tau BIG User manual

1

BIG Series

MANUALE D’USO E MANUTENZIONE

USE AND MAINTENANCE MANUAL

BEDIENUNGS - UND WARTUNGSANLEITUNG

MANUEL D’EMPLOI ET D’ENTRETIEN

MANUAL DE USO Y MANTENIMIENTO

BIG

Motoriduttore per cancelli scorrevoli ad uso industriale

Sliding Gate Operator – Industrial

Schiebetorantrieb für Gewerbe und Industrie

Automatisme pour Portails Coulissants – Usage Industriel

Accionador para Puertas Correderas – Uso Industrial

Via Enrico Fermi, 43 - 36066 Sandrigo (VI) Italia

Tel +39 0444 750190 - Fax +39 0444 750376 - info@tauitalia.com - www.tauitalia.com

IT - Istruzioni originali

D_MNL0BIG 17-04-2018 - Rev.18

11

BIG Series

MANUFACTURER’S DECLARATION OF INCORPORATION

(in accordance with European Directive 2006/42/EC App. II.B)

Manufacturer: TAU S.r.l.

Address: Via E. Fermi, 43

36066 Sandrigo (Vi)

ITALY

Declares under its sole responsibility, that the product: Electromechanical actuator

designed for automatic movement of: Sliding Gates

for use in a: Industrial

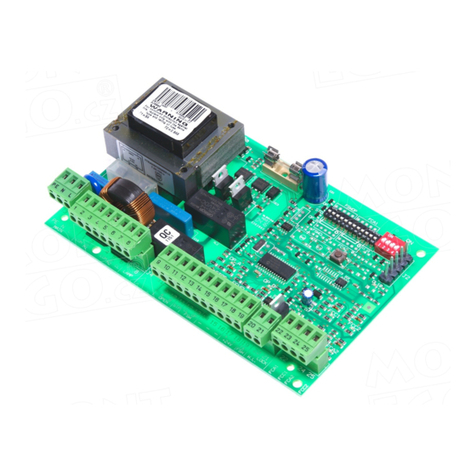

complete with: Electronic control unit

Model: BIG

Type: BIG18QI / BIG30QI / BIG40Q

Serial number: SEE SILVER LABEL

Commercial name: AUTOMATION FOR SLIDING GATES

Has been produced for incorporation on an access point (sliding gate) of for assembly with other devices used to move such an access

point, to constitute a machine in accordance with the Machinery Directive 2006/42/EC.

Also declares that this product complies with the essential safety requirements of the following EEC directives:

- 2014/35/EU Low Voltage Directive

- 2014/30/EU Electromagnetic Compatibility Directive

and, where required, with the Directive:

- 2014/53/EU Radio equipment and telecommunications terminal equipment

Also declares that it is not permitted to start up the machine until the machine in which it is incorporated or of which it will be a com-

ponent has been identied with the relative declaration of conformity with the provisions of Directive 2006/42/EC.

The following standards and technical specications are applied:

EN 61000-6-2; EN 61000-6-3; EN 60335-1; ETSI EN 301 489-1 V1.9.2; ETSI EN 301 489-3 V1.6.1;

EN 300 220-2 V2.4.1; EN 12453:2000; EN 12445:2000; EN 60335-2-103

The manufacturer undertakes to provide, on sufciently motivated request by national authorities, all information pertinent to the quasi-

machinery.

Sandrigo, 29/11/2017

Legal Representative

_________________________________________

Loris Virgilio Danieli

Name and address of person authorised to draw up all pertinent technical documentation:

