QUATTROCODE Operating manual - English

Copyright Silca 1999 3

INDEX

CONSULTING THE MANUAL ........................................................................................ 5

GENERAL ....................................................................................................................... 6

PROTECTION AND SAFETY PRECAUTIONS FOR THE OPERATOR ...................... 7

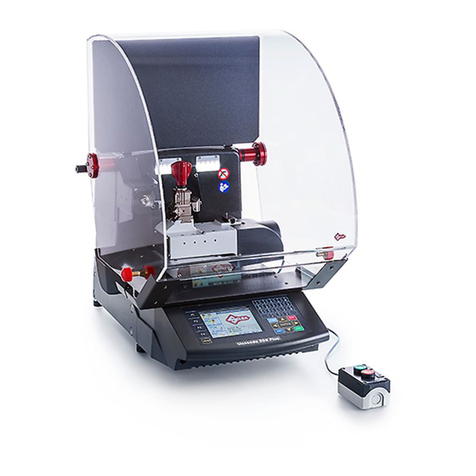

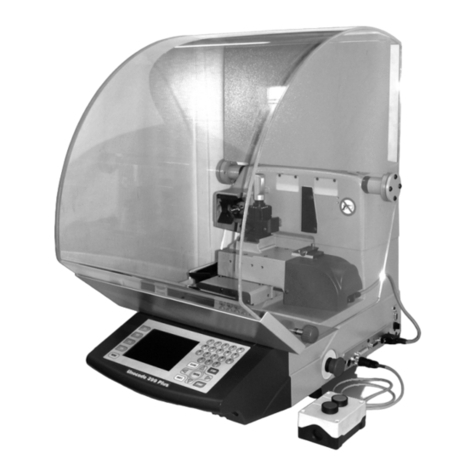

1 GENERAL DESCRIPTION .........................................................................................8

1.1 Main operating features ...................................................................................8

1.2 Safety devices .................................................................................................9

1.3 Technical data ...............................................................................................11

2 TRANSPORT ............................................................................................................12

2.1 Packing ..........................................................................................................12

2.2 Unpacking ......................................................................................................13

2.3 Handling the machine ....................................................................................13

3 INSTALLATION AND SETTING UP ........................................................................14

3.1 Checking for damage .....................................................................................14

3.2 Positioning .....................................................................................................14

3.3 Graphics ........................................................................................................15

3.4 Installation of the Silca Quattrocode Program software .................................15

3.5 Starting the Silca Quattrocode Program ........................................................15

4 MACHINE REGULATION .........................................................................................16

4.1 Machine keypad and functions of keys ..........................................................16

4.2 Decoder pocket ..............................................................................................17

4.3 Cutting tool replacement ................................................................................18

4.4 Use of the clamp ............................................................................................19

4.5 Fitting the clamp to the machine ....................................................................20

4.6 Turning the mobile jaw (P1) on clamp ‘J1’ .....................................................20

4.7 Key stop .........................................................................................................21

4.8 Anti-tilting device ............................................................................................22

4.9 Clamp detection .............................................................................................23

4.10 Clamp calibration ...........................................................................................23

5 DECODING KEYS ....................................................................................................25

5.1 Decoding ........................................................................................................25

6 KEY CUTTING ..........................................................................................................26

6.1 Data storage in the machine memory ............................................................26

6.2 Code selection ...............................................................................................26

7 TEST FUNCTIONS ...................................................................................................27

7.1 Sensor test .....................................................................................................27

7.2 Photocell test .................................................................................................30

7.3 Motor tests .....................................................................................................31

7.4 Display and keypad test .................................................................................33