Safety

Read and observe operating instructions

before installing and operating the flow

detector.

Do not attempt to install, use, or trouble-

shoot prior to fully understanding all safety

and operational instructions.

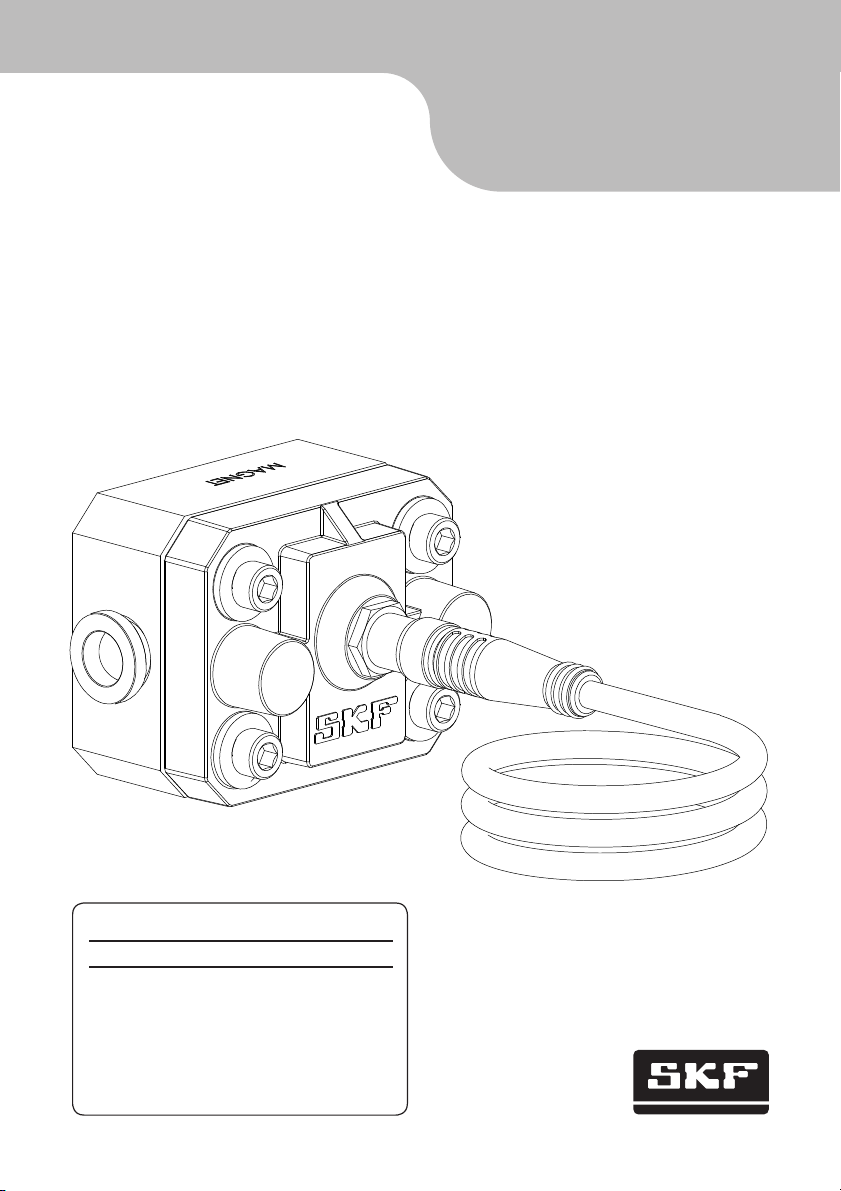

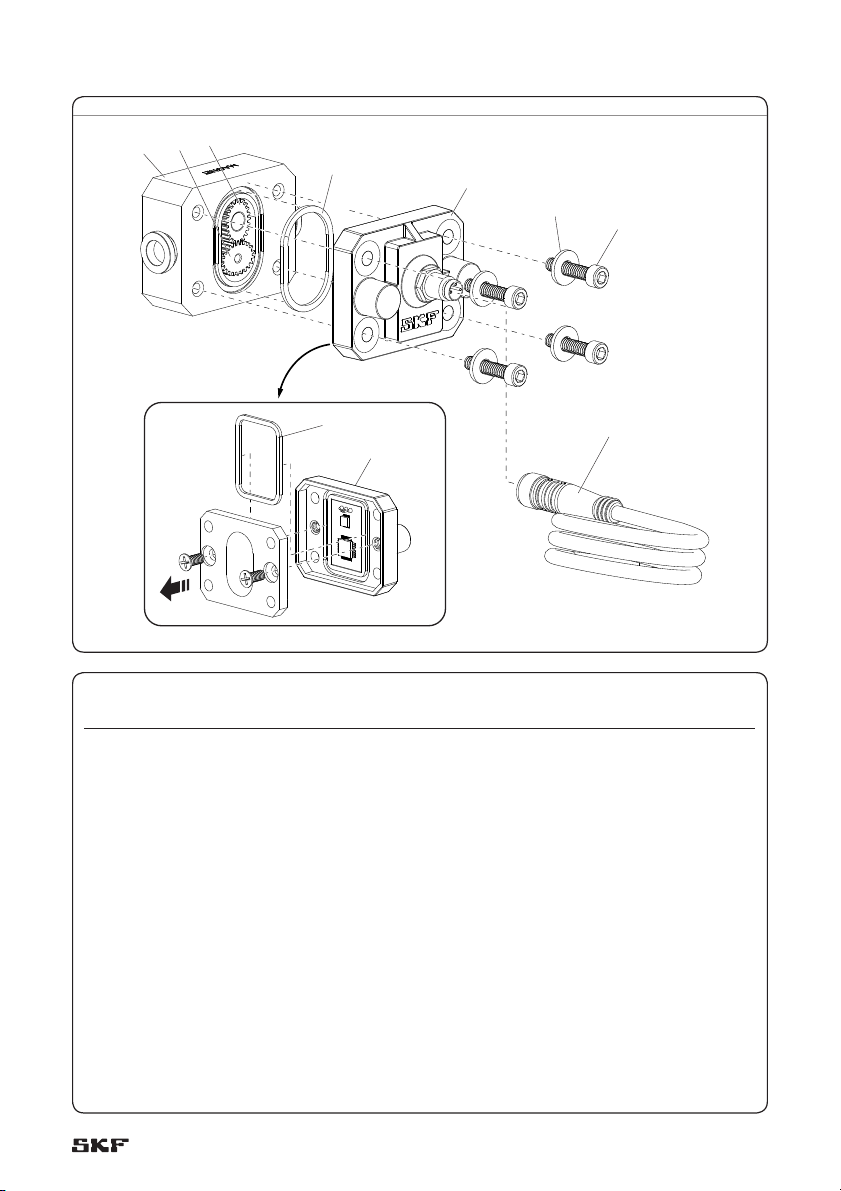

Application

Model 800030 was designed to generate a

confirmation signal to verify lubrications

events of a critical lubrication point. The unit

would be installed between the lubrication

point of the bearing and the lubricating device

like the injector. Signals are communicated to

SKF LMC 301 or PLC. Detecting both small

0.002 in.3 (32 mm3) and large

0.5 in.3 (8 195 mm3) f low of grease.

!Notice

Follow all local safety regulations

regarding installation, use and

maintenance.

Introduction

Model 800030 a positive displacement flow

detector consisting of oval gears. One gear has

a built-in diametric magnet. As the magnet

turns with the gear, a rotating motion of

magnetic flux results.

