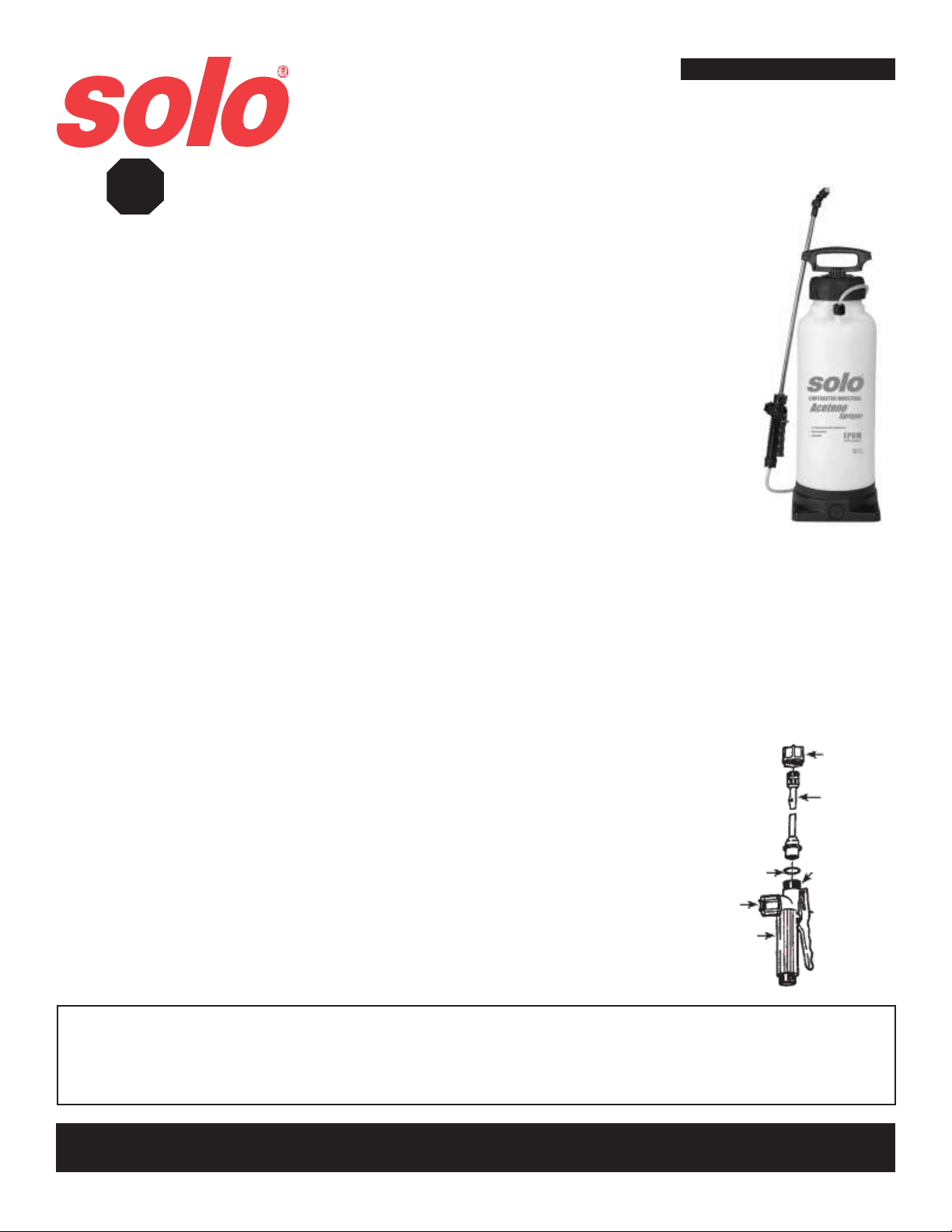

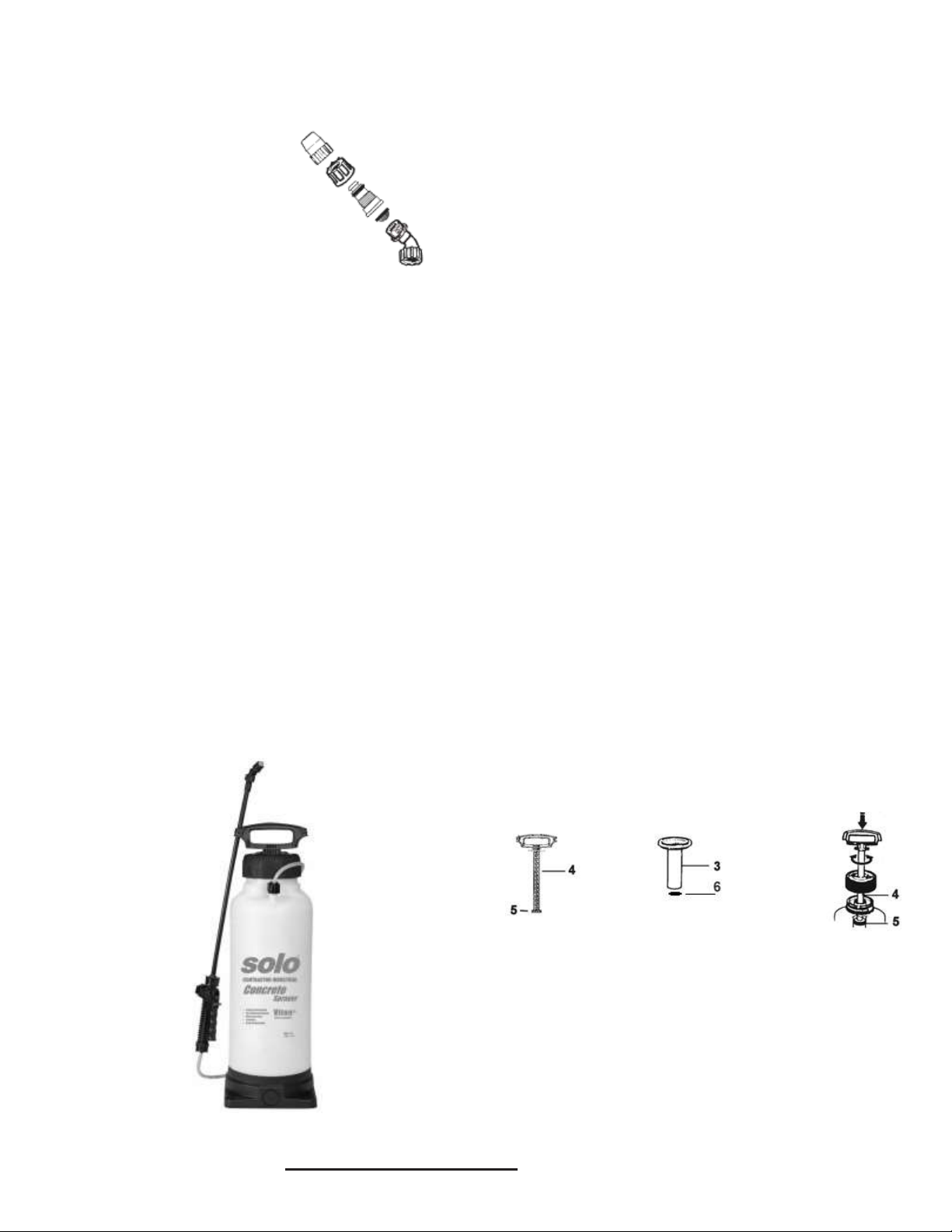

USING THE ADJUSTABLE NOZZLE

To change the spraying pattern, first make sure the retaining nut

(2) is screwed tight to the elbow (5). If it is not tight, the nozzle

cap (1) and nozzle body (3) will

CLEANING:

•Carefully clean sprayer after every use.

