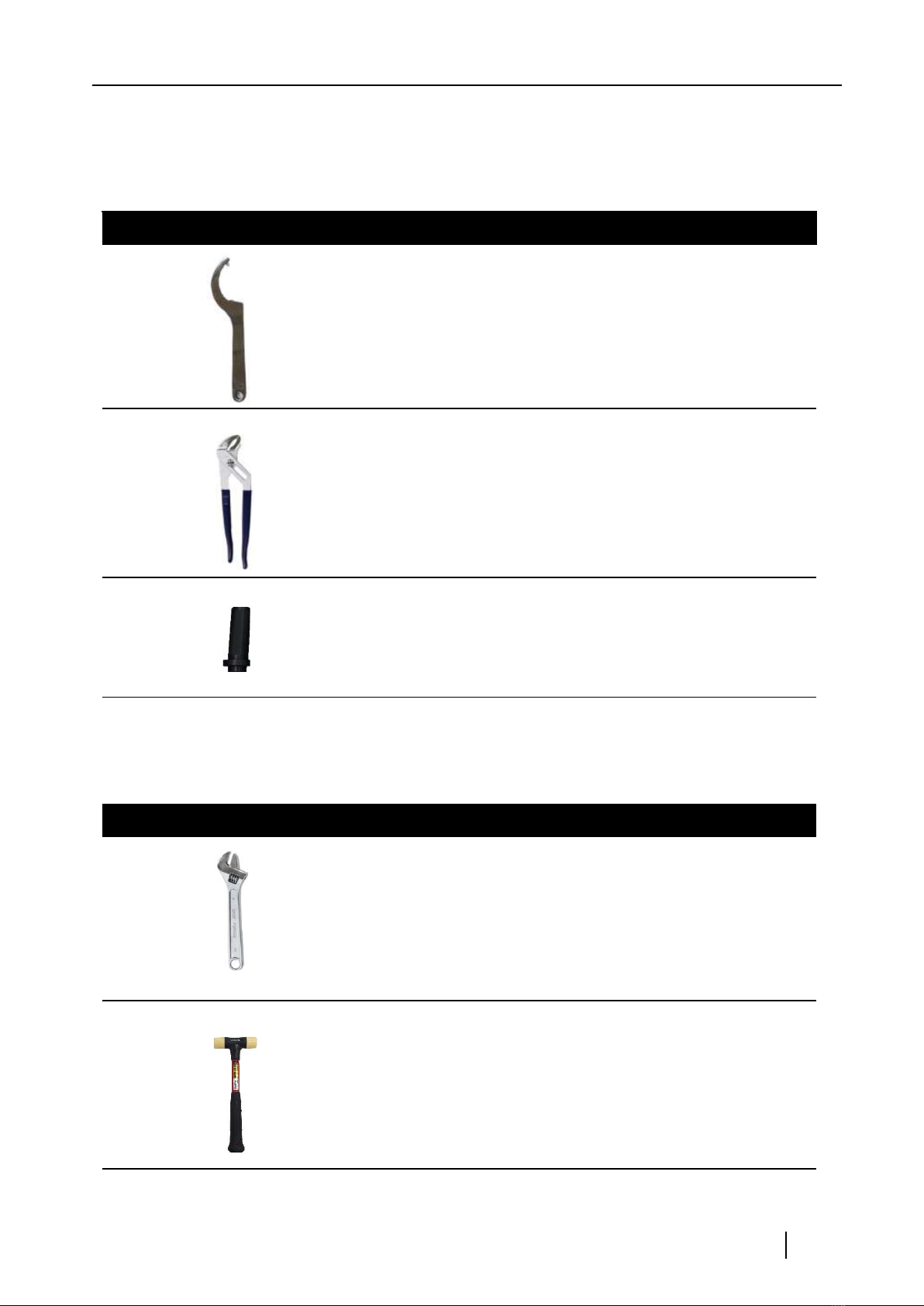

[General Tools] - 2

1.5~10,0mm 9 types

Used to open and close the bowl cap

3L-wrench

4Balancing tool set Tools for body balancing

Lubrication between bowl cap nut and

drag bushing

5Grease

For grease replenishment, Teflon

sheet, and sludge separation

62 Specials

For separating bowl and Teflon

sheet For sludge separation

7Bowl cleaner

Bowl cleaning tools

3 types

8Bowl cleaning tool

9Tool box Tool storage

HANIL Scientific Inc. │ ihanil.com │Service: +82-2-3452-8966 / [email protected] 17