As the magnet rotates, a hall sensor detects

the magnet flux motion. This motion is

processed by an encoder creating and sending

a digital signal to an outside controller.

A blinking LED indicates processed signals.

Specifications

Media Grease grade 0 to 2

Grease ports 1/8 in. NPT F

Wetted parts Aluminum, steel, nitrile, rubber and nylon

Maximum pressure 3,000 psi (206 bar)

Maximum operation temperature 140 °F (60 °C)

Minimum operation temperature –30 °F (–34 °C)

Sensitivity1) 0 – 140 °F –17 – 60 °C ) 0.002 – 0.5 in3(32 – 8 195 mm3) per signal generated

–30 – 0 °F (–34 – 17 °C ) 0.005 – 0.5 in3(81,9 – 8 193 mm3) per signal

Maximum altitude 10,000 ft. *3 048 m)

Maxiumum humidity 100%

Dimensions 2 x 1.6 x 1.9 in. (51 x 42 x 48 mm)

Protection IP67

Weight 0.35 lbs. (0.159 kg)

Supply voltage 12 to 30 V DC

Polarity protection 12 to 30 V DC

Nominal supply current 5 mA

Maximum supply current 35 mA

Output signal 12 to 30 V DC

Maximum output signal 30 mA

1) Entrapped air may compromise minimum sensi t ivi t y level.

3