service record Airon 9 von 36

2021-06-10

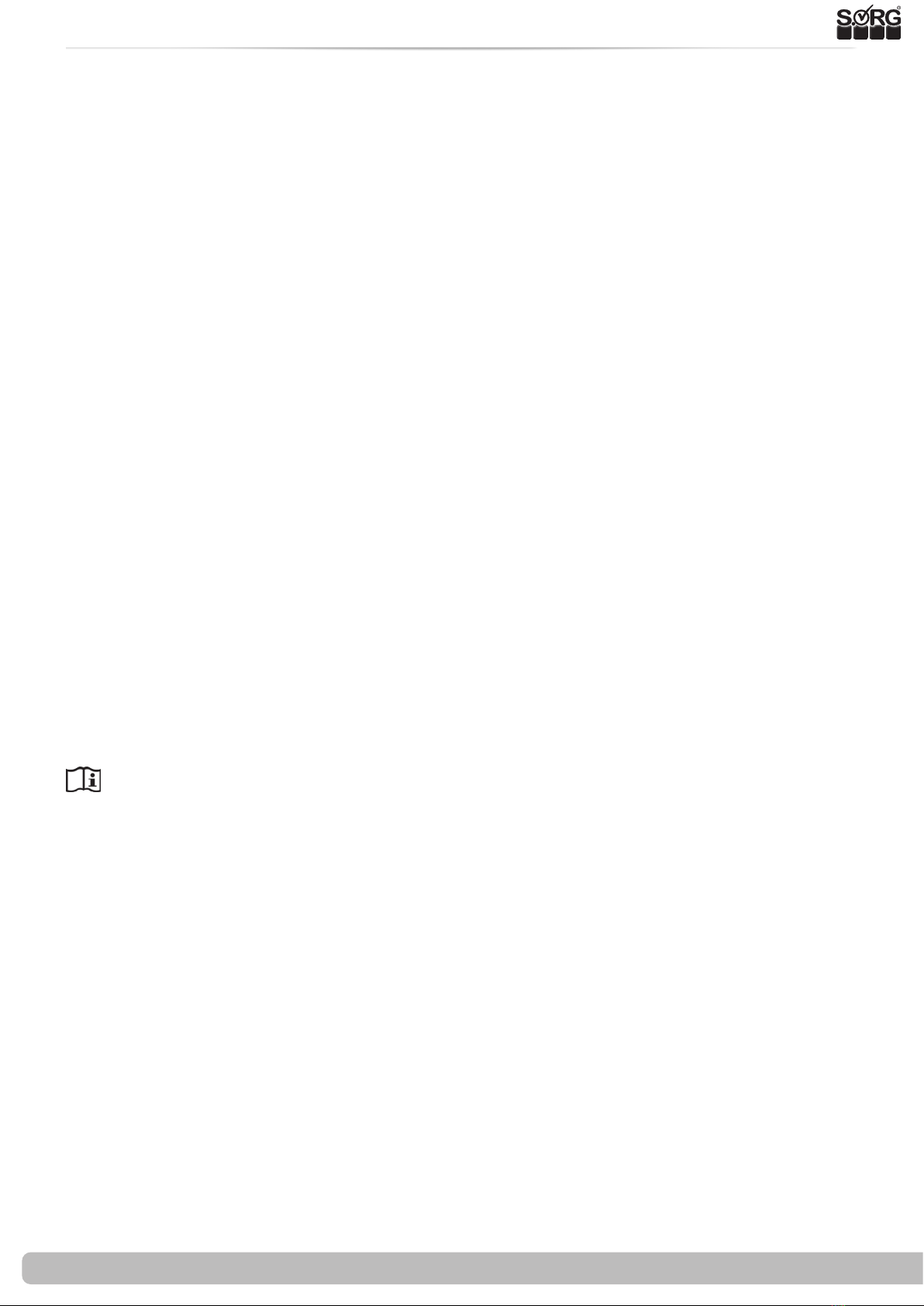

3.1 Wheels assembly

3.1.3 Rear seat height, seat inclination

(A)

(1)

(2)

(B)

(A)

