Instructions for use Jump alpha 3 of 48

2019-08-16

Table of Content

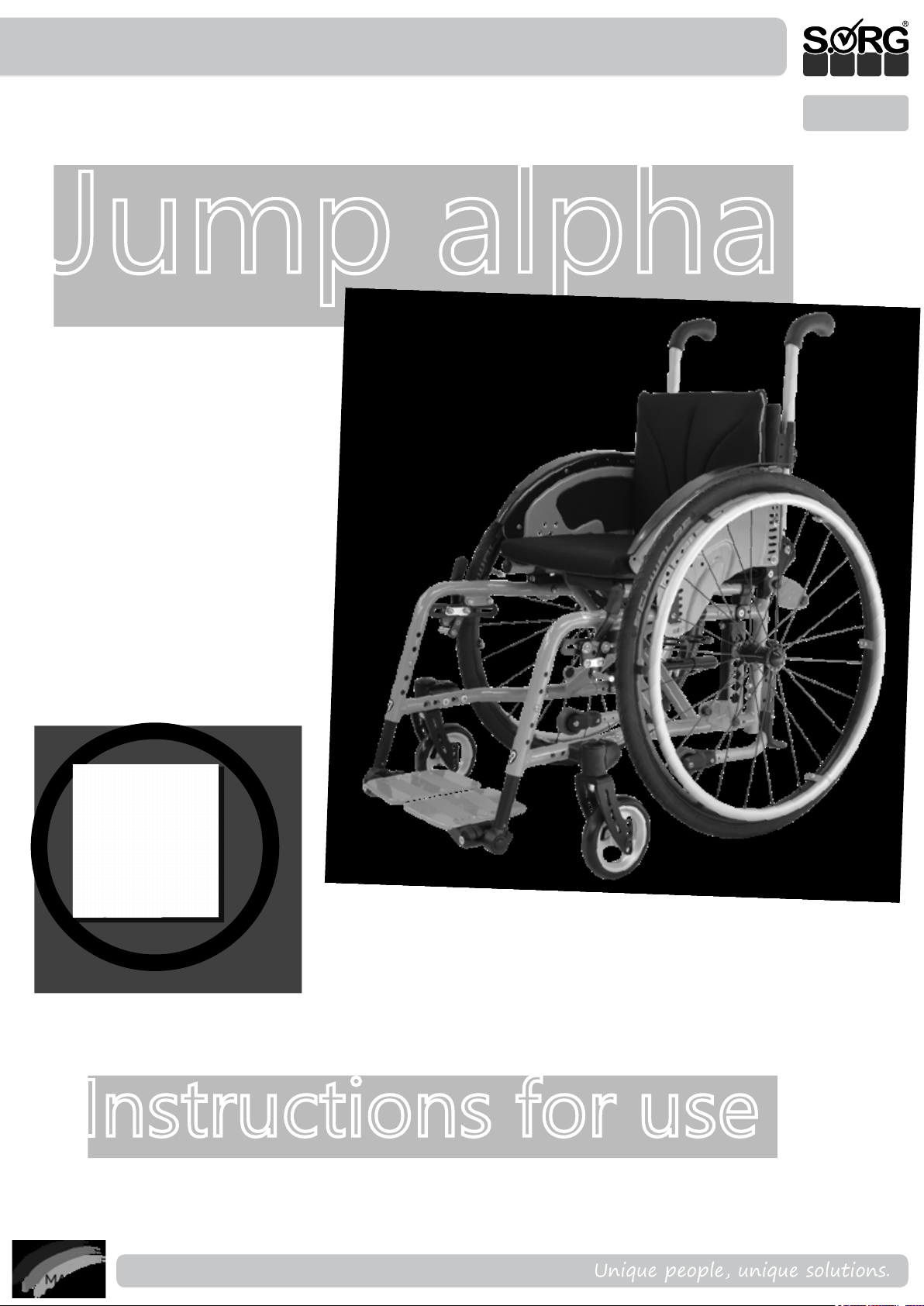

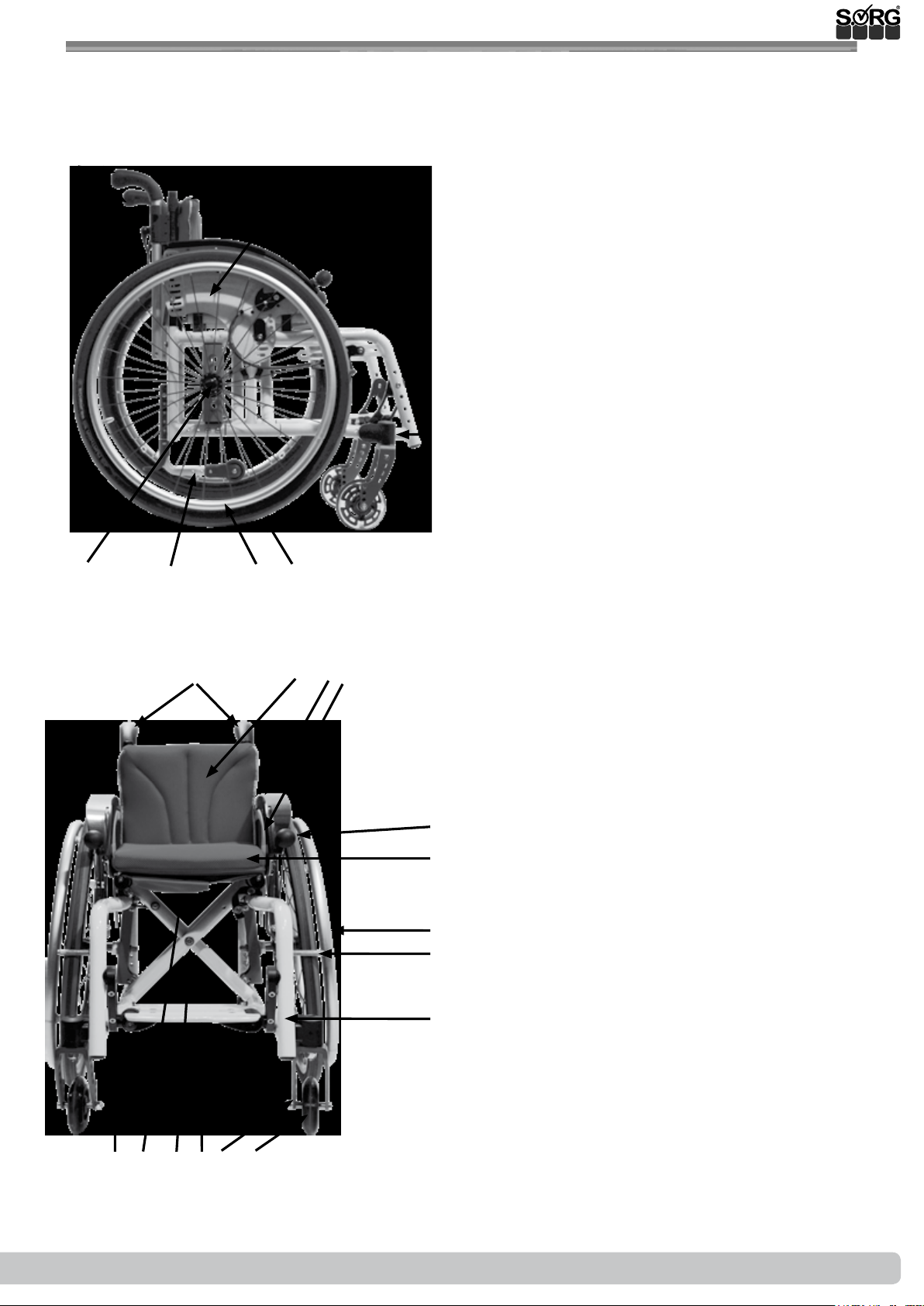

1 Wheelchair overview 5

2 General information 6

2.1 Preface 6

2.2 General information regarding instruc-

tions for use 6

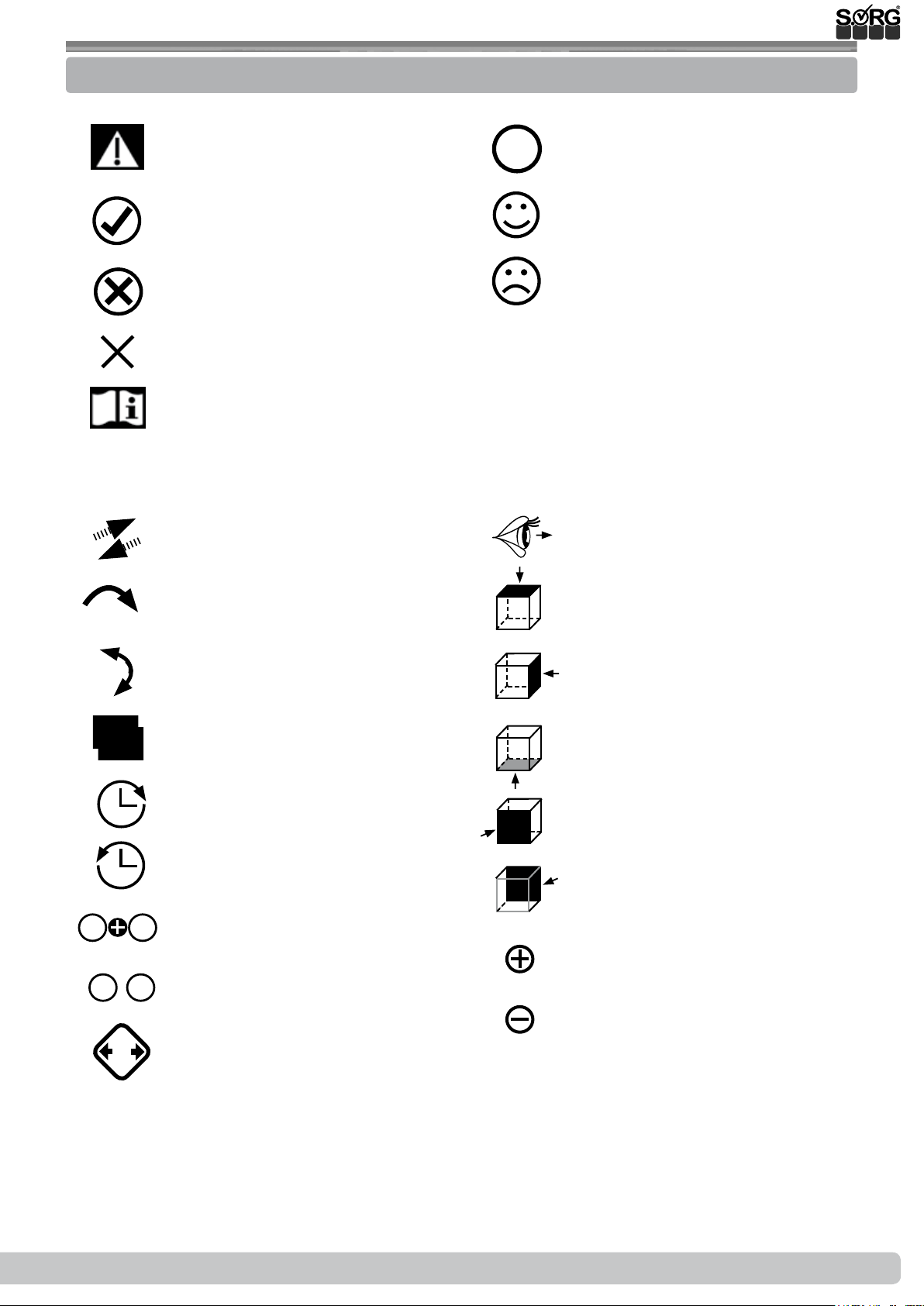

2.2.1 Signs and symbols 7

2.2.2 Intended purpose 8

2.2.3 Indication 8

2.2.4 Contraindication 8

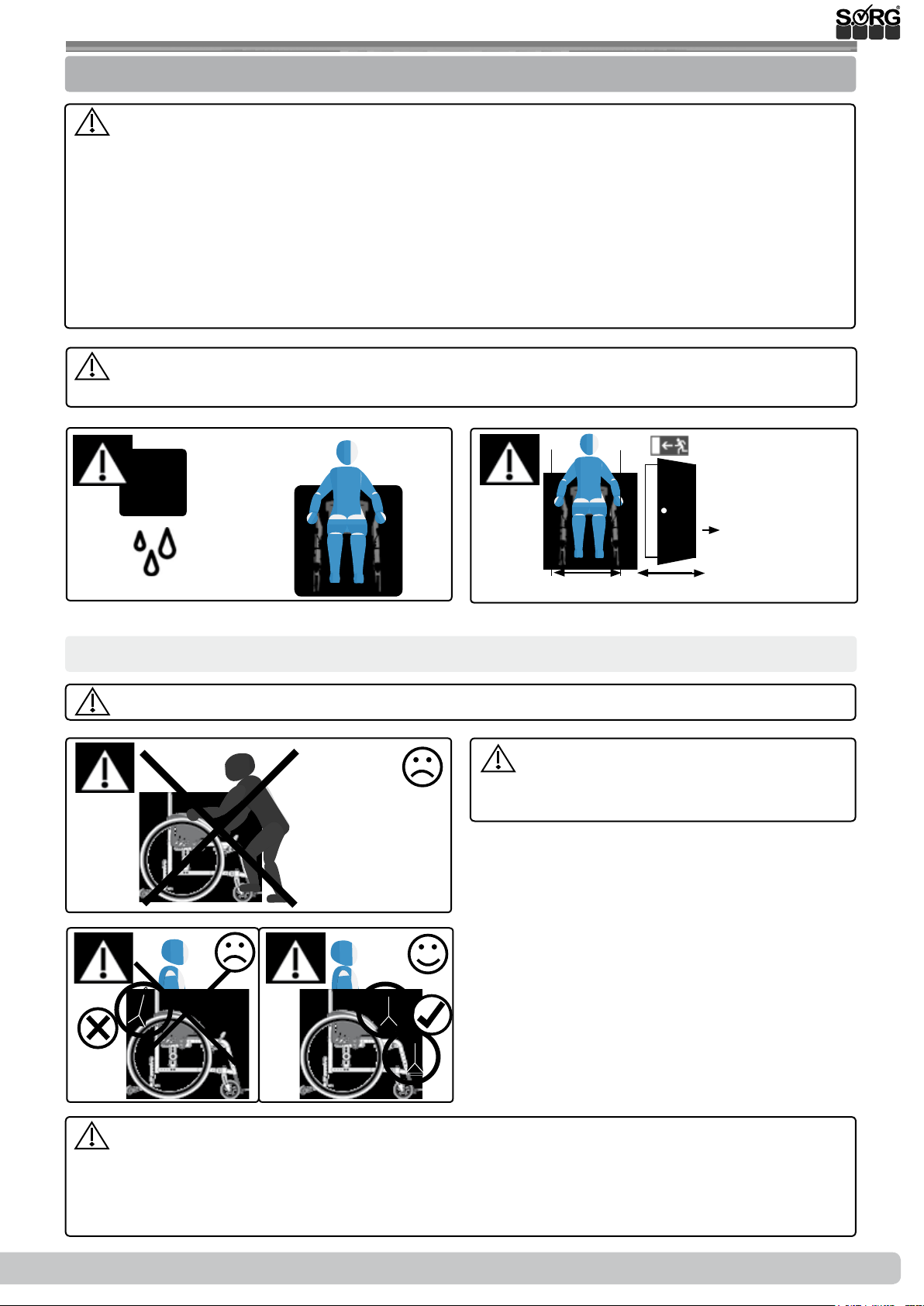

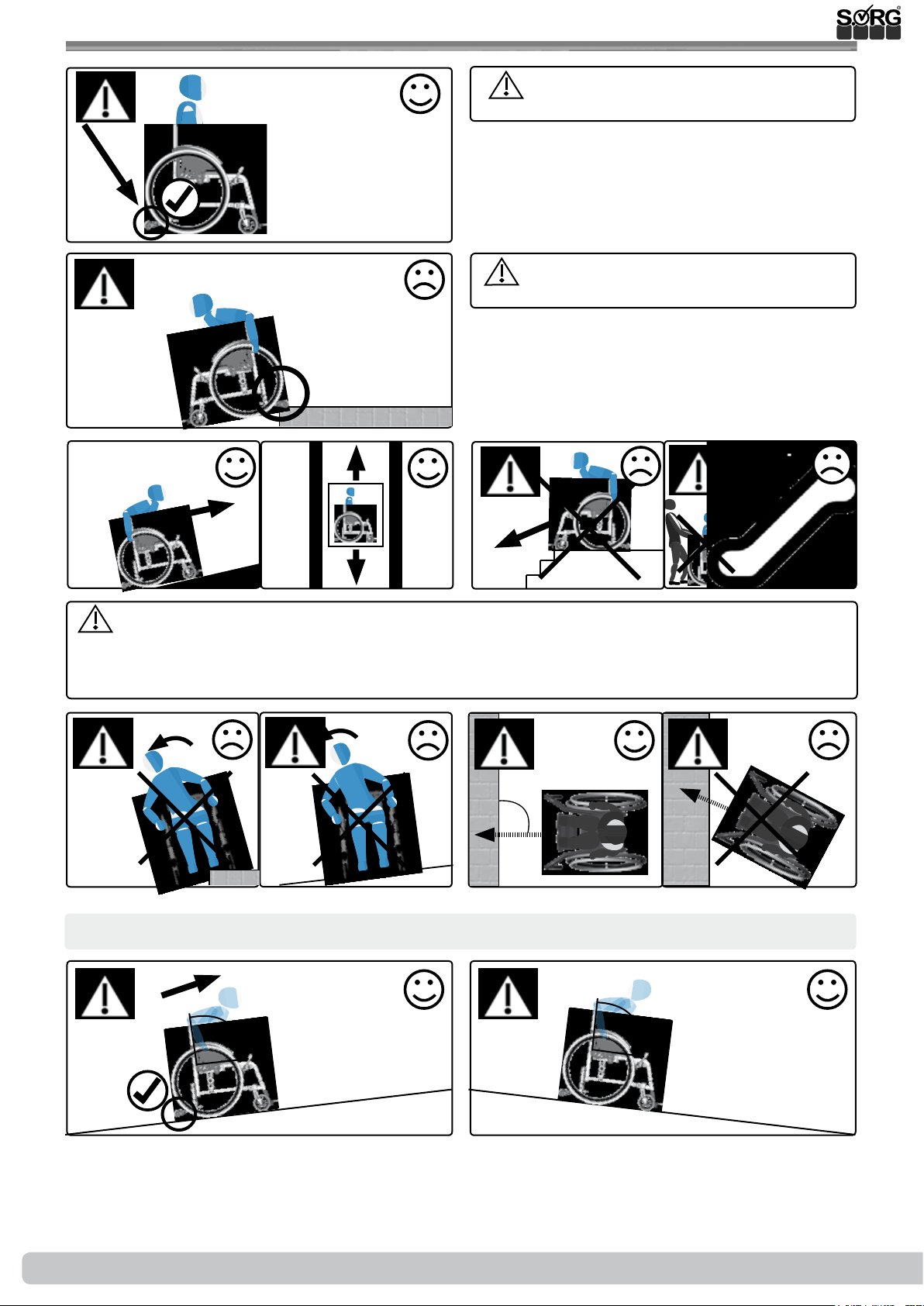

2.3 General safety information 9

2.3.1 Loading and transport without

occupants 11