Loris Virgilio Danieli - via E. Fermi, 43 - 36066 Sandrigo (Vi) Italy

ENGLISH

12

BIG Series

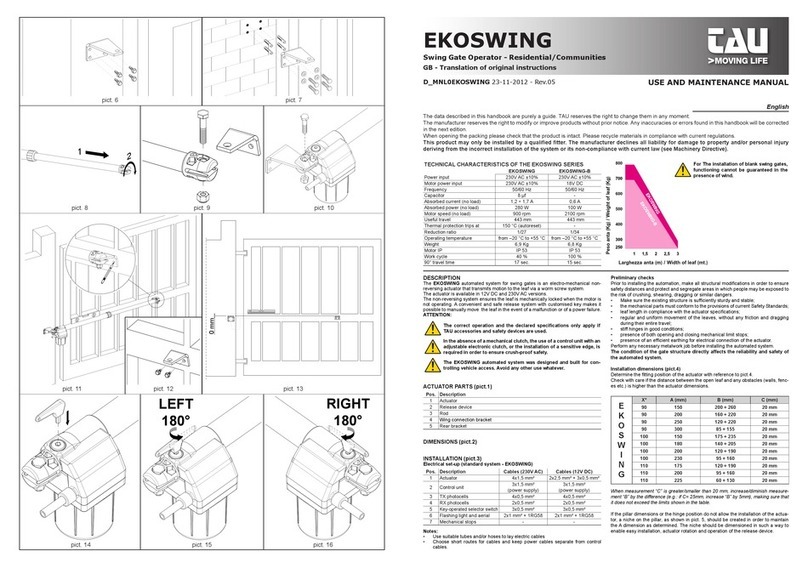

INSTALLATION

The product may only be installed by a qualied tter. The manu-

facturer, Tau, declines all liability for damage to property and/or in-

jury to people deriving from the incorrect installation of the system

or its noncompliance with current law (see Machinery Directive).

Use on gates with a gradient or slope is not allowed.

FIG. 1 - STANDARD SYSTEM

1. Gear motor

2. Release

3. Photocells

4. Posts + Photocells

5. Aerial and Flashing light

6. Key switch

7. Electromechanical edge

8. Gate guide

9. Limit switch shoe

10. Rack

FIG. 2 - INSTALLATION MATERIAL

1. gear motor

2. counterplate

3. rack

4. self-tapping screws

5. limit switch shoes

6. release key

7. rack brackets

8. bent pins for counterplate

Place the control unit (external versions) in the immedi-

ate vicinity of the motors.

Be careful not to run cables for auxiliary devices in-

side raceways housing other cables supplying power

to large loads or lights with electronic starters.

In the event control pushbuttons or indicator lights are

installed inside homes or ofces several metres from

the actual control unit, it is advisable to decouple the

signal by means of a relay in order to avoid induced

interference.

OVERALL DIMENSIONS

Figs. 3,4,5 show the main overall dimensions for the sliding gate;

gs.6-7 show the dimensions of the foundation counterplate, while

g.8 shows the dimensions of the adjustable counterplate for mod-

el BIG18.

PRELIMINARY OPERATIONS

Carefully read the instructions contained in the handbook before

starting work.

Before proceeding with installation, make sure that all the compo-

nents are present, use suitable work equipment and do not touch

live electrical parts.

CONSIDERATIONS PRIOR TO INSTALLATION

Before proceeding with installation check that:

- The wheels of the gate are mounted in such a way as to make

it stable and that they are in good condition and perfect working

order;

- The whole of the slide rail is unobstructed, straight and clean

and a travel stop is tted at either end.

INSTALLATION DISTANCES

To install the gear motor correctly, make sure it is at a distance of

65 mm from the gate.

See g. 09 for xing to a concrete oor, g. 10 for digging and g.

11 for positioning the counterplate.

PREPARING THE BASE

Dig foundations at least 15 cm deep and sufciently wide. Use

protective sheaths for the cables.

FIXING THE FOUNDATION COUNTERPLATE

Fill the hole with concrete and sink the bet pins into it; the counterplate

must be perfectly at at 1 or 2 cm from the level of the nished oor

and at a distance of approximately 65 mm from the gate.

NB: it is also possible to install the gear motor without the founda-

tion counterplate by using four foundation bolts on a at concrete

base; the measurements shown in g. 9 must always be respected.

A height-adjustable counterplate may be used for model BIG18; in

this case, the xed bent pins must be welded to the rail, see g. 12/a.

This makes it possible to adapt the gear motor to a pre-existing

system; the measurements shown in g. 12/b must be respected.

ANCHORING THE GEAR MOTOR

Tighten the screws (as shown in g. 13) on both sides of the gear

motor. Fit all the cables into the sheath, which passes through the

hole made in the base of the foundation counterplate.

