Sterling Power Pro Batt Ultra User manual

Sterling Power Products

Copyright

STERLI G

POWER

Pro Batt Ultra

Copyright © 2020

Sterling Power

December 2020 V4

BBS1230 - New to 2020

battery temp

sensor

TSAY

USERS MANUAL.

Sterling Power Products

H Charge Float

In / Unit Out / Rem

Batt.

V12.2

Temp

Menu

Change

Volts

Select

Audible alarm on/off

hold > 3 sec

On / Off

hold>3 sec

Fault

Absorption

Cond.

Optional Remote

Instructions inside

BBURC

technology

4

D

U

:

L

R

A

A

T

I

B

G

L

I

E

D

:

:

D

C

I

E

S

M

I

A

G

N

N

Y

D

ProDigital

RoHS

compliant

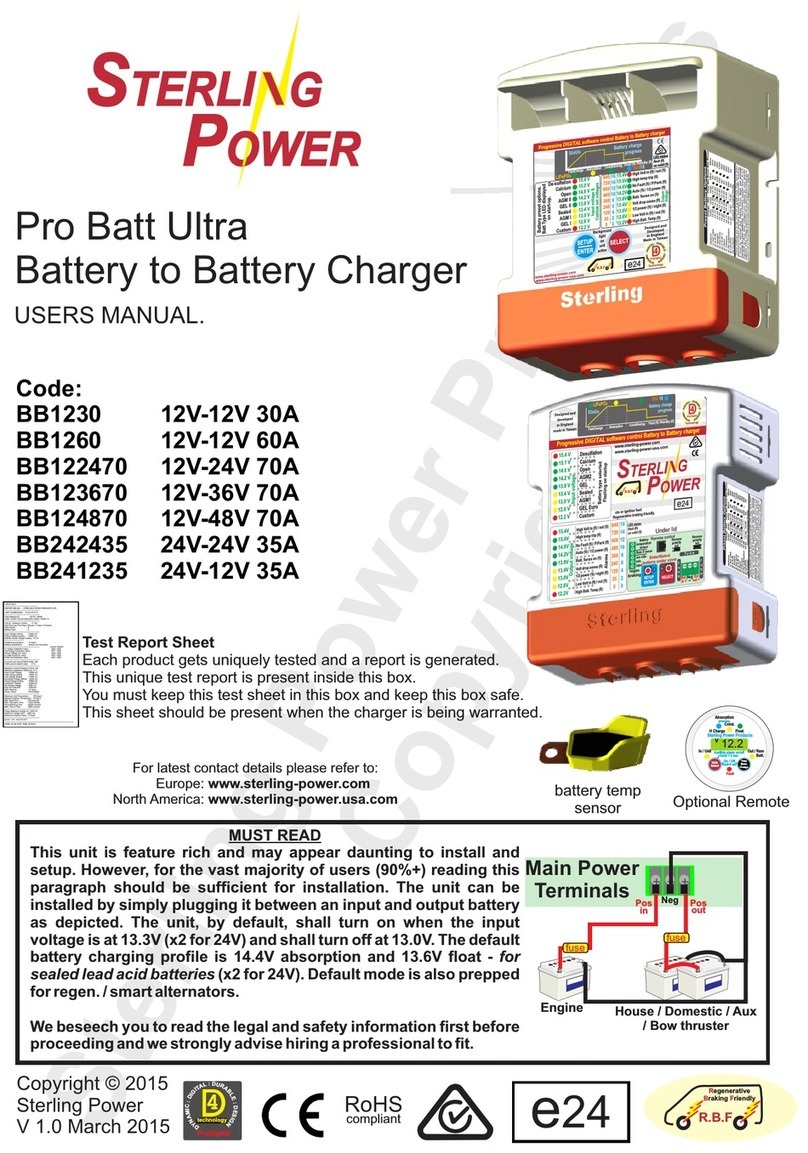

Test Report Sheet

Each product gets uniquely tested and a report is generated.

This unique test report is present inside this box.

You must keep this test sheet in this box and keep this box safe.

This sheet should be present when the charger is being warranted.

English Manual

These instructions are for the & ( ) stripe BB modelsBLUE YELLOW solar

New

software V71+

+

++

++

+

Battery temp

sensor

Remote Voltage Sense

Remote

socket

ign

ctrl

Neg

+

Ignition

BMS (1)

BMS (2)

++

+

++

++

+

Battery temp

sensor

Remote Voltage Sense

Remote

socket

ign

ctrl

Neg

+

Ignition

BMS (1)

BMS (2)

++

Engine Starter

Battery

(connected to alternator)

House / Domestic / Aux

Battery Bank

(arranged here as a 12V bank)

fuse fuse

BB1 (master)

BB2 (slave)

150A rated cable

200A fuse 150A fuse

120A rated cable

input output

60A rated cable 60A rated cable

ignition (paralleled)

+

BB1230 | BB122430

BB244860

BB1260 | BB122470 | BB123670

BB124870 | BB241235

Aux

Bat

out +

Engine

Batt.

input +

Solar Neg

Max V

31V Com.

Neg.

BMS 2 (5)

BMS 1 (6)

Battery temp.

sensor (1,2)

Ignition

feed (4)

Remote

Voltage

sense (3)

Upper

Lower Remote

control

Solar

Pos+

+ + +

- -

1 2 3

4 5 6 Output To

Aux Batt

Starter

Engine Bat.

House / Domestic / Aux / Bow thruster

fuse

50A

fuse

50A

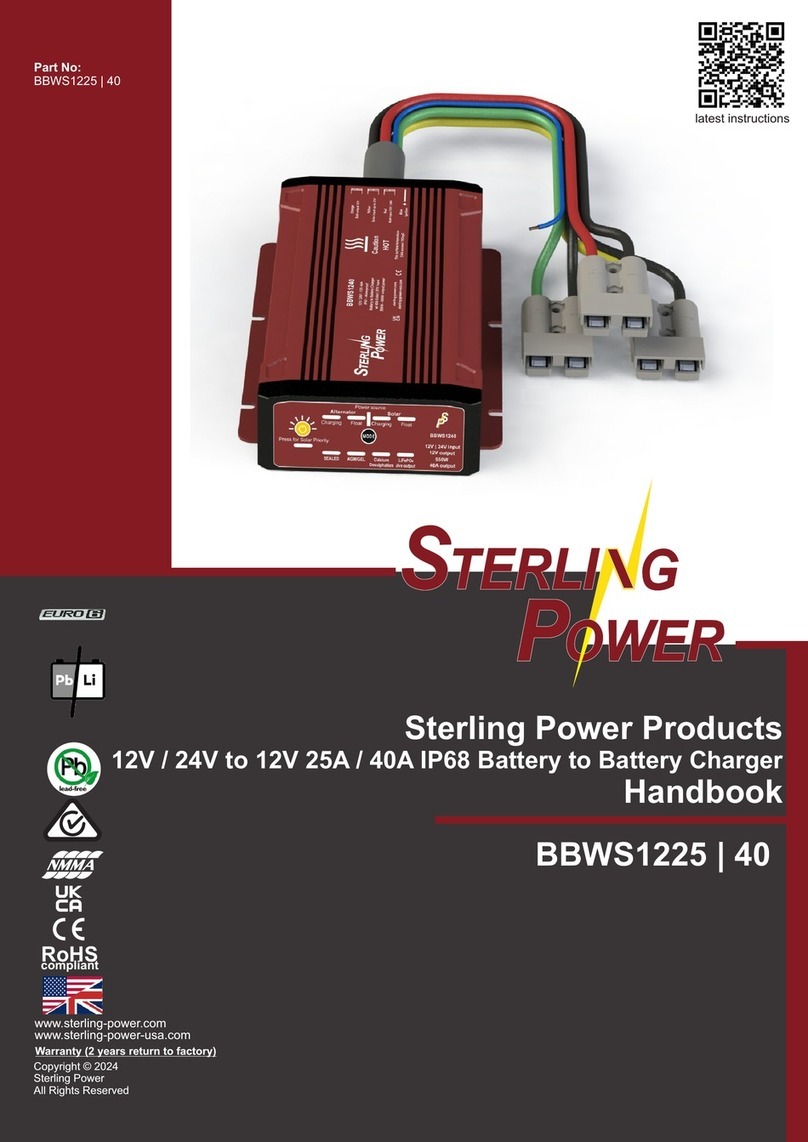

MUST READ

For the majority of users, reading this paragraph should be sufficient for installation. The unit can be

installed by simply connecting it between an input and output battery, as depicted. The solar panel’s

positive and negative connectors go to the +ve and -ve connectors (BBS1230 model only) - voltage should

not exceed 31V (12V panel). The BB, by default, shall start charging when the starter input voltage exceeds

13.5V and switches off when the voltage drops below 13.3V (all models). The default charging profile is

14.4V abs. and 13.6V float - for sealed lead acid batteries (x2 for 24V | x3 for 36V | x4 for 48V). This means that

the vast amount of installations can be fitted out of the box without any adjustments. In certain

circumstances, when installing in a Euro 6 vehicle, we recommend using an ignition feed to the unit. When the

ignition is live, unit starts charging (may take up to 60 seconds). Please read the manual for additional information. If

in doubt, and installing on a New Euro 6+, use ignition feed. For info on BMS, remote sense, temp sensors and

remote control, please consult the manual. Solar charge shall operate when engine off and predominately go to the

leisure battery. There shall be a small 0.5A-1A back feed to the starting battery to keep it topped up, too. Maximum

wattage that can be harvested from the solar panels is 350W - 31V maximum and 16A maximum.

BBS1230 - New to 2020

Solar Panel up to 31V (nominal 12V rated) - do not exceed.

No limit to wattage, however, max harvest is ~350W

Negatives should all be common.

