V.I.A.™V2 Captured Glass

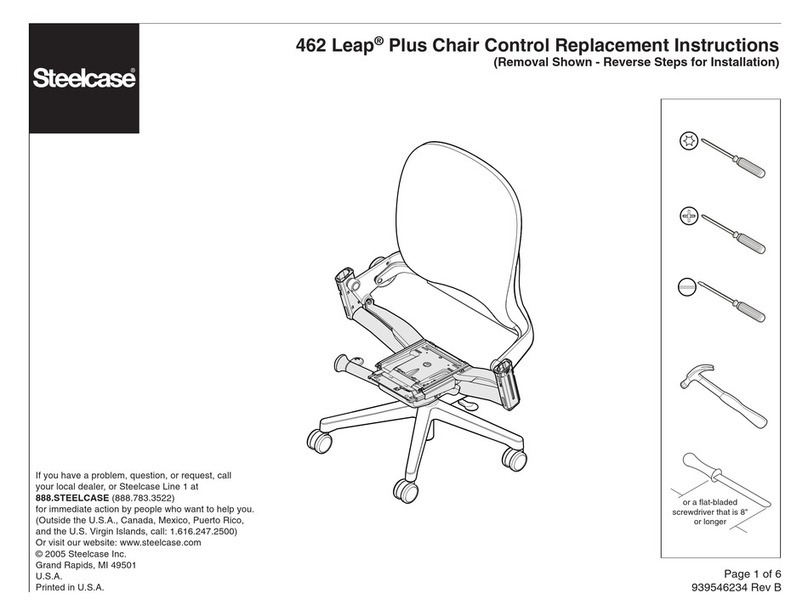

If you have a problem, question, or request, call

your local dealer, or Steelcase Line 1 at

888.STEELCASE(888.783.3522)

for immediate action by people who want to help you.

(Outside the U.S.A., Canada, Mexico, Puerto Rico,

and the U.S. Virgin Islands, call: 1.616.247.2500)

Or visit our website: www.steelcase.com

©2015 Steelcase Inc.

Grand Rapids, MI 49501

U.S.A.

Printed in U.S.A.