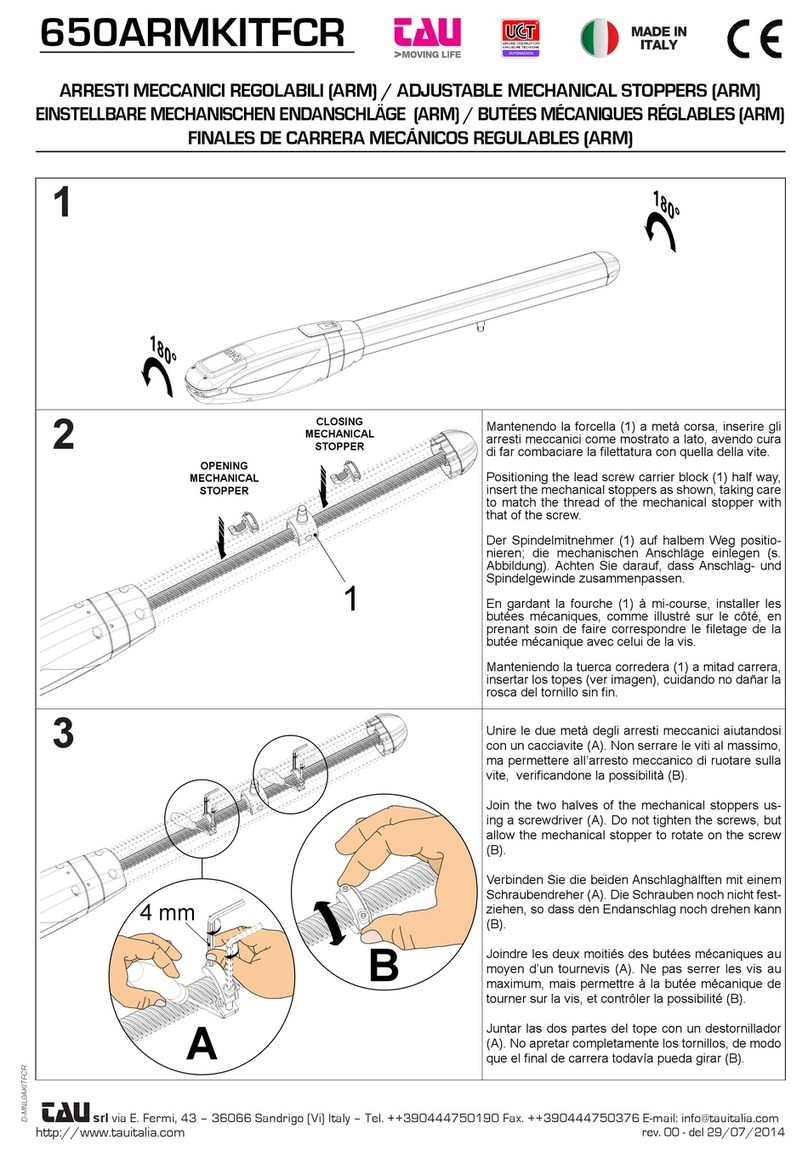

FIXING THE RACK

Prepare the rack with the relative brackets (g. 14).

Place the rack on the motor pinion (released) respecting the dis-

tance between the tooth of the gear and the tooth of the rack as

shown in g. 15. Make a hole in the leaf at the centre of the slot

and x with the relative screws. Slide the leaf along the pinion and

x each bracket in turn.

FIXING AND ADJUSTING THE LIMIT SWITCH SHOES

Fix the shoes as shown in g. 16, one near either end of the rack.

Move the leaf by hand and position the shoes so that they touch

the microswitch lever just before the leaf hits the travel stops at

both ends of the rail; then tighten the screws.

A single factor or combination of factors (thermal ex-

pansion, climate, frequency of use, etc.) may result in

the position the gate stops in changing over the course

of the day, both when opening and when closing. Con-

sequently, we cannot guarantee that the gate will al-

ways stop in the same position.

ADJUSTING THE MECHANICAL CLUTCH

Before starting, make sure to disconnect the gear motor from the

power supply.

BIG18: Make a 1/2 or a whole turn at a time using the sup-

plied wrench (g. 17).

