1. Product Identification........................................................................................................................ 4

2. Safety Warnings ............................................................................................................................... 4

3. Introduction....................................................................................................................................... 5

3.1. Technical Description .............................................................................................................. 5

4. Technical Data ................................................................................................................................. 6

4.1. Options .................................................................................................................................... 6

5. Standard Full Scale and Resolution................................................................................................. 7

6. Recommended Mechanical Mounting.............................................................................................. 7

6.1. Positioning ............................................................................................................................... 7

6.2. Installation................................................................................................................................ 7

7. Connections ..................................................................................................................................... 8

7.1. RS-232C Serial Output connection ......................................................................................... 8

7.2. Analogue Output connection ................................................................................................... 8

7.3. Relay Output connection ......................................................................................................... 9

7.4. Digital Input connection ........................................................................................................... 9

8. Power Supply ................................................................................................................................. 10

8.1. Power On............................................................................................................................... 10

8.2. Power Off............................................................................................................................... 10

9. Error Messages .............................................................................................................................. 11

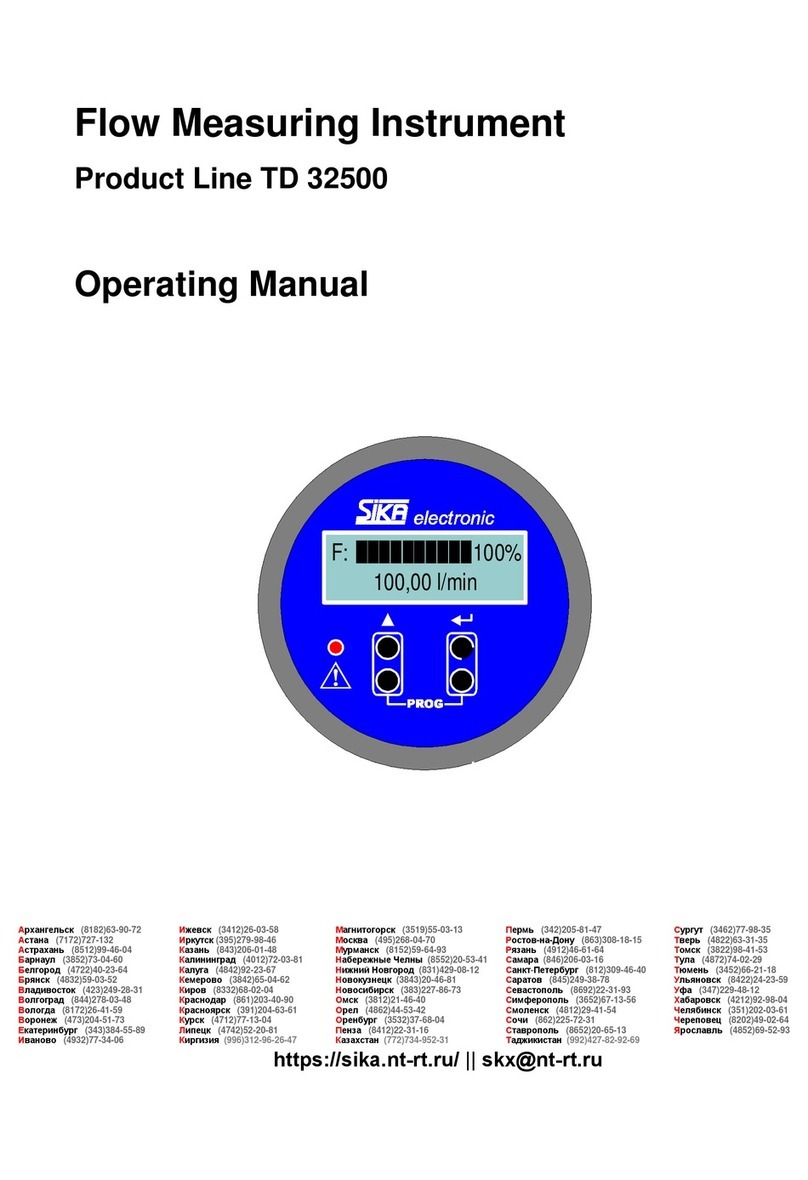

10. Keys Description........................................................................................................................ 11

11. Parameter Programming ........................................................................................................... 12

12.Software Version ....................................................................................................................... 12

13. Parameter Settings .................................................................................................................... 13

13.1. How to get access to the MENU............................................................................................ 13

13.2. How to set parameter values................................................................................................. 13

14. Parameter Description ............................................................................................................... 13

14.1. Set point 1.............................................................................................................................. 13

14.2. Hysteresis 1 ........................................................................................................................... 13

14.3. Set Point 2 ............................................................................................................................. 13

14.4. Hysteresis 2 ........................................................................................................................... 14

14.5. Password ............................................................................................................................... 14

15. Parameters Protected by Password 0007................................................................................. 15

15.1. Measurement Resolution....................................................................................................... 15

15.2. Digital Filters .......................................................................................................................... 15

15.3. Serial Communication ........................................................................................................... 15

15.4. Peak....................................................................................................................................... 15

15.5. Analogue Output.................................................................................................................... 16

15.6. Analogue Output Zero Correction.......................................................................................... 16

15.7. Analogue Output Full Scale................................................................................................... 16

15.8. Analogue Output Signal Amplitude ....................................................................................... 16

16. Parameters Protected by Password 4256................................................................................. 17

16.1. Calibartion Cancellation......................................................................................................... 17