Contents

Safety.......................................................................4

Safety-AlertSymbol............................................4

GeneralSafety...................................................4

SafetyandInstructionalDecals..........................5

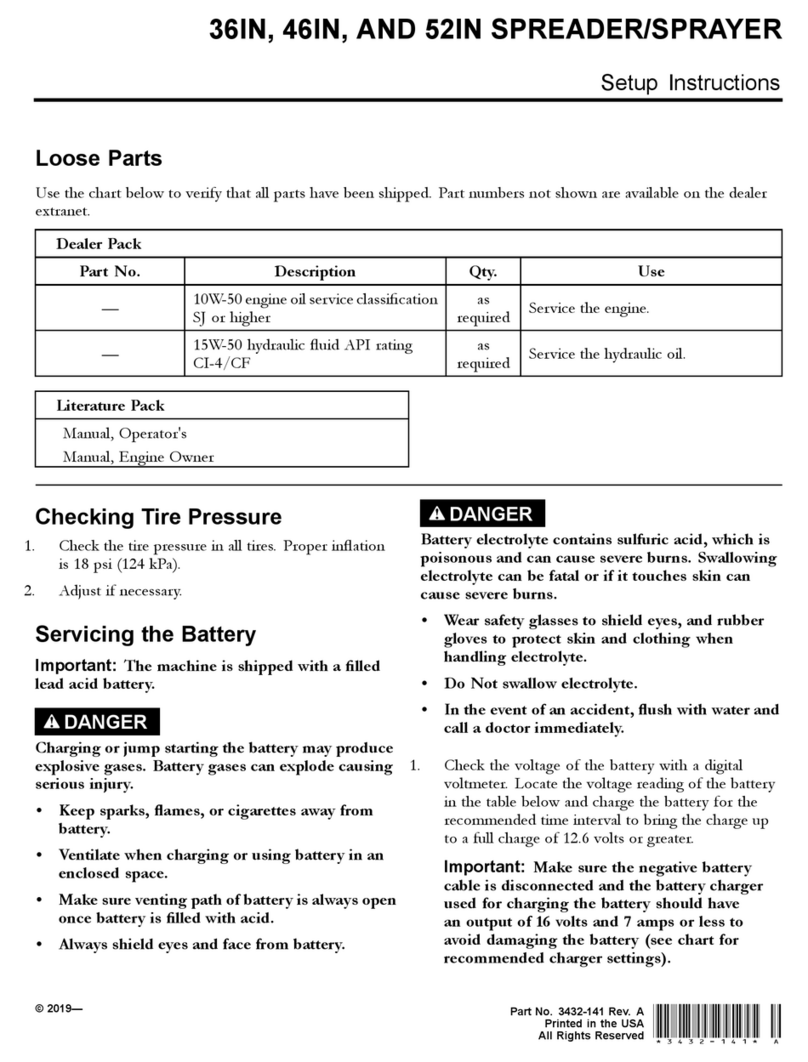

Setup......................................................................10

1CheckingtheTireAirPressure.......................10

2CheckingtheEngine-OilLevel.......................10

3CheckingtheHydraulic-FluidLevel................10

4ConnectingtheBattery...................................11

5LoweringtheAnti-TipBrackets........................11

ProductOverview...................................................12

Controls...........................................................13

MachineControls..........................................13

EngineControls............................................14

SpreaderControls.........................................14

SprayerControls...........................................15

Specications..................................................17

BeforeOperation.................................................18

PerformingDailyMaintenance..........................18

BeforeOperationSafety...................................18

FuelSpecication.............................................20

UsingStabilizer/Conditioner.............................20

FillingtheFuelTank..........................................20

DuringOperation.................................................21

DuringOperationSafety...................................21

OperatingtheMachine.....................................23

OperatingtheSpreader....................................26

OperatingtheSprayer......................................34

AfterOperation....................................................41

AfterOperationSafety......................................41

CleaningandLubricatingtheSpreader.............42

CleaningtheSprayer........................................43

TransportingtheMachine.................................46

Maintenance...........................................................49

MaintenanceSafety..........................................49

RecommendedMaintenanceSchedule(s)...........50

NotationforAreasofConcern...........................51

Pre-MaintenanceProcedures..............................51

PreparingtheMachine......................................51

AccessingtheMachine.....................................52

Lubrication..........................................................53

GreaseSpecication........................................53

GreasingtheCasterPivots...............................53

LubricatingtheCaster-AxleBearings................53

GreasingtheBeltTensioner..............................54

EngineMaintenance...........................................54

ServicingtheAirCleaner..................................54

EngineOilSpecication....................................55

CheckingtheEngine-OilLevel..........................55

ChangingtheEngineOilandEngine-Oil

Filter..............................................................56

ServicingtheSparkPlug...................................58

FuelSystemMaintenance...................................59

ReplacingtheFuelFilter...................................59

ElectricalSystemMaintenance...........................59

ServicingtheBattery.........................................59

RemovingandInstallingtheBattery..................61

Jump-StartingtheMachine...............................62

ServicingtheFuses..........................................64

DriveSystemMaintenance..................................65

CheckingtheTirePressure...............................65

CheckingtheWheel-LugNuts..........................65

CheckingtheWheel-HubNut...........................65

BrakeMaintenance.............................................66

AdjustingtheParkingBrake..............................66

BeltMaintenance................................................66

ReplacingtheBelt............................................66

AdjustingtheBeltTension.................................67

ControlsSystemMaintenance.............................68

AdjustingtheMaximumForwardSpeed............68

AdjustingtheMotion-ControlLinkage...............68

AdjustingtheMotionControlTracking...............70

HydraulicSystemMaintenance...........................70

HydraulicFluidSpecication.............................70

CheckingtheHydraulicFluidLevel...................70

ChangingtheHydraulicFluidand

Filter..............................................................71

PurgingAirfromtheHydraulicSystem..............72

CheckingtheHydraulicSystemFittings............72

MaintainingtheChassis.......................................73

CheckingtheMachineforLoose

Hardware......................................................73

MaintainingtheSprayerandSpreader

Systems........................................................73

CheckingtheSprayerSystem...........................73

CheckingtheSpreaderSystem........................73

Cleaning..............................................................74

CleaningtheEngineandtheExhaust

SystemArea.................................................74

CleaningtheDebrisfromtheMachine...............74

CleaningtheEngineDebrisGuardand

Hydraulic-OilCooler......................................74

WasteDisposal.................................................75

Storage...................................................................75

Short-TermStorage..........................................75

PreparingtheMachineforExtendedor

WinterStorage..............................................76

Troubleshooting......................................................77

TheChargingSystem.......................................77

Schematics.............................................................83

3