®

Page 1 of 13

939502344 Rev D

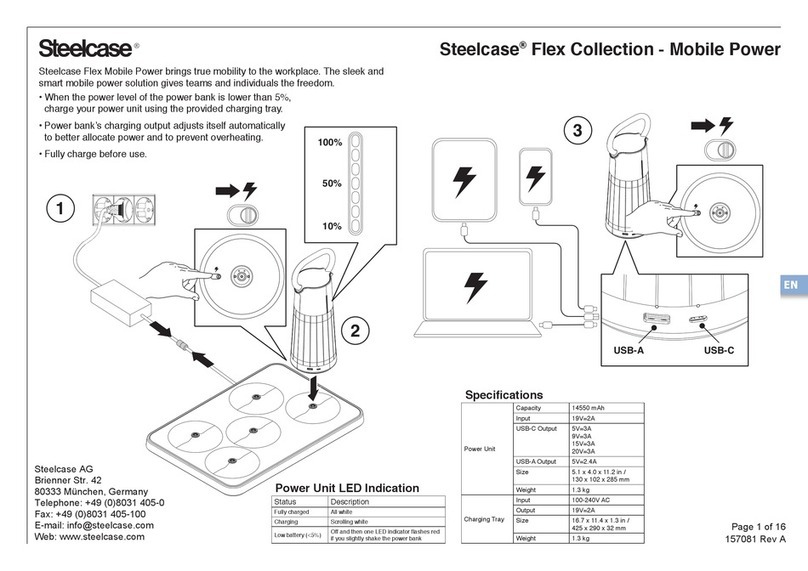

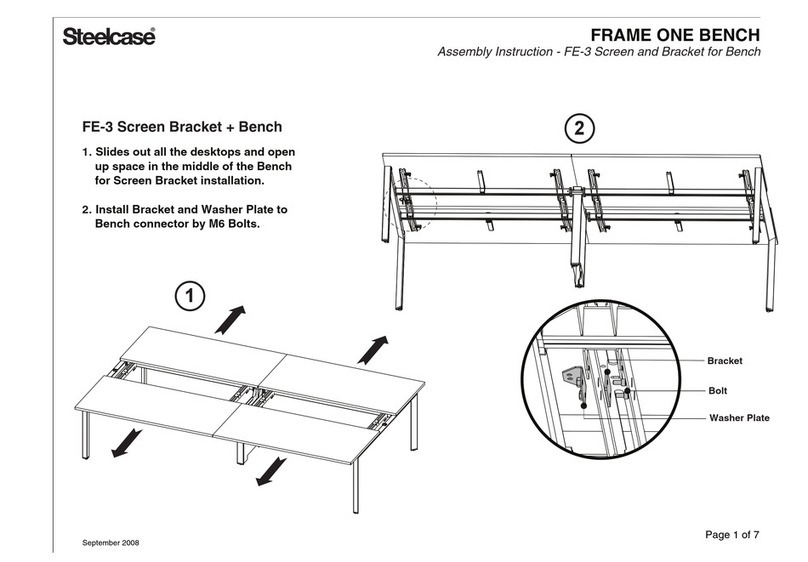

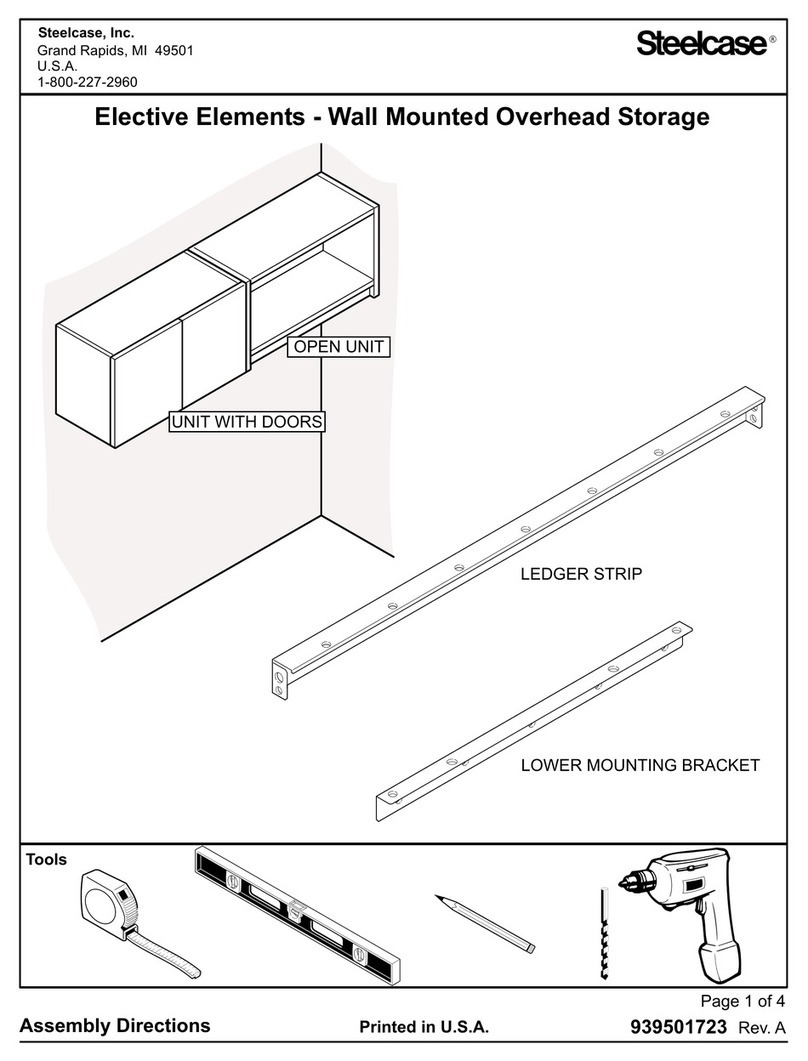

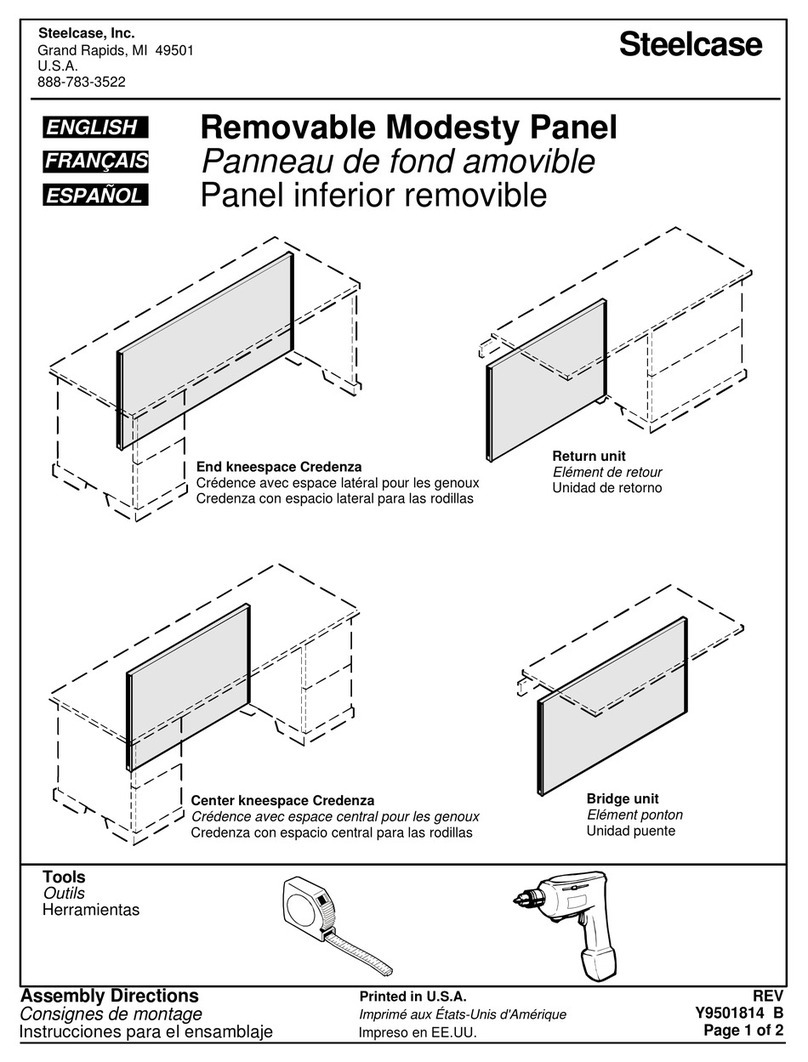

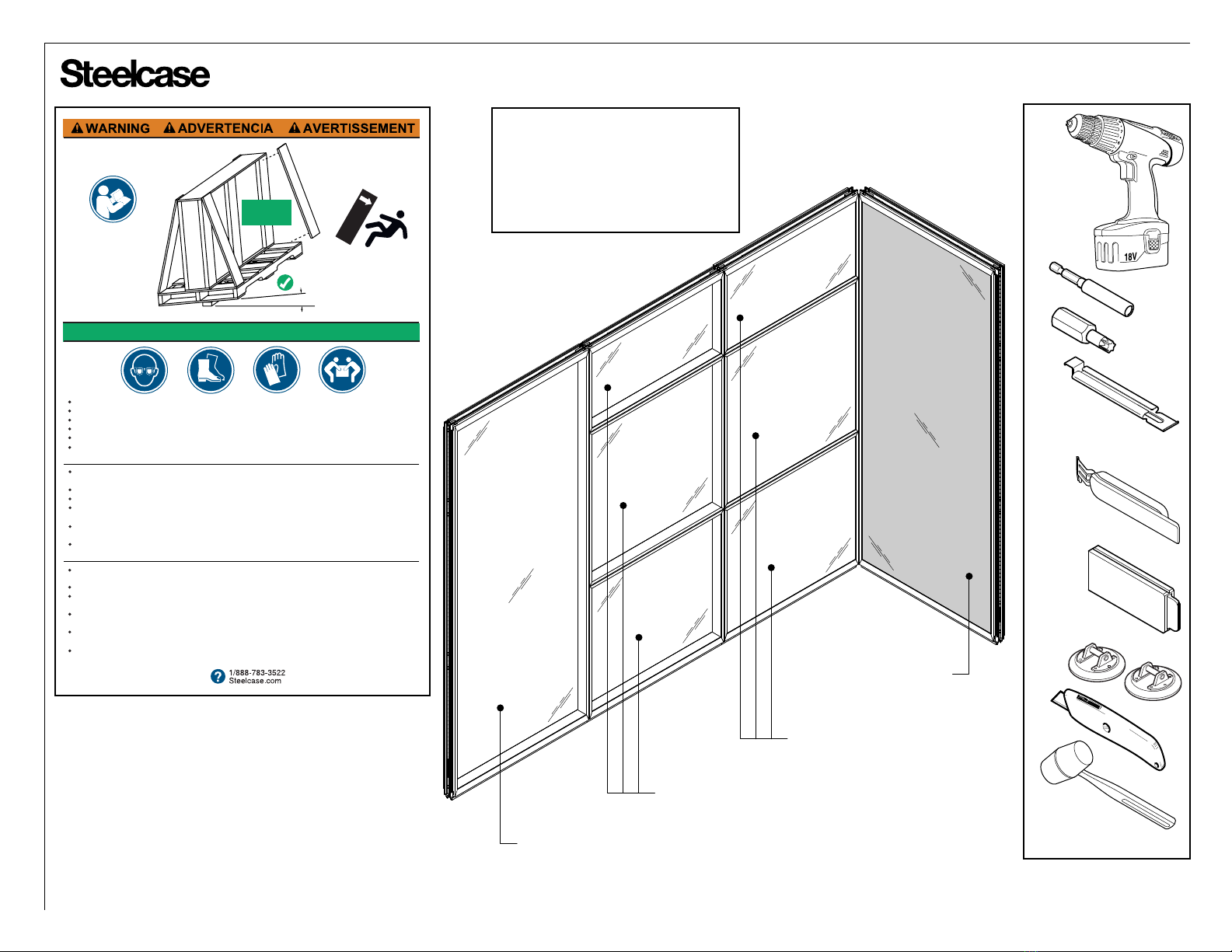

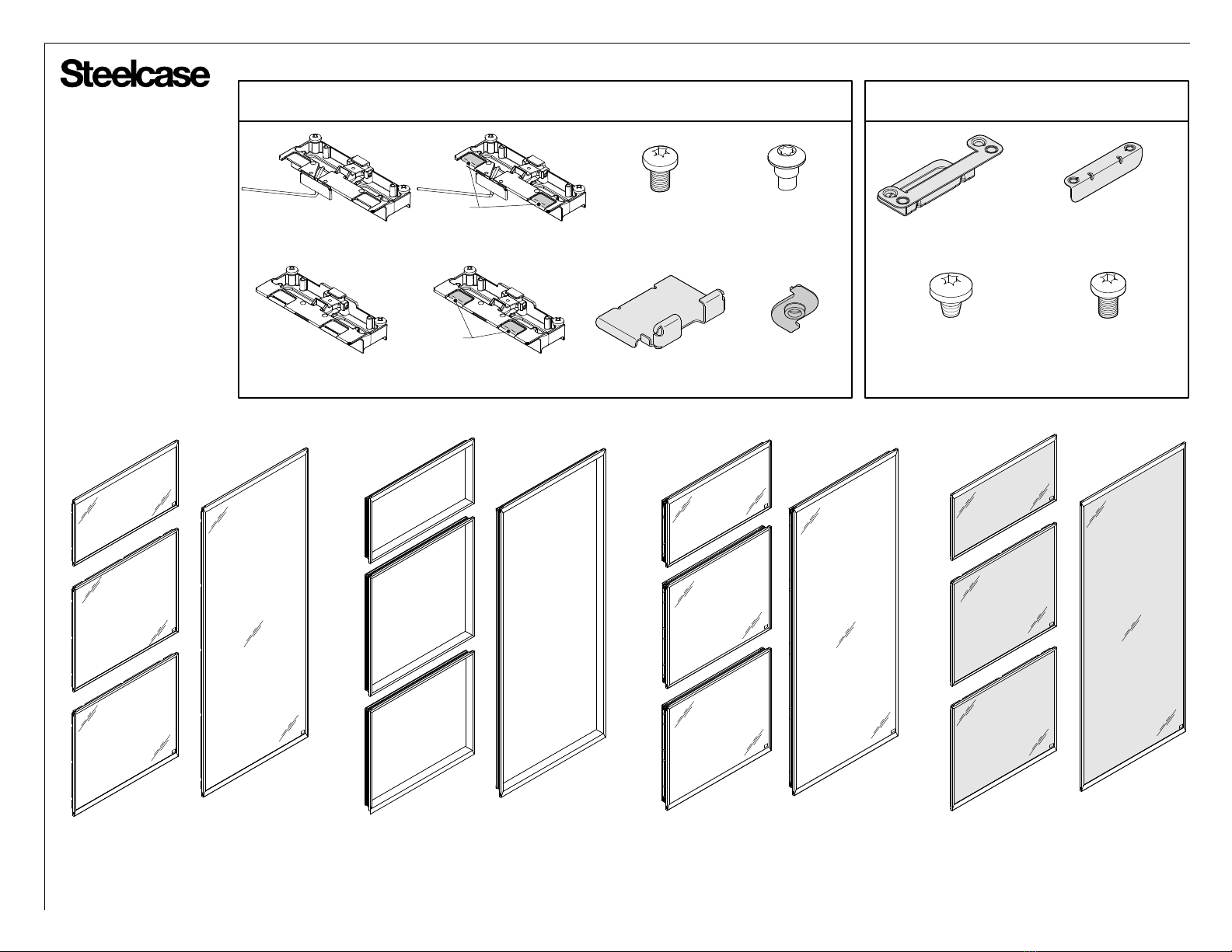

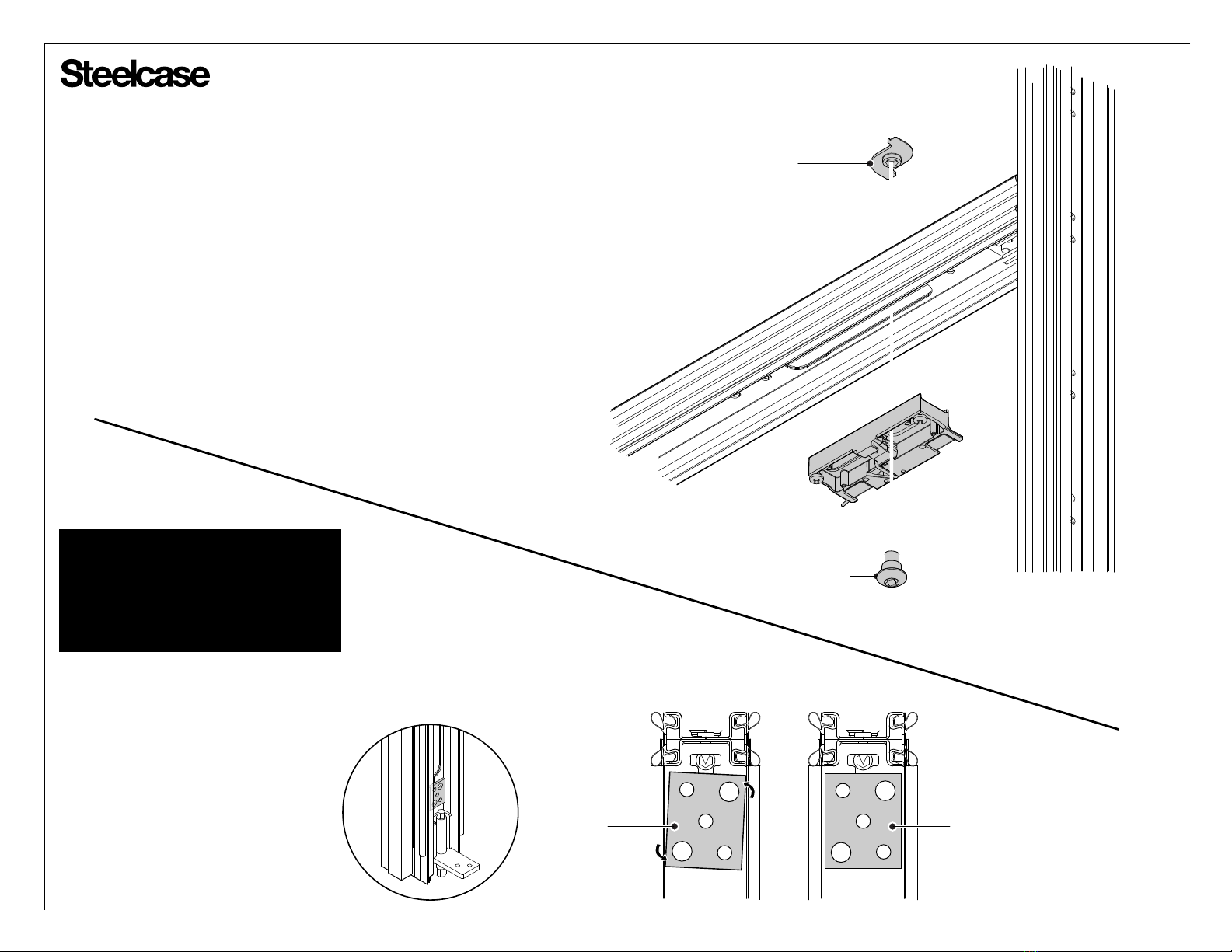

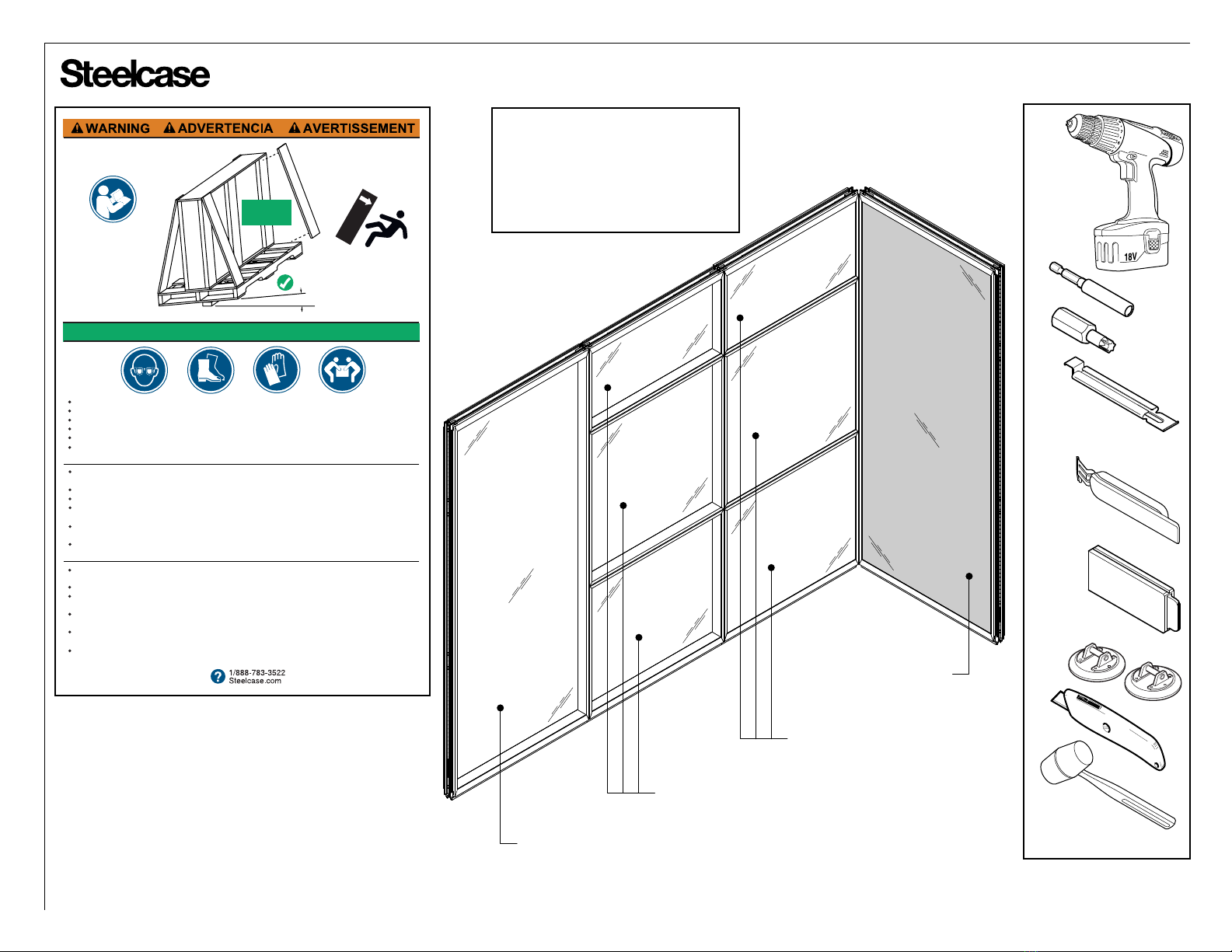

SINGLE-SIDED

GLASS MONOLITHIC

DOUBLE-SIDED GLASS

BACK PAINTED

GLASS MONOLITHIC

T-20 & T-30