Use cable, do NOT use chassis.

Aux

Bat

out +

Engine

Batt.

input +

Com.

Neg.

Battery temp.

sensor (1,2)

Upper

Lower

Remote

control

+

-

1 2 3

4 5 6

f u s e

+

Starter

Engine Bat.

House / Domestic / Aux / Bow thruster

FUSE

FUSE

BMS 2 (5)

BMS 1 (6)

Ignition

feed (4)

ignition feed (4)

recommended for

Euro 6 vehicles (optional)

ignition feed (4)

recommended for

Euro 6 vehicles

(optional fit)

BB1230 layout

shall be slightly

Different

All BB models except solar

Sterling Power Products

Copyright

STERLI G

POWER

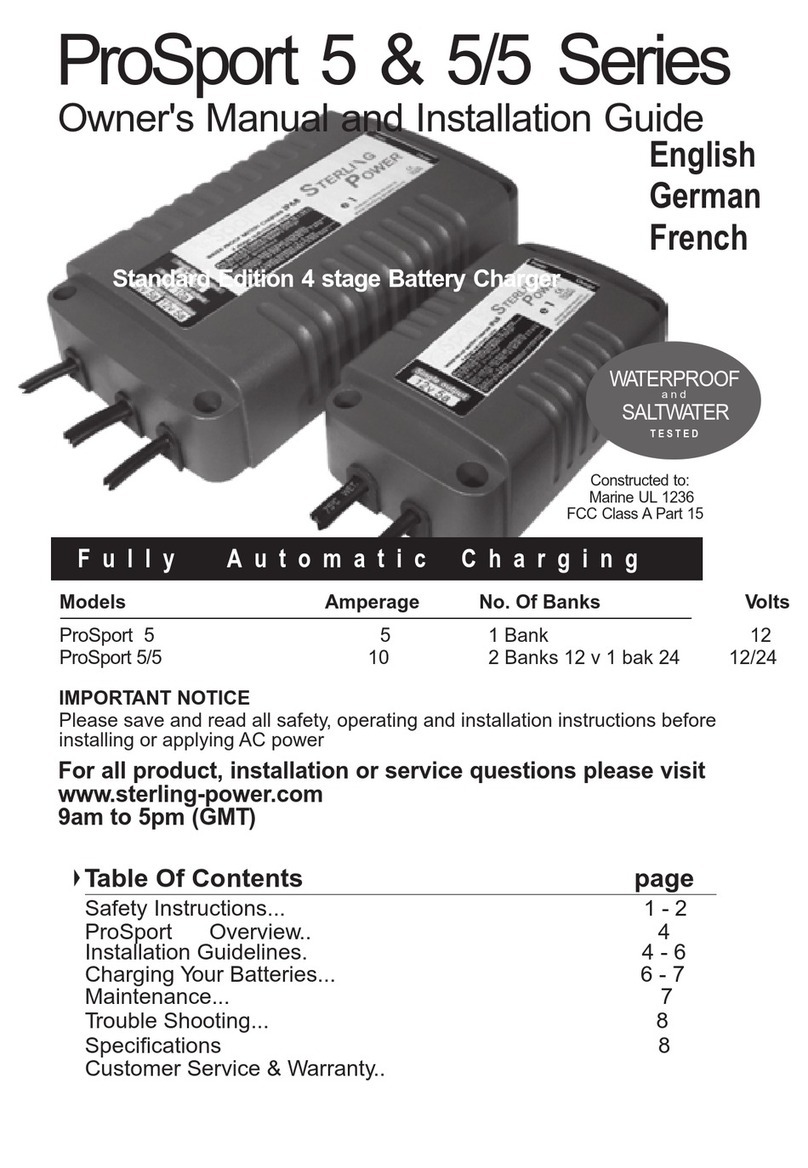

Contents Page

Product Specifications

2

BB1230 BB1260 BB122470 BB123670 BB124870 BB241235 BB242435 BBS1230

Input Voltage (V DC) 11 - 20 11 - 20 11 - 20 11 - 20 11 - 20 22 - 40 22 - 40 11 - 20

Solar input voltage (V DC) N/A N/A N/A N/A N/A N/A N/A Up to 31V

Input Current (A) 30 60 70 70 70 35 35 30

Battery types (all models)

IP rating IP21 IP21 IP21 IP21 IP21 IP21 IP21 IP21

Ignition Protected Yes Yes Yes Yes Yes Yes Yes YES

Quiescent Current (mA) 1 1 1 1 1 1 1 1

Battery Connector WJ116VW WJ116VW WJ116VW W J116VW WJ116VW

Weight (Kg) 1.2 1.4 1.4 1.4 1.4 1.4 1.4 1.4

Dimensions (LxWxD) mm 190 x 160 x 50 190 x 160 x 50

AGM | GEL | SEALED | OPEN | LiFePO4 (2) | CALCIUM | CUSTOM

8mm input | WJ116VW output

190 x 160 x 70

Legal and Safety Information Page 3 Automatic | Ignition Feed Modes Page 9

How to use the instructions Automatic activation (non ignition mode)

Copyright and Plagiarism 2x Ignition feed modes EURO 6

Maintenance and Repair First time use Page 10

Safety and Precautions Changing battery profile type

Front Panel Display I Page 4 First and second LED column meter readings

Front Label display annotated Guide to the 2 buttons Page 11

What the LEDs mean Simplified chart corresponding to button use

Front Panel Display II Page 5 FACTORY RESET

Under the red end cap Force Option feature explanation Page 12-13

Scaled dimensions of the BB Detailed description of button / force functions

Cable and fuses guide Custom Settings Page 14-15

Installation Diagram (non Solar) Page 6 How to set a custom charge profile

wiring diagram for installation Adjusting bulk / absorption / float / times

temperature sensor install Adjusting operation on / off voltages

BMS connectors operations Remote Control Operations Page 16

Remote voltage sense use Comprehensive breakdown of remote functions

Installation SOLAR BBS1230 Page 7 Troubleshoot | understanding panel LEDs Page 17

wiring diagram for installation Fault Finding Page 18

Fundamental fault + troubleshootings

Lithium Battery Installation Page 8 LED displays w/ meanings and solutions

Lithium Battery Charging Profiles Sterling's Warranty Statement Page 19

External and Internal BMS shutdowns Customer service and warranty declaration

0 Deg C temperature sensor trip

Sterling Power Products

Copyright

4

2

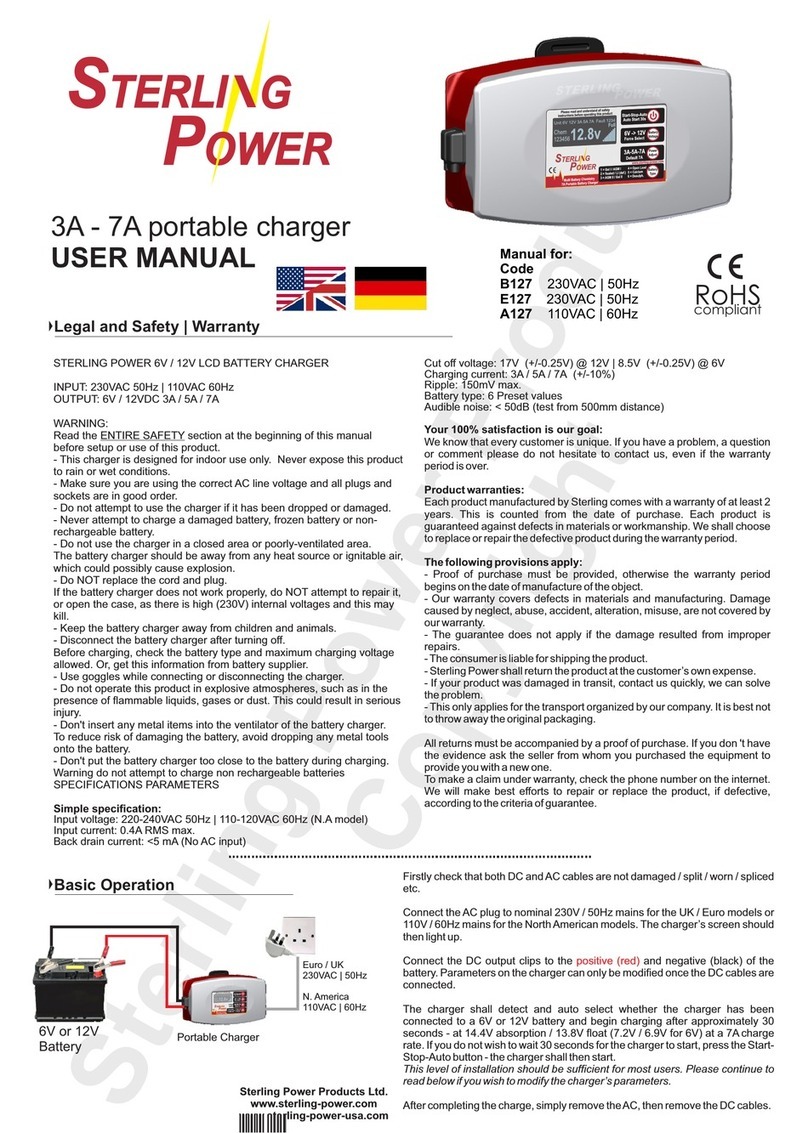

Using the Instruction Manual

This manual must be read throughout before installing

this electronic device. Do not lose these instructions -

keep them safe. The most up to date instructions can

be found on the Sterling Power website. Please refer to

the latest instruction manual before contacting Sterling.

At Sterling, we endeavour to include all of the product

information that we can think of into the manual.

Installation of the electronic device must be carried out

by a qualified and trained personnel only. The

personnel must be familiar with the locally accepted

guidelines and safety measures.

