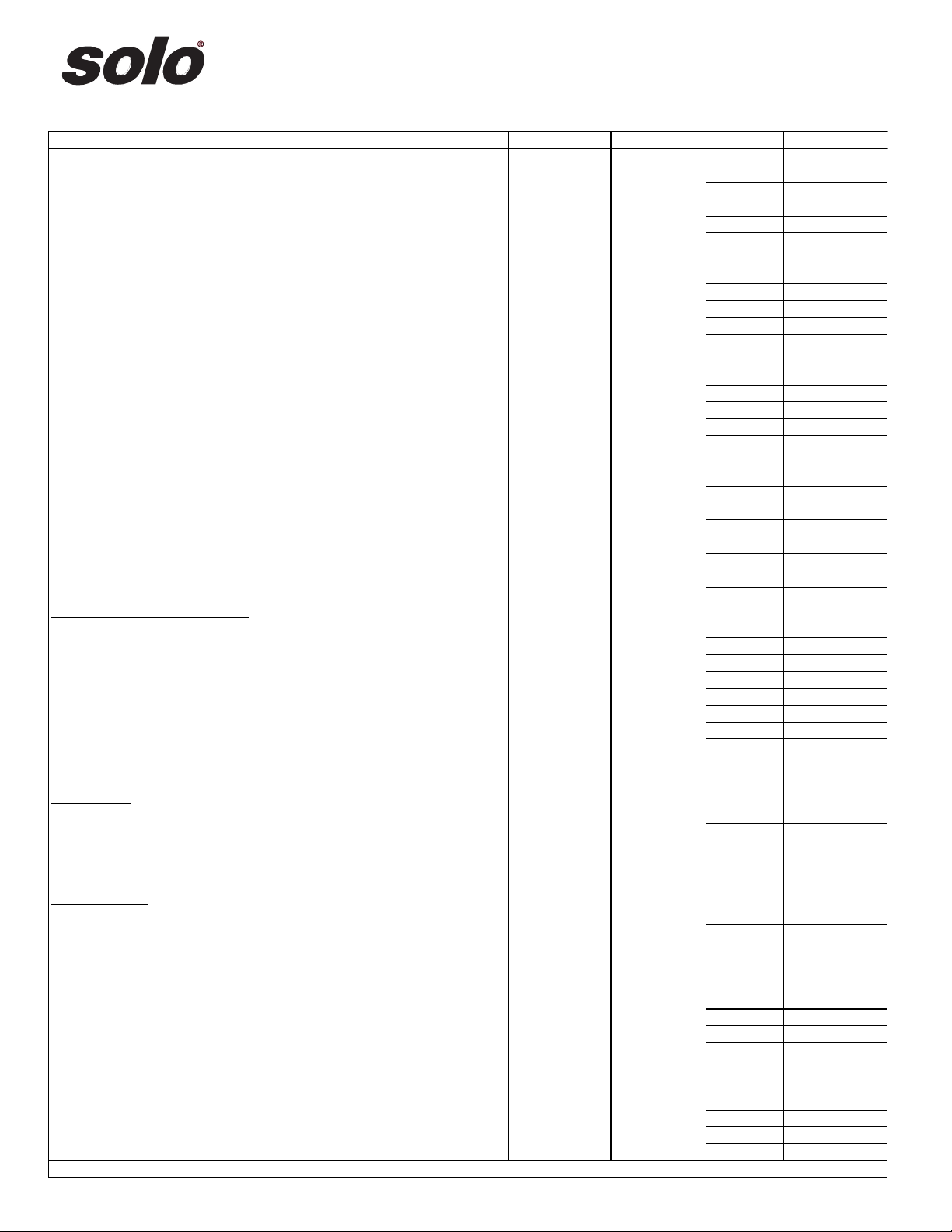

6

PO S . # O rde r # F or M o del D esc ri pt ion Fr anc ai s Españo l

2 00 10 138 Bolt Boulon Tornillo

3 00 12 185 Bolt Boulon Tornillo

4 00 30 131 Washer Rondelle Arandela

6 00 12 185 Bolt Boulon Tornillo

7 06 10 402-K Shut-off Valve repairkit Kit de réparation de valve Kit de reparación de válvulas

- 06 10 413-K 315- A, 475's, 473D,485 Shut-off Valve repairkit(Viton®) Kit de réparation de valve(Viton®) Kit de reparación de válvulas(Viton®)

8 00 62 258 O-ring Joint bague Anillo de sellado

10 00 62 115 O-ring Joint bague Anillo de sellado

11 00 62 291 O-ring Joint bague Anillo de sellado

12 00 62 139 O-ring Joint bague Anillo de sellado

13 00 62 140 O-ring Joint bague Anillo de sellado

14 00 64 234 Hose 48" (incl. 26, 34, 49, 103) Tuyau 1,2m(incl. 26, 34, 49, 103) Manguera 1,2m (incl. 26, 34, 49, 103)

