- 4 -

951-180-083-EN

Version 02

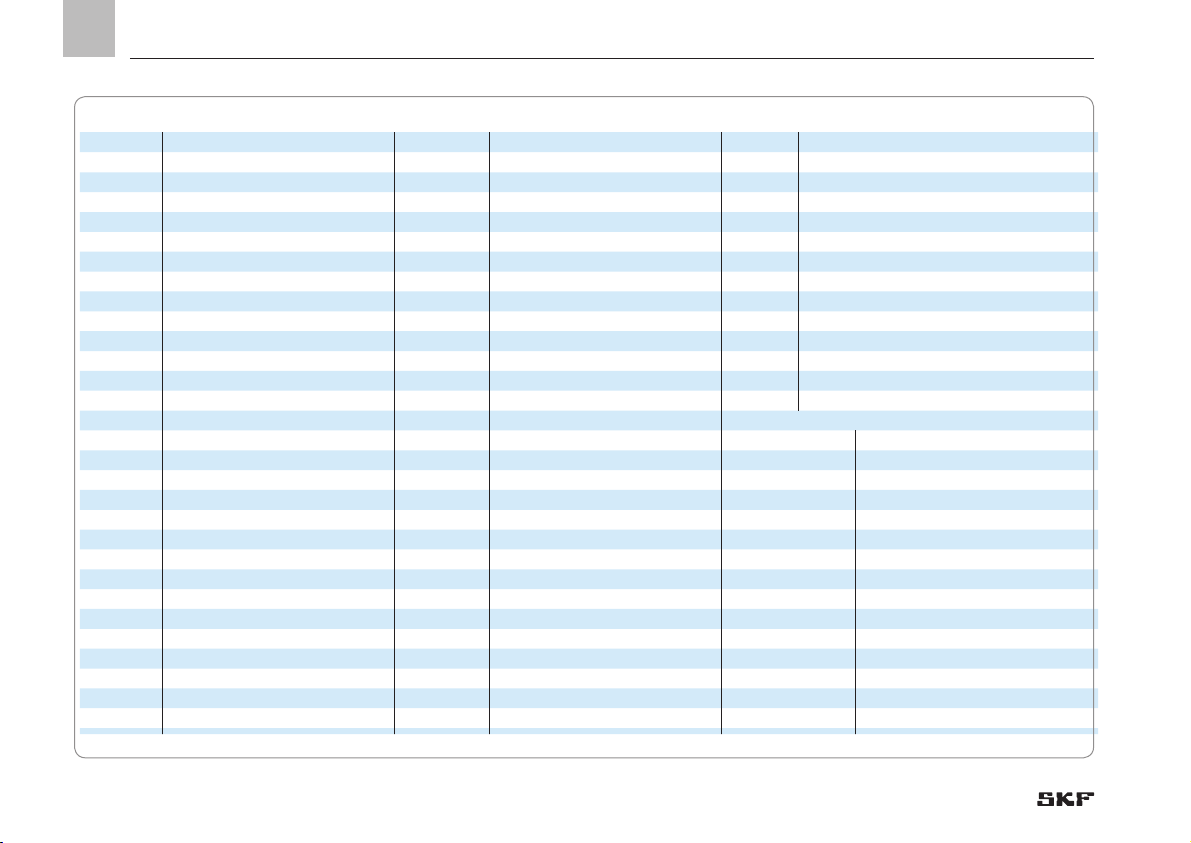

EN Table of contents

Table of contents

Masthead .......................................................................................... 3

Explanation of symbols and signs ....................................................... 7

1. Safety instructions ................................................................ 9

1.1 General safety instructions ....................................................................9

1.2 General behavior when handling the product .....................................9

1.3 Intended use ..........................................................................................10

1.4 Foreseeable misuse ..............................................................................10

1.5 Painting plastic components ...............................................................11

1.6 Modifications to the product ................................................................11

1.7 Prohibition of certain activities ............................................................11

1.11 Notes on the type plate ........................................................................12

1.12 Note on CE marking .............................................................................12

1.8 Inspections prior to delivery ................................................................12

1.9 Referenced documents ........................................................................12

1.10 Markings on the product ......................................................................12

1.13 Persons authorized to use the product ..............................................13

1.13.1 Operator ...........................................................................................13

1.13.2 Qualified mechanic .........................................................................13

1.13.3 Qualified electrician ......................................................................13

1.16 Operation ...............................................................................................14

1.17 Emergency stop ....................................................................................14

1.18 Transport, assembly, maintenance, malfunction, repair,

shutdown, disposal ...............................................................................14

1.13.4 Specialist in maintenance and servicing in

potentially explosive atmospheres ...............................................14