Sterling Power’s warranty statement

A comprehensive warranty statement is provide at the

back of the instruction manual. A comprehensive

warranty statement can also be found on sterling-

power.com.

Copyright and plagiarism

Copyright © 2015 Sterling Power. All rights reserved.

Reproduction, transfer, distribution or storage of part or

all of the contents of this document is strictly prohibited.

If you wish to use all of this document, or excerpts from

it, Sterling Power must be contacted.

Liability

Sterling Power can not accept liability for:

Ÿconsequential damage due to use of this device

Ÿpossible errors in the manuals and the results

thereof

Device modification

Please do not modify the device unless you have been

instructed to do so by Sterling Power, directly. Product

modification shall be done at Sterling, when needed.

Warranty shall be voided if personal attempts are made

to modify the device, without Sterling’s approval.

Use the battery to battery charger only:

ŸFor DC to DC conversion.

ŸFor DC current limiting.

ŸWith fuses protecting the DC cables.

ŸIn a well ventilated, dry, dust-free and condensation

free environment.

ŸWhen instruction manual has been read through.

Safety Symbols

ŸExample - WARNING. Never use the device in

situations where there is danger of gas / dust

EXPLOSION or potentially flammable products.

General maintenance and repair

The device must be switched off during maintenance. It

must also be protected against unexpected switching

off. Remove battery connections and ensure unit is off.

If repair is required, only use original parts.

General safety and installation precautions

ŸInstall device in well ventilated space. Do not

expose device to: Rain, snow, spray, moisture,

pollution, condensation. Do not cover or obstruct

ventilation openings.

ŸDevice connects to common negative. Common

negative must be earthed.

ŸIn case of fire use a fire extinguisher.

ŸEnsure reverse polarity and short circuiting is

avoided - to prevent damage to battery.

ŸProtect DC wires with the appropriate sized fuse.

ŸCheck cabling annually- fix where needed.

ŸAvoid contact with device with damp hands.

ŸEnsure the device is adequately and securely

mounted to prevent the unit from displacement.

ŸUse a professional to install device.

Battery safety

Excessive charge or discharge and high voltages can

cause serious damage to batteries. Never exceed the

recommended limits. If battery acid contacts skin or

clothing, wash immediately with soap and water. If acid

enters the eye(s), immediately flood the eye(s) with

running cold water for 20 minutes and seek medical

attention.

Give extra care to not drop metal tools or jewellery on to

the battery terminals as short circuiting can take place.

Refrain from charging battery up to 4 hours prior of

installation to avoid the formation of explosive gases.

Never smoke / generate a spark around batteries.

CAUTION

WARNING

EXPLOSION

Legal and Safety

3

Sterling Power Products

Copyright

Front label display

1 & 26) ENTER / SETUP and SELECT buttons, used to

adjust settings.

2 & 25) Background light for button, used also to show

unit is operational.

3)-11) The first column of LEDs have 3 different

functions. Firstly, on unit start up the battery type is

displayed. Secondly, after startup it becomes an input

voltmeter. Thirdly, during custom setting the voltage

scale is used to set the voltage - refer to later.

12) This LED has 2 meanings. Firstly, when on battery

type selection mode this is the Desulphation setting

indicator. Secondly, on default mode (most times) this

shows the charger is on fast charge mode.

13-15) These LEDs show the battery charge

progression through its cycle.

15) Flash when in asleep.

16-24) Has 3 functions: Firstly, during operation they

show the output voltage. Secondly, if an alarm is

present the alarm shows up. Thirdly, this row is used in

the custom setup procedure to set timing functions,

voltages and time factors. Its general function is as an

output voltmeter, in the event 2 LEDs are on the

voltages is between the 2 settings, if the top or bottom

red LED is on then the voltage is outside the

parameters off the voltmeter.

16) High voltage, if on solid it is high output voltage, if

flashing it is high input voltage.

17) High temp trip, if flashing then high unit temperature

trip.

18) No faults (solid on). Power Pack mode / live voltage

output (flashing).

19) No regen. mode or regen. timer at 0 = solid LED.

Regen on / timer on = flashing LED.

20) Remote Battery sense cable connected (solid).

Battery sense voltage drop in cable outside the 21)

prescribed 1.5V drop maximum, thicker cable

required - LED flashing. PIM = Pure Ignition feed

mode - if this LED is on solid during status, then the

unit is set to operate only if ignition feed is live.

22) Device’s power ability reduced due to high

ambient temperature or voltage drop in output cable

too large. Alarm will be in conjunction with other

information alarm. If flashing, unit is in night mode

with reduced power and lower fan speed.

23) Low voltage alarm, low voltage on input = flashing

LED. Input alternator not supplying enough power or

failed. Low voltage output = solid LED. Something

consuming a lot of power or unit not working. No

voltage output then LED on solid.

24) If flashing then battery temperature too high. TCO

Temperature Compensation Off LED means that

when illuminated the temp comp is off.

31) Numbers relating to battery custom setup (if

used) this is the charge factor number.

32) Numbers relating to custom setup mode these

numbers relate to timing, i.e. maximum and minimum

time settings.

33) Solar voltage reading - this column becomes a

solar input voltmeter when solar power is on.

34) Low temperature thermometer readings.

MODELS:

BB1260 / BB122470 / BB123670

BB124870 / BB241235

BB123670 / BB124870

Model:

BB1230

BB122430

Bb244830

Auxiliary Information

Solar power live

Ignition feed live

Solar High V Trip live

28

27

29

27) Solar power live LED comes on when the solar is

active. this also means that the voltmeter LEDs

voltage legend changes to the yellow / solar voltage

input. BBS Solar only.

28) If solar voltage exceeds 32V the red LED comes on

+ unit stops. BBS solar only.

29) Ignition feed LED - if ignition feed is connected

AND live, this LED shall come on. BBS solar only.

Bulk / Boost Abs / Solar (fl) Conditioning Float (S) /Standby

IUoUo

SELECT

15.4V

15.0V

14.6V

14.2V

13.8V

13.4V

13.0V

12.6V

12.2V

Input voltage &

Custom set voltages

Battery preset options.

Batt Type LED displayed

on start-up.

SETUP

ENTER

15.4V

15.0V

14.6V

14.2V

13.8V

13.4V

13.0V

12.6V

12.2V

16

14

12

10

8

6

4

2

0

840

720

600

480

360

240

120

30

0

Battery charge

progress

960 18

High Volt in (fl) / out (S)

High temp trip (fl) /BMST(S)

No Fault (S) / P.Pack (fl)

Regen timer off (S) / on (fl)

Batt. Sense on (S)

Volt drop sense (fl)

1/2 power (S) / night (fl)

Low Volt in (fl) / out (S)

High bat temp (fl) / TCO (S)

Output

Voltage

11

10

9

8

7

6

5

4

3

16

17

18

19

20

21

22

23

24

12 13 14 15

1 26

Designed and

developed

in England

made in Taiwan

12V-12V 30A continuous

- 350W solar processing

-1A engine batt. maintain

- Unlimited solar size

- Current limiting

+

Battery to Batter charger and Solar MPPT

with starter battery maintainer

Aux

Bat

out +

Engine

Batt.

input +

Solar Neg

Max V

31V Com.

Neg.

BMS 2 (5)

BMS 1 (6)

Battery temp.

sensor (1,2)

Ignition

feed (4)

Remote

Voltage

sense (3)

Upper

Lower

www.sterling-power-usa.com

www.sterling-power.com

(fl)

Auxiliary Information

Solar power live

Ignition feed live

Solar High V Trip live Sterling Power

Alitech

BBS1230

12V - 12V

10R-0513963

Remote

control

Solar

Pos+

+ + +

- -

1 2 3

4 5 6

Active

30.0V

28.0V

26.0V

24.0V

22.0V

20.0V

18.0V

16.0V

14.0V

Output To

Aux Batt

Batt. to Batt. Charger | MPPT solar reg. | Starter batt. maintainer

25 25

28

27

29

+2

0

-2

-4

-6

-8

-10

-12

-30

C

+

o

LT Trip

1x blue flash

= 1 second

Due to poor conductivity through

chassis. Please use appropriately

rated DC cable direct from engine to

auxiliary battery. Do NOT use chassis.

Bulk / Boost Absorption Conditioning Float (S) /Standby (fl)

12V-12V

60A input

Batt. to Batt.

Charger

IUoUo

Pro Batt Ultra - 4 Stage battery to battery charger DIGITAL control

SELECT

15.4V

15.0V

14.6V

14.2V

13.8V

13.4V

13.0V

12.6V

12.2V

SETUP

ENTER

www.sterling-power-usa.com

www.sterling-power.com Designed and Developed in England

Made in Taiwan

15.4V

15.0V

14.6V

14.2V

13.8V

13.4V

13.0V

12.6V

12.2V

16

14

12

10

8

6

4

2

0

840

720

600

480

360

240

120

30

0

Battery charge

progress

960 18

High Volt in (fl) / out (S)

High temp trip (fl)

No Fault (S) / P.Pack (fl)

Regen timer off (S) / on (fl)

Batt. Sense on (S)

Volt drop sense (fl)

1/2 power (S) / night (fl)

Low Volt in (fl) / out (S)

High bat temp (fl)

Specifications:

12V-12V 60A input

- Current limiting

- Thermostatic control fan

- Auto or ignition feed

- Suitable for use with

- Smart alternators

- Regen. braking

11

10

9

8

7

6

5

4

3

16

17

18

19

20

21

22

23

24

12 13 14 15

1 26

+2

0

-2

-4

-6

-8

-10

-12

-30

C

o

LT Trip

Input voltage

D-Sulf.