15 00 66 388 Hose clamp Colliercpl. Abrazadera

16 00 66 394 Pump clamp Colliercpl. Abrazadera

17 40 43 123 475's, 473D,485 Stop plate Plaque d'arrêt Placa de parada

18 40 35 111 Pump shaft Arbre de pompe Eje de la bomba

19 40 73 725 101's, Deluxe's, Prof's Carrying handle (red) Poignée de transport(rouge) Asa de transporte (rojo)

- 40 73 727 HD's Carrying handle (black) Poignée de transport (noir) Asa de transporte (negro)

- 40 737 2539 315- A Carrying handle (blue) Poignée de transport(bleu) Asa de transporte (azul)

20 40 61257 Valve plate Joint de soupape Sello de valvula

21 42 00 242 Tank cap (red)(incl. 48, 98, 99) Casquette (rouge)(incl. 48, 98, 99) Tapa (rojo)(incl. 48, 98, 99)

- 40 73 181 HD's Tank cap (black)(incl. 48, 98, 99) Casquette (noir)(incl. 48, 98, 99) Tapa (negro)(incl. 48, 98, 99)

- 32 00 503 315-A Tank cap (blue)(incl. 48, 98, 99) Casquette (bleu)(incl. 48, 98, 99) Tapa (azul)(incl. 48, 98, 99)

22 40 74 148 Retaining nut Ecrou de raccord Tuerca de conexión

23 40 74 323 Valve body Corpsde soupape Cuerpo de la válvula

24 40 74 350 Sealing plug Joint Tapón de sellado

25 00 70 260 Compression spring Ressortde compression Resorte de compresion

26 40 74 337 Retaining nut Ecrou de raccord Tuerca de conexión

27 40 74 344 Controlknob Bouton de controle Botón de control

28 40 74 410 Bushing Coussinet Cojinete

29 40 74 263 Flat spray jet Buse à diffusion large Tobera de chorro ancho

30 40 74 756 Swirl plate Tourbillon plaque Placa de remolino

31 40 74 283 Jet filter Filtre Filtro

32 40 74 755 Jet cap Capuchon de gicleur Casquillo deljet

33 49 00 527 Plastic adjustable nozzle Buse réglable en plastique Boquilla de plástico ajustable

- 49 00 207 101's, Deluxe's, Prof's, HD's Brass adjustable nozzle Buse en laiton réglable Boquilla de latón ajustable

34 40 74 500 Clamp Colliercpl. Abrazadera

35 40 74 527 Elbow Coude Recodo

36 42 00 162 425's, 475's Tank and frame, 4 gal. Réservoiret cadre, 15l Tanque y marco, 15l

- 42 00 428 435, 485 Tank and frame, 5 gal. Réservoiret cadre, 19l Tanque y marco, 19l

- 42 00 421 473P, 473D Tank and frame, 3 gal. Réservoiret cadre, 11l Tanque y marco, 11l

37 42 00 106 Filterbasket Panierfiltre Cesta de filtro

38 43 00 315 425, 475-B Shoulderstrap (incl. 73) Bretelle (incl. 73) Bandolera (incl. 73)

- 43 00 340 101's, Deluxe's, HD's Deluxe shoulderstrap (incl. 73) Bretelle de luxe (incl.73) Bandolera de lujo (incl.73)

- 43 00 343 Prof's Shouldersaverharness Harnais de protection d'épaule Arnés de protección de hombro

39 44 00 240 HD's, Prof's, 435, 485 Pressure cylinder(incl.107) Chambre de pression (incl.107) Camara de presion (incl. 107)

- 44 00 240N 425, 475- B, 473P, 473D Pressure cylinder Chambre de pression Camara de presion

40 40 73 190 Piston cylinder(incl. 12, 13, 20x2) Cylindre de piston (incl. 12, 13, 20x2) Cilindro del pistón (incl. 12, 13, 20x2)

41 40 74 409 Connecting rod without stud Leviersans goujon Biela sin yeguada

42 40 74 270 Piston lever Levierde piston Palanca delpistón

43 40 73 558 Piston Piston Pistón

44 44 00 189 Viton® collar Viton® bague Viton® anillo

45 48 00 170 425's, 473P, 435 Shut-off valve Vanne marche / arrêt Válvula de encendido / apagado

- 48 00 249 475's, 473D, 485 Shut-off valve (Bleach resistant) Vanne marche / arrêt (javel) Válvula de encendido / apagado

- 38 00 502 315- A, HD's Shut-off valve (Viton®/FKM) Vanne marche / arrêt (Viton®) Válvula de encendido / apagado

46 48 00 173 25 425, 475-B, 3 & 5 gal. Pump Lever Levierde pompe Palanca de bomba

