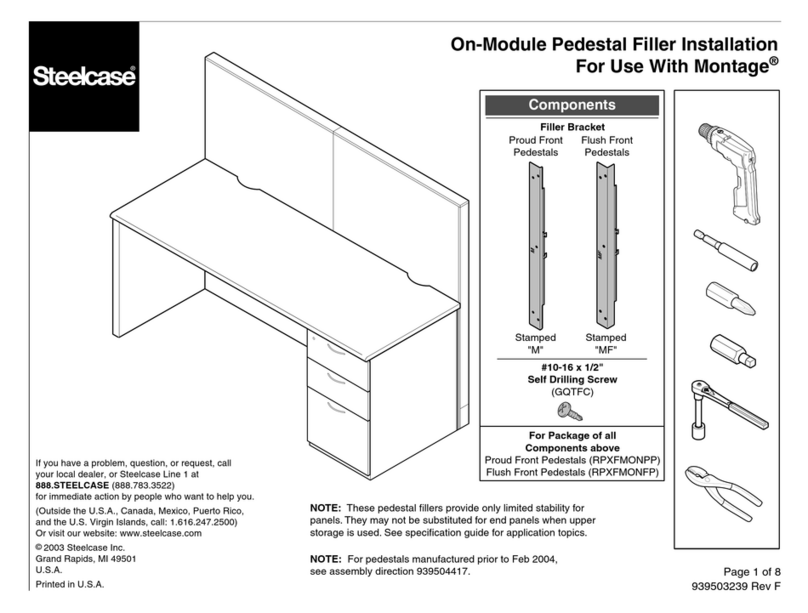

Steelcase Elective Elements Freestanding Worksurface User manual

Other Steelcase Indoor Furnishing manuals

Steelcase

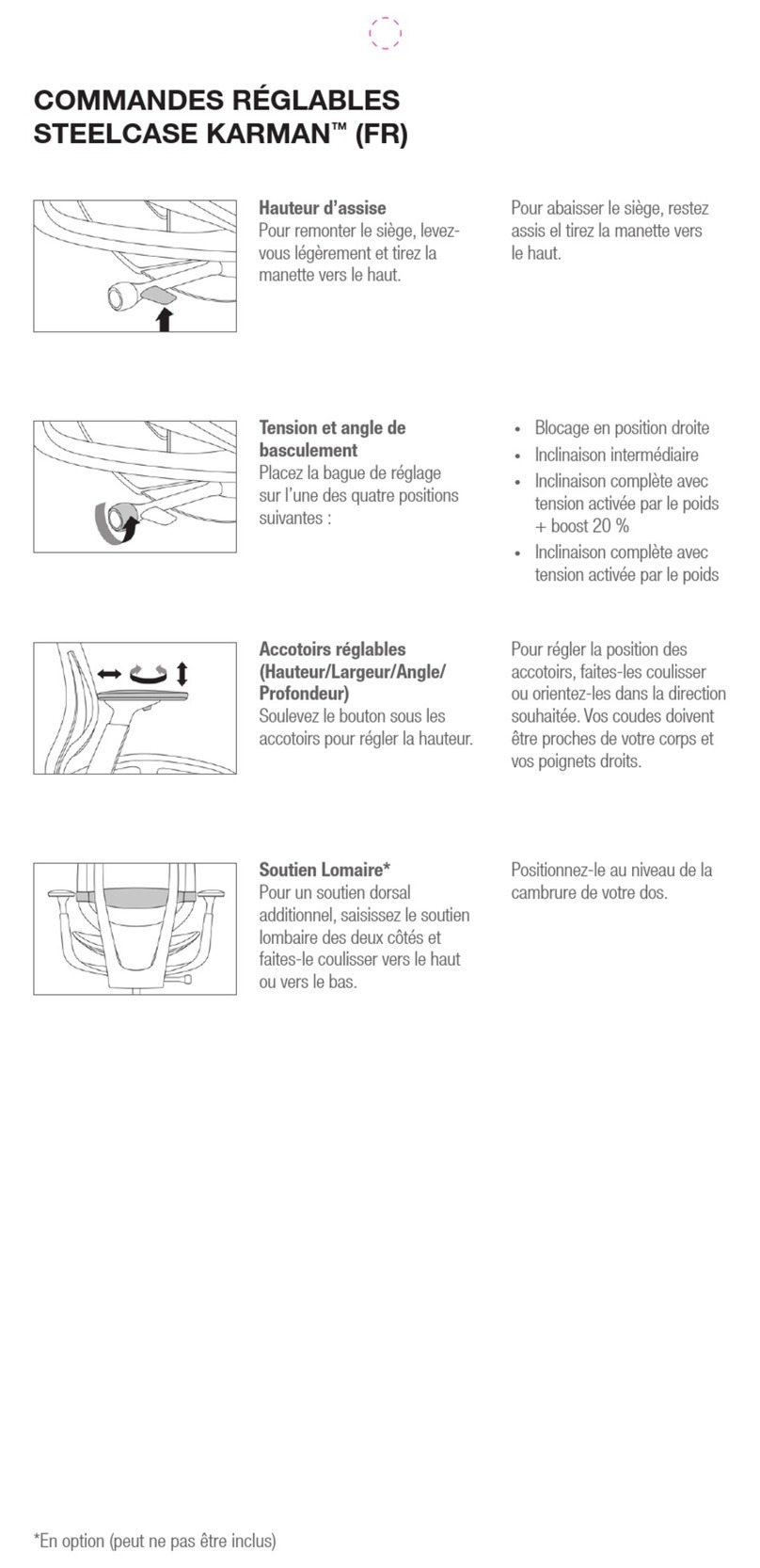

Steelcase Karman User manual

Steelcase

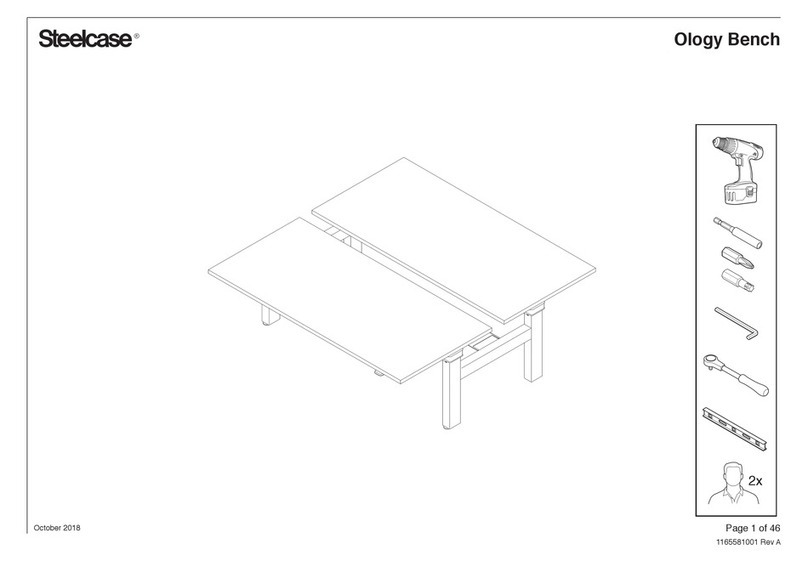