Calcium

Open

AGM II

Lithium II

Lithium I

Sealed

AGM I

GEL

Custom

1 sec =

1x blue flash

+

Sterling Power

Alitech

BB1260

10R-0513962

12V - 12V

Alarms

Battery preset options.

Batt Type LED displayed

on start-up.

Output

Voltage

IUoUo Battery charge

progress

15.4 V

15.1 V

14.6 V

14.2 V

13.8 V

13.4 V

13.0 V

12.6 V

12.2 V

www.sterling-power-usa.com

www.sterling-power.com

Designed and

developed

in England

made in Taiwan

15.4V

15.0V

14.6V

14.2V

13.8V

13.4V

13.0V

12.6V

12.2V

Battery type selected

Flashing on startup

Alarms

Input voltage

16

14

12

10

8

6

4

2

0

840

720

600

480

360

240

120

30

0

4

:

D

U

L

A

R

T

A

I

B

G

I

L

D

E

:

:

C

D

I

E

M

S

A

I

G

N

Y

N

D

ProDigital

Technology

D

960 18

High Volt in (fl) / out (S)

High temp trip (fl)

No Fault (S) / P.Pack (fl)

Regen timer off (S) / on (fl)

Batt. Sense on (S)

Volt drop sense (fl)

1/2 power (S) / night (fl)

Low Volt in (fl) / out (S)

Bulk / Boost Absorption Conditioning Float (S) /Standby (fl)

D-Sulf

12V-12V 30A

- Current limiting

- Thermostatic control fan

- Automatic or ignition feed

- Thermal compensation

- Lithium thermal adjust

Under lid

11

10

9

8

7

6

5

4

3

16

17

18

19

20

21

22

23

24

12 13 14 15

High bat temp (fl)

Progressive DIGITAL software control Battery to Battery charger

Output V

+2

0

-2

-4

-6

-8

-10

-12

-30

C

+

o

LT Trip

Calcium

Open

AGM II

Lithium II

Lithium I

Sealed

AGM I

GEL

Custom

10

11

8

9

7

6

5

4

3

2

1

16

17

18

19

20

21

22

23

24

25

26

10

11

13

8

9

7

6

5

4

3

12 14 15

16

17

18

23

24

19

21

20

22

1312 14 15

16

17

18

19

20

21

22

23

24

25

26

1312 14 15

D-Sulf.

Calcium

Open

AGM II

Lithium II

Lithium I

Sealed

AGM I

GEL

Custom

10

11

8

9

7

6

5

4

3

2

1

29

27

28

Model: BB solar

BBS1230

2434

2434 2434

35) Solar input voltage. When

solar power live LED (27) is on,

the left panel displays solar panel

input voltage. BBS solar model

only.

2435

Front Panel Display 4

Models: BB1230 | BB122430 |

BB242435 | BB244860

MODELS:

BB1260 / BB122470 / BB123670

BB124870 / BB241235

Front Panel II (under red end cap)

4.60

73.00

4.60

158.00

198.51

43.13

158.00

5.50

10.60

4.60

112.13

4.00

199mm(H)

158mm(W)

70mm(D)

50mm(D)

units in millimetres (mm)

Under the lid

1) N/A

2) Negative fuse (position, model dependent).

3) DC output to auxiliary battery.

4) Common negative.

5) DC input from start battery (green connector or brass

nut / bolt - model dependent).

6) N/A

7) Remote control socket.

8) BMS 1 - 0V signal from BMS shall trip BB.

9) BMS 2 - positive signal (+ve) from BMS shall trip BB.

10) Ignition feed connector (on) Euro 6 engines.

11) Remote battery sense wire to compensate for voltage

drop in cable (optional, does not need to be used).

12) Battery temperature sensor, optional fit, if not used

product will work on default at 20 deg C setting. Polarity

does not matter when connecting.

13) Other wire associated with the temp sensor, as per 12.

Dimensions

5

Aux

Bat

out +

Engine

Batt.

input +

Solar Neg

Max V

31V Com.

Neg.

BMS 2 (5)

BMS 1 (6)

Battery temp.

sensor (1,2)

Ignition

feed (4)

Remote

Voltage

sense (3)

Upper

Lower

Remote

control

Solar

Pos+

+ + +

- -

1 2 3

4 5 6 Output To

Aux Batt

111213

10 8 9

3415 165 7

15) Solar positive input from 12V solar panel (up to 31V)

16) Solar negative input from 12V solar panel (up to 31V)

Models:

BBS1230

This chart is a guideline based on the

typical lengths of cable that shall run

to and from the BB. Please only use

this chart as a guide. If you wish to

make the cable longer than typical,

then you would generally use thicker

cable. We recommend rating the

fuse based on cable thickness. Rate

the cable based on the current going

down the cable and the length of the

run.

input cable output cable

Model (mm2) / AWG (mm2) / AWG input fuse output fuse

BB1230 10mm2 / 8 10mm2 / 8 40A 40A

BBS1230 10mm2 / 8 10mm2 / 8 40A 40A

BB122430 10mm2 / 8 6mm2 / 10 40A 30A

BB242435 10mm2 / 8 10mm2 / 8 40A 40A

BB244830 10mm2 / 8 4mm2 / 12 40A 20A

BB1260 16mm2 / 6 16mm2 / 6 80A 80A

BB122470 16mm2 / 6 10mm2 / 8 80A 40A

BB123670 16mm2 / 6 6mm2 / 10 80A 30A

BB124870 16mm2 / 6 4mm2 / 12 80A 20A

BB241235 10mm2 / 8 16mm2 / 6 40A 80A

Cables and fuses (guideline only)

2

f u s e

Aux

Batt

out +

Engine

Batt.

input +

Com.

Neg.

BMS 2 (5)

BMS 1 (6)

Battery temp.

sensor (1,2)

Ignition

feed (4)

Upper

Lower

Remote

control

+ +

-

1 2 3

4 5 6

111213

10 8 9

345 7

2

f u s e

SETUP SELECT

Aux

Batt

out +

Engine

Batt.

input +

Com.

Neg.

BMS 2 (5)

BMS 1 (6)

Battery temp.

sensor (1,2)

Ignition

feed (4)

Remote

Voltage

sense (3)

Upper

Lower

Remote

control

+

-

1 2 3

4 5 6

111213

10 89

34

5

72

f u s e

+

Sterling Power Products

Copyright

Engine Starter

Battery

(connected to alternator)

Important

NEGATIVES

should all be common.

DON'T USE CHASSIS

We recommend joining

the BB’s neg. to the

starter battery negative.

For improved efficiency.

House / Domestic / Aux

Battery Bank

(arranged here as a 12V bank)

Temperature Sensor

(TSAY) optional fit.

Polarity of wires into

(1) and (2) does NOT

matter.

Installation Diagram / all non Solar Models

BMS (1)

BMS (2)

Use BMS 1 - if your BMS trips and provides a 0V

(ground signal), then use BMS 1. This shall result in the

BB turning off. Once the BMS removes this trip status,

i.e. the 0V signal goes back to a +ve signal, the BB shall

start charging again.

Use BMS 2 - if your BMS trips to a +ve voltage (2V-17V), then

use BMS 2. This shall result in the BB turning off when this

voltage is received. Once the BMS removes this trip status,

i.e. the +ve signal goes back to 0V signal, the BB shall start

charging again.

BMS 1

status:

operational: 2-17V

trip voltage: 0V

BMS 2

status:

operational: 0V

trip voltage: 2V-17V

line to ignition

(recommended if vehicle is Euro 6)

Aux

Batt

out +

Engine

Batt.

input +

Com.

Neg.

BMS 2 (5)

BMS 1 (6)

Battery temp.

sensor (1,2)

Ignition

feed (4)

Upper

Lower

Remote

control

+

-

1 2 3

4 5 6

f u s e

+

5 6

fuse fuse

6

BMS and remote features appear later

Temperature sensor cables are not polarity sensitive, install either way. If you wish to install, connect the temp

sensor to the negative of the domestic / aux. batteries.

When temperature sensor senses the temperature lower than 20Deg C the voltage shall go up on the

charger’s output and when the temperature is higher than 20Deg C the charge voltage shall drop. The rate is

18mV (0.018V) per Deg C or 0.018V / Deg C. If sensor temperature is at 10 Deg C the voltage elevation shall

be 0.018 x 10 = 0.18V. This shall explain why, in cooler climates / seasons you may see slightly elevated charge

voltage / voltage at your batteries. This is no concern. In warmer climates / seasons you shall see slightly lower

charge voltages. This voltage fluctuation is only with ‘lead acid style’ batteries. For lithium profiles, there is no

voltage fluctuation.

The temperature sensor shall trip the charger if the temperature at the battery >55DegC.

If the BB is in either lithium profiles the unit shall trip at 0DegC, if temp sensor is connected. This temperature

can be adjusted. If you do not want the 0DegC trip or any trip, please uninstall the temperature sensor.

remote voltage sense

compensates for

potentially long cable

runs to domestic

battery.

BMS connectors

Temperature sensor (part no. TSAY)

These BMS connectors can also be used as simple on/off signal connectors. If you wish for the BB to turn off with a live (+ve) signal

please use BMS 2. If you wish for the BB to turn off based on a ground (0V) signal, use BMS 1. These signals do not have to come

from a BMS, they can come from any source.

Fuse ratings

on Page 5

fuse

Remote voltage sense

The remote voltage sense is designed to achieve the correct charge voltage at the charging battery (house) itself.

There is often voltage drop across DC cabling, this sense feeds back to the BB what the charge voltage at the BB

should be in order to get the correct charge voltage at the battery. The sense cable, itself, carries no current, it can

be as thin as you can find. Please connect between (3) and the positive terminal of output battery.