TRIM AND

GLASS TOOL

SINGLE-SIDED GLASS

SKIN

REMOVAL TOOL

CAPTURED GLASS

TRIM TOOL

NON-MARKING

SOFT MALLET

IMPORTANT NOTE: When

installing Double Glazed

Frames, see page 7 for

critical information related

to acoustic seals.

Avant d'ouvrir, assurez-vous que la caisse à claire-voie est stable et inclinée d'au moins 5 degrés pour éviter

que la vitre bascule hors de la caisse.

Pour ouvrir, coupez d'abord les bandes d'emballage, puis écartez les bords sur le devant de la caisse.

Avant de retirer la vitre, vérifiez la caisse et enlevez les clous ou les vis qui pourraient dépasser et qui

pourraient égratigner la vitre.

Portez de l'équipement de protection individuelle approprié (lunettes de sécurité, gants, chaussures de

sécurité et vêtements de protection).

Le verre trempé est très lourd et peut se briser en éclats lorsqu'on le manipule. Au moins deux personnes

sont nécessaires pour manipuler la vitre.

Manipulez avec soin. Une surface égratignée ou endommagée ou encore un choc sur le rebord peut faire en

sorte que le verre se brise soudainement en éclats tranchants.

Antes de abrir, asegúrese de que la caja esté estable e inclinada al menos por 5 grados para evitar que el

vidrio se salga de la caja.

Para abrir, corte primero las bandas de embalaje y luego separe las tablas del frente de la caja.

Antes de retirar el vidrio, chequee la caja y quite los clavos o tornillos salientes que puedan rayar el vidrio.

Use el equipo apropiado de protección personal (gafas de seguridad, guantes, zapatos de seguridad y

protección para la piel).

El vidrio templado es muy pesado y se puede romper durante su manipulación. Use dos o más personas

para manipular el vidrio.

Manéjelo con cuidado. Una superficie rayada o dañada, o el impacto sobre el borde pueden causar que el

vidrio se rompa de repente en trozos afilados.

