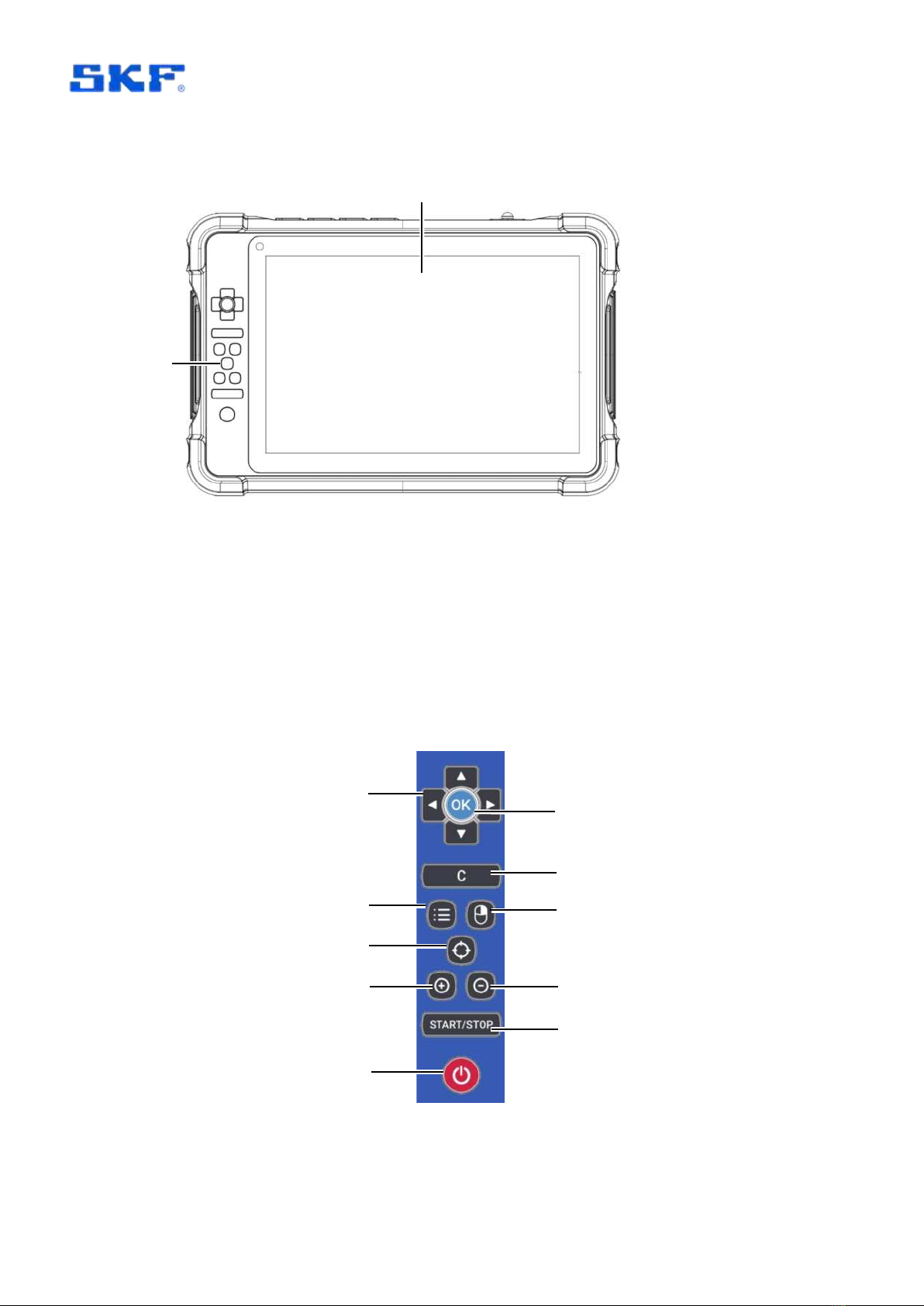

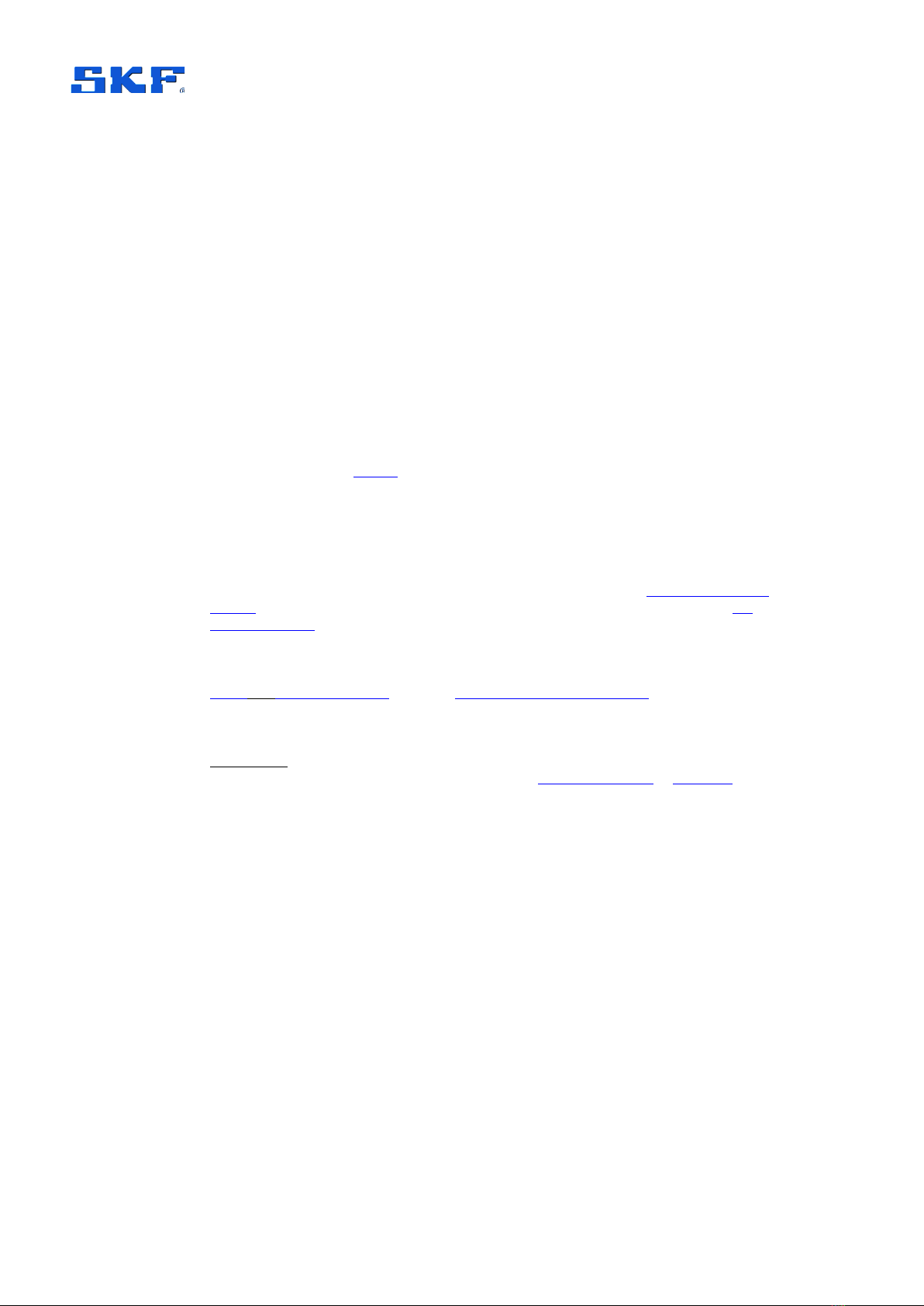

SKF Microlog Analyzer dBX

Quick Start Guide

Revision A

® SKF is a registered trademark of the SKF Group.

The Bluetooth® word mark and logos are registered trademarks owned by Bluetooth SIG, Inc. and

any use of such marks by SKF is under licence.

ICP® with associated logo is a registered trademark of PCB Piezotronics, Inc. in the United States

and ICP® is a registered trademark of PCB Piezotronics Europe GmbH in Germany and other

countries.

All other trademarks are the property of their respective owners.

The contents of this publication are the copyright of the publisher and may not be reproduced

(even extracts) unless prior written permission is granted. Every care has been taken to ensure the

accuracy of the information contained in this publication, but no liability can be accepted for any

loss or damage whether direct, indirect or consequential arising out of the use of the information

contained herein. SKF reserves the right to alter any part of this publication without prior notice.

Product Registration

Please take a moment to register your product to receive exclusive benefits offered only to our

registered customers, including technical support, tracking your proof of ownership and staying

informed about upgrades and special offers. (Please visit our website for more details on these

benefits.)

General Product Information

General information such as datasheets and catalogues are published on the Condition Monitoring

Systems site on SKF.com. Supporting product information can also be downloaded from the SKF

Technical Support self-service web portal.

Product Support Contact Information

Repair and Calibration Services –Submit a Return Authorization (RA) request to arrange for repair

or calibration of your product. You will receive an RA number and shipping instructions usually

within 48 business hours.

Product Sales –For information on purchasing condition monitoring products, services and

support on products out of warranty, please contact your local SKF sales office or distributor.

How to request Technical Support –Please open a support case using the Technical Support

group’s self-help portal at www.skf.com/cm/tsg. Once your support case is submitted, a

technician will contact you to begin working on your issue. For urgent issues we are available at

these times:

•Monday through Friday, 5:00 a.m. to 4:00 p.m. Pacific Time

Phone: +1 800 523 7514 within the US or +1 858 496 3627 outside the US.

•Monday through Friday, 8:00 a.m. to 4:00 p.m. Central European Time

Phone: +46 31 337 65 00.

•Monday through Friday, 7:30 a.m. to 4.30 p.m. India Standard Time

Phone: +60 16 699 9506.