3 of 36

2019-07-16 Service Record Boogie Drive

Table of content

1 Standing aid overview 5

2 General information 6

2.1 General indications 6

2.2 Documentation indications 6

2.3 Required torques and tools 6

2.4 Explanation of symbols 7

2.5 General safety instructions 8

3 Assembly Groups 9

3.1 Assembly Group Wheels 9

3.1.1 Wheel position 9

3.1.2 Camber 10

3.1.3 Sprung back casters 11

3.2 Assembly Group Centre Column 12

3.3 Assembly Group Leg support 14

3.3.1 Food plates standard 14

3.3.2 Setting the angle of the 3D foot

plates 15

3.4 Assembly Group foot shells 16

3.4.1 To shift 16

3.4.2 To displace 16

3.5 Assembly Group Chest truss pad 17

3.5.1 Chest truss pad 17

3.5.2 Side chest truss pas 18

3.6 Assembly Group Pelvis truss pad 19

3.7 Assembly Group Posterior truss pad 20

3.7.1 Posterior truss pad pluggable 20

3.7.2 Side posterior truss pads 20

3.7.3 Truss pad with crank and swivel

bracket 21

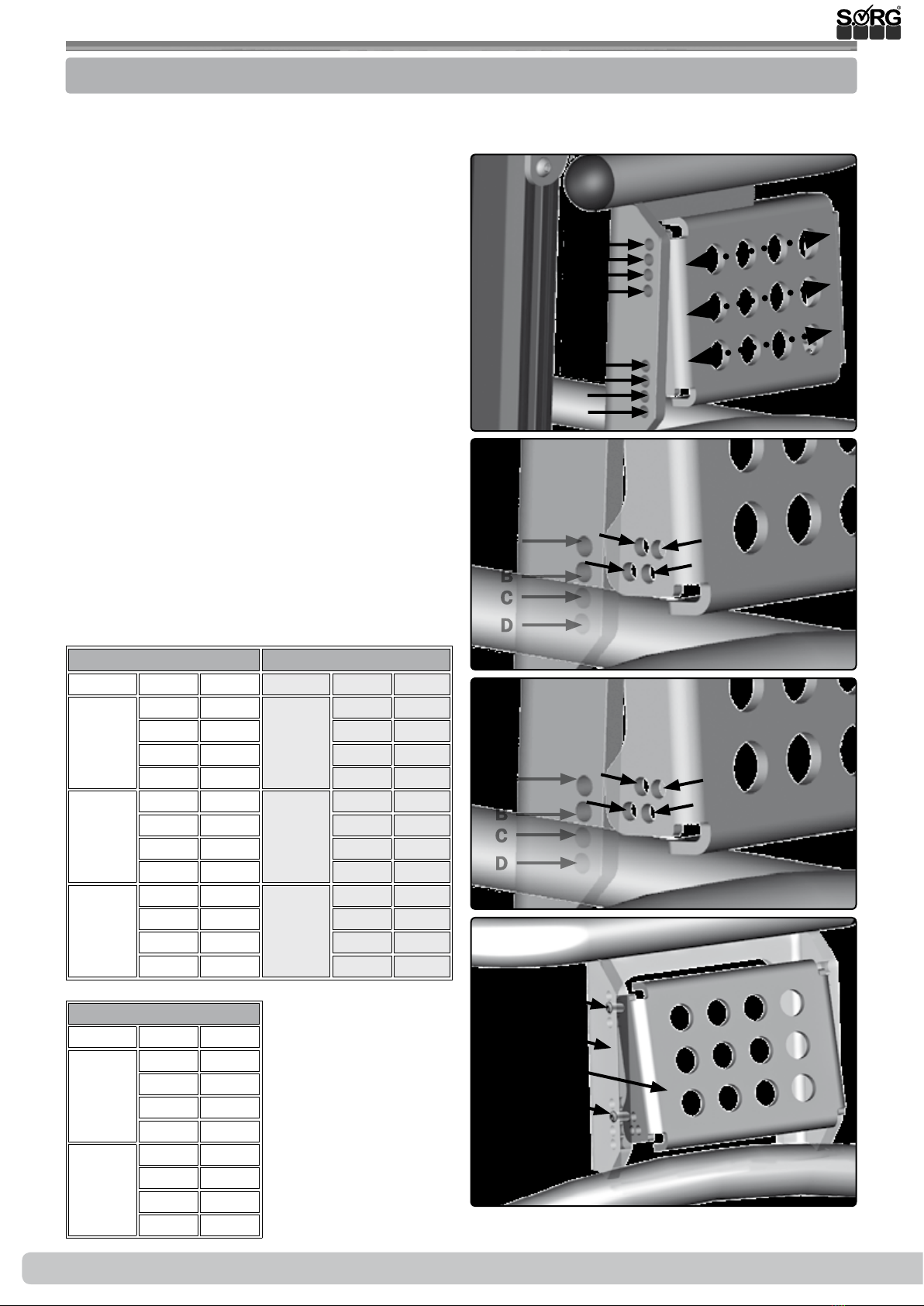

3.8 Assembly Group Back truss pad 22

3.8.1 Back truss pads 22

3.9 Assembly Group Knee truss pad 23

3.9.1 Standard knee truss pad 23

3.9.2

Knee truss pads with resting brackets

24

3.10 Assembly Group Theraphy table 26

3.10.1 Standard mounting 26

3.10.2 Mounting on the chest truss pad

holder 27

3.11 Assembly Group Frame 28

3.11.1 Frame size 1 and 2

(gas pressure spring or telescop) 28

3.11.2 Frame size 3 and 4 (telescop) 28

3.11.3 Frame size 3 and 4 (telescop) 28

3.12 Assembly Group Belt 29

4 Repairs and maintenance 30

4.1 Repairs 30

4.2 Spare parts 30

4.3 Maintenance 30

4.4 Disinfection 30

4.5 Storage 30

4.6 Reinstatement 31

4.7 Disposal 31

4.8 Maintenance/ Inspection 31

5 Technical specications 33

5.1 Data and measurements 33

5.2 Meaning of labels 34

5.3 Declaration of conformity 34