No. Photo Name Purpose

USER MANUAL │ J1250

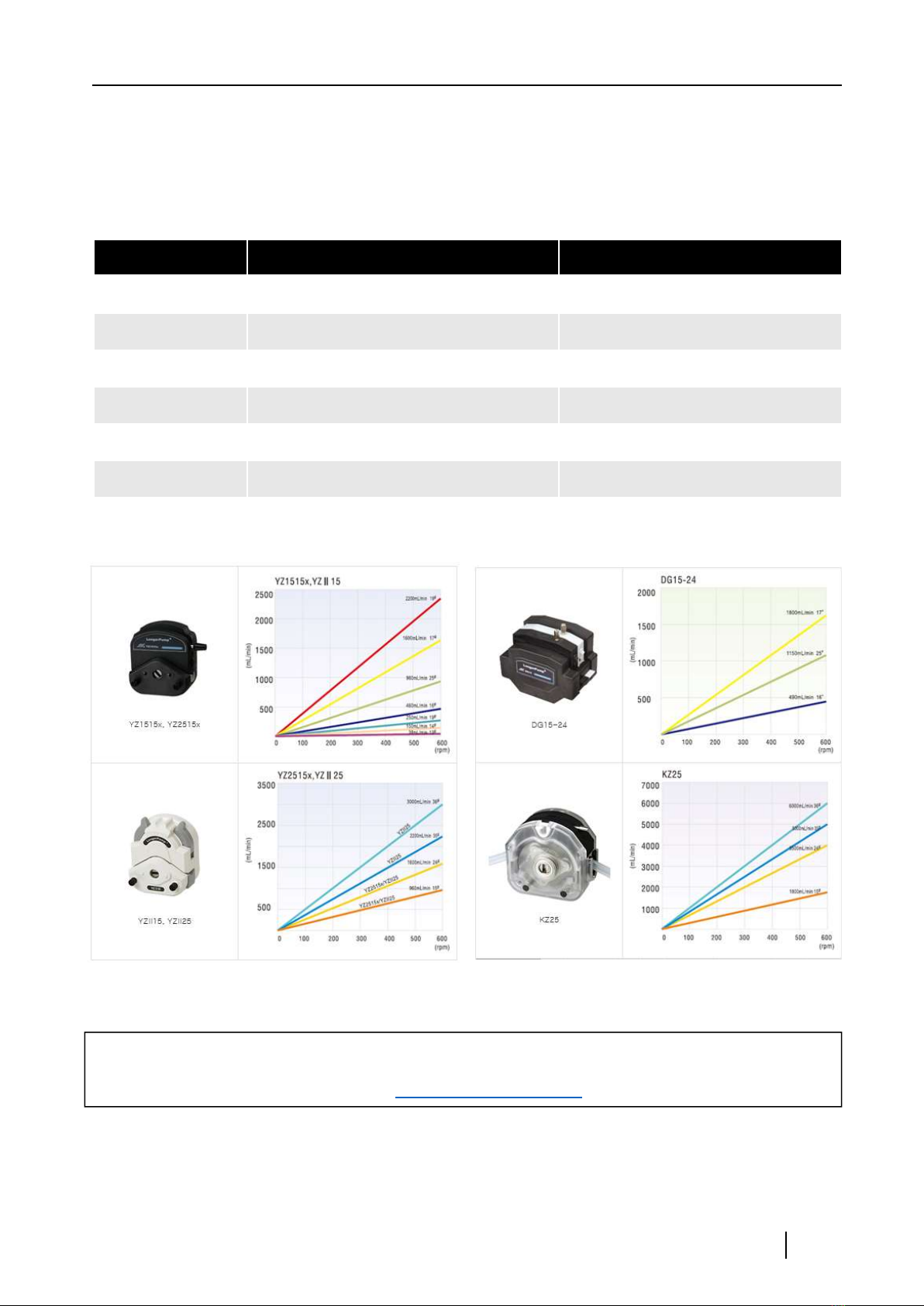

2.4.3 Sample feeding pump

: WT600-2J Basic peristaltic tubing pump

Speed

speed resolution

speed accuracy

output torque

60~600 rpm, CW/CCW

1 rpm

<±1%

≥1.50N·M

Control panel, external signal control and

communication control available

control mode

Display 3-digit LED displays current speed

Start/stop, cw/ccw control

speed control; 4 to 20 mA, 0.5 to 5 V, 1 to 10 V, 1 to 10 KHz

external control

power supply

Power consumption

Operating condition

AC 176-264V 50/60Hz

≤200W

Temperature; 0~40℃

relative humidity; <80%

285 L x 207 W x 180 H /mm

5.2 kg

IP31

Dimensions

Weight

IP rating

USER MANUAL │ J1250

[Pump head and Tube selection guide]

pump head Tubing Flow rates (mL/min)

YZ1515 # 13, 14, 19, 16 25, 17, 18 4 to 2,200

YZ2515 #15, 24 100 to 1,600

YZII15 # 13, 14, 19, 16, 25, 17, 18 4 to 2,200

YZII25 #15, 24, 35, 36 100 to 3,000

DG15-24 #16, 25, 17 500 to 1,800

KZ25 #15, 24, 35, 36 200 to 6,000

When ordering a pump, please order the pump head & tubing according to the conditions.

inquiry :[email protected]

USER MANUAL │ J1250

2.4.4 Control unit composition and Dimensions

Emergency Stop switch power switch

Operation status indicator

7” Display LCD Screen - Stop

- Running : Green

- Alarm : Red

: Yellow

USB Port Imbal Door Foot RS232

Temp L1 L2

Ext. conn

Pump Conn.

Spare Conn

Motor Cable Conn.

Power Cable Conn.

