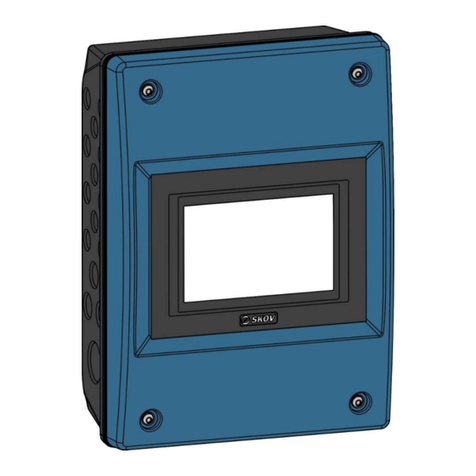

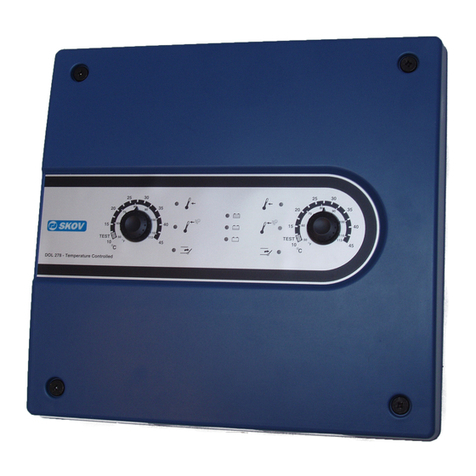

DOL 635 • DOL 639

Technical Manual

1 Product description........................................................................................................................................6

2 Procedure........................................................................................................................................................7

3 Installation guide ............................................................................................................................................8

3.1 Technical menus.......................................................................................................................... 8

3.2 Selecting components.................................................................................................................. 8

3.2.1 Installation wizard ........................................................................................................................ 9

3.3 The installation menu................................................................................................................. 10

3.3.1 Feed weighers ........................................................................................................................... 11

3.3.1.1 Shared feed weigher.................................................................................................................. 11

3.3.1.2 Shared Silo ................................................................................................................................ 12

3.3.1.3 Electronic silo weighing.............................................................................................................. 13

3.3.2 Dry feeding................................................................................................................................. 14

3.3.2.1 Dry feeding - monitoring of feed chain ....................................................................................... 15

3.3.3 Water ......................................................................................................................................... 15

3.3.4 Light control ............................................................................................................................... 15

3.3.4.1 Light sensor ............................................................................................................................... 15

4 Connecting components .............................................................................................................................16

4.1 Menu for show connection ......................................................................................................... 16

4.2 Manual I/O allocation ................................................................................................................. 16

5 Adjustment....................................................................................................................................................17

5.1 Menu for Adjustment.................................................................................................................. 17

5.1.1 Feed weigher ............................................................................................................................. 17

5.1.2 Feed........................................................................................................................................... 18

5.1.3 Silo ............................................................................................................................................. 18

5.1.4 Water meter ............................................................................................................................... 18

5.1.5 Light control ............................................................................................................................... 18

5.1.6 24-hour clock ............................................................................................................................. 18

5.2 Select type of unit of measurements.......................................................................................... 19

5.3 View week number..................................................................................................................... 19

6 Calibration.....................................................................................................................................................20

6.1 The menu calibration ................................................................................................................. 20

7 Service information ......................................................................................................................................21

8 Testing...........................................................................................................................................................22

8.1 Testing basis components ......................................................................................................... 22

8.1.1 Testing Alarm............................................................................................................................. 22

8.2 Testing optional components: Manual control ........................................................................... 22

8.2.1 The menu Manual/Auto.............................................................................................................. 22

8.2.2 Testing Production Functions .................................................................................................... 23

8.2.2.1 Testing the Tip Weigher............................................................................................................. 23

8.2.2.2 Testing the feed demand sensor and cross auger sensor......................................................... 24

8.2.2.3 Testing the drum weigher .......................................................................................................... 24

8.2.2.4 Testing DOL 9940 ..................................................................................................................... 25

8.2.2.5 Testing of shared feed weight – drum weigher and DOL 9940 ................................................. 25

8.2.2.6 Testing the electronic silo weigher............................................................................................. 25

8.2.2.7 Testing light................................................................................................................................ 26

8.2.2.8 Testing the water meter and water supply ................................................................................. 26

8.2.2.9 Testing relay for 24-hour clock................................................................................................... 26

8.2.2.10 Testing feed relay, silo relay and silo auger............................................................................... 26

8.3 Testing network connection ....................................................................................................... 27

9 Settings .........................................................................................................................................................28

9.1 The menu Settings..................................................................................................................... 28