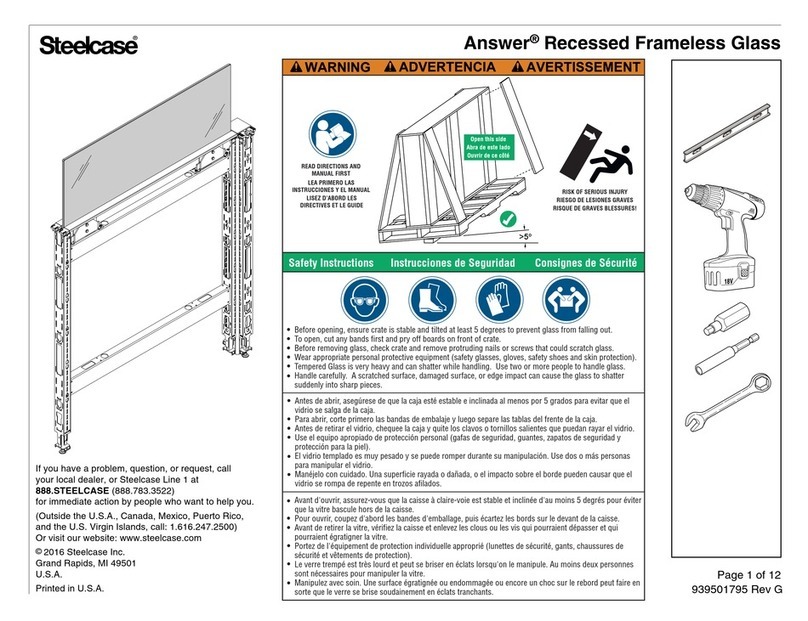

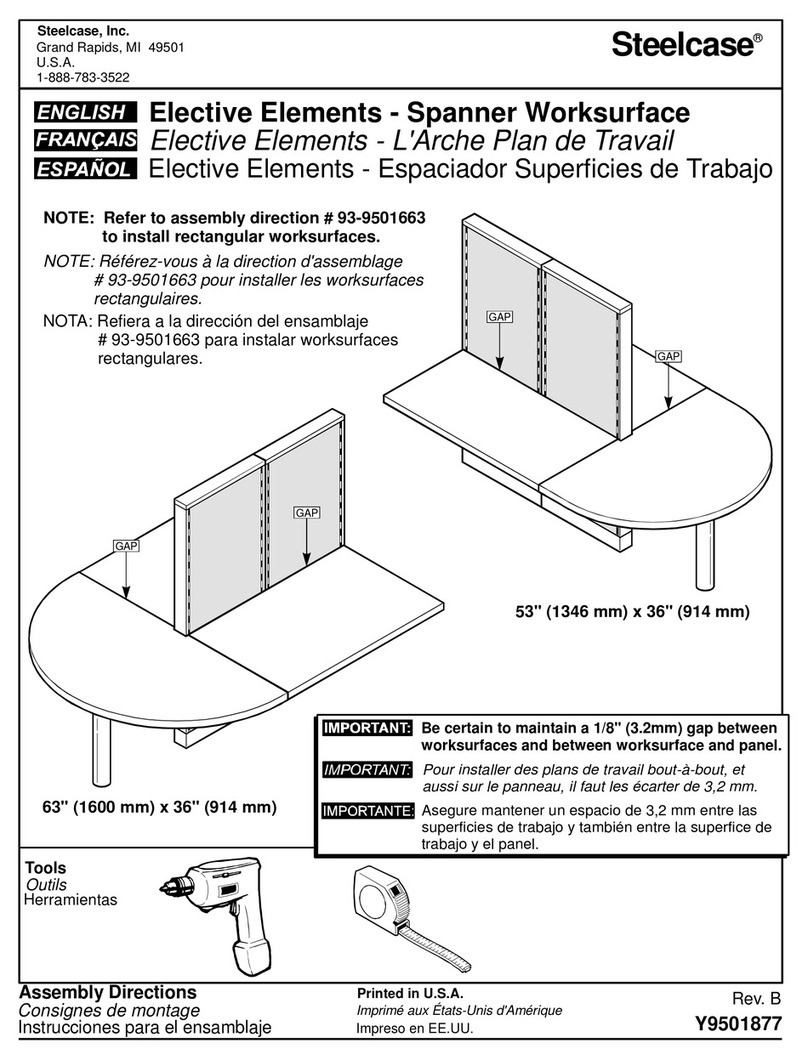

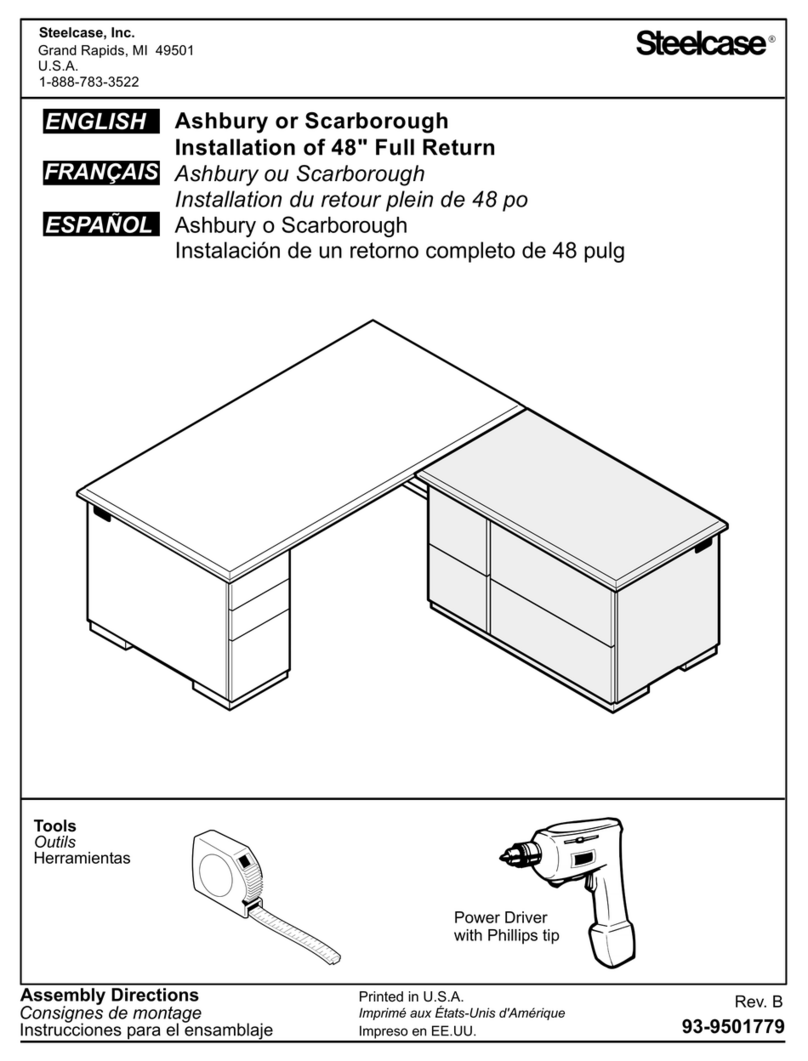

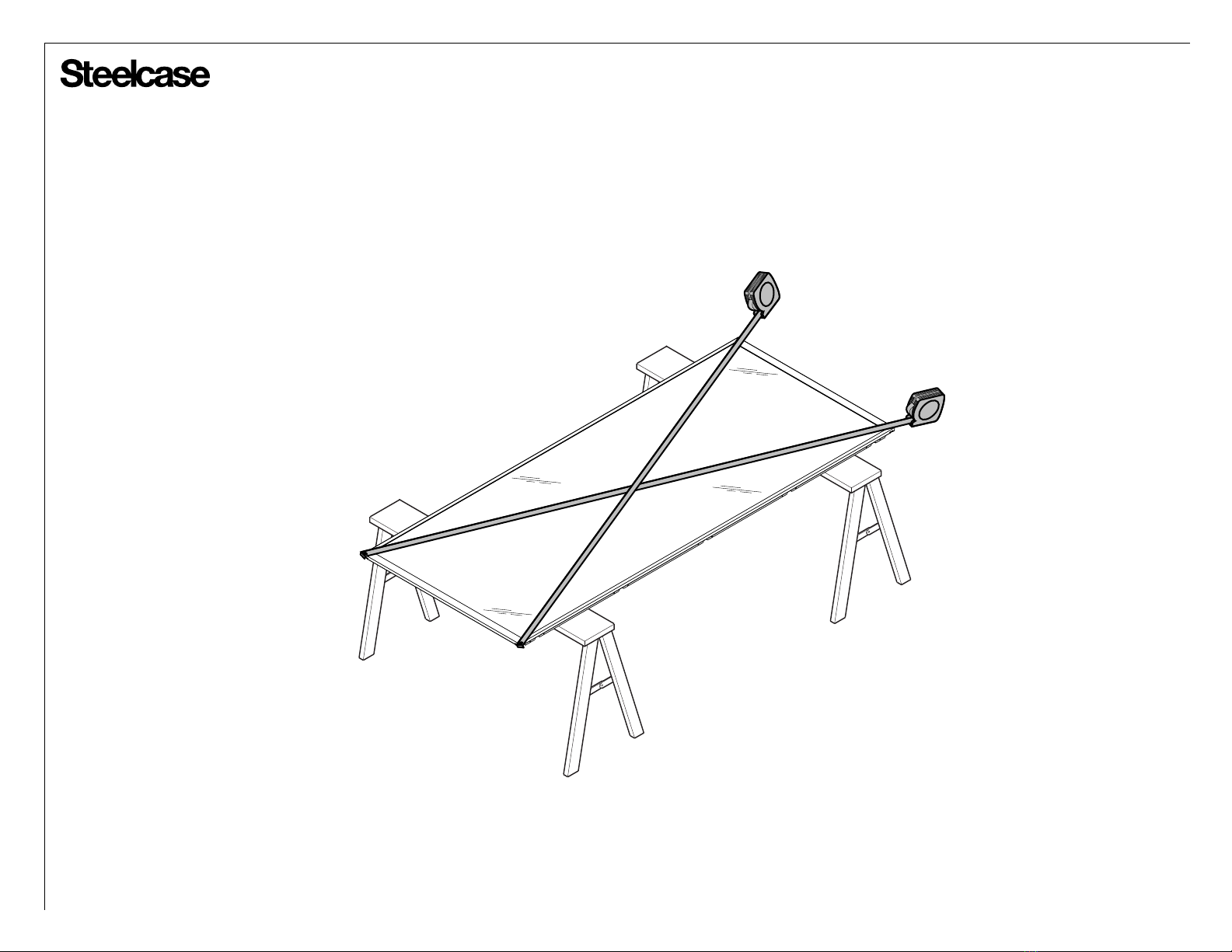

Before opening, ensure crate is stable and tilted at least 5 degrees to prevent glass from falling out.

To open, cut any bands first and pry off boards on front of crate.

Before removing glass, check crate and remove protruding nails or screws that could scratch glass.

Wear appropriate personal protective equipment (safety glasses, gloves, safety shoes and skin protection).

Tempered Glass is very heavy and can shatter while handling. Use two or more people to handle glass.

Handle carefully. A scratched surface, damaged surface, or edge impact can cause the glass to shatter

suddenly into sharp pieces.

Safety Instructions Instrucciones de Seguridad Consignes de Sécurité

RISK OF SERIOUS INJURY

RIESGO DE LESIONES GRAVES

RISQUE DE GRAVES BLESSURES!

>5º

READ DIRECTIONS AND

MANUAL FIRST

LEA PRIMERO LAS

INSTRUCCIONES Y EL MANUAL

LISEZ D’ABORD LES

DIRECTIVES ET LE GUIDE

Open this side

Abra de este lado

Ouvrir de ce côté