Steelcase Ology User manual

Steelcase

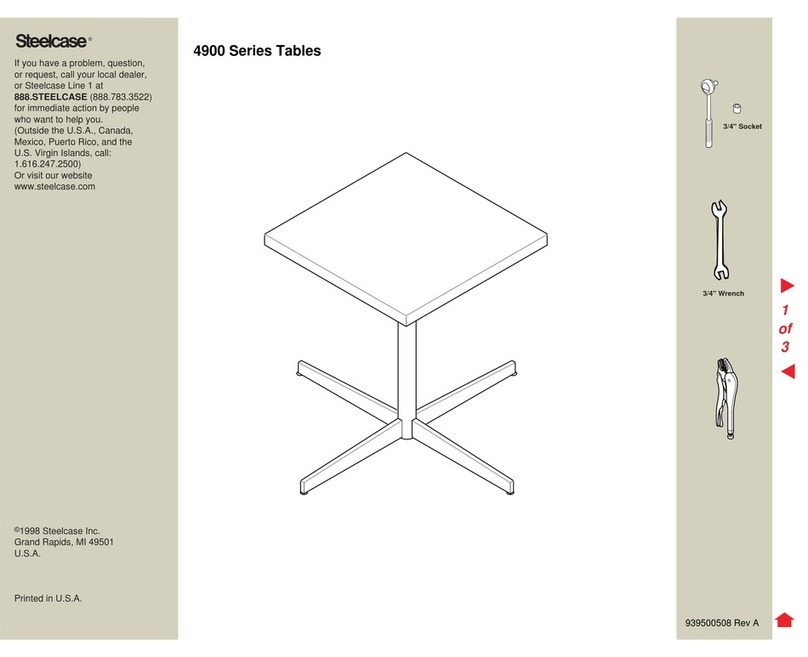

Steelcase 4900 Series User manual

Steelcase

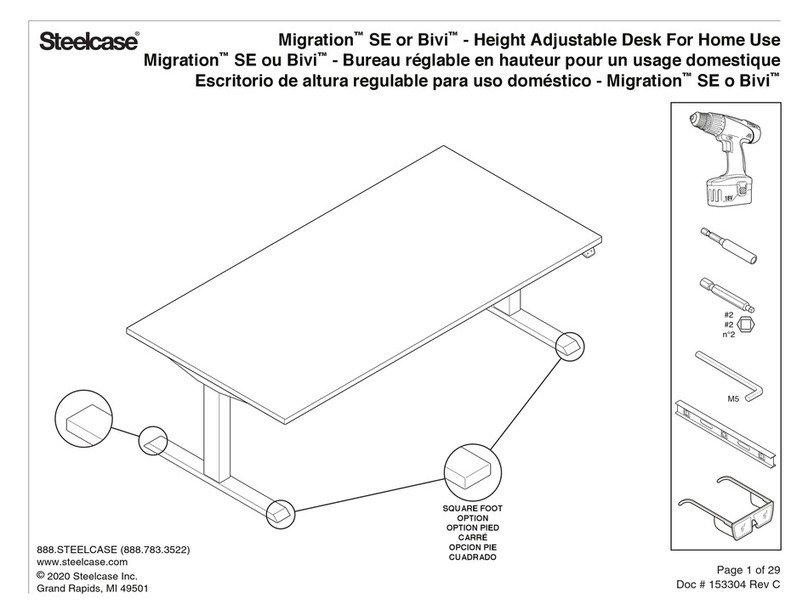

Steelcase Migration SE User manual

Steelcase

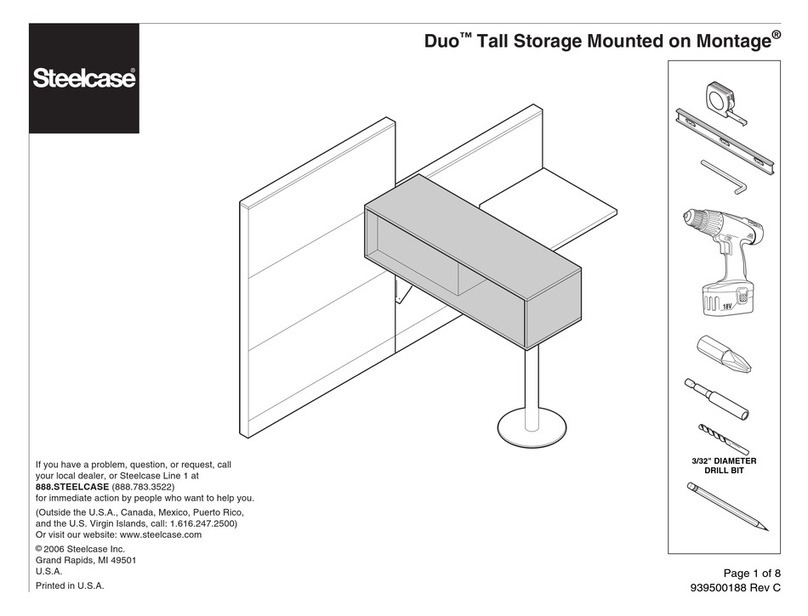

Steelcase Duo Tall Storage Mounted on Montage User manual

