INDEX

USE OF THE MANUAL....................................................................................................................... 1

GENERAL WARNINGS....................................................................................................................... 3

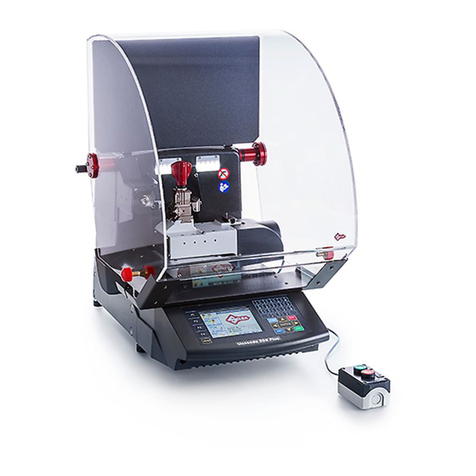

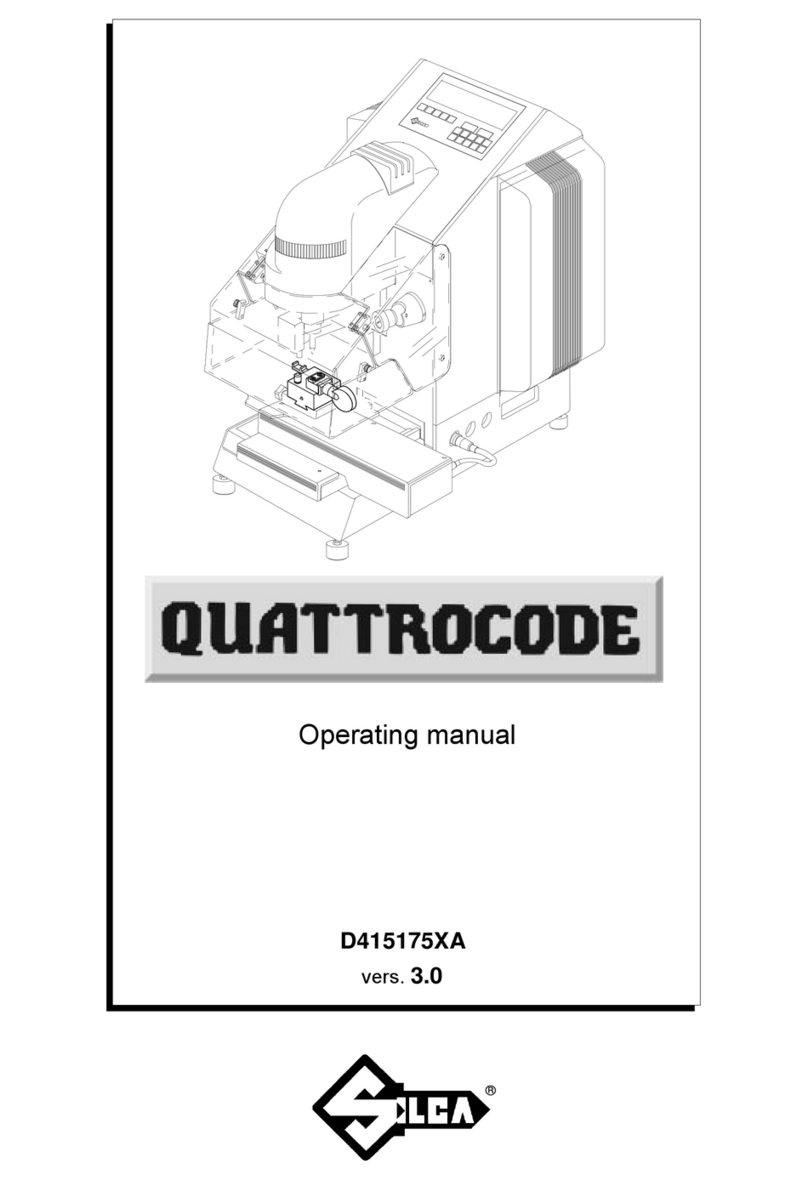

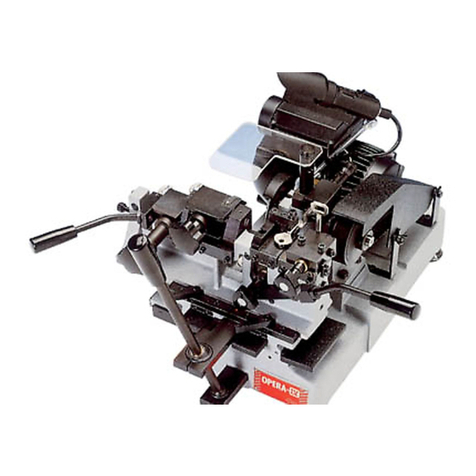

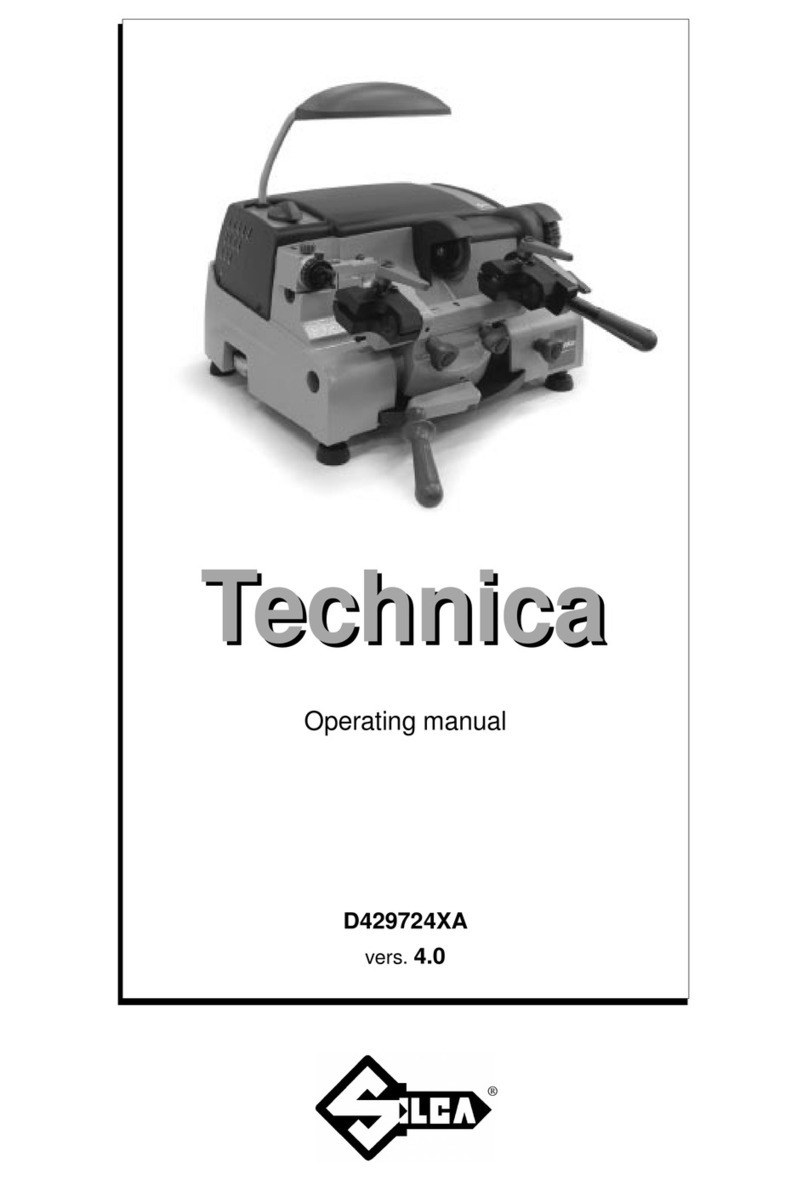

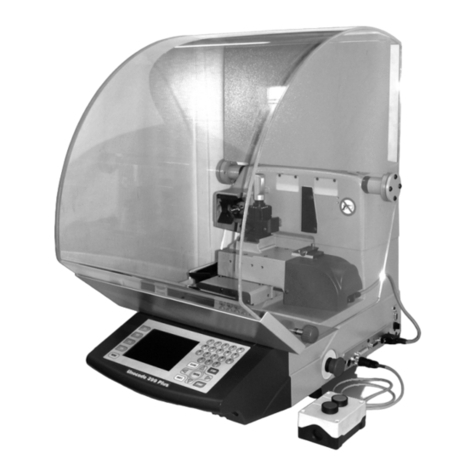

1 MACHINE DESCRIPTION ............................................................................................................................4

1.1 MAIN OPERATING PARTS............................................................................................................................ 5

1.2 SAFETY.......................................................................................................................................................... 6

1.3 TECHNICAL DATA ......................................................................................................................................... 7

1.4 ACCESSORIES PROVIDED.......................................................................................................................... 8

2 HANDLING....................................................................................................................................................9

2.1 PACKING........................................................................................................................................................ 9

2.2 UNPACKING .................................................................................................................................................. 9

2.3 HANDLING THE MACHINE ........................................................................................................................... 9

3 MACHINE INSTALLATION AND PREPARATION .......................................................................................10

3.1 CHECKING FOR DAMAGE ......................................................................................................................... 10

3.2 ENVIRONMENTAL CONDITIONS ............................................................................................................... 10

3.3 POSITIONING.............................................................................................................................................. 10

3.4 SEPARATE PARTS .......................................................................................................................................11

3.4.1 Power pack and lead .................................................................................................................................. 11

3.4.2 Fixing bracket ............................................................................................................................................. 11

3.4.3 Quick Guide................................................................................................................................................ 12