Sterling Power Products

Copyright

Engine Starter

Battery

(connected to alternator)

House / Domestic / Aux

Battery Bank

(arranged here as a 12V bank)

Temp

Sensor on

negative

Installation Diagram Solar BBS1230

Negatives: The reason to

not use CHASSIS ground

is that the conductivity is

poor. This shall result in

worsened performance.

Output voltage shall climb

at a slower rate. Charging

rate shall be slower.

Please use direct cable for

best performance.

Please be advised that the solar

charger and the BB charger do

not work at the same time. When

your engine is running, the BB

aspect of the BBS charges.

When the engine / ignition is off,

the solar charger works. They do

not work simultaneously.

in compliance with good

electrical practice all wires

directly connected to a

battery should be correctly

fused. The applicable fuse

must be fitted close to the

battery side of the cable.

Aux

Batt.

out +

Engine

Batt. in+

Solar

Negative

Common

Negative

BMS (2)

BMS (1)

Ignition

feed

Remote

Voltage

sense

Upper

Lower

Remote

control

Solar

Pos +

+ + +

- -

lithium

BMS

Controller

(if used)

Ignition feed

a live feed when

engine is running.

A live voltage when

running and 0V

when engine off.

fuse

fuse

50A

50A

Sterling Power Products

H Charge Float

In / Unit Out / Rem

Batt.

V12.2

Temp

Menu

Change

Volts

Select

Audible alarm on/off

hold > 3 sec

On / Off

hold>3 sec

Fault

Absorption

Cond.

optional

remote BBURC

Must fit

Must fit

Optional fit

Optional fit

Battery

temperature

sensor

Solar input. There is no limit to

the solar panel array combined

wattage, however, the BBS unit

can only process up to 350W.

However, in milder climates

larger cells can be used as the

mean average - because in non

sunny climates panels shall not

produce full power.

Max 31V DC. Max harvest 350W

Important

NEGATIVES

should all be common.

DON'T USE CHASSIS

We recommend joining

the BB’s neg. using cable

direct to the

starter battery negative.

For improved efficiency.

7

BBS1230 - New to 2020 battery maintainer

The battery maintainer is a unique BB Solar feature. It

allows the back feed of current from surplus output battery

current back to the starter battery. The current rate is

somewhere between ~0.3A-1A depending on the voltage

differential. Basically, if the output battery is full and the

starter battery is very empty the current flow shall be on the

higher end and vice versa. The maintainer only operates

when there is charging on the output battery (i.e. when the

solar power is charging your domestic battery or an

independent battery charger) it does NOT deplete your

house batteries! The mode is on as default and can be

turned off by pressing the SELECT button down for 35

flashes and letting go.

when the domestic battery is being charged,

surplus current shall flow back into the starter

battery

main current flow during

solar charging

small backfeed current

only when house battery is charging

House / Domestic / Aux

Battery Bank

(arranged here as a 12V bank)

Engine Starter Battery

(connected to alternator)

1 2 3

4 5 6

see previous

page about BMS

Optional fit

line to ignition

(recommended if vehicle is Euro 6)

Lithium Battery Installation

Certain lithium batteries shall have an external battery management system. Particularly if the bank is large or contains multiple

batteries and/or in sophisticate setups. External BMS generally do a better job of managing multiple lithium batteries within a

large bank. These external BMSs give out either a positive signal or ground signal when they wish to tell the charger to stop

charging (trip signal). The BMS 1 and BMS 2 connectors on the BB are the connectors that the external BMS’s signal shall feed

into. Make sure you select the correct port.

External BMS shutdown

This page is unique to those installing lithium batteries as a domestic battery bank. This page assumes that you have a lead acid

style starter battery and a domestic lithium battery bank that is within the C rating of the battery to battery charger that you have

chosen. Typically, an individual 100Ah lithium battery has a 0.5C maximum charge current (~50A) and a 1C discharge current

(100A) - these current figures double, triple by parallelling 2x, 3x etc.. lithium batteries together. Please consult your lithium

battery documentation to ensure that the BB selection is suitable for your lithium battery and within about 70-80% of the rating of

your alternator (or lower) - to increase lifespan of your alternator. The BB shall operate with an internal or external BMS. A BMS

is a must have when charging lithium batteries. If this paragraph means little to nothing to you we would consult advise before

proceeding.

If you want the BB to stop charging when your lithium battery is at 0Deg C then please read here.

Firstly, connect the temperature sensor (TSAY) that is supplied with the device to the negative terminal of the lithium battery bank

and then connect the other end (two wires) to the appropriate connector on the BB - normal temp sensor installation.

Secondly, set the BB to lithium battery type (I or II) - using the normal ‘battery type setup’. Once you have selected either lithium

battery Preset I 14.2V (x2 for 24V etc) or lithium battery Preset II (x2 for 24V etc). By selecting either of these presets and by putting

on the temperature sensor the BB now defaults to 0 Deg C trip.

If you want a different temperature trip then you must go through the custom charge profiles as appears on page .15

If you do not want this feature at all, please remove the temperature sensor from the connector on the BB. This shall immediately

engage the BB to charge.

As there is no temp sensor now connected there shall be no tripping based on battery temperature.

0 Deg C trip

Use BMS 1 - if your BMS trips and provides a 0V (ground

signal), then use BMS 1. This shall result in the BBC turning

off. Once the BMS removes this trip status, i.e. the 0V signal

goes back to a +ve signal, the BBC shall start charging again.

Use BMS 2 - if your BMS trips to a +ve voltage (2V-17V), then use

BMS 2. This shall result in the BBC turning off when this voltage is

received. Once the BMS removes this trip status, i.e. the +ve

signal goes back to 0V signal, the BBC shall start charging again.

BMS 1

status:

operational: 2-17V

trip voltage: 0V

BMS 2

status:

operational: 0V

trip voltage: 2V-17V

or

Remote trip - the BMS connector can also be used as a basic remote trip. Simply apply the correct trip signal voltage to the

relevant BMS connector for the desired effect.

Changing battery type

We provide 2 lithium profile presets. Lithium I is 14.2V charge and 13.8V float. Lithium II is 14.4V charge and 13.8V float. These

can be selected in the normal battery type selection process. By putting the BB into either of these modes immediately removes

the reverse polarity protection and put the BB into ‘power supply mode’. If you wish to customise your charge profile proceed

through the custom route, however, please change the power supply mode to on in the settings.

Drop in style, off the shelf, lithium batteries tend to have an internal BMS that looks after that specific battery. The parameters

of that BMS shall trip and engage when the BMS deems the environment either hostile or acceptable to accept charge. There

is no back-feed mechanism to the BB required here as the BMS itself trips the battery internally. Some specifications of these

BMS require the BB to not provide any charge at low temperature 0 DegC or below. Please read below.

Internal BMS shutdown

8

1 2 3

BMS (1)

BMS (2)

5 6

BMS 2 (5)

BMS 1 (6)

Battery temp.

sensor (1,2)

Ignition

feed (4)

Remote

Voltage

sense (3)

Upper

Lower 1 2 3

4 5 6

xx

+2

0

-2

-4

-6

-8

-10

-12

-30

C

o

After custom charging profiles have been set, the last

option in the custom procedure is to set temperature trip.

The default, as it assumes lead acid, is -30 Deg C, so the

RED LED at the bottom shall illuminate. For lithium,

bring this LED up to your desired trip temperature. E.g 0,

-2, -4 Deg C etc.

temp sensor connection

Sterling Power Products

Copyright

Engine Starter

Battery (alternator)

6

Please refer to the installation diagrams on pages 6 and 7 for installation instructions.

9

Ensure the charger is wired up as depicted above (larger diagram on previous page). The Pro Batt Ultra shall light

up provided it has battery voltage across the and neg terminal. If is also connected the unit shall Pos in Pos out

start charging for 120 seconds (1/2 of the regen. braking timer). During the first start up you can change the battery

chemistry profile.

In default mode (1) the Batt Ultra shall simply turn off and goes to sleep after 240 seconds (can be changed) if the

input voltage has not risen above 13.2V. If you have it set to Ignition Mode, and the ignition is live, then WARNING -

the charger shall continue charging until the input battery drops to (default) x2 for 24V. . 10.0V VERY LOW

With no ignition the input voltage needs to rise to above 13.2V-19.0V (x2 for 24V) in order for the Batt Ultra to start

charging. This can be achieved by starting your engine. Above 13.2V, for 5 seconds, the regenerative braking timer

activates (120 sec (first time after start/wakeup) then 240 seconds default).

There may be a delay of up to 60 seconds before the BB ultra starts charging.

This is required to complement the regenerative braking aspect of modern Euro 5/6+ engines - where the

alternator’s voltage can drop below 13V for a short period of time. When the alternator’s voltage rises above 13.2V

the 240 second timer ends (+ reactivates the timer) and the charger remains charging.

Automatic mode & Ignition feed modes

++

Pos

in Pos

out

Neg

fuse

fuse

House / Domestic

/ Aux / Bow thruster

Main Power

Terminals +

Ignition Feed Mode (mode 2).

Apply an ignition feed cable to the ‘Ignition’ terminal on the

connector block. As soon as there is a signal (> 4V) on this

connector, the unit will wake up (can take up to 60 seconds)

and will start to charge the output battery. The only limit is the

input voltage. The BB shall operate down to 10V on the input

side. When ignition is turned off (0-4V) the BB shall turn off

when input voltage drops below 13.0V (x2 for 24V).

WARNING: If ignition on the vehicle is left on and the engine

is off, you shall deplete your starter battery down to 10V. Also,

if your alternator is less than 60A or can not produce 60A at

idle revs you may discharge your starter battery.