2.3.2 Transport of the wheelchair with

passengers in the motor vehicle 11

2.3.3 Other important information 13

3 Handling 15

3.1 Handling driving wheel 15

3.1.1 General information regarding wheels 15

3.1.2 Tyre ination pressure 15

3.1.3 Quick-release axles 15

3.1.4 Double hand rim-wheels 16

3.2 Handling swivel caster 17

3.2.1 General information regarding

swivel casters 17

3.2.2 Caster track lock 17

3.3 Handling seat and back 18

3.3.1 General information regarding backs 18

3.3.2 Fixed seat plate (SeatFix) 18

3.3.3 Fixed seat plate with locking

mechanism (SeatFix) 19

3.3.4 Firm curved back plate 20

3.3.5 Back with raster 21

3.3.6 Back with gas pressure spring 22

3.3.7 Back extension 22

3.4 Handling: folding up and

unfolding 23

3.4.1 General information regarding

folding up and unfolding 23

3.4.2 of seat and back cover 24

3.4.3 of SeatFix and/or rm curved

back plate 25

3.5 Handling pushing aid 26

3.5.1 General information regarding

pushing aids 26

3.5.2 Push handles 27

3.5.3 Handle bar 28

3.6 Handling leg support 29

3.6.1 General information regarding

leg supports 29

3.6.2 Foldable footrest with

locking mechanism 30

3.7 Handling brake 31