Steelcase

Steelcase Flex Series User manual

Steelcase

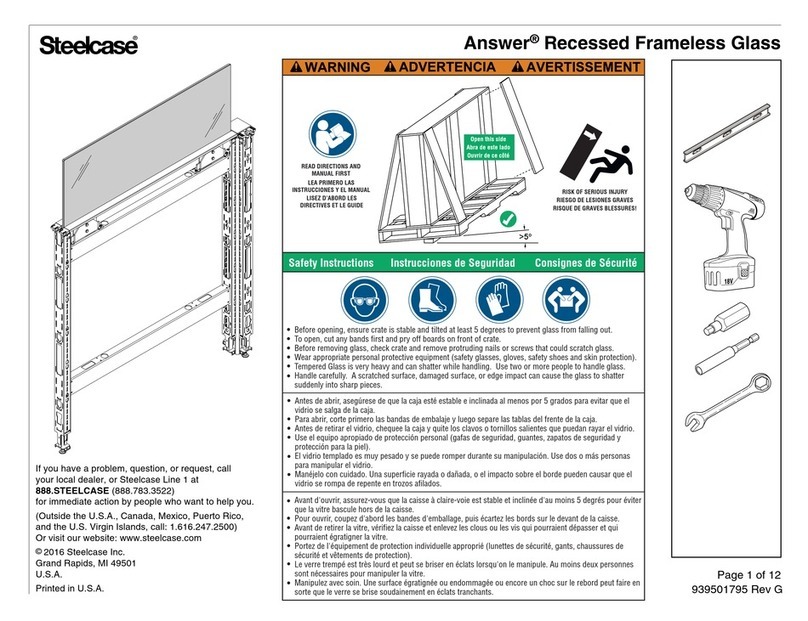

Steelcase Answer User manual

Steelcase

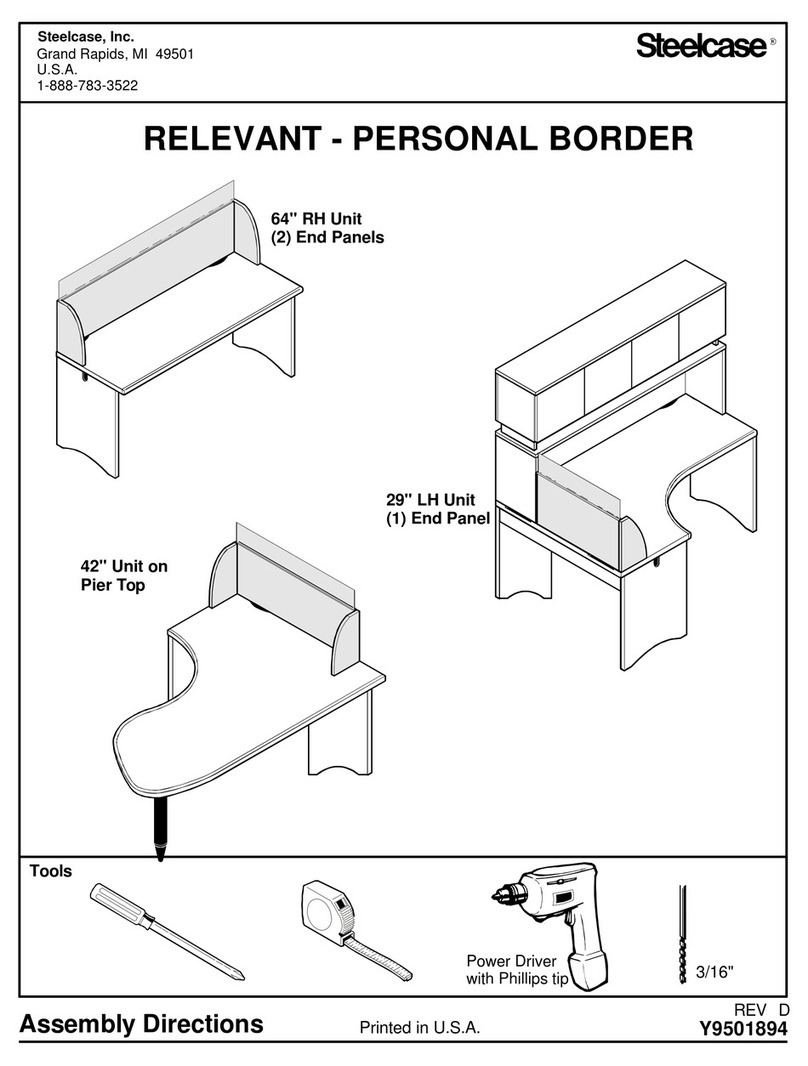

Steelcase RELEVANT PERSONAL BORDER 64" RH Unit End... Firmware update

Steelcase

Steelcase FrameOne Plus User manual

