OPERATOR’S MANUAL & PARTS LIST 456, 457, 456F

If you are missing parts, instructions or have questions, DO NOT take this unit back to the store.

Call 1300 798 022. Solo will send the missing parts/information to you promptly.

STOP

Visit us on the web at www.soloaustralia.com.au Troubleshooting and parts ordering available on-line.

CUSTOMER SERVICE COMMITMENT FROM SOLO’S SERVICE DEPARTMENT: In the event the sprayer you have purchased has missing or damaged parts,

please call 1300 798 022, 9:00am – 5:00pm Mon-Fri. In order to assist your service representative, please have the following information available: sprayer model number,

part description and part number. A parts list is included in your operator’s manual. Solo is committed to your satisfaction and is continuing its efforts to earn your future business.

If you suspect or observe indications that the material may be unsafe

in a Solo sprayer... STOP! Do Not Use or Apply Chemical. ALWAYS

WEAR RUBBER GLOVES, SAFETY GOGGLES AND APPROPRIATE

PROTECTIVE CLOTHING.

Read and follow operating instructions.

• Donotllsprayerovermaximumllmark.Releasingpressureinan

overllconditioncancauseharmfulventingofsprayercontents.

• Relievepressureonlywithsprayeruprightandwhilestandingon

the side of the sprayer opposite the pressure relief valve. Venting of

sprayer contents can occur if liquid is over bottom of relief valve.

• CAUTION:Topreventinjuryfromejectedpumpassemblyand/or

solution,neverstandwithfaceorbodyoverthetopofthetankwhen

pumping, or loosening pump.

• Donotmodifysprayerorpressurereliefvalve.

• Neversprayinthedirectionofhumans,animalsorpropertywhich

mightbeinjuredordamagedbysprayformula.

• Donotusedisinfectants,solventsorimpregnatingagentsunlessrst

tested to ensure they are not harmful to the environment and sprayer.

• Donotuseliquidswithatemperatureabove45°C.

• Rememberthatasprayerwithliquidisasignicantamountofweight

(1kgperlitre).Usecautionwhenbending,leaningorwalking.Bend

onlyatthekneesandsupportyourselfasrequiredtoensurepersonal

safety.

• Donotinatesprayerwithoutliquidinthetank.

• Donotclimbonladders,treesorotherunsteadyorpotentiallyunsafe

structures.