1.14 Instruction of outside fitters .............................................................14

1.15 Provision of personal protective gear .................................................14

1.19 First start-up, daily start-up ...............................................................16

1.20 Cleaning .................................................................................................16

1.21 Special safety instructions regarding explosion protection .............17

1.22 Nullification of ATEX approval .............................................................19

1.23 Operation in potentially explosive atmospheres ...............................19

1.24 Explosion protection marking .............................................................19

1.25 Obligations of the operator ..................................................................19

1.25.1 Identification of hazards ................................................................19

1.25.2 Explosion protection measures.....................................................19

1.25.3 Provision of necessary information ..............................................20

1.25.4 Duty to provide instruction and training ......................................20

1.26 Residual risks ........................................................................................22

1.27 Residual ATEX risks...............................................................................23

2. Lubricants .......................................................................... 25

2.1 General ...................................................................................................25

2.2 Selection of lubricants ..........................................................................25

2.3 Material compatibility ...........................................................................26

2.4 Aging of lubricants ................................................................................26

2.5 Lubricants in potentially explosive atmospheres ..............................26

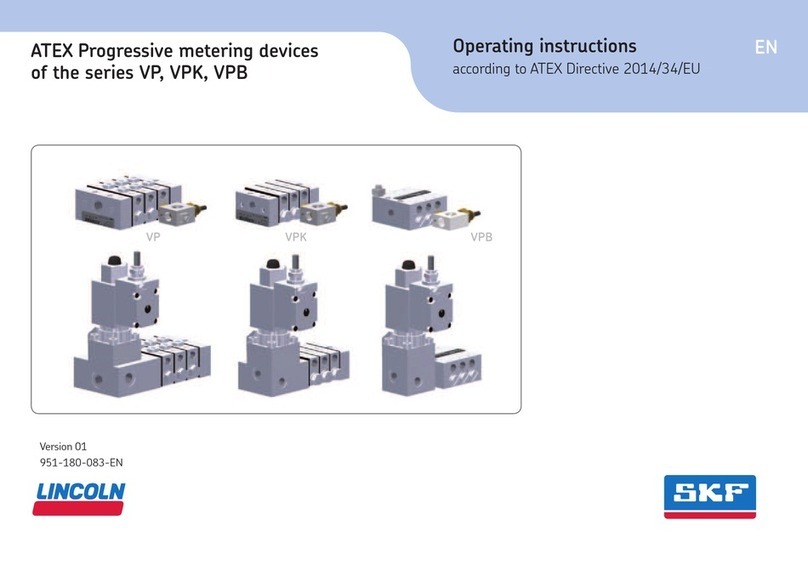

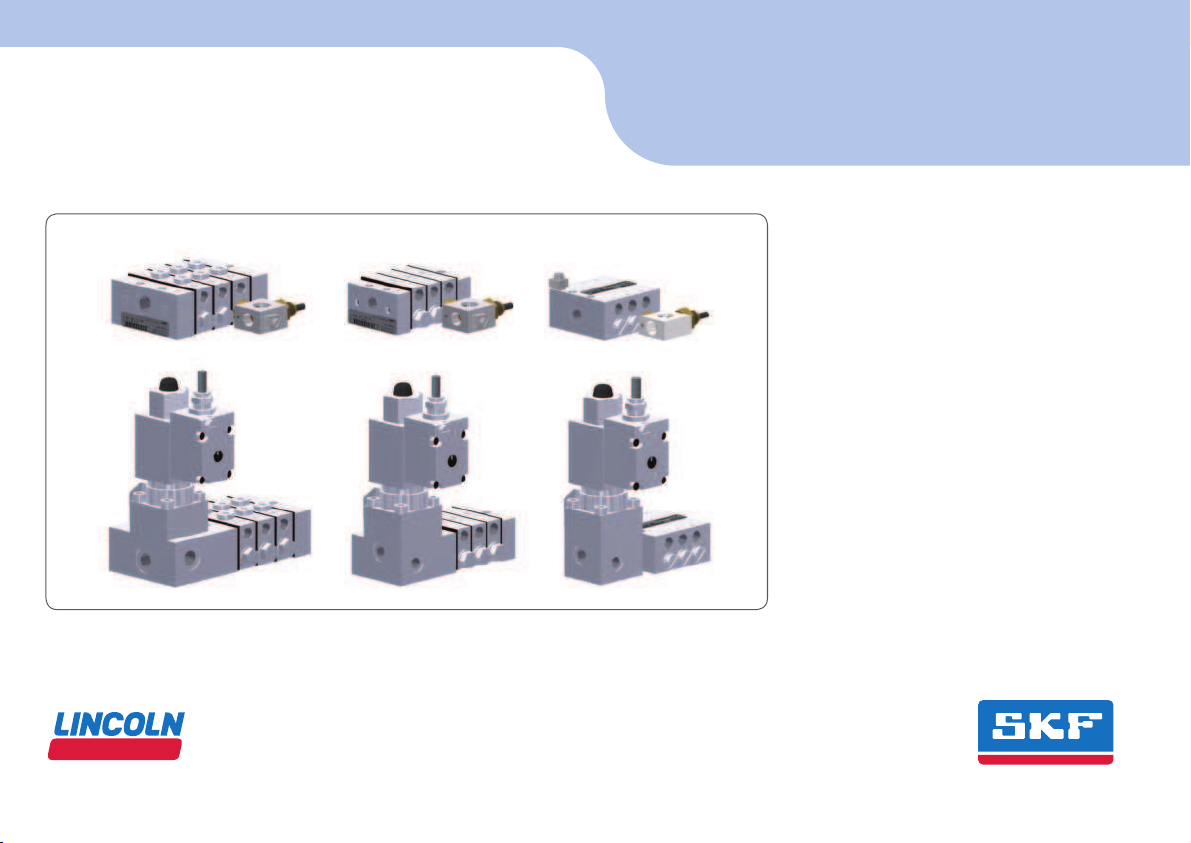

3. Overview, functional description .......................................... 27

3.1 Overview of progressive metering devices ........................................27

3.2 ATEX marking according to Directive 2014/34/EU (ATEX) ..............27

3.3 Information on volume data ................................................................28

3.4 Overview of VP progressive metering device series .........................29

3.4.1 Functioning of a VP progressive metering device .......................31

3.5 Overview of VPK progressive metering device series ......................33

3.5.1 Functioning of a VPK progressive metering device ....................35

3.6 Overview of VPB progressive metering device series ......................37

3.6.1 Functioning of a VPB progressive metering device ....................39