WARNING: the BB shall start up by mode 1 voltage

parameters if there is no ignition feed. We have done this to

allow users to put solar or an AC to DC charger onto the

starter to enable the BB to charge the leisure / aux battery

without running an additional ignition supply. Can be turned

off (page 9)

12

line to

ignition

feed

+

+

+

Ignition

BMS (1)

BMS (2)

+

+

+

Ignition

BMS (1)

BMS (2)

Leave ‘ignition’ connector vacant

6

2x Ignition feed modes

Important

NEGATIVES

should all be common.

DON'T USE CHASSIS

POOR CONDUCTORS

RESULT IN WORSE

CHARGE RATE

When engine running, starter battery above 13.3V, then use 1

Euro 6 vehicle (which to choose).

If your usage of the vehicle includes situation applications

where the vehicle engine is being run for long periods at idle

and stationary. I.e. you are simply switching the engine on to

charge the auxiliary battery system but not driving, then

you must use the ignition feed mode, Mode 2.

We appreciate ign. feeds are a hassle (hence it is optional).

Fitting one gives the driver/user more autonomy. Generally

speaking, if in doubt, fit one!

mode 1 mode 2

wrong small connector diagram

BMS 2 (5)

BMS 1 (6)

Battery temp.

sensor (1,2)

Ignition

feed (4)

Remote

Voltage

sense (3)

Upper

Lower 1 2 3

4 5 6

Automatic activation (default setting) - no ignition feed required. This means that the battery to battery

charger operates based on sensing voltages at the input battery connector. No ignition feed. When the

input voltage exceeds 13.5V-19.0V (x2 for 24V) then the unit will simply start charging. If the voltage drops

below 13.3V the unit shall turn off. With a caveat, read on.

However, if the input voltage has exceeded 13.5V (2x for 24V) for 5 seconds the regen. braking timer is

prepped and shall become active if the input voltage drops down to 12.0V-13.3V. This timer is 240s (default -

can be changed) and allows the charger to continue charging at these lower input voltages. If the voltage drops

below 11.9V the charger goes to sleep irrespective of the timer. If the input voltage remains between 11.9V-

13.0V for over 240s the charger also goes to sleep. To wake the charger, the input voltage needs to rise above

13.2V - this shall also reset the regen. braking timer. These parameters can be modified.

Ignition feed mode 1. Apply an ignition feed cable to the ‘Ignition’ terminal on the connector block. As soon as

there is a signal (> 4V) on this connector, the unit will wake up (can take up to 60 seconds) and will start to charge

the output battery. The only limit is the input voltage. The BB shall operate down to 10V on the input side. When

ignition is turned off (0-4V) the BB shall turn off ONLY if input voltage drops below 13.0V (x2 for 24V). Therefore,

this ignition mode enables the BB to operate based on the same voltage parameters as ‘Auto Mode’ above.

WARNING: If ignition on the vehicle is left on and the engine is off, you shall deplete your starter battery down to

10V. Also, if your alternator is less than 60A or can not produce 60A at idle revs you may discharge your starter

battery.

WARNING: the BB shall start up by Auto activation voltage parameters if there is no ignition feed. We have

done this to allow users to put solar or an AC to DC charger onto the starter to enable the BB to charge the leisure

/ aux battery without running an additional ignition supply. Can be turned off (page 9)

Ignition feed mode 2 (Pure ignition). This mode is slightly different to mode 1. If, you want the BB to simply be

on/off based purely on ignition then you shall want to use this mode. For example, if the only time you ever want

the BB to work is when you’re driving (ignition live) then this is ideal. It shall not operate based on the DC voltage

at the input terminal. If you have a live ignition the BB shall turn on, when the ignition is off the BB shall stop

charging. Simple on/off. There are no voltage parameters at the DC input terminal that need to be met here,

simply 10V+ (2x for 24V). To put it in this mode, apply an ignition feed cable to the ‘Ignition’ terminal on the

connector block, as above. ALSO, you shall need to turn on ‘pure ignition feed’ mode by holding down SETUP

button for 20 flashes and letting go. The unit shall now ONLY operate when there is a live ignition feed - if the BB

is wired up without an ignition the unit shall simply not function. This shall limit the unit’s flexibility. However, this

mode shall be ideal for those that have solar chargers or auxiliary chargers who wish for the BB to be OFF when

vehicle is parked up. Apply a factory reset if you wish to restore default settings.

WARNING: If ignition on the vehicle is left ON and the engine is OFF, you shall deplete your starter battery down

to 10V. Also, if your alternator is less than 60A or can not produce 60A at idle revs you may discharge your starter

battery.

With any of these modes selected, the BB may take up to 60 seconds to turn on. This is due to the BB being

asleep, when not in use. This preserves battery life. It brings the quiescent current down to 1mA.

Ignition

feed (4)

Upper

Lower 1 2 3

4 5 6

+ve

Ignition feed mode 1. This mode

Ignition mode 1 (default when ignition feed is applied) allows the user to operate the BB based on the

automatic activation voltage parameters, as above, whilst also having control of the BB using the ignition signal.

If your vehicle’s alternator is putting out a voltage below that of 13V (26V for 24V) the live ignition feed signal

shall still operate the BB (10V+). Whereas, in the mode above the BB shall turn off when the voltage drops below

13.0V or may never even turn on if this voltage is never met. This is why we recommend installing an ignition

feed for Euro 6 vehicles. The BB shall turn off only when the input voltage drops below 13.0V AND the ignition

feed switches off. The possible downside of this mode is that the BB shall work even when the ignition feed is not

applied - provided the input voltage is above 13V (x2 for 24V). This may be sub optimal if you wish for your BB to

remain off when the vehicle is parked up and you have alternative charging sources onto your DC system.

However, this mode may be what you wish for precisely that reason. If you want a more classic binary on/off

ignition mode - please see ignition feed mode 2 below. Mode 1 is default, once live ignition is applied.

for both ignition feed modes

wire like this

Automatic Activation

when BB receives ignition feed signal the regen. braking timer = 0 seconds

Sterling Power Products

Copyright

On first start up all LEDs will light up. A beep should

sound. The fan shall then start running for around 5

seconds. If, after this, 2 red LEDs flash for 8 seconds

you may have a calibration issue and the unit should be

returned to Sterling. If 2 solid red LEDs are on at the top

or bottom then you either have high or low input voltage

(respectively) - check your voltages.

Changing charging profile during startup

After the initial start up an LED on the first column shall

light up for 5 seconds, this shall indicate the battery type

selected - default is ‘Sealed’ lead acid. This is your

window of opportunity to change the charging profile. If

you have missed the opportunity, you can wait for the

unit to go in to normal operation and follow the

instructions immediately below.

Left and right meter readings (BB larger model).

During normal operation

Out of range voltage values

If voltage exceeds the meter’s range the upper right

LED shall flash. If the voltage falls short of the meter’s

range the lower LED shall flash. If two neighbouring

LEDs, on the voltmeter, are on simultaneously then the

real voltage is between these two parameters.

Example, if LEDs at 14.6V and 14.2V were on then the

approximate voltage shall be ~14.4V.

Low or high output voltages

If the output voltage is below 1V (2V at 24V) or reverse

polarity then the low output voltage LED will flash

(number 23). Similarly, if the output voltage is above

15.5V (31.0V at 24V) the high voltage LED shall flash

(number 16). To resurrect these problems, bring the

voltage above 1V on the output and below 15.5V,

correct the polarity and then restart the device.

Return to factory default: This shall irreversibly

erase all previously entered settings. Press and hold

both buttons for 8+ flashes and let go. 3 green LEDs on

both columns shall flash. The unit should then reboot with

the default settings.

To view charger’s status:

Simply hold the SELECT button for 1 second and the right

LED should flash indicating the status of the charger. This

shall flash for 8 seconds. To return quickly, press the

SETUP/ENTER button once.

Input voltage

(x2 for 24V)

Output voltage

(x2 for 24V, x3 for 36V, x4 for 48V)

Remember it is the voltages that are more important than

our battery types. After installation, test the voltage from

the BB is the desired voltage. Ensure you remove at

least 1 wire from the battery temperature sensor as

the product voltage may be higher (if in cold climate)

or lower (if in warm climate) than the preconceived

voltage. The voltage requirements of the battery

company will override our recommendations as it is them

who are supporting the battery warranty.

Changing charging profile during operation.

While the unit is running, hold down SETUP button for 10

flashes. All LEDs on the first column shall now flash. By

using both buttons toggle through the various profiles

(see below). The right button is up the column and the left

button takes you down the column. The LED shall light up

demonstrating which profile you have selected. When the

LED has illuminated at your desired profile simply hold

both buttons for a couple of seconds or simply just leave

the charger alone for 30 seconds and it will set the desired

profile. The corresponding LED shall flash to confirm. The

unit shall then restart and go through the starting cycle

again in this new charging profile.

*Lithium profiles have reverse polarity protection

disabled. **All voltages shall be 0.1V higher for the

first 3 minutes of the chargers operation.

If either lithium settings are selected AND the

temperature sensor is connected to the negative terminal

of the lithium battery, the BB shall trip at <0Deg at the

sensor. This can be adjusted in custom profile, or simply

remove temp sensor.

First Time Use (when wiring up)

If battery temperature sensor is connected then

all voltages are based on 20 Deg C. If sensor

senses less than 20DegC = increased voltage.