3.5 WORK STATION DESCRIPTION ................................................................................................................ 12

4 CLAMPS .....................................................................................................................................................13

4.1 CLAMPS ROTATION.................................................................................................................................... 14

4.2 USE OF THE GAUGES................................................................................................................................14

4.3 STOP POSITIONS (KEY STOP).................................................................................................................. 16

4.4 USE OF PINS .............................................................................................................................................. 17

4.5 CUTTING CRUCIFORM KEYS.................................................................................................................... 17

5 KEY COPYING / CUTTING.........................................................................................................................18

6 OPERATION OR ERROR INDICATION LIGHTS .......................................................................................20

7 CLEANING..................................................................................................................................................21

8 MAINTENANCE ..........................................................................................................................................22

8.1 OPERATIONS .............................................................................................................................................. 22

8.2 REMOVING / FITTING THE CLAMPS......................................................................................................... 22

8.3 REPLACING THE CUTTER ......................................................................................................................... 23

8.4 ACCESS TO REAR COMPARTMENT ......................................................................................................... 24

8.5 CHECKING AND REPLACING THE FUSE.................................................................................................. 24

8.6 REPLACING THE TOP COVER / KEYPAD ................................................................................................. 25

9 DISPOSAL ..................................................................................................................................................26

10 ASSISTANCE..............................................................................................................................................27

10.1 HOW TO REQUEST SERVICE................................................................................................................... 27

11 ELECTRICAL DIAGRAMS .........................................................................................................................29