•Pour or spray all remaining chemical out of sprayer.

•Pour a small amount of water for water soluble chemicals, or

rotate inside the retaining nut and

the nozzle will not adjust. For a

straight stream pattern, rotate the

nozzle cap outward. For a hollow

cone pattern, rotate the nozzle cap

inward towards the retaining nut.

If it becomes difficult to rotate the

nozzle cap, remove the nozzle cap

from the nozzle body and lubricate

the O-ring on the nozzle body with

a non-water-soluble grease*.

1. Nozzle cap

2. Retaining nut

3. Nozzle body

4. Filter with gasket

5. Elbow

mineral spirits for oil-based chemicals, into the tank.

•Pressurize and spray through system until all liquid is gone.

•Repeat process with warm soapy water.

•Repeat process with warm clear water.

•Use an absorbent cloth to dry all internal surfaces.

•Follow the recommendations of the chemical manufacturer for

disposing of waste water and chemicals.

•Do not use aggressive or abrasive cleaning agents.

REMOVING ADJUSTABLE NOZZLE

Unscrew the nozzle cap (1) from the nozzle body (3). This

is best accomplished while the retaining nut (2) is securely

fastened to the elbow (5). Next, unscrew the retaining nut (2).

Push the nozzle body (3) out of the retaining nut (2). Tore-

install the nozzle, reverse the above instructions.

OPERATION:

•Before using sprayer with chemicals, fill sprayer with fresh

water to assure that you have it properly assembled;

pressurize and then practice spraying. When thoroughly

familiar with sprayer operation, follow normal operating

procedures.

•Turn pump handle counter clockwise to remove pump.

•Fill tank with premixed formula up to desired level. (Do not

exceed maximum fill mark.) Observe recommendations of

chemical manufacturer.

•Tighten cap and pump assembly for a good seal.

•Pump to a maximum 45 psi or 3 bar pressure. The valve

stem on the pressure relief valve will rise up to vent excess

pressure over 45 psi.

•Start or stop spraying by squeezing or releasing the lever on

the shut-off valve. The spray pressure can be monitored with

an optional pressure gauge.

•Prior to every removal of pump, release pressure first by

pulling up on the pressure relief valve stem.

MAINTENANCE:

•Prior to storage, empty, clean and dry sprayer.

•Always store the sprayer in a dry area, protected from

freezing, heat and sunlight.

•Lubricate O-ring in pressure relief valve with non-

water-soluble grease (Silicone grease for model 388)

on a regular basis.

Disassembly: Unscrew pressure relief valve from tank

and pull the valve body out of the screw cap. Clean,

lubricate, and replace.

