5

SAFETY INSTRUCTIONS

BEFORE OPERATING:

1. Operate the vehicle only after reading and

understanding the contents of this manual A

replacement manual is available by sending

complete model and serial number to: Hahn

Equipment Co., A subsidiary of The TORO

Company, 1625 N Garvin, Evansville, Indiana

47711-4596

Read and understand the Engine Manufacturer's

Operator's Manual Follow the safety alert

messages

1. Make sure operators are thoroughly trained

and familiar with the Operator's Manual and all

labels on the vehicle

2. Be sure to establish your own special

procedures and work rules for unusual operating

conditions (e g slopes too steep for vehicle

operation)

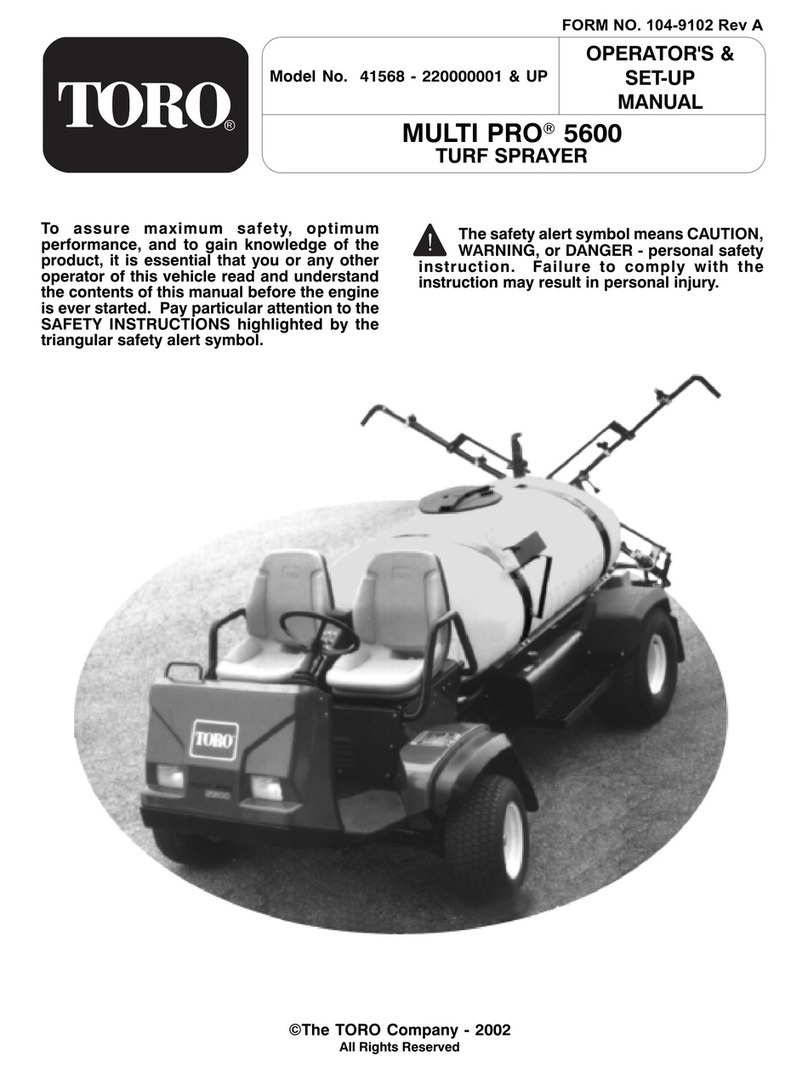

The MULTI PRO® 1200 Turf Sprayer was

designed and tested to offer safe servi e when

operated and maintained properly. Although

hazard ontrol and a ident prevention

partially are dependent upon the design and

onfiguration of the vehi le, these fa tors are

also dependent upon the awareness, on ern,

and proper training of the personnel involved

in the operation, maintenan e, and storage of

the vehi le. Improper use or maintenan e of

the vehi le an result in injury or death.

This is a spe ialized Turf Sprayer designed for

off road use. Its ride and handling will have a

different feel than what drivers experien e with

passenger ars or tru ks. So take time to

be ome familiar with your MULTI PRO® 1200.

The atta hments that adapt to the MULTI PRO®

1200 are not overed in this manual. See the

spe ifi Operator's Manual provided with the

atta hment for additional safety instru tions.

READ THESE MANUALS.

TO REDUCE THE POTENTIAL FOR INJURY

OR DEATH, COMPLY WITH THE FOLLOWING

SAFETY INSTRUCTIONS:

3. This vehicle is designed to carry Only You,

the Operator. Never carry passengers on the

vehicle

4. Never operate the vehicle when under the

influence of drugs or alcohol

5. Become familiar with the controls and know

how to stop the engine quickly

6. Keep all shields, safety devices, and decals

in place If a shield, safety device, or decal is

malfunctioning, illegible, or damaged, repair or

replace it before operating the vehicle

7. Always wear substantial shoes Do not

operate vehicle while wearing sandals, tennis

shoes, or sneakers Do not wear loose fitting

clothing or jewelry which could get caught in

moving parts and cause personal injury

8. Wearing safety glasses, safety shoes, long

pants, and a helmet is advisable and required by

some local safety and insurance regulations

9. Keep everyone, especially children and pets,

away from the areas of operation

10. Before operating the vehicle, always check

all parts of the vehicle and any attachments If

something is wrong, stop using the vehi le

Make sure the problem is corrected before vehicle

or attachment is operated again

11. Since gasoline is highly flammable, handle

it carefully

A. Use an approved gasoline container

B. Do not remove cap from fuel tank when

engine is hot or running

C. Do not smoke while handling gasoline

D. Fill fuel tank outdoors and to

approximately one inch below top of tank,

(bottom of filler neck) Do not overfill

E. Wipe up any spilled gasoline

12 Entering tank is prohibited Some spray

chemicals could be hazardous Entering tank

could increase exposure to hazardous chemicals

SUPERVISOR'S RESPONSIBILITIES:

2. Never allow children to operate the vehicle

or adults to operate it without proper instructions

Only trained and authorized persons should

operate this vehicle Anyone who operates the

vehicle should have a motor vehicle license