Higher than 20DegC = decrease voltage. The

further from 20DegC in either direction leads to

proportional increase or decrease in the

voltage. (x2 for 24V | x3 for 36V | x4 for 48V)

10

Preset Battery Options

Bulk / Abs. Cond. Float Min | Abs. | Max

Custom Charging Profile

Volts

13.70

13.40

13.60

13.60

13.80

13.70

13.30

13.60

-------

Mins

600

60

120

30

30

60

60

60

240

Mins

1440

480

480

30

30

480

480

360

240

Volts

13.80

13.75

14.15

13.60

13.80

14.10

14.00

14.30

-------

Options

1) Gel

2) AGM I

3) Sealed

4) Lithium I

5) Lithium II

6) AGM II

7) Open

8) Calcium

9) Desulphation

10) Custom

Volts

14.00

14.10

14.40

14.20

14.40

14.60

14.80

15.10

15.50

Bulk / Boost Absorption Conditioning Float (S) /Standby (fl)

IUoUo

15.4V

15.0V

14.6V

14.2V

13.8V

13.4V

13.0V

12.6V

12.2V

15.4V

15.0V

14.6V

14.2V

13.8V

13.4V

13.0V

12.6V

12.2V

16

14

12

10

8

6

4

2

0

840

720

600

480

360

240

120

30

0

Battery charge

progress

960 18

High Volt in (fl) / out (S)

High temp trip(fl) BMST(S)

No Fault (S) / P.Pack (fl)

Regen timer off (S) / on (fl)

Batt. Sense on (S)

Volt drop sense (fl) PIM (S)

1/2 power (S) / night (fl)

Low Volt in (fl) / out (S)

High bat temp (fl) / TCO (S)

+2

0

-2

-4

-6

-8

-10

-12

-30

C

o

LT Trip

Input voltage

D-Sulf.

Calcium

Open

AGM II

Lithium II

Lithium I

Sealed

AGM I

GEL

Custom

Alarms

input

voltage output

voltage

# flashes

Both buttons

8 - 35

Factory Reset

# flashes

only buttonSetup

0-1

Silence Buzzer /

Status display / Change to voltage display

5

Software version

10

Select battery type

15

Power supply mode / live output voltage

20

Pure ignition feed mode

25

Change operational on/off voltage

30

Set auto regen. braking timer

35

Temperature voltage compensation

40

Buzzer off (long term)

45

Maintenance Mode

11

If BB is in sleep mode, either buttons can be pressed to wake the BB up.

# flashes

Select only button

0-1

Silence Buzzer / Status display

Change to voltage display

5

Display temperature

10

Force to float

15

Night Mode

20

1/2 Power Mode

25

Standby

30

Turn unit off / on again

40

OEM Lock

45

Solar Charger on*/off

50

BB Charger on*/off

SELECT

SETUP

ENTER

The LEDs around the buttons shall flash to denote one second.

Maintaince mode, this mode lock on the unit so it does not switch

off, and keeps the input and output volt meters in operation which

you work on the system for fault finding. if ther is a fault and the

output voltage leds only are on then its no longer a volt meter

display it is simply displaying a fault condition which needs to be

resolved, the unit is only displaying voltage if both rows off leds are

active

ØÞÒŃÔ ŐǾÑŒŒ ĂÊĈŒÑŃÅ 5 10 15 20 25 30 35 40 45 45 50

Both

GÑNÞŊ ŎŌCŎŅŅ Ǻ

(not documented)

ŒÒÕÑŌŃÑ NÞŖŖÑǾ ĂÒŌŒPMŌPÅ

change to status display

change to voltage display

silence buzzer (instant)

change to status display

change to voltage display

NN Ą ŒŎÕMǾ

mode

on/off*

ĘĘ ŃOMǾŊÑ

on*/off

(solar)

Ĭ ĜI ĜFİ

ĞŎǾŃÑ PŎ ĞÕŎMP

GÒŒŐÕMŘ PÑÖŐ

Î ĜÌ ÕŎŃÔ

Ĭ Ĝİ Į Ĩ

ŒŎŅPR MǾÑ QÑǾŒÒŎŌ

ĘMPPÑǾŘ PŘŐÑ

ĞMŃPŎǾŘ Ī ÑŒÑP ǼǼǼË

Í ÒŊOP ÖŎŇÑ

ĈCČ ŐŎR ÑǾ Ö ŎŇÑ

Ĭ PMŌŇNŘ

İ ÞǾŌ ŎŅŅ ÞŌÒP

ĘMPPÑǾŘ ÖMÒŌPMÒŌÑǾ

on*/off (solar)

ŃOMŌŊÑ

operational

on-off voltage

Ĩ ŎR ÑǾ ŒÞŐŐÕŘ

mode

ŐÞǾÑ ÒŊŌÒPÒŎŌ

mode

Ĭ ÑP ĞMŌ Ĭ ŐÑÑŇ ĂŌŎP ŇŎŃÞÖÑŌPÑŇÅ

ÖMÒŌPÑŌMŌŃÑ

mode

ŒŎÕMǾ ŃOMǾŊÑ

on*/off

(solar)

Ĭ ÑP ĖÞPŎ

Regen timer

İ ÑÖ Ő QŎÕPMŊÑ

comp

NÞŖŖÑǾ ŎŅŅ

(long term)

Guide to the buttons

For a more detailed description of these options please look at the next 2 pages

BBS solar only

The BB needs to be on (lit up) for any of these buttons to operate

To restore the BB to default settings simply press and hold both buttons together for

between 8-35 flashes and let go. This shall restore the BB to factory default settings.

To confirm a successful reset, 6x Green LEDs shall flash.

A factory reset may be worth doing if your BB is behaving incorrectly after having

made adjustments to it, as it allows your start again.

Factory Reset

SETUP SELECT

1x blue LED flash = 1 second

Sterling Power Products

Copyright

Force Options

Regen timer adjustment: default 240 seconds

If you wish to adjust the length of time that the BB stays

charging for when the input voltage drops between 12.0V-

13.2V then you can change that here. Use the second

column of LEDs and the orange numbers on that column

that shows the time in seconds. You can enter this menu

by pressing down SETUP button for 30 flashes. The

second column of LEDs shall flash. Use the SETUP and

SELECT buttons to toggle up and down through the

relevant numbers in orange. When you have selected the

appropriate number press both buttons to confirm.

12

Silence Buzzer

If the buzzer is sounding and you wish to silence it, simply press SETUP button with a quick but firm press. This

should silence the buzzer. It is a short term feature. If you wish to turn the buzzer off forever, please press the SETUP

button down for 40 flashes.

to view the status of the charger - do a quick press.

to view the BB as a voltmeter - do a quick press.

Software version

If you are interested in the software version of your BB, press and hold the SETUP button down for 5 flashes. The

display is in binary format.

Battery type select

Please consult page 10 regarding changing battery type. Also, for custom battery type please consult page 14.

Force unit to output live charge voltage without output battery connected (i.e. as a power pack / live output ) -

(default off).

This mode shall allow the unit to operate without needing a voltage on the output terminal. Hold down the SETUP

button for 15 flashes and let go. A charge voltage shall now be applied to the output terminal - irrespective of whether

there is a battery there. Press SETUP for 15 flashes then let go.

Pure ignition feed mode (default off)

Pure ignition feed mode, if this mode is enabled the BB shall ONLY operate if there is an ignition feed. It shall NOT

activate based on voltage DC input at the Batt input terminal. Press SETUP for 20 flashes.

Change operational on/off voltages (13.2V on / 13.0V off default x2 for 24V)

If you wish to change the BB’s activation voltages then you can do it here. The default is 13.2V on (x2 for 24V etc) and off

is 13.0V (x2 for 24V etc). Press the SETUP button down for 25 flashes. Then the second column of LEDs shall flash. The

voltages on this column then become the reference to activation voltages. The first option to select is ‘on’ activation

voltage. Default is 13.2V (hence that LED flashes) - use the SETUP / SELECT buttons to toggle up and down to column

to the desired activation voltage. Press and hold both buttons together to confirm voltage selection. Only the on voltage

needs to be selected, the off voltage is always 0.2V below. These settings shall last until a factory reset has happened.

Set auto regenerative braking timer (default 240 seconds).

If no ignition feed is being used on the BB then this timer is relevant with EURO 6+ installations. With Euro 6 engines the

alternator is often turned off during driving. This timer enables the BB to continue working even when the alternator is off.

Within this timer window the ECU on board should prompt the alternator to turn on again as the ECU is monitoring the

starter battery’s depletion. When the alternator turns on again the voltage should climb up and the regen. braking timer

restarts. The timer engages when the input voltage drops below the operational off voltage (default 13.0V, as above)

and reactivates above the on voltage (13.2V, as above). IF ignition feed is applied to the unit this deactivates this braking

timer. When ignition feed is no longer in use this timer reactivates. Press SETUP for 25 flashes. The second column of

LEDs shall flash. Use the orange numbers as a reference with regards time in seconds. Use the SETUP / SELECT

buttons to toggle the LEDs up and down that column to select the time you wish to set as the regen. braking timer. For

EURO 6+ simply use ignition feed and do not worry about this feature.

Temperature voltage compensation (default on)

If you do not wish the BB to fluctuate output voltage based on temperature at the temperature sensor then this mode

needs to be set to off. Default mode means that the BB shall elevate the voltage by the rate of 18mV per Deg C below

20Deg C and reduce the voltage by 18mV per Deg C above 20Deg C. You may need to set this to off if: You have a lithium

battery and have set custom charge profile feature and you want to monitor the temperature at the battery because you

want a 0Deg C trip, for example. If you are in a lithium profile (I or II) this mode is off anyway.

Turn off buzzer (buzzer on as default)

If the buzzer alarm is coming on and it annoys you, you can turn it off!. Please press the SELECT button down for 40+

flashes. This shall disable the buzzer altogether, indefinitely. You can reapply the buzzer function by repeating this

procedure.

Maintenance Mode (default off)

This mode locks the unit in voltmeter mode so you can fault find. The columns of LEDs stay on as voltmeters. This is

ideal if you do not have a voltmeter and you wish to provide information above what the input and output voltages are at

the BB itself. The unit shall remain in Maintenance Mode until you repeat the 45 flashes or do a factory reset.