47 49 00 230 Spray tube 20", plastic (incl. 8, 26) Tube de pulvérisation ,5m(incl.8, 26) Tubo rociador,5m(incl.8, 26)

- 49 00 645 315-A Stainlesssteelwand Tube en acier inoxydable Varita de acero inoxidable

48 40 61345 Gasket Joint Sello

- 40 61346 315- A, HD's Gasket, Viton® Joint, Viton® Sello, Viton®

49 00 31356 Washer Rondelle Arandela

50 40 74 412 473P, 473D, 435, 485 Strap buckle Bretelle boucle Hebilla de correa de hombro

50A 40 74 425 425's, 475's, 315-A Strap pin Bretelle goujon Correa de hombro clavija

51 40 74 680 Protective cover Couvercle de protection Cubierta de protección

52 00 10 110 Bolt Boulon Tornillo

53 00 20 101 Hex. Nut Écrou, hex. Tuerca, hex

54 40 74 408 Connecting rod with stud Levier avec goujon Biela con yeguada

55 49 00 454 101's, Deluxe's, Prof's Fold- away pump lever(incl. 4, 56, 57, 58) Poignée rabattable Asa plegable

56 00 20 119 Nut Écrou Tuerca

57 00 12 192 Bolt Boulon Tornillo

58 40 74 996 Wand retaining clip Agrafe de tube de pulvérisation Pinza de tubo en spray

60 40 73 411 Housing, diaphragm Boîtier, diaphragme Cubierta, diafragma

61 40 73 412 Flange, diaphragm Boudin, diaphragme Brida, diafragma

63 44 00 222 Valve assy. (incl. 12, 20x2) Ensemble de soupape(incl. 12, 20x2) Montaje válvula (incl. 12, 20x2)

64 00 18 275 Screw, flange Vis, boudin Tornillo, brida

64A 00 18 275 Screw, plunger Vis, piston Tornillo, pistón

65 40 74 256 Plunger Piston Pistón

66 40 74 246 Diaphragm(Bleach resistant) Diaphragme (javel) Diafragma

67 40 74 255 Diaphragmlever Levierà diaphragme palanca de diafragma

68 40 31130 Wrist pin Goujon Clavija

69 40 74 243 "L" Left connecting bracket Gauche support Izquierda soporte

70 40 74 234 "R" Right connecting braket Droite support Derecha soporte

72 00 10 141 Bolt Boulon Tornillo

73 40 74 837 Strap hook Bretelle crochet Gancho para correa

90 27 00 316 HD's No drip check valve Pas de filtre goutte Válvula de retenci

97 40 74 295 Pin Goujon Alfiler

98 40 61464 Vent plate Plaque d'aération Placa de ventilación

99 40 74 123 Vent cap Bouchon d'aération Tapa de ventilación

100 40 74 329 Lockclip Clip de verrouillage Clip de bloqueo

101 40 74 336 Retaining nut Ecrou de raccord Tuerca de conexión

102 40 74 335 Shut-off valve lever Levierde soupape Palanca válvula

103 00 62 271 O-ring Joint bague Anillo de sellado

106 00 62 324 O-ring Joint bague Anillo de sellado

107 48 00 182 Dlx,HD's, Prof's, 435, 485 Pressure control valve (incl. 8, 23-25, 27) Régulateur de pression Reguladorde presion(incl. 8, 23-25, 27)

1 42 00 215 Plug (incl. 8) Bouchon (incl. 8) Tapón (incl. 8)

76 49 00 430 Drif guard Anti-dérive Protectorde la deriva

80 49 00 477 Double nozzle Buse à double jet Doble boquilla

93 49 00 622 Pressure gauge (incl. 94, 95) Jauge de pression (incl. 94, 95) Manómetro (incl.94, 95)

94 40 74 338 Retaining nut Ecrou de raccord Tuerca de conexión

95 00 62 249 O-ring Joint bague Anillo de sellado

96 40 74 666 Speed tip nozzle Buse à jet multiple Boquilla de chorro múltiple

- 49 00 421 Brasswand 20" Tube de pulvérisation en laiton Tubo de latón

- 49 00 528 60" Brass wand 2pc 1,5mTube de pulvérisation en laiton 1,5mTubo de latón

- 00 65 210 Brassflat spray jet Buse à jet plat en laiton Boquilla de chorro plano de latón

- 06 10 410-P Brassadjustable nozzle kit (incl.22, 31) Kit de buses en laiton réglable Kitde boquilla de latón ajustable

- 49 00 513 20" plastic extension tube ,5m Tube d'extension ,5mTubo de extensión

- 49 00 258N Elbownozzle assy.(incl.10, 22, 31, 33, 35) Ensemble de buse coudée Juego de boquilla angulares