3.7.1 General information regarding

brakes 31

3.7.2 Wheel lock 31

3.7.3 Drum brake 33

3.7.4 Reverse-roll locking 33

3.8 Handling anti-tipper 34

3.8.1 General information regarding

anti-tipper 34

3.9 Handling headrest 35

3.9.1 General information regarding

headrest 35

3.10 Handling abduction wedge 36

3.10.1 General information regarding

abduction wedge 36

3.11 Handling therapy table 37

3.11.1 General information regarding

therapy table 37

3.12 Handling lateral truss pad 37

3.12.1 General information regarding

lateral truss pad 37

3.13 Handling steering & pushing aid 38

3.13.1 General information regarding

steering and pushing aids 38

3.14 Handling one-hand steering aid 39

3.14.1 General information regarding

one-hand steering aid 39

3.15 Handling sun shade 41

3.15.1 General information regarding

sun shade 41

4 Repairs and maintenance 42

4.1 Repairs 42

4.2 Spare parts 42

4.3 Maintenance 42

4.4 Disinfection 42

4.5 Storage 42

4.6 Reinstatement 43

4.7 Disposal 43

4.8 Maintenance/ inspection 43

5 Technical data 45

5.1 Data and measurements 45

5.2 Meaning of labels 46

5.3 Declaration of conformity 46

6 Verication of yearly inspection 47