Service Record LoopSORG 3 of 44

2019-08-15

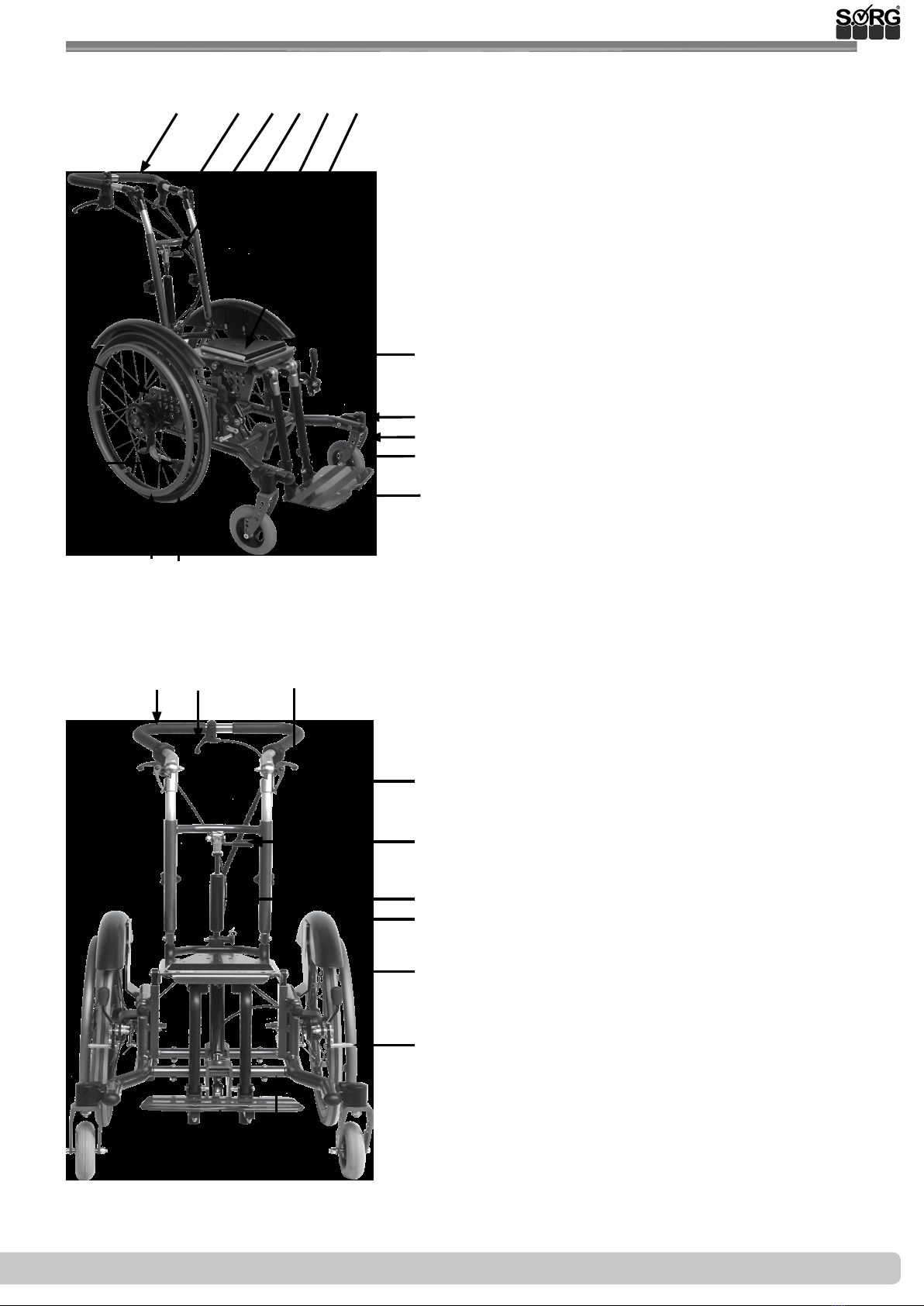

1 Seat shell base frame overview 5

2 General information 6

2.1 General indications 6

2.2 Documentation indications 6

2.3 Required torques and tools 6

2.4 Explanation of symbols 7

2.5 General safety instructions 8

3 Assembly Group 9

3.1 Assembly Group Wheels 9

3.1.1 Position rear wheel 9

3.1.2 Displacing the wheels without a

camber adapter (20",22",24") 9

3.1.3 Displacing the wheels with a

camber adapter (20",22",24") 10

3.1.4 12"/16" wheels 10

3.1.5 Camber 11

3.1.6 Wheel base extension for 20" + 22"12

3.1.7 Casters 13

3.2 Assembly Group Frame 14

3.2.1 Frame arch for closed frames 14

3.2.2 Widening the frame 15

3.2.3 Additional crossbar 16

3.3 Assembly Group Seat 17

3.3.1 Adjusting the tilting direction 17

3.3.2

Displacing the seat plate horizontally

18

3.3.3 Displacing the seat plate vertically 19

3.3.4 Position wedge adapter 19

3.3.5 Release lever-seat wedge 20

3.3.6 Position push bar 20

3.3.7 Double gas spring 21

3.4 Assembly Group Back 25

3.4.1 Setting back depth 25

3.4.2 Setting height of the push bar 25

3.4.3 Setting back angle 25

3.4.4 Adjustment of back guide 26

3.4.5 Conversion from back angle

setting to back angle adjustment 27

3.4.6 Changing the basic setting of the

push height 27

3.5 Assembly Group Leg Supports 28

3.5.1 Positioning the leg supports 28

3.5.2 Leg supports: standard or angle

adjustable 29

3.5.3

Leg supports which swing to the side

30

3.5.4 Leg support can be elevated with

a physiological turning point 31

3.5.5 Multidirectional leg support 33

3.6 Assembly Group Brakes 34

3.6.1 Trum brake 34

3.6.2 Knee lever brake 36

3.7 Assembly Group Frame 37

3.7.1 Anti-tipper 37

3.7.2 Tipping lever 37

3.7.3 Outdoor Front End 38

4 Repairs and maintenance 39

4.1 Repairs 39

4.2 Spare parts 39

4.3 Maintenance 39

4.4 Disinfection 39

4.5 Storage 39

4.6 Reinstatement 40

4.7 Disposal 40

4.8 Maintenance/ Inspection 40

5 Technical specications 42

5.1 Data and measurements 42

5.2 Meaning of labels 43

5.3 Declaration of conformity 43

Table of content