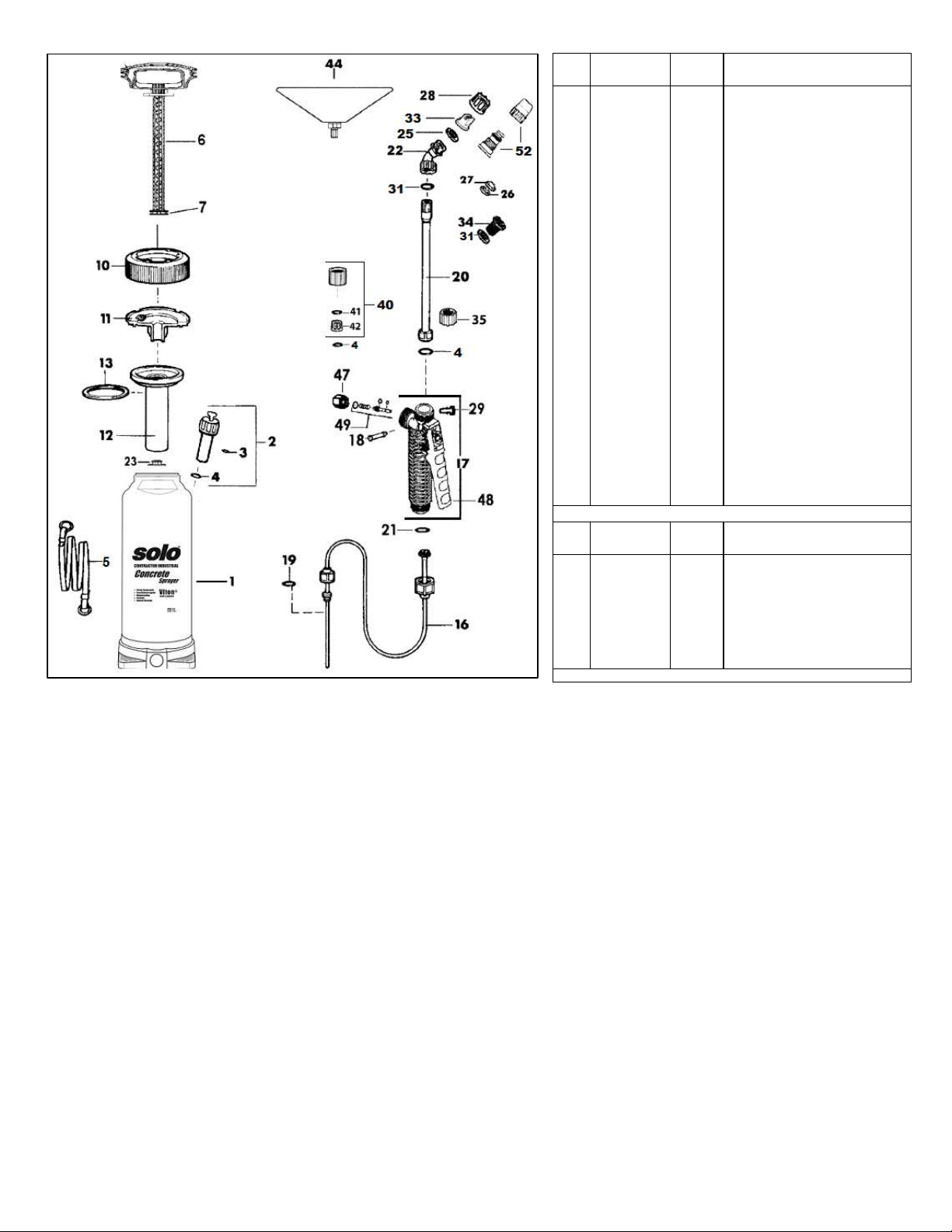

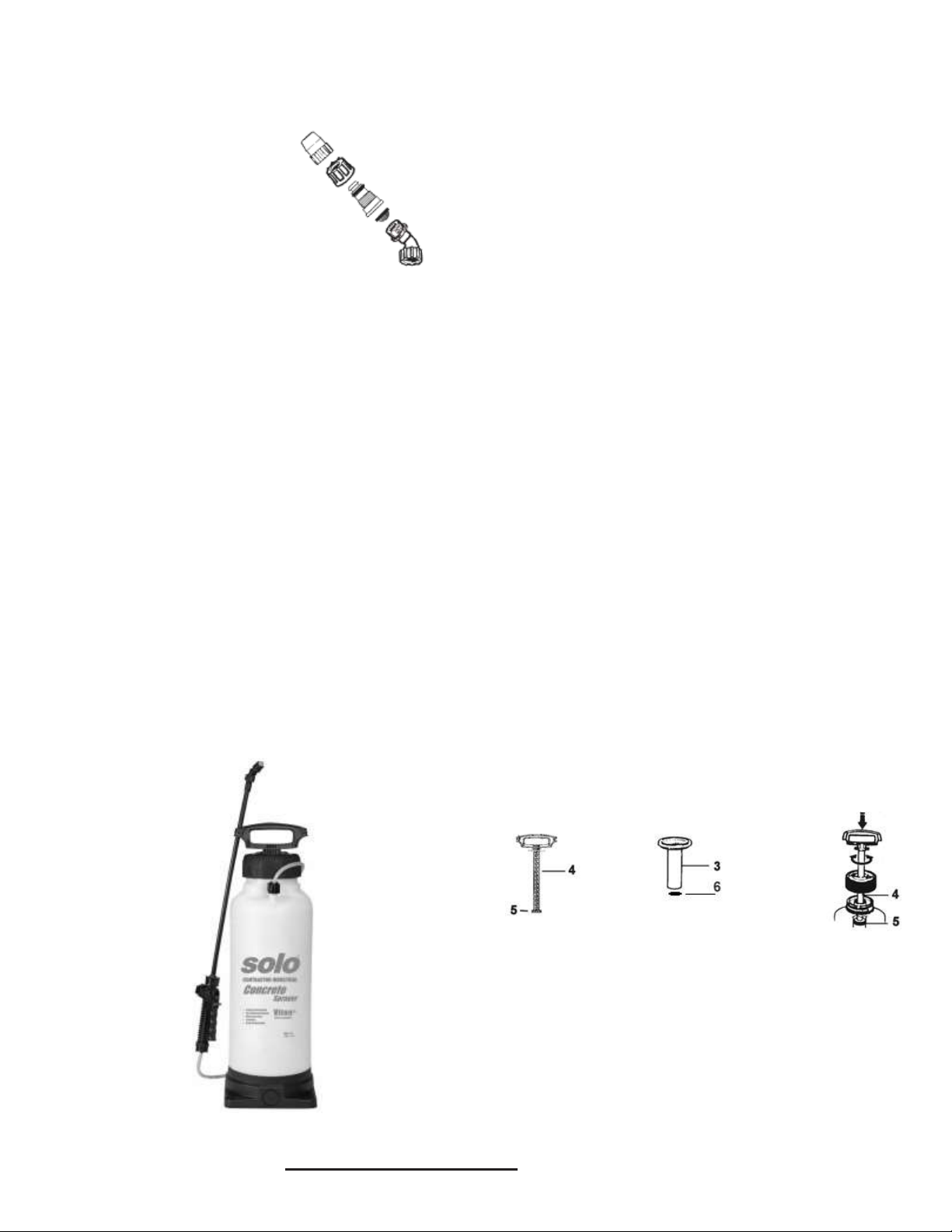

•Pump Maintenance: Pump pressure sealing is accomplished

with an O-ring (5) on the pump piston (4) which moves

within the cylinder (3). Periodically this O-ring should be

greased with a non-water-soluble grease (Silicone Grease

for model 388). If worn, it should be replaced. A small

umbrella valve (6) at the bottom of the cylinder prevents the

formula from entering the cylinder. Keep these parts clean

and replace if worn.

Disassembly: Unscrew pump assembly from tank.

Carefully remove umbrella valve (6) from the bottom of

cylinder (3). While holding cylinder firmly with one hand

and the handle of the pump piston (4) firmly in the other,

with the piston fully inserted in the cylinder, pull back on

the piston quickly and forcefully. To re-assemble, place

the piston assembly back into cylinder, place heel of

hands on opposite sides of the tank cap, while keeping

cylinder in place with fingers, tap bottom of cylinder

against a flat padded surface. Assembly will lock into

place.

•Tank Cap: A small amount of non-water-soluble grease

(Silicone Grease for model 388) on tank cap threads

and the gasket eases tightening and loosening.

•Regular Inspection: Inspect and replace worn or damaged

parts promptly. Pay particular attention to tank cap gasket,

pressure relief valve and seal, inflation valve (if fitted),

umbrella valve, O-rings and seals throughout sprayer. Regular

lubrication of O-rings and seals is recommended. (Silicone

Grease for model 388)

* Solo Model 378 –Use Solo Superior Grease or petroleum jelly.

*Solo Model 388 –Use a Silicone based lubricant.