back side

front side right side

Other manuals for J1250

1

Table of contents

Other Hanil Laboratory Equipment manuals

Hanil

Hanil Ultra 5.0 User manual

Hanil

Hanil FLETA 40P User manual

Hanil

Hanil Micro 12 User manual

Hanil

Hanil Smart R17 User manual

Hanil

Hanil T04B User manual

Hanil

Hanil J1250 User manual

Hanil

Hanil M 13 User manual

Hanil

Hanil Component R6 User manual

Hanil

Hanil Fleta 5 User manual

Hanil

Hanil Fleta5 User manual

Popular Laboratory Equipment manuals by other brands

Streck

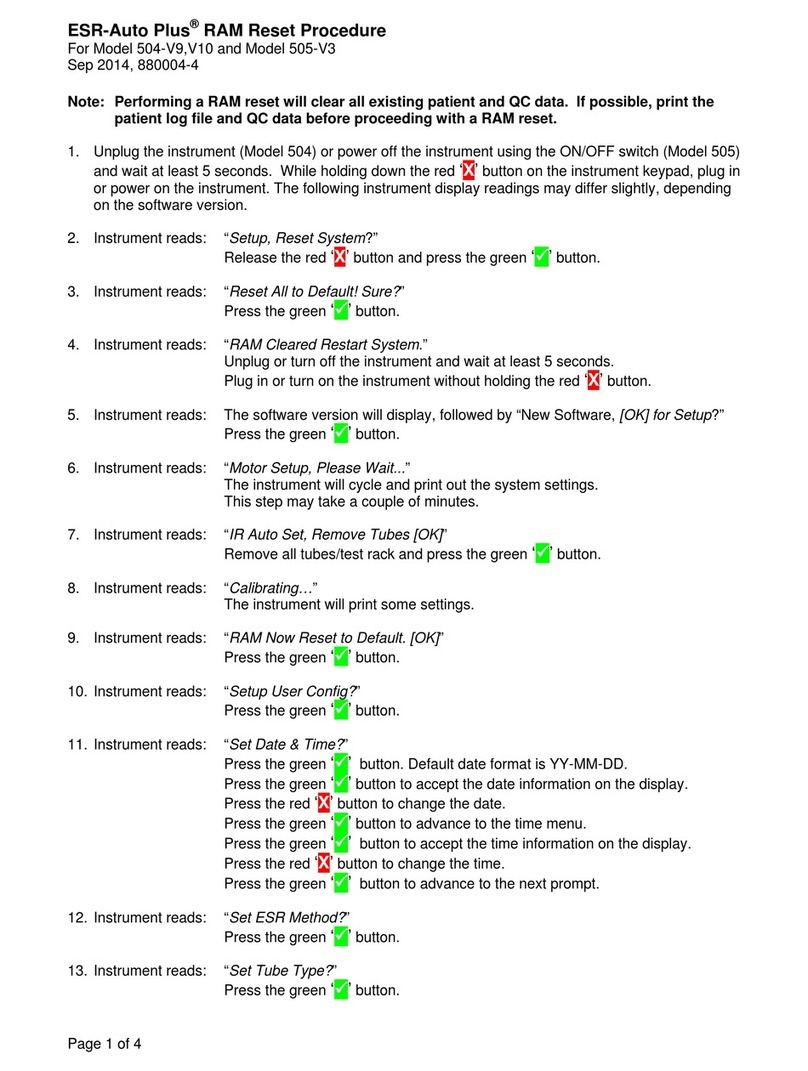

Streck ESR-Auto Plus 504-V9 manual

Ameson

Ameson MINI AIR PRO user manual

TOSOH BIOSCIENCE

TOSOH BIOSCIENCE TSKgel HPLC Column instruction manual

10x Genomics

10x Genomics Chromium Controller Readiness Test manual

PHI

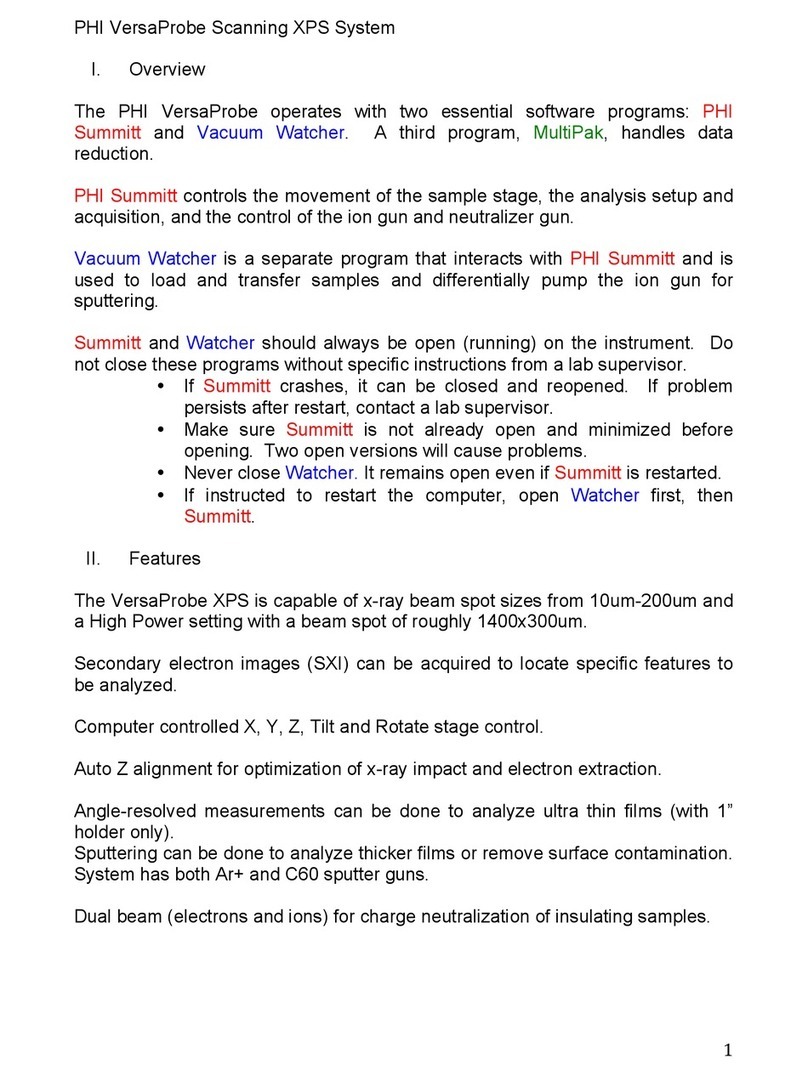

PHI VersaProbe Operations

BioSpec Products

BioSpec Products Mini-BeadBeater 96 user manual