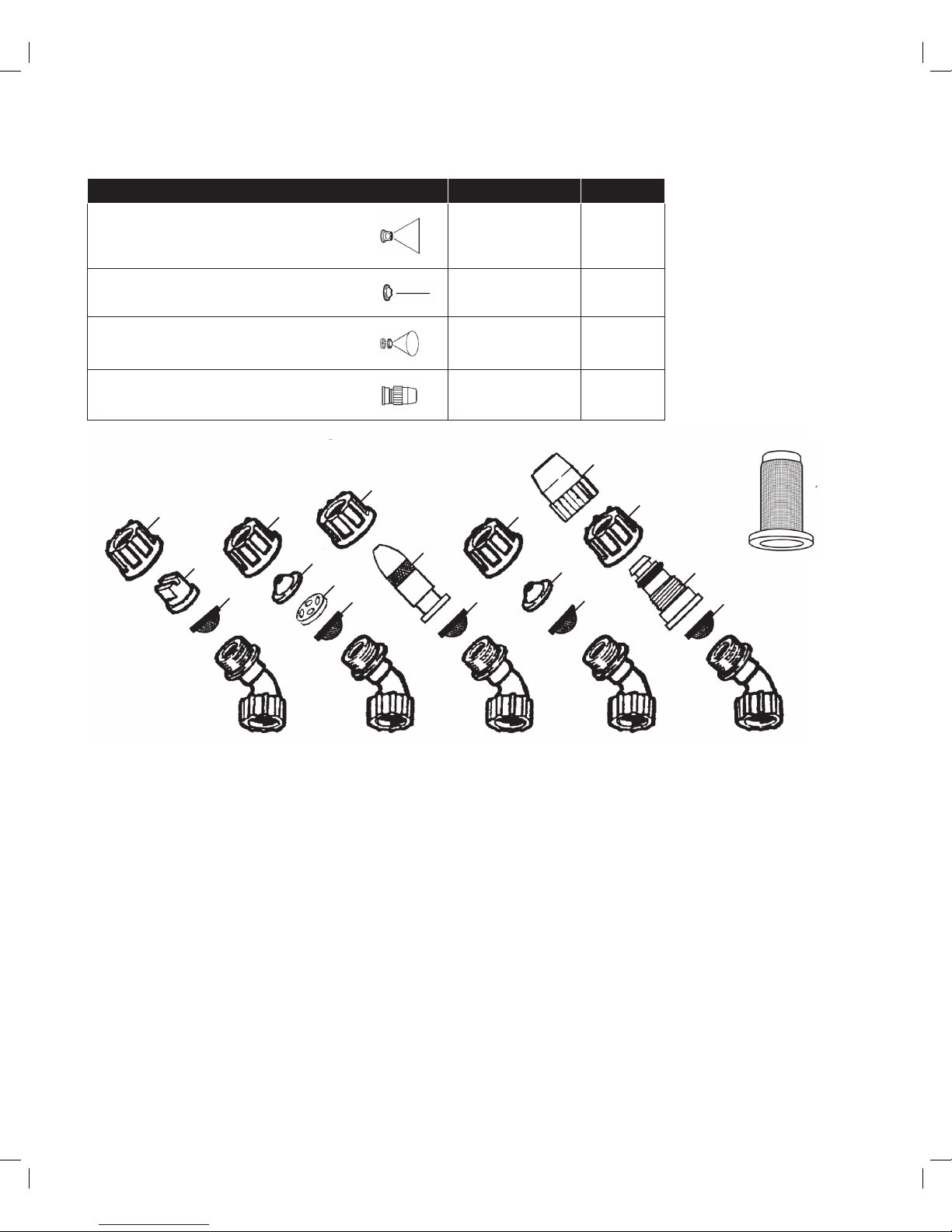

ASSEMBLY INSTRUCTIONS FOR WAND

1. Ensure that the O-ring is on the

non-threaded end of the wand.

2. Insert the non-threaded end of the

wand into the O-ring into the open

end of the shut- off valve.

3. Tighten the screw cap.

WARRANTY

SolobackpacksprayersarecoveredbySolo’sWARRANTY

(2yearsformodels456,457,456F).Solomanufacturedpartswhichfail

duetodefectivematerialorworkmanshipwillberepairedorreplaced

without charge. Refer to Warranty sections for consumer and commercial

use, of this Owners Manual, for full details.

SAFETY PRECAUTIONS

•Do not exceed 3 bar (45 psi) pressure.

•Do not fill with, use or spray flammable

materials.

•Do not use gasoline, acid, acetone, caustic or

potentially injurious chemicals.

• Atthetimeofmanufactureofthissprayer,

we are not aware of any approved plant

protection chemicals which would adversely

affect this sprayer when applied in their usual

concentration.

•Observe the recommendations of the

chemical manufacturer.

•Prior to removing any part of the sprayer pull the pressure relief

valve to release any pressure in the tank.

•Wear rubber gloves, safety goggles and appropriate protective

clothing.

•After pumping be sure handle is in the locked down position.

• Individualsshouldbetrainedintheproperuseofthissprayer.Where

training is not available, individuals should study and follow the

procedures detailed in this manual.

• Donotuseacetonebasedchemicals.

WARNING

Chemicals can be harmful to individuals and the environment if

improperly used. In addition, some chemicals are caustic, corrosive,

or poisonous and should be avoided. Read warnings and chemical

manufacturer’s instructions. Solo high density polyethylene sprayers

arettedwithViton®sealswhichareresistanttoawidevarietyof

agricultural, industrial and household chemicals; however, care should

beexercisedtoensurethatsprayercomponentsareclean,functioning

properly, and in a good state of repair before and during use. If in doubt

aboutaparticularchemical,checkwithmanufacturer.

1