- 4 -

951-181-026

Version 02

EN Table of contents

Table of contents

EU Declaration of conformity following ATEX directive 2014/34/EU ..........2

Legal notice .................................................................................................3

Explanation of symbols, signs and abbreviations........................................7

1. Safety instructions.........................................................................9

1.1 General safety instructions....................................................................9

1.2 General behaviour when handling the product...................................9

1.3 Intended use..........................................................................................10

1.4 Foreseeable misuse..............................................................................10

1.5 Modifications of the product................................................................11

1.6 Prohibition of certain activities............................................................11

1.7 Other applicable documents................................................................11

1.8 Notes related to the type identification plate.....................................12

1.9 Notes related to the CE marking .........................................................12

1.10 Explosion protection marking according to ATEX directive 2014/34/EU12

1.11 Persons authorized to operate the pump ..........................................13

1.11.1 Operator.................................................................................................13

1.11.2 Specialist in mechanics ........................................................................13

1.11.3 Specialist in electrics ............................................................................13

1.12 Provision of personal protective equipment......................................13

1.13 Operation...............................................................................................14

1.14 Emergency stopping.............................................................................14

1.15 Transport, installation, maintenance, malfunctions, repair,

shutdown, disposal...............................................................................14

1.16 Initial commissioning / daily start-up.................................................15

1.17 Cleaning .................................................................................................16

1.18 Safety-related protective and emergency devices must..................16

1.19 Special safety instructions regarding explosion protection .............17

1.20 Expiry of the ATEX approval.................................................................19

1.21 Operation in explosion-protected areas.............................................19

1.22 Explosion protection marking..............................................................19

1.23 Markings and conventions...................................................................20

1.24 Residual risks ........................................................................................21

1.25 Residual risks ATEX...............................................................................22

2. Lubricants................................................................................... 24

2.1 General information .............................................................................24

2.2 Selection of lubricants..........................................................................25

2.3 Material compatibility...........................................................................25

2.4 Temperature characteristics................................................................25

2.5 Ageing of lubricants..............................................................................25

2.6 Solid lubricants in lubrication greases................................................26

2.6.1 Chisel pastes..........................................................................................26

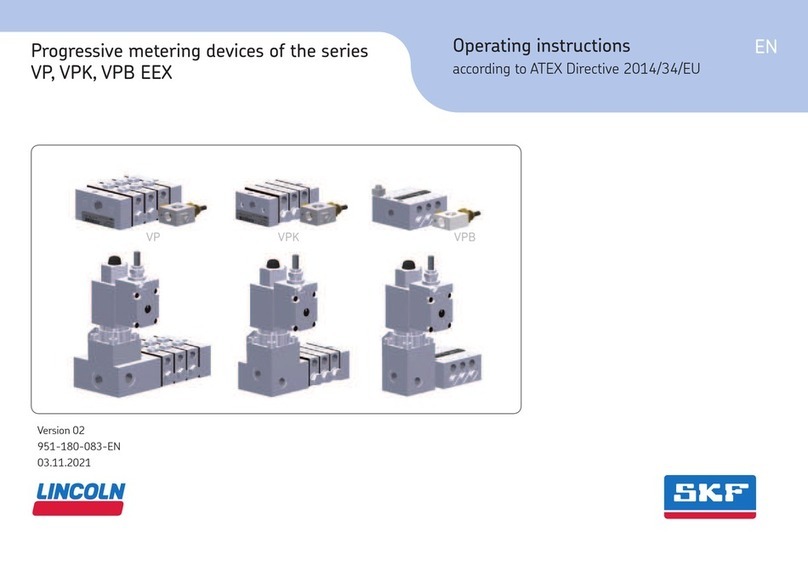

3. Overview, functional description ................................................ 27

3.1 General information .............................................................................27

3.2 Typical fields of application ..................................................................28

3.3 Function monitoring.............................................................................29

3.3.1 Function monitoring via proximity switch ..........................................29

3.4 Course of the lubricant in the SSV metering device..........................30

3.5 Course of the lubricant in the SSVD metering device.......................35

4. Technical data ............................................................................. 42

4.1 Technical data SSV...EEX / SSV-E...EEX .............................................42

4.1.1 Construction sizes, dimensions and weights SSV...EEX/ SSV-E...EEX

43

4.1.2 Tightening torques SSV...EEX / SSV-E...EEX.....................................44

4.2 Technical data SSVD...EEX / SSVD-E...EEX........................................45

4.2.1 Construction sizes, dimensions and weights SSVD...EEX / SSVD-E...EEX.46

4.2.2 Tightening torques SSVD...EEX / SSVD-E...EEX................................47

4.3 Technical data SSVL...EEX / SSVDL...EEX ..........................................48

4.3.1 SSVL...EEX / SSVDL...EEX....................................................................49