Pressure relief

procedure

Always perform this procedure before

servicing:

1 Disconnect air supply to pump.

2 Point dispensing valve away from yourself

and others.

3 Open dispensing valve into container until

pressure is relieved.

If above procedure does not relieve pressure,

dispensing valve or hose may be restricted.

To relieve pressure, very slowly loosen hose

end coupling. Then, loosen completely and

clear dispensing valve and/or hose.

Operation

Inspect before use

Any pump that appears to be damaged in

any way, shall be removed from use until

repairs are made. Contact factory authorized

service center for repairs.

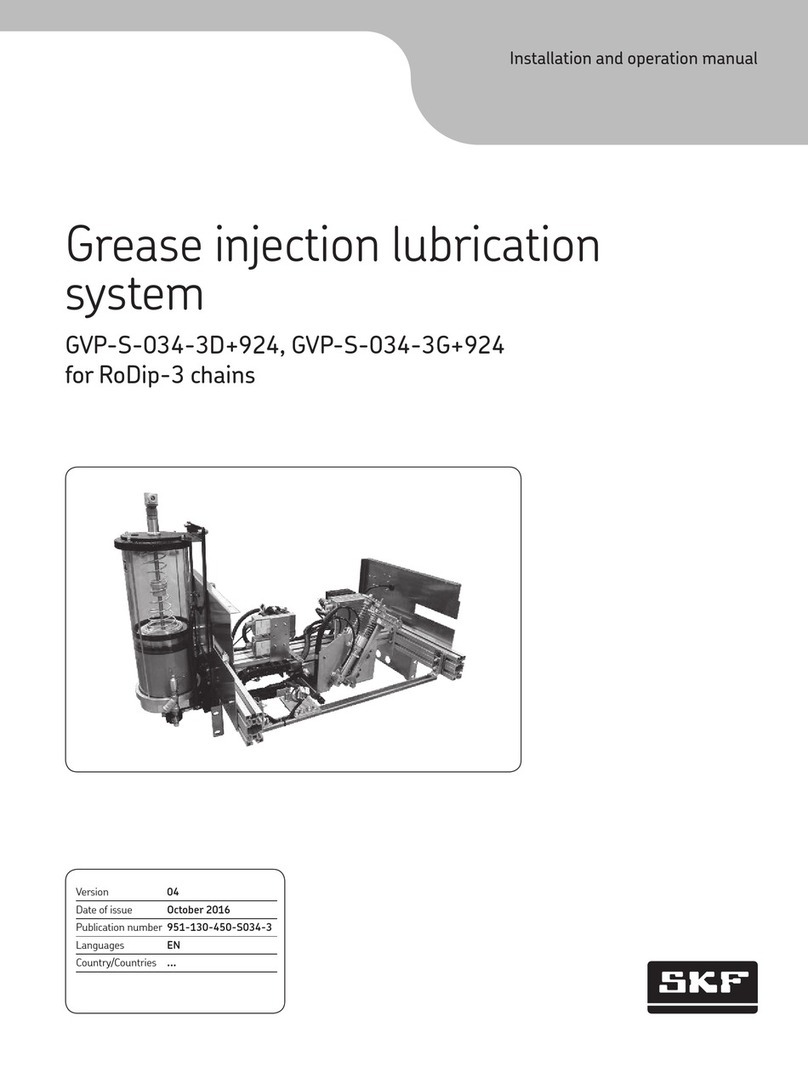

Pump use

To start pump, turn on main air supply.

Slowly open air regulator. Regulate air

pressure from 20–40 psi (1,3–2,7 bar) and

throttle to prime pump. Open dispensing

valve to allow air to be purged from system.

Allow pump to cycle until grease, without air

pockets, flows from dispensing valve, and

then close dispensing valve.

After pump is primed, adjust air pressure

to achieve smooth flow of grease from

dispensing valve. Do not allow pump to

operate when out of material. Pump will

accelerate quickly and run too fast, resulting

in costly damage to pump.

If pump accelerates quickly or is running

too fast, stop it immediately. Check grease

supply and refill it if necessary.

In circulating system, pump runs

continuously and slows down or speeds up

as supply demands, until the air supply is

shut off.

In direct supply system, with adequate air

pressure supplied to motor, pump starts

when gun or dispensing valve is opened and

stalls against pressure when it is closed.

Use air regulator to control pump speed

and grease pressure. Always use lowest

pressure required to achieve desired results.

WARNING

Do not operate pump or system with

pressure applied. Perform pressure relief

procedure prior to starting pump.

Failure to comply may result in serious

injury or damage to equipment.

WARNING

Failure to heed the following warnings

including misuse, over pressurizing, modify-

ing parts, using incompatible chemicals and

fluids, or using worn or damaged parts, may

result in serious personal injury and/or

equipment damage, fire, explosion, or prop-

erty damage.

• Do not exceed the stated maximum work-

ing pressure of the pump, or of the lowest

rated component in your system.

• Do not alter or modify any part of this

equipment.

• Do not operate this equipment with com-

bustible gas.

• Do not attempt to repair or disassemble

the equipment while the system is

pressurized.

• Make sure all grease connections are

securely tightened before using this

equipment.

• Always read and follow the grease manu-

facturers recommendations regarding

grease compatibility, and the use of pro-

tective clothing and equipment.

• Check all equipment regularly and repair

or replace worn or damaged parts

immediately.

• Never point the dispensing valve at any

part of the body or at another person.

• Never try to stop or deflect material from

dispensing valve, leading connection or

component with your hand or body.

• Always check equipment for proper opera-

tion before each use, making sure safety

devices are in place and operating

properly.

• Always follow the pressure relief procedure

after shutting off the pump, when checking

or servicing any part of the system, and

when installing, cleaning or changing any

part of the system.

5