Steelcase

Steelcase Migration SE Installation instructions

Steelcase

Steelcase Think 465 User manual

Steelcase

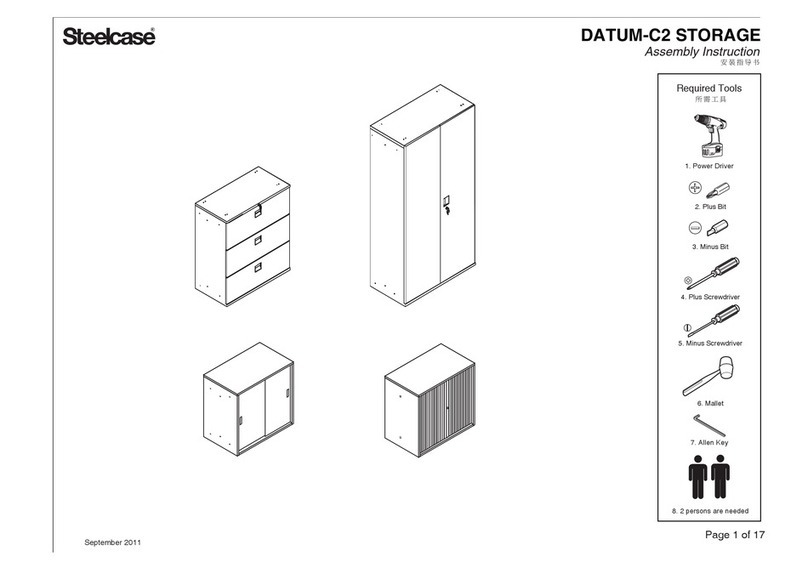

Steelcase DATUM-C2 User manual

Steelcase

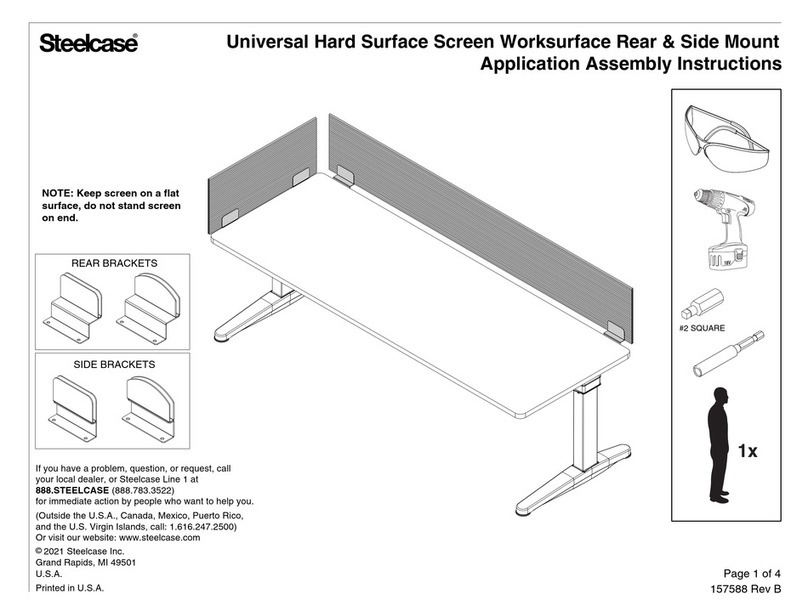

Steelcase Universal Hard Surface Screen User manual

