INDEX

GUIDE TO THE MANUAL .........................................................................................................1

GENERAL .................................................................................................................................2

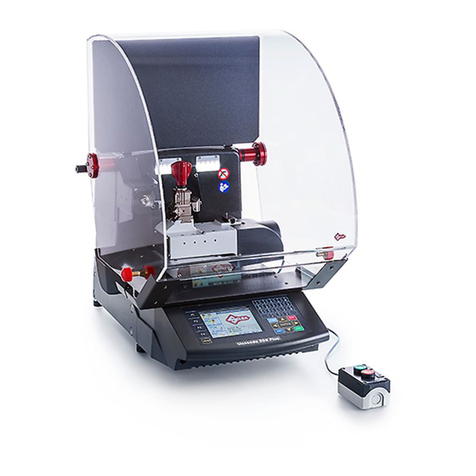

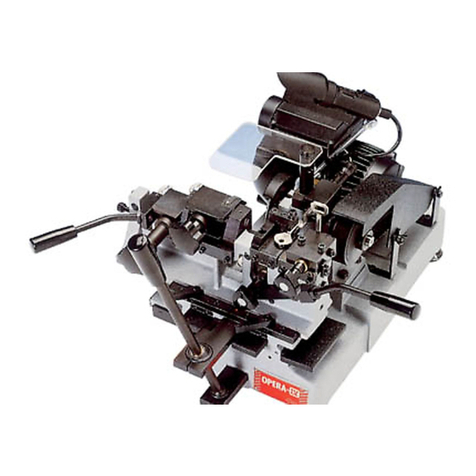

1 MACHINE DESCRIPTION ..........................................................................................4

1.1 Main Characteristics ...........................................................................................4

1.2 Working parts .....................................................................................................5

1.3 Technical Data ...................................................................................................6

1.4 Accessories provided .........................................................................................6

1.5 Safety .................................................................................................................7

1.6 Electric circuit .....................................................................................................7

2 TRANSPORT ..............................................................................................................8

2.1 Packing ...............................................................................................................8

2.2 Unpacking ..........................................................................................................8

2.3 Machine handling ...............................................................................................8

3 MACHINE INSTALLATION AND PREPARATION ....................................................9

3.1 Checking for damage .........................................................................................9

3.2 Positioning ..........................................................................................................9

3.3 Description of work station .................................................................................9

3.4 Environmental conditions ...................................................................................9

3.5 Graphics .............................................................................................................9