BIG30-40: After removing the lock nut (1 g. 18A) and the stop

dowel (2 g. 18A), adjust the thrust force using the

hex wrench provided (3 g. 18B) (rotate clockwise to

increase the thrust force, rotate counter-clockwise

to decrease it). After adjusting as needed, reas-

semble the stop dowel (2 g. 18D) until it reaches

the mechanical stop, then fasten the lock nut (1 g.

18D).

VERSION WITH CHAIN PINION: R30 / R40

The door can also be power-operated as shown in g. 19. Pass the

chain as shown in g.

Fig. 19 also shows the type of chain required (pitch 5/8” x 3/8”).

ELECTRICAL CONNECTIONS

For electrical connection, please refer to the specic instructions

for each electrical control panel. The following tips apply to all models.

Do not put the power cables in the same sheath as the motor ca-

bles. Always choose the shortest routes for the cable lines. Make

sure the equipment is well earthed. A general switch should be

ENGLISH

2

GUIDA UTENTE - USER GUIDE - FÜHRER BENUTZER - GUIDE USAGER - GUÍA USUARIO

INSTRUCTIONS AND WARNINGS FOR AUTOMATIC SYSTEM USERS

CONGRATULATIONS on choosing a Tau product for your automation system!

Tau S.r.l. produces components for automatic gates, doors, barriers and shutters. These include gear motors, control units, radio control

devices, ashing lights, photocells and accessories.

Tau products are exclusively made with top quality materials and processes and, as a company, we constantly research and develop innovative

solutions in order to make our equipment increasingly easier to use. We also pay great attention to all details (technology, appearance and

ergonomics). The extensive Tau range makes it possible for your tter to choose the product which best meets your requirements.

Tau, however, does not produce your automated system as this is the outcome of a process of analysis, evaluation, choice of materials and

installation performed by your tter.

Each automated system is unique, therefore, and only your tter has the experience and professionalism required to create a system that is

tailor-made to your requirements, featuring long-term safety and reliability, and, above all, professionally installed and compliant with current

regulations.

An automated system is handy to have as well as being a valid security system. Just a few, simple operations are required to ensure it lasts for

years.

DESCRIPTION

The BIG automated system for sliding gates is an electro-mechanical non-reversing operator that transmits motion to the leaf via a worm screw

system.

The operator is available in 400V AC versions.

The non-reversing system ensures the leaf is mechanically locked when the motor is not operating. A convenient and safe release system with

customised key makes it possible to manually move the leaf in the event of a malfunction or of a power failure.

Even if your automated system satises regulatory safety standards, this does not eliminate “residue risks”, that is, the possibility of dangerous

situations being generated, usually due to irresponsible and/or incorrect use. For this reason we would like to give you some suggestions on

how to avoid these risks:

- Before using the system for the rst time: ask your tter to explain how residue risks can arise and read the instructions and warnings in

the user handbook that your tter will have given you. Keep this manual for future use and, if you should ever sell your automated system,

hand it over to the new owner.

- Your automated system carries out your commands to the letter: irresponsible and/or incorrect use may cause it to become dangerous.

Do not use the system if people, animals and/or objects enter its operating area.

- IT IS NOT A TOY! Make sure children do not play near the system and keep the remote control device out of their reach.

- Faults: If you notice any abnormal behaviour, disconnect the system from the power supply immediately and perform the manual release

operation (see gure). Do not attempt to repair the door but call in your tter: the system will operate manually as it did before installation.

- Maintenance: to ensure long life and totally safe operation, the system required routine maintenance, just like any other piece of machinery.

Establish maintenance times together with your tter. Tau recommends a frequency of 6 months for normal domestic installations but this

may vary depending on the intensity of use (always every 3000 work cycles).

N.B.: All controls, maintenance work and/or repairs may only be carried out by qualied personnel.

- Do not modify the plant or the relative programming and adjustment parameters: your tter will see to that.

N.B. Final testing, routine maintenance and any repairs must be documented by the tter (in the relative spaces) and such documents

kept by the owner of the system (IF THE DOCUMENTS ARE NOT PRODUCED, THE WARRANTY WILL EXPIRE).