Steelcase

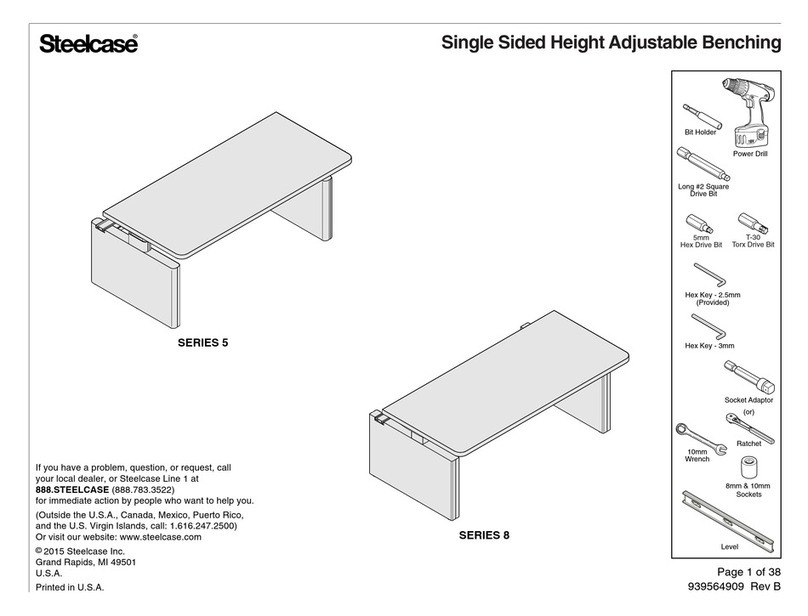

Steelcase SERIES 8 User manual

Steelcase

Steelcase Ology User manual

Steelcase

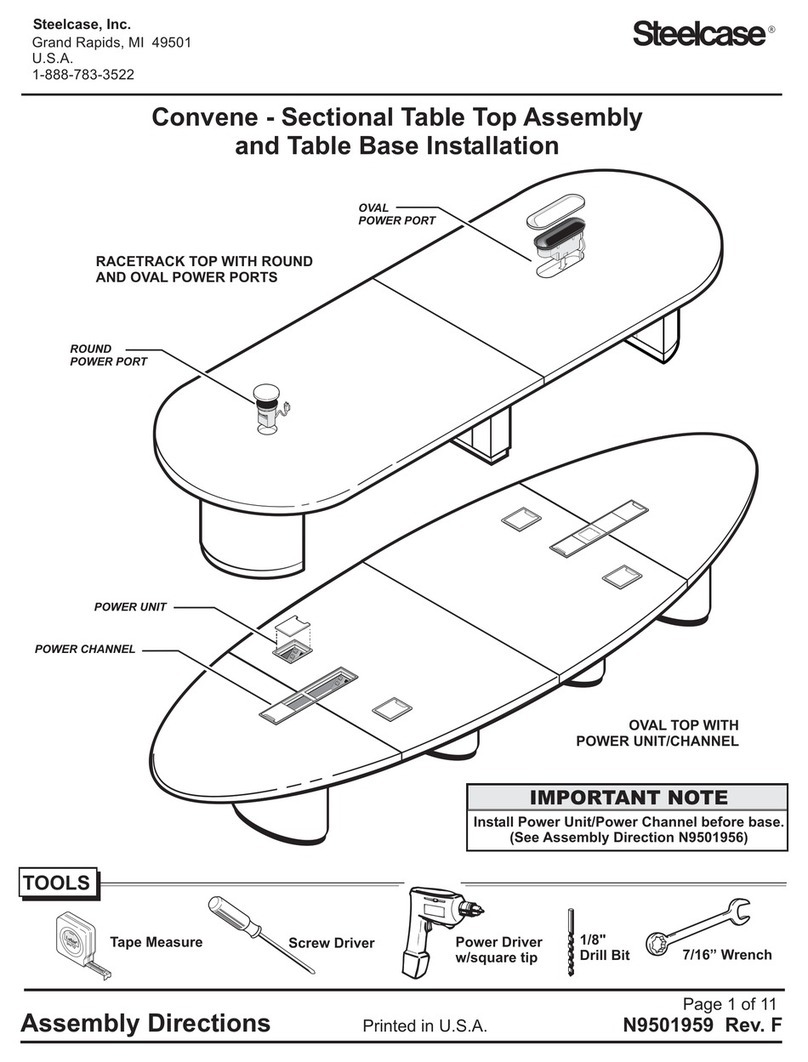

Steelcase Convene User manual

Steelcase

Steelcase IMPACT Firmware update

Steelcase

Steelcase Leap User manual