4 REGULATION AND USE OF THE MACHINE .........................................................10

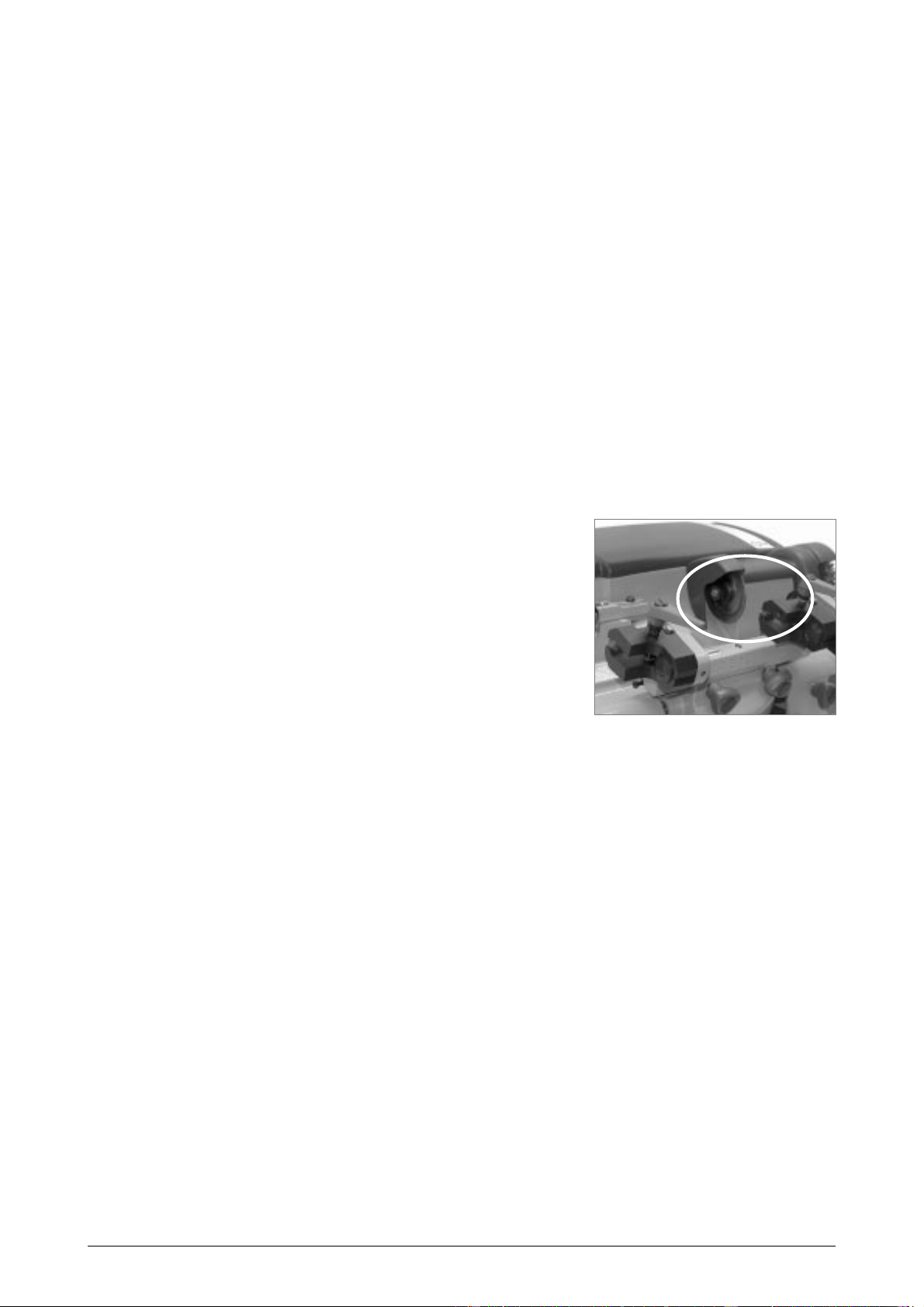

4.1 Micrometric tracer point ....................................................................................10

4.2 Tracer point spring ...........................................................................................10

4.3 Right-hand clamp movement ...........................................................................10

4.4 Checking and gauging ......................................................................................11

4.4.1 A

XIAL GAUGING ON BIT

/

DOUBLE BIT KEYS

...............................................................11

4.4.2 D

EPTH GAUGING

...................................................................................................12

4.5 Cutting operations 1............................................................................................3

4.6 Cutting bit and double bit keys .........................................................................13

4.6.1 C

UTTING SHORT KEYS

...........................................................................................14

4.6.2 C

UTTING DOUBLE FEMALE BIT KEYS

.......................................................................14

4.7 Cutting keys with centre stop ...........................................................................15

4.8 Cutting pump keys ............................................................................................16

5 MAINTENANCE ........................................................................................................17

5.1 Cleaning ...........................................................................................................17

5.2 Carriage replacement .......................................................................................17

5.3 Replacing the tracer point ................................................................................17

5.4 Replacing the cutter .........................................................................................18

5.5 Replacing the brush .........................................................................................18

5.6 Belt replacement and/or tensioning - Belt tightening pulley replacement .........19

5.6.1 B

ELT TIGHTENING PULLEY REPLACEMENT

..............................................................20

5.7 Replacing the master switch ............................................................................20

5.8 Replacing the fuses ..........................................................................................21

5.9 Replacing the light bulb ....................................................................................21

5.10 Clamp spring replacement ...............................................................................21

5.11 Condenser (motor) and/or Feeder (lamp) replacement ....................................22

5.12 Speed commutator ...........................................................................................23

5.12.1 R

EPLACING THE COMMUTATOR

..............................................................................23

5.13 Motor replacement ...........................................................................................24

6 DECOMMISSIONING ...............................................................................................26

7 AFTER SALES SERVICE ........................................................................................27

7.1 How to request service .....................................................................................27