Maintenance mode maintains charging function but the BB does not go into sleep and remains constantly live. The

charger shall not go to sleep and shall remain on (not necessarily charging). The BB shall charge if the input voltage /

ignition feed is as per normal operation. As the unit does not go to sleep the BB shall consume about 200mA at 12V

(2.5W). This is compared with 1mA at 12V (0.12W) when in sleep mode.

quick press

5 flashes

10 flashes

15 flashes

20 flashes

25 flashes

30 flashes

35 flashes

40 flashes

# flashes

Both buttons

8 - 35

Factory Reset

# flashes

only buttonSetup

0-1

Silence Buzzer

5

Software version

10

Select battery type

15

Power supply mode

20

Pure ignition feed mode

25

Change operational on/off voltage

30

Set auto regen. braking timer

35

Temperature voltage compensation

40

Buzzer off (long term)

45

Maintenance Mode

12

If BB is in sleep mode, either buttons can be pressed to wake the BB up.

# flashes

Select only button

0-1

Silence Buzzer

5

Display temperature

10

Force to float

15

Night Mode

20

1/2 Power Mode

25

Standby

30

Turn unit off

35

Batt Maintainer on / off

40

OEM Lock

45

Solar Charger on*/off

50

BB Charger on*/off

55

BB + Solar mode on/off*

Guide to the buttons

For a more detailed description of these options please look at the next 2 pages

BBS solar only

Maintaince mode, this mode lock on the unit so it does not switch

off, and keeps the input and output volt meters in operation which

you work on the system for fault finding. if ther is a fault and the

output voltage leds only are on then its no longer a volt meter

display it is simply displaying a fault condition which needs to be

resolved, the unit is only displaying voltage if both rows off leds are

active

45 flashes

If BB is in sleep mode, either buttons can be pressed to wake the BB up.

Sterling Power Products

Copyright

Force Options 13

Silence Buzzer

If the buzzer is sounding and you wish to silence it, simply press SETUP button with a quick but firm press. This should

silence the buzzer. It is a short term feature. If you wish to turn the buzzer off forever, please press the SETUP button

down for 40 flashes.

to view the status of the charger - do a quick press.

to view the BB as a voltmeter - do a quick press.

Display temperature

If you wish to view the temperature at the battery temperature sensor (if installed) - you can view it here. The

temperatures that can view are between -30DegC and +2DegC on the front panel. If you wish to view a full range of

temperature then you shall need the remote control BBURC.

Force unit to float

We recommend that you understand what float means before committing to float mode. It is basically a lower

maintenance voltage - fairly harmless. Once you have forced the unit into float mode it shall remain there, forever - until

you either do a factory reset or repeat this procedure.

Force unit to 1/2 power mode

This mode shall put the charger into half power mode. As the name suggests, if you have a 60A charger it shall put the

maximum current to 30A. A 30A BB charger shall reduce to 15A (approximately) etc... The BB shall remain at half power

forever, until either a factory reset is done or this method is repeated. You may need this mode if you want to reduce the

current for the sake of keeping within the maximum charge rate of your batteries or due to pre-existing cabling being

insufficient for the full power of the charger.

Force unit to night mode

This mode shall put the charger into half power mode (as above) but only for 8 hours at a time. The BB shall be on half

power mode for these 8 hours only. It shall then resume as normal full power after these 8 hours. You have to repeat this

procedure every time you need it.

Turn the charger to standby

If you wish to put your BB into standby then apply this mode. Standby is a one off setting. It shall stop the boost of the BB but

shall remain on - pending a button press to get out of standby. The BB shall come out of standby during the next charge

cycle, so is not a permanent setting. To indicate that standby is on LEDs 12 and 15 shall flash. Press any button to take out of

standby.

Turn charger off

If you wish to turn your BB off then apply this mode. Off means the BB shall stop charging awaiting you to press either button.

To turn off is a one off indefinite setting. It shall stop the boost of the BB - pending a button press to get out of standby. The BB

shall turn on again only when a button is pressed. If the charger is disconnected and reconnected the BB shall remain off,

also, during power cycles it shall remain off. To display the charger being off the top row of LEDs 12, 13,14,15 shall flash.

OEM lock

If you are an installer and wish to make settings to the BB and then lock the charger in these settings, to prevent tampering

by the end user, then apply OEM lock. Once this mode has been applied NO options can be adjusted. Factory reset is the

only method to remove this feature and restores the BB to defaults. The BB demonstrates OEM lock by flashing 4 Red

corner LEDs.

quick press

# flashes

Action

0-1

Silence Buzzer

5

Display temp

10

Force to Float

15

1/2 Power Mode

20

Night mode

25

Standby

30

Turn unit off

35

40

OEM Lock

5 flashes

10 flashes

15 flashes

20 flashes

25 flashes

30 flashes

40 flashes

Maintaince mode, this mode lock on the unit so it does not switch

off, and keeps the input and output volt meters in operation which

you work on the system for fault finding. if ther is a fault and the

output voltage leds only are on then its no longer a volt meter

display it is simply displaying a fault condition which needs to be

resolved, the unit is only displaying voltage if both rows off leds are

active

# flashes

Select only button

0-1

Silence Buzzer

5

Display temperature

10

Force to float

15

Night Mode

20

1/2 Power Mode

25

Standby

30

Turn unit off

35

Batt Maintainer on / off

40

OEM Lock

45

Solar Charger on*/off

50

BB Charger on*/off

55

BB + Solar mode on/off*

BBS solar only

Solar charger on* / off

the solar charge feature of the

BBS1230 can be turned off, if not

required. Default is on. Press the

SELECT button for 45 flashes

and let go, to turn off.

BB charger on* / off

If you wish for the BBS1230 to be pure a solar charger

and for the BB aspect to be switched off - use this mode.

Press the SELECT button for 50 flashes and let go to

turn the BB charging off. Solar charging ONLY! May be

ideal for a bright sunny day and you wish to save a very

small amount of fuel.

BB + Solar mode on* / off

This mode turns the entire BBS off.

Both the solar charger and BB charger

turns on / off with this feature. Default is

on. To turn off press SELECT button for

55 flashes.

45 flashes 50 flashes

55 flashes

BBS1230 only BBS1230 only

Sterling Power Products

Copyright

CUSTOM BATTERY TYPE SETTING (for expert use

only - not required for general operation)

Before proceeding with this, please read and

understand all instructions as it is quite complex and

could take more than one attempt. There are timed

intervals of 30 seconds per setting so it is very

important to know exactly what you require before

starting. If any errors are made simply wait a few

minutes and you can start the cycle again. The

settings offered for adjustment in sequence:

Important information: If during these operations

you get yourself in a mess and find yourself pushing

buttons aimlessly, then please resort to the factory

reset. To delete all and return the product to its default

factory settings.

A) Boost / absorption voltage (high voltage charge).

B)Conditioning voltage (medium charge rate

normally between boost and float voltage).

C)Float voltage (no longer charging, this will provide

voltage at a reduced level to maintain the batteries

and provide power for any loads applied).

D) Absorption time factor adjust. The length of time

spent in absorption can be adjusted by a factor 0-18.

This may be beneficial for different battery

chemistries. Gel, for example, tends to absorb current

at a low rate, thus, increasing the length of time spent

in absorption may be beneficial (set nearer 18). AGM,

the reverse (set nearer 0). If in any doubt, ask your

battery retailer or simply use one of our preset values.

To calculate the absorption time from the time factor

simply multiply the factor number (0-18) by the length

of time it takes for the charging voltage to hit the

absorption voltage (typically 14.4V). If it takes 40

minutes to reach absorption and you set your ATF to 4

then 4x40mins = 160 minutes. The maximum time the

unit can stay in absorption is 24 hours 1440 minutes.

E) Minimum and maximum absorption times.

Here you can set the maximum and minimum time the

unit stays in absorption. For example, you may have

AGM that may need a maximum of one hour, or GEL

which could require a minimum of 720 minutes (12

hours).

We recommend that you write down your required

voltages and times in the space below. This is so you

know what to programme during setup.

Desired custom values - make a note.

Boost / bulk / absorption (V) ________

Conditioning (V) ________

Float (V) ________

Absorption Time Factor (0-18) ________

Absorption Minimum (0-960 minutes) ________

Absorption Maximum (0-960 minutes) ________

Operation

Press and hold SETUP button for 10 flashes, let go.

All of the first column of LEDs shall flash

Press the setup/select button to move LED down to

custom. Hold both buttons for 2 seconds to confirm.

STERLI G

POWER

Opportunity to adjust Fast Charge / Bulk /

Absorption voltage.

Red Custom LED will flash for 3 seconds to confirm.

Red Custom LED will come on constant, Green Fast

Charge LED will flash (section 1 on graph). Adjust

Fast Charge voltage by using the Select and Setup

buttons to go up and down the right LED column to

select the correct Fast Charge voltage. Once content,

wait 30 seconds, or press both buttons to confirm. The

unit shall then proceed to Conditioning charge voltage

(next below).

Opportunity to adjust Conditioning charge

voltage

Red Custom LED will come on constant and Green

Conditioning LED will flash (section 3 on graph).

Likewise, adjust the conditioning voltage by using the

Select and Setup buttons to go up and down the right

LED column to select the correct Conditioning

voltage. Once content, wait 30 seconds, or press both

buttons to confirm. The unit shall then proceed to float

voltage set (next below).

Opportunity to adjust float charge voltage

Red Custom LED will come on constant and Blue

Float LED will flash (section 3 on graph). Likewise,

adjust the float voltage by using the Select and Setup

buttons to go up and down the right LED column to

select the correct Float voltage. Once content, wait 30

seconds, or press both buttons to confirm. The unit

shall then proceed to float voltage set (next below).

Opportunity to adjust absorption time factor

Red High Temp LED will come on constant. Green

Fast Charge LED will flash and will Blue Float LED