Steelcase

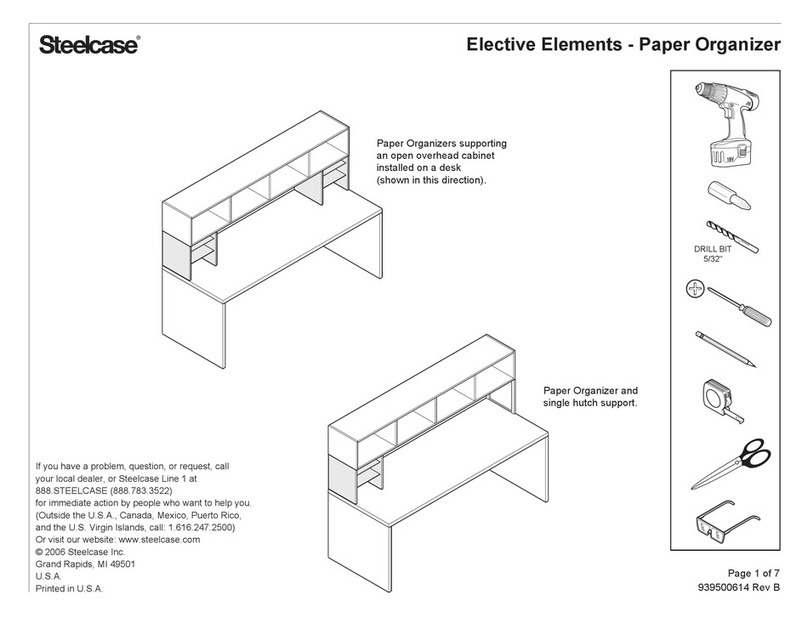

Steelcase Elective Elements Paper Organizer User manual

Steelcase

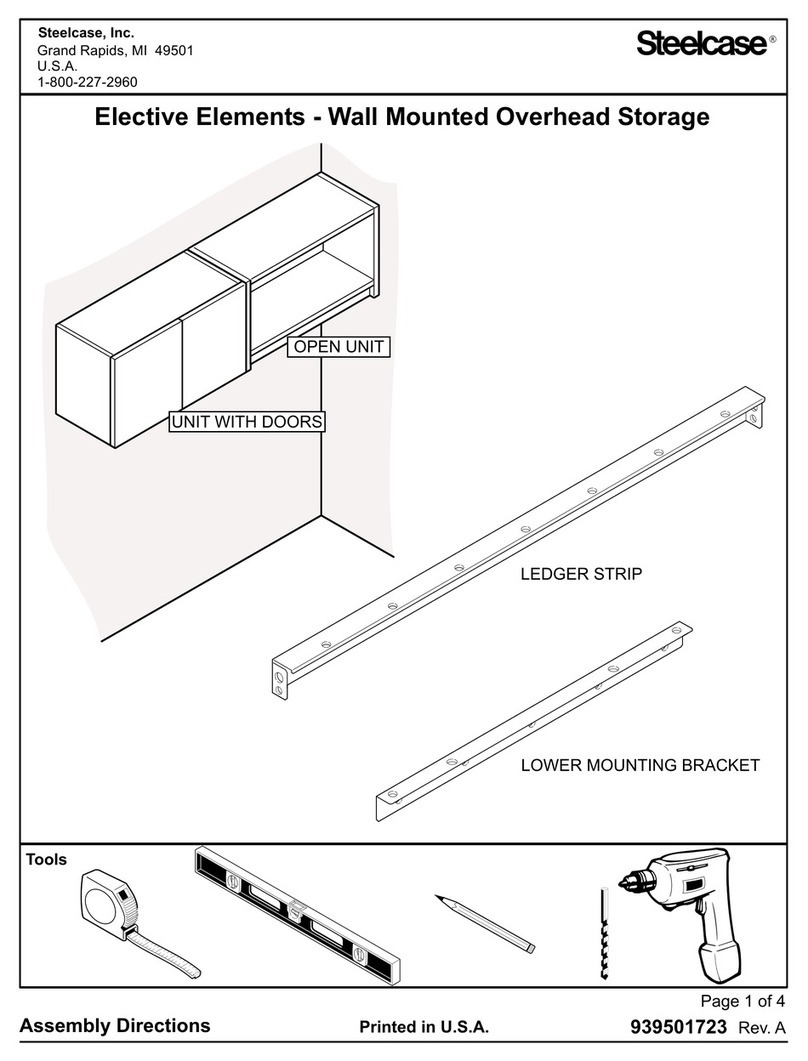

Steelcase 939501723 Firmware update

Popular Indoor Furnishing manuals by other brands

Coaster

Coaster 4799N Assembly instructions

Stor-It-All

Stor-It-All WS39MP Assembly/installation instructions

Lexicon

Lexicon 194840161868 Assembly instruction

Next

Next AMELIA NEW 462947 Assembly instructions

impekk

impekk Manual II Assembly And Instructions

Elements

Elements Ember Nightstand CEB700NSE Assembly instructions