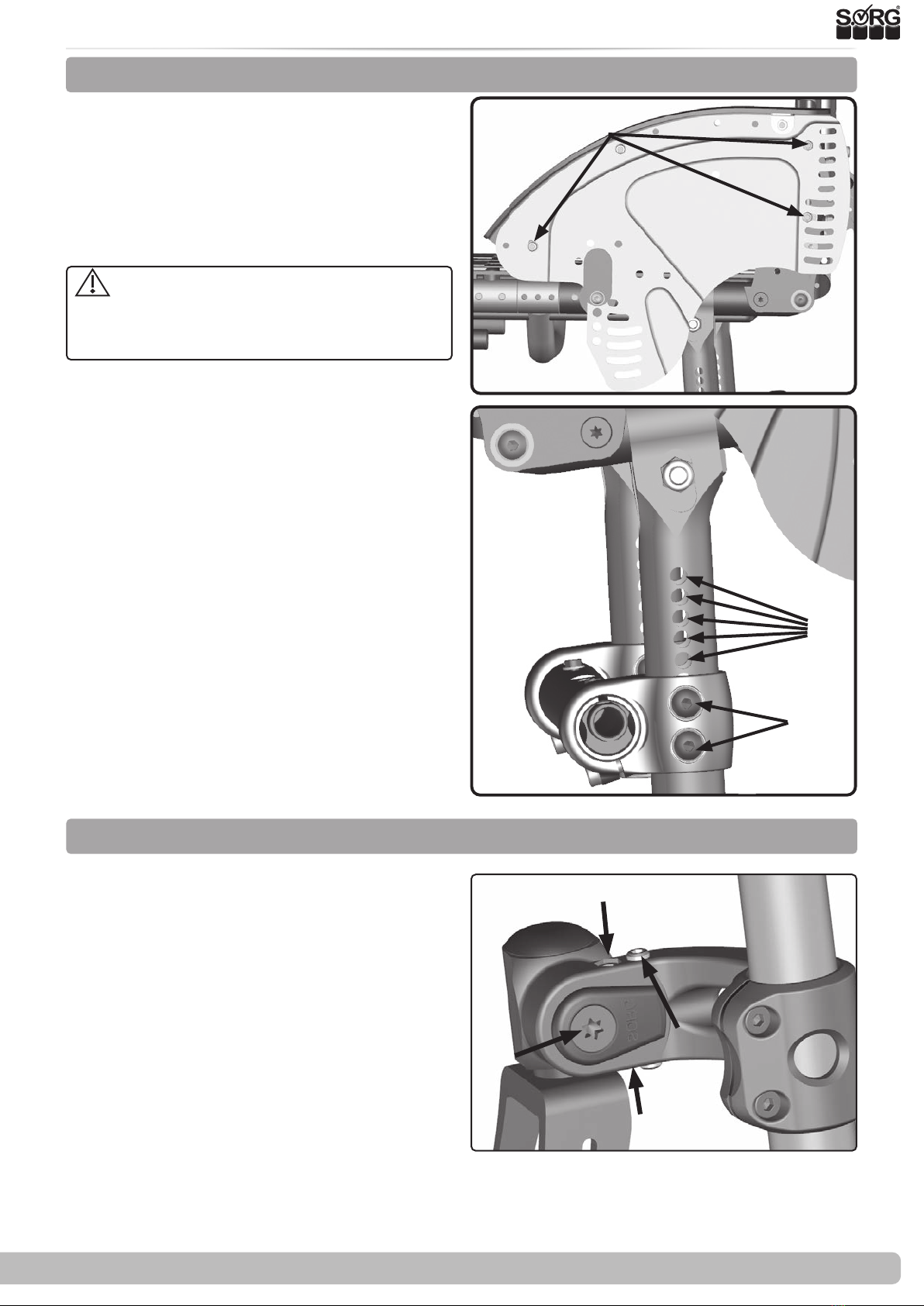

3.1.4 Positioning the steering angle

(3)

(B)

(C)

After every change to the drive wheel,

the functionality of the parking brakes must

be checked and the caster wheels and the

wheel track must be readjusted.

As a rule, the seat height at the back is selec-

ted approx. 2-3 cm lower than the seat height

in front in order to achieve a safe and comfor-

table sitting position with good distribution

of the seat pressure and to avoid "slipping

forward". However, other settings can also be

useful in individual cases.

• (1) Remove the drive wheels,

• remove the side panels / clothes guards

with the screws (1A) (simply remove the

plug-in side panels),

• (2) Remove the screw connection and

the threaded sleeves on the clamping

ange (2A),

• move the clamping ange to the desi-

red holes (2B)

• attach the screws and threaded sleeves

and tighten all screws again.

• Mount the side parts and put the drive

wheels back into the quick-release axle.

The clamping anges must be attached at the

same height on both sides. The lateral dis-

tance between the top tires and the side panel

should be as small as possible, but at least 10

mm.

An incorrectly set steering axis angle can lead to caster wheel utter and when cornering (due to

the wheel caster) to obstructive "uphill and downhill driving".

The steering axis angle must be readjusted after

each change to the rear and front seat height.

For adjusting the steering angle:

(A)

(A)

• Loosen the screws (3A) + (3C)

• Unscrew the threaded pins (3B) suci-

ently to be able to readjust the steering

head angle.

• Tighten the screws (3A) and (3C) so

that the steering head can just be mo-

ved and set the steering head angle to

90 °.

• Carefully screw in one of the threa-

ded pins (3B) until the rst resistance.

Then tighten the second set screw (3B)

against it.