- Disposal: At the end of system life, make sure that it is demolished by qualied personnel and that the materials are recycled or disposed

of according to local regulations.

The manual manoeuvre must ONLY be done with the door stopped and AFTER disconnecting power from the electrical control unit.

N.B.: if your remote control unit (if supplied) starts working badly after a time, or does not work at all, the batteries may be at (they can last

from several months to 2/3 years depending on what type is used). This can be seen from the fact that the transmission conrmation LED gets

dimmer or only turns on for brief moments. Before contacting your tter, try exchanging the battery with one from a good transmitter: if this is the

reason for the fault, simply replace the battery with another one of the same type.

If you wish to add a new automated system to your house, contact your tter and we at Tau to have the advice of a specialist, the most developed

products on the market, best operation and maximum automation compatibility.

Thank you for reading these suggestions and we trust you are fully satised with your new system: please contact your tter for any further

requirements.

> ENGLISH

User

Guide

MANUAL OPERATION

In case of blackout, place the key in

the lock and turn it. Remove the cas-

ing to access the release mechanism.

Turn the handle clockwise to release

the automation for model BIG18

as shown in Fig. 1. Using the hex

wrench provided, rotate the release

assembly counter-clockwise at least

one complete turn for models BIG30

and BIG40 (g. 3). To restore normal

operation, simply tighten the release

assembly (1 g. 2) by screwing it in

until it reaches the mechanical stop.

1 2 3

1

13

BIG Series

BIG40BIG30

BIG18

Serie BIG

2x0,5mm²

4x0,5mm²

4x0,5mm²

2x0,5mm²

4x0,5mm²

2x0,5mm²

2x0,5mm²

2x0,5mm²

3x0,5mm²

3x1,5mm²

4x0,5mm²

440 370

422

616

141

Fig.2 Fig.3

60

312 312

Ø 78

420

262

Fig.4 Fig.5

Fig.1

370 300

352,5

573

141

- - -- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

BIG SERIES Disegni - Drawings - Zeichnen - Projets - Dibujos

14

BIG Series

Fig.6 Fig.7

Fig.8

P-400CP12

5526055

50 370 50

55 215 100

1090

100105

12

470

370

R20

60 100 105

R20

6

P-400CP30

P-400CP40

max. 94 mm

min. 65 mm

320

310

55

55

P-550CPR1

Fig.9

BIG SERIES Disegni - Drawings - Zeichnen - Projets - Dibujos

15

BIG Series

65mm

min 15cm

40 mm

10-20mm

Fig.10 Fig.11

Fig.12

65mm

Fig.13

Fig.14 Fig.15

BIG SERIES Disegni - Drawings - Zeichnen - Projets - Dibujos

A

B

16

BIG Series

Fig.17

Fig.18

A B

CD

Fig.19

1

2

3

1

2

Fig.20 Fig.21

A

B

1

- - -- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

BIG SERIES Disegni - Drawings - Zeichnen - Projets - Dibujos

5/8” x 3/8”

Fig.16

Table of contents

Other tau Gate Opener manuals

Popular Gate Opener manuals by other brands

GiBiDi

GiBiDi PASS 1200 Instructions for installations

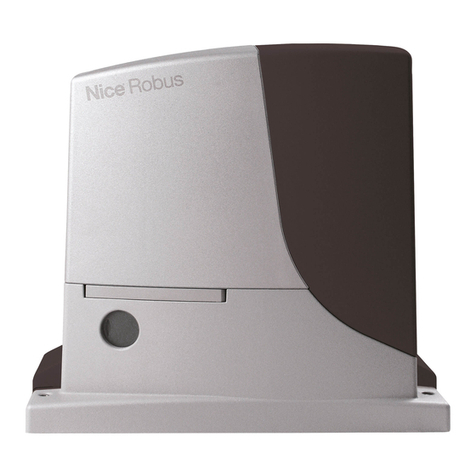

Nice

Nice ROBUS RB600 Instructions and warnings for installation and use

RIB

RIB SUPER 4000 manual

E.T. Systems

E.T. Systems Drive 500 User instructions

Airlift Doors

Airlift Doors Magnaglide Air Opener install guide

Mighty Mule